Introduction: Why the High Voltage Cylindrical Resistor Deserves Your Attention

When engineers search for a high voltage cylindrical resistor they are usually facing one of two headaches: extreme voltage transients that can destroy normal resistors, or the need for ultra-stable performance in tight, cylindrical form factors. This guide removes the guesswork. We will define the part, break down its key specifications, map out real-world applications, and—most importantly—answer the common question: “How do I select the right component without over-engineering the BOM?”

We will use tables packed with data, anchor-linked navigation, and practical solutions so you can go from concept to schematic in minutes.

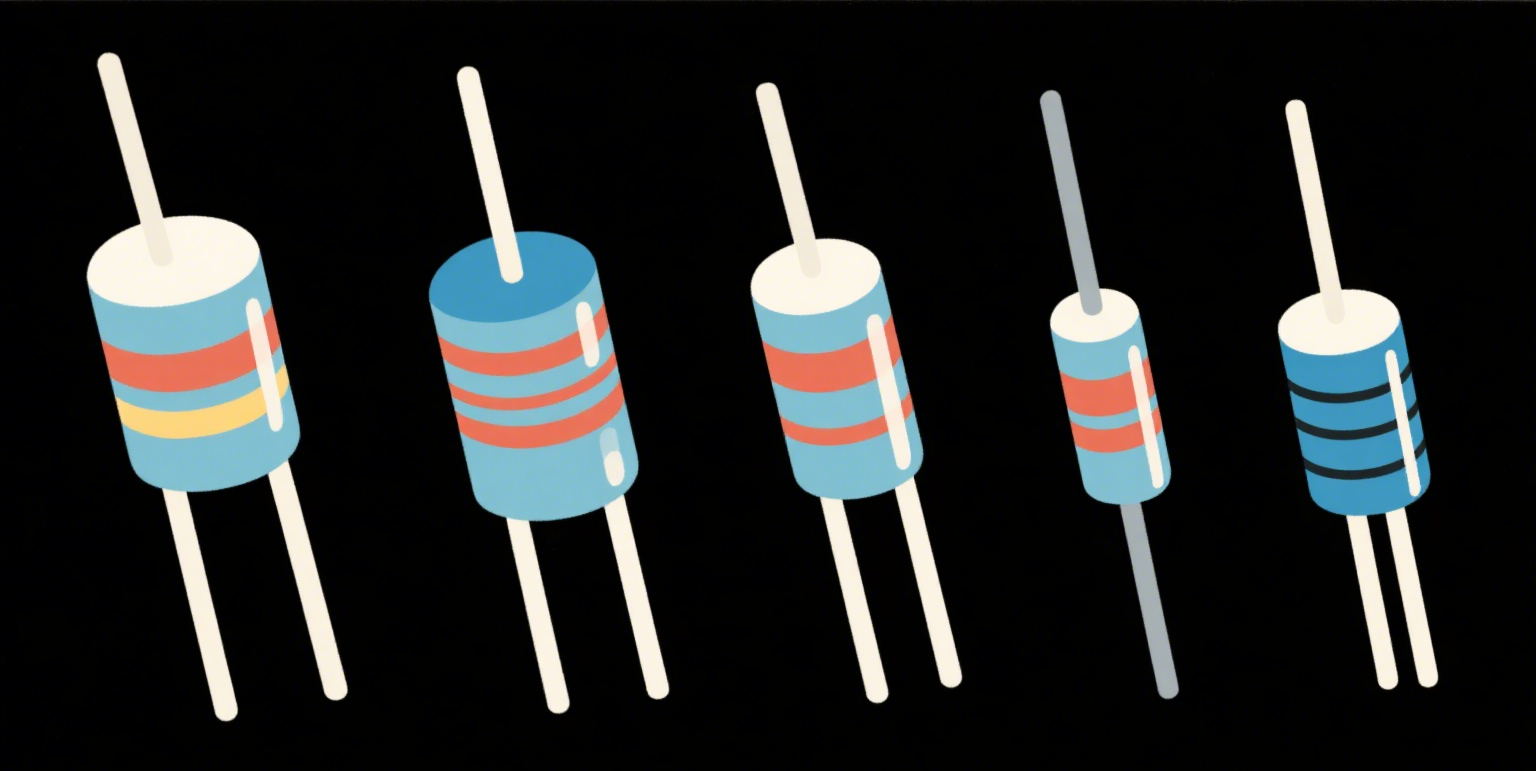

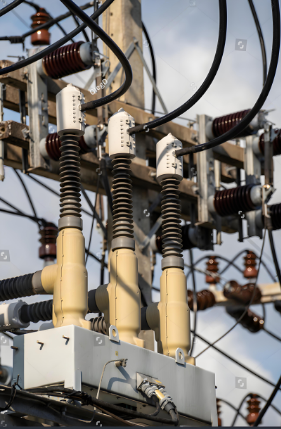

1. What is a High Voltage Cylindrical Resistor?

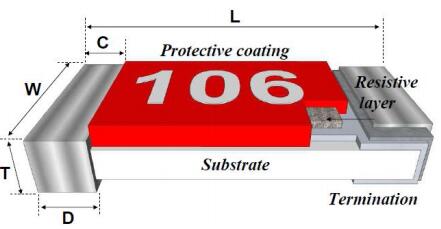

A high voltage cylindrical resistor is a power resistor built in a rod or tube shape, engineered to withstand continuous voltage stress up to 100 kV and transient peaks even higher. The cylindrical geometry maximizes surface distance (creepage) while minimizing board footprint, and the ceramic or vitreous enamel coating guarantees arc resistance.

