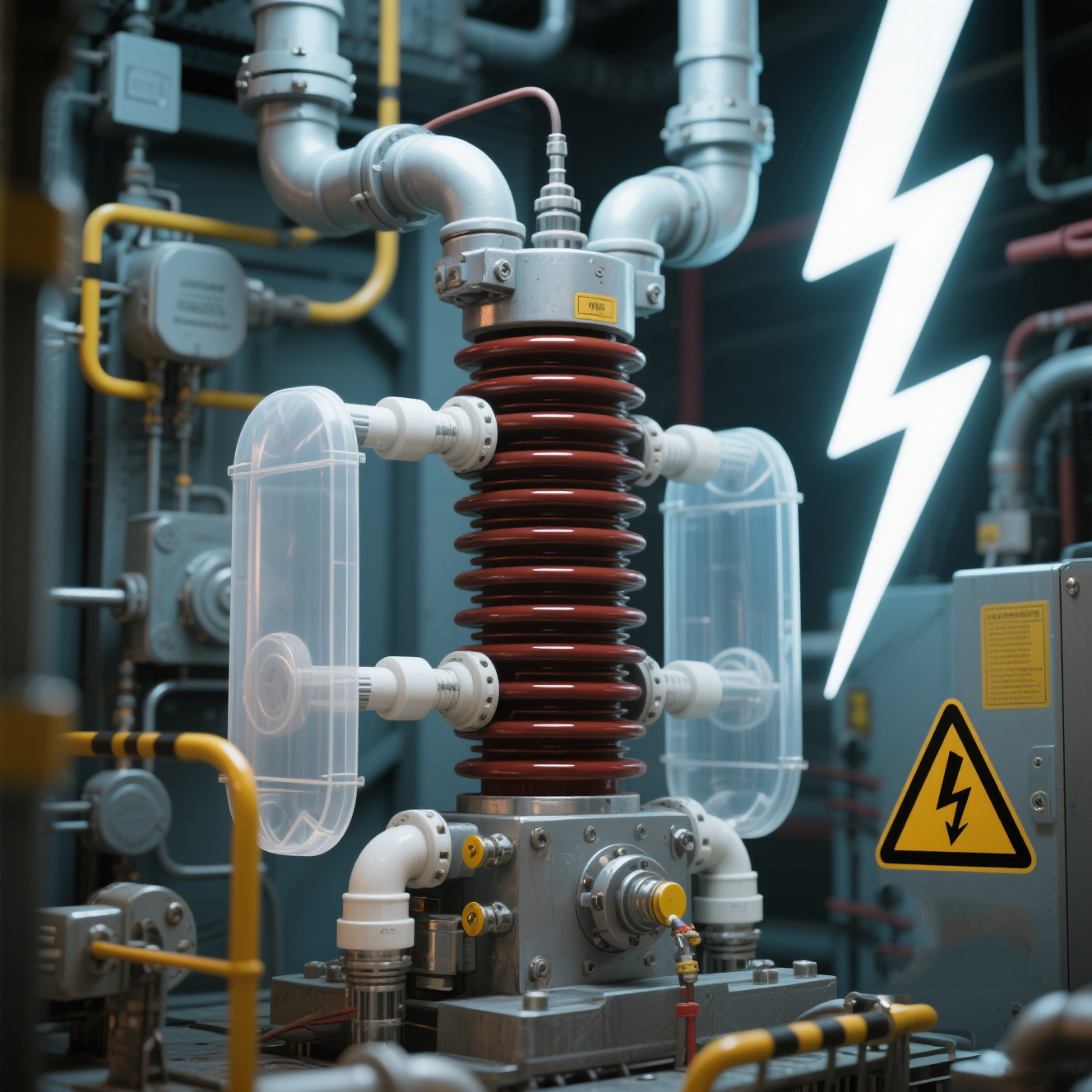

High Voltage Resistor Stability: Ensuring Long - Term Performance in High - Voltage Applications

In high - voltage applications, the stability of resistors is crucial for the reliable operation of electrical systems. This article explores the factors affecting high voltage resistor stability and provides solutions to ensure long - term performance. Properly designed and selected high voltage resistors can maintain their performance over time, even under harsh conditions.