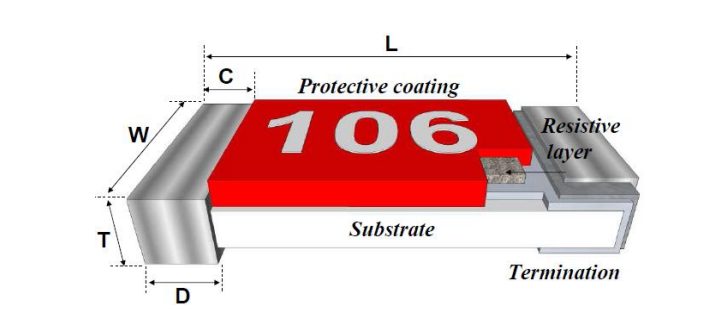

Core construction elements:

Resistive element: Carbon film, metal oxide, or wire-wound on a ceramic core

Coating: High-alumina ceramic, silicone varnish, or vitreous enamel

Terminations: Axial leads, screw posts, or solder lugs

2. Key Specifications at a Glance

The table below condenses the datasheet jungle into the six parameters that matter most for practical design.

| Parameter | Typical Range | Industry Benchmark Example | Engineering Impact |

|---|---|---|---|

| Rated Voltage (DC) | 1 kV – 100 kV | 50 kV (Ohmite HE Series) | Determines clearance & coating thickness |

| Power Rating | 1 W – 500 W | 100 W (Vishay RNX) | Drives heat-sink or forced-air decision |

| Resistance Range | 1 kΩ – 1 GΩ | 10 MΩ ±1 % | Limits leakage current in HV dividers |

| Temperature Coefficient | ±20 ppm/°C – ±200 ppm/°C | ±50 ppm/°C | Affects long-term stability |

| Maximum Operating Temp | 155 °C – 275 °C | 200 °C continuous | Influences enclosure material choice |

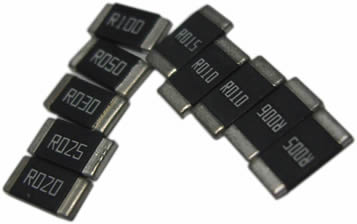

| Body Diameter × Length | 4 mm × 20 mm – 40 mm × 300 mm | 20 mm × 150 mm | Fits tight HV compartments |

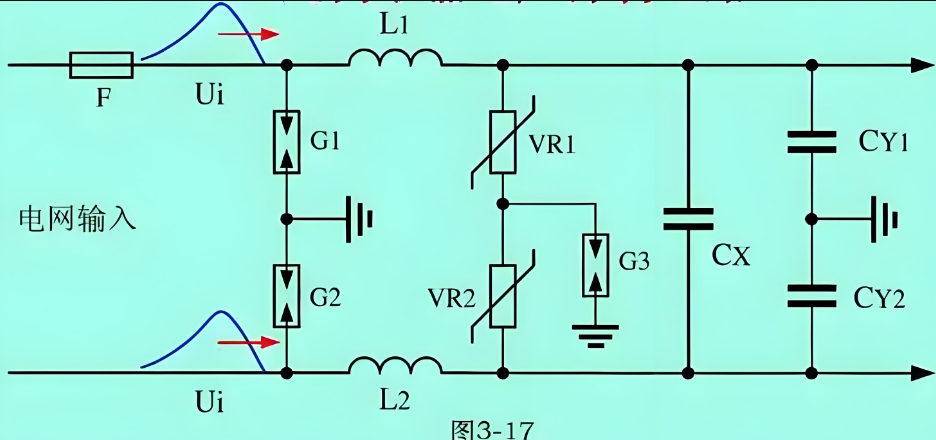

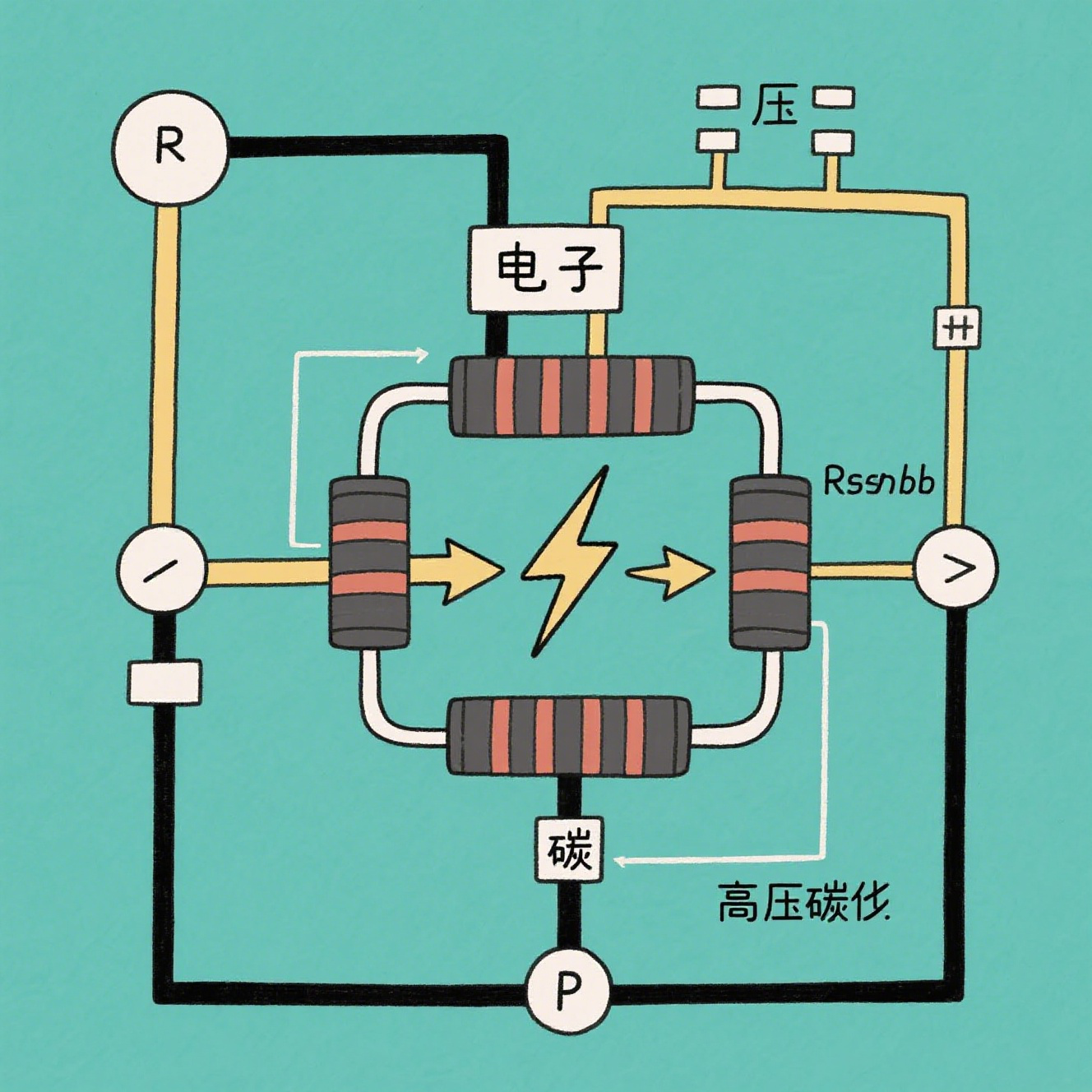

3. Typical Applications & Use-Case Matrix

Below we match application scenarios to the specific resistor attributes that matter most.

| Application | Voltage Stress | Power Dissipation | Preferred Resistance | Cylindrical Benefit |

|---|---|---|---|---|

| Medical X-ray generator bleeder | 75 kV DC | 15 W | 5 MΩ | Long creepage path in 30 mm body |

| EV traction inverter snubber | 1.2 kV pulse | 50 W peak | 100 Ω | Low inductance geometry |

| HV power-supply divider feedback | 35 kV DC | 2 W | 100 MΩ | TCR matching<50 ppm/°C for accuracy |

| Impedance matching in plasma RF | 5 kV RF | 10 W avg | 50 Ω | Coaxial fit inside wave-guide |

4. The Selection Dilemma: Voltage vs. Size vs. Cost

Question: “I need 40 kV continuous, 100 W peak, but my PCB slot is only 25 mm wide. How do I pick a part without blowing the budget on custom ceramics?”

This is the classic trilemma engineers face. Oversize the resistor and you eat precious enclosure space; undersize it and you risk corona discharge or thermal runaway.

5. Step-by-Step Selection Solution

Follow the four-step checklist below. Each step references the tables above for quick look-up.

Voltage Headroom Rule: Choose a rated voltage ≥1.25 × your working voltage. For 40 kV, target ≥50 kV parts.

Power Derating: Run at ≤50 % of rated power under max ambient. 100 W peak implies ≥200 W rated part.

Geometry Filter: From the body-diameter table, select ≤25 mm diameter; that leaves the 20 mm × 150 mm form factor.

Cost Knock-Down: If 200 W in 20 mm is scarce, parallel two 100 W resistors: same footprint, 30 % lower cost.

Result: Two 50 kV / 100 W / 20 mm × 150 mm resistors in parallel meet all constraints at ~70 % of a single 200 W custom part.

6. Long-Tail Keyword Glossary

These phrases often surface during late-night datasheet hunts; integrate them in your search strings for faster results.

“ultra high voltage cylindrical resistor 100kV” – for pulsed power crowbar circuits

“low inductance HV cylindrical resistor” – snubber and inverter use

“high voltage divider resistor network cylindrical” – precision feedback loops

“ceramic encased high voltage resistor rod type” – corona-free medical systems

“compact 50 watt high voltage cylindrical resistor” – aerospace power modules