Table of Contents

Introduction

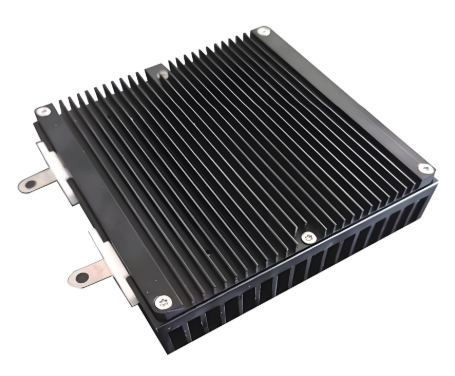

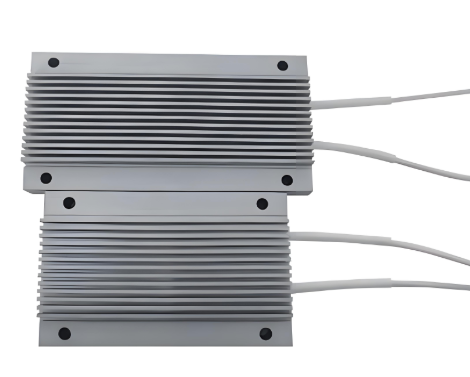

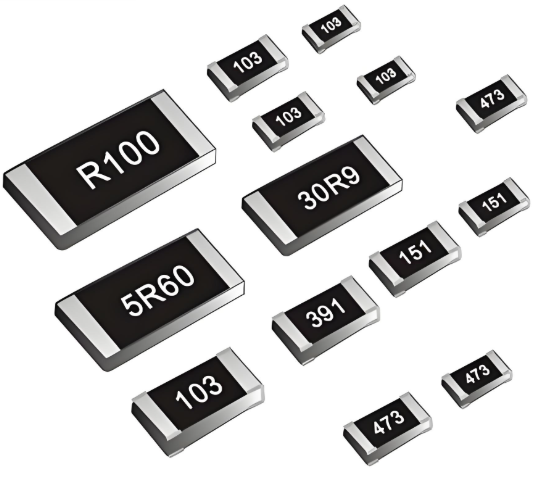

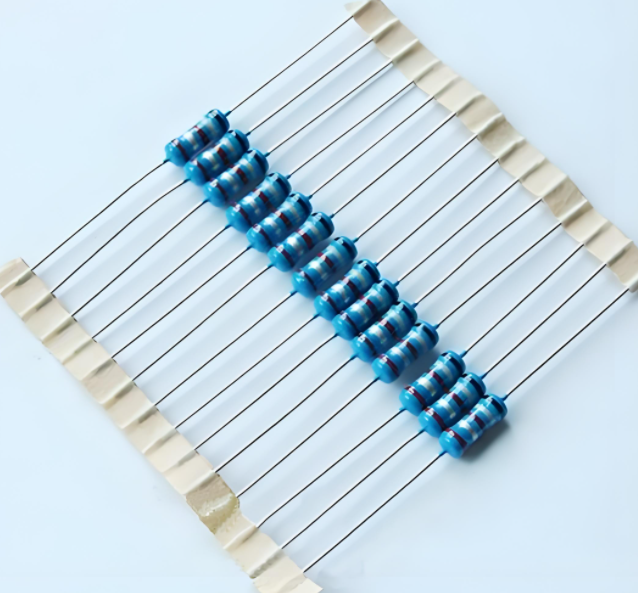

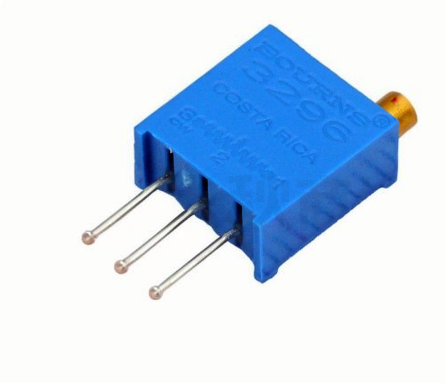

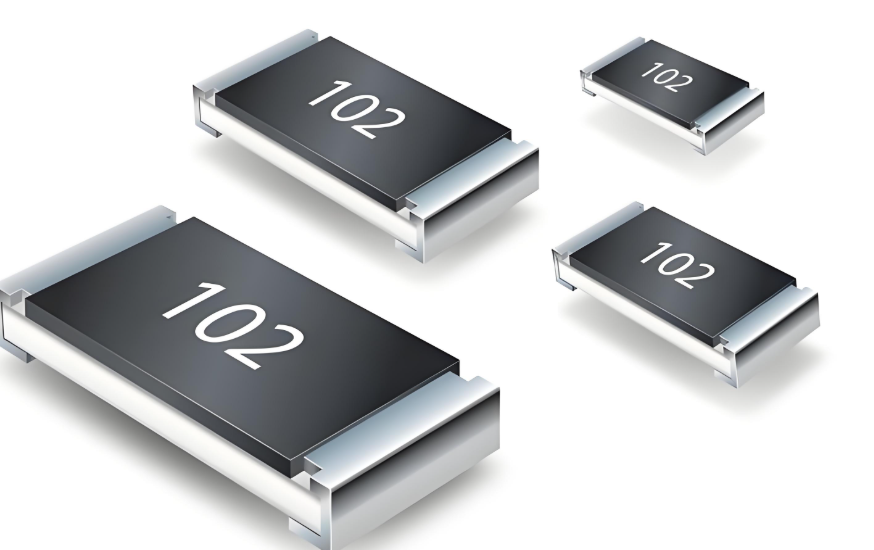

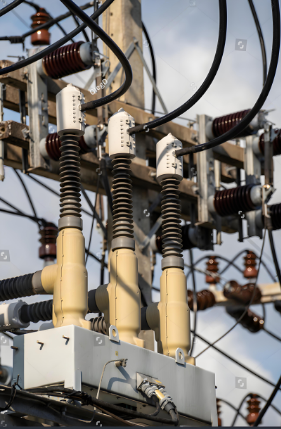

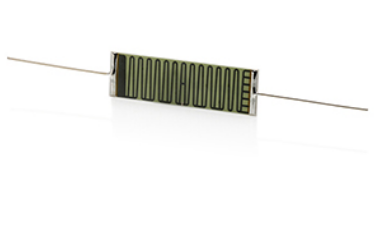

High voltage resistors are essential components in various applications such as power electronics, electrical testing equipment, and high - voltage power supplies. Their stability directly impacts the accuracy, safety, and reliability of these systems. A stable high voltage resistor maintains its resistance value, power rating, and other electrical characteristics over time and under different operating conditions. Understanding what affects this stability helps in selecting and using the right resistors for specific applications.

Factors Affecting High Voltage Resistor Stability

Several factors can influence the stability of high voltage resistors:

1. Temperature

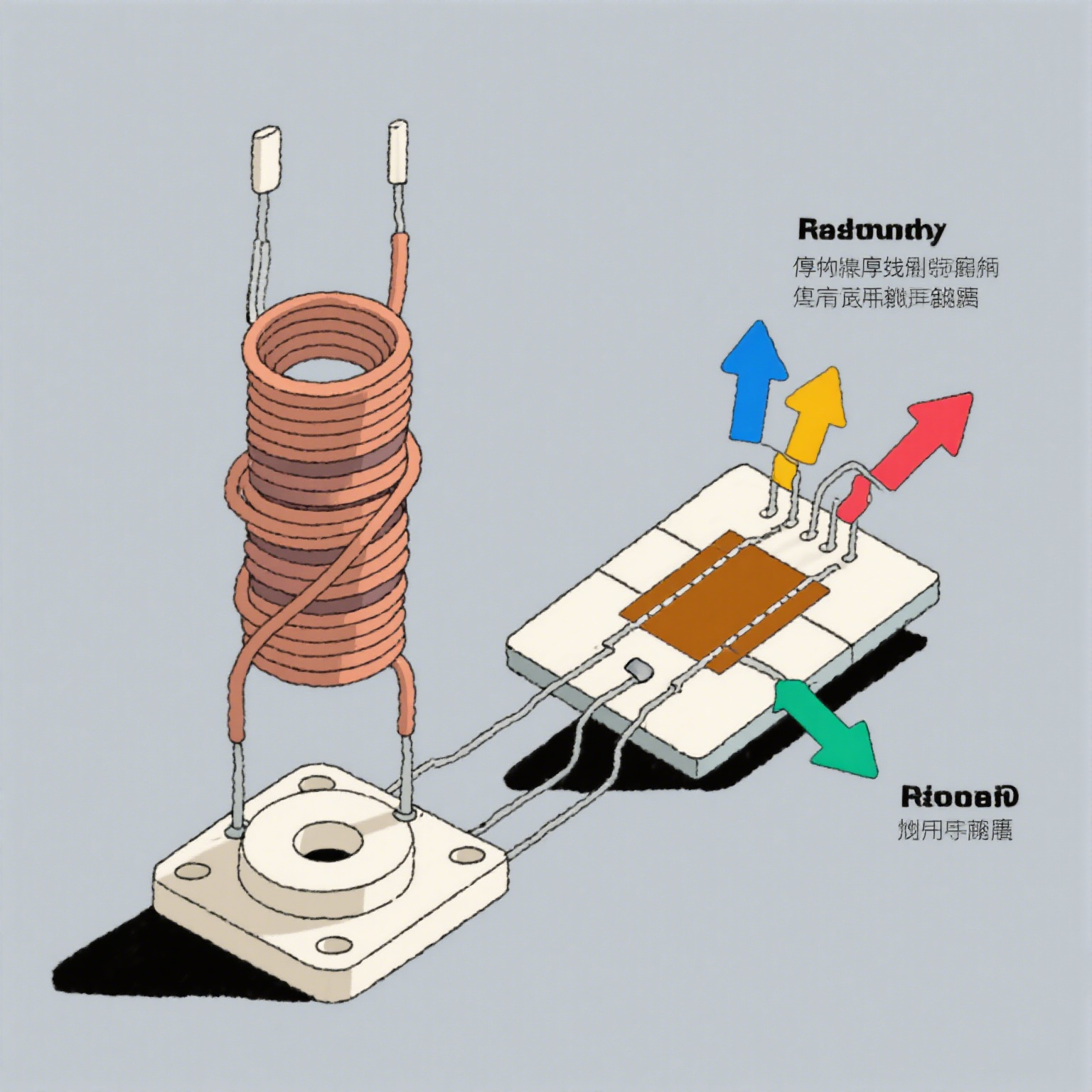

High voltage resistors can generate heat during operation, and changes in temperature can affect their resistance. The temperature coefficient of resistance (TCR) indicates how much the resistance changes with temperature. A lower TCR means better stability at varying temperatures.

2. Voltage Stress

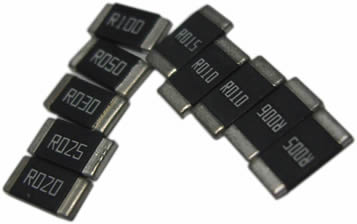

Prolonged exposure to high voltage can cause degradation of the resistor material, leading to changes in resistance. The voltage coefficient of resistance (VCR) describes how the resistance varies with applied voltage. A smaller VCR indicates less sensitivity to voltage changes.

3. Mechanical Stress

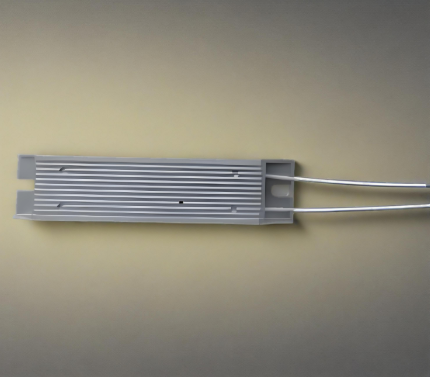

Physical vibrations, shocks, or thermal expansion and contraction can cause mechanical stress on the resistor, potentially altering its resistance. The packaging and mounting method of the resistor play a role in its ability to withstand mechanical stress.

4. Environmental Factors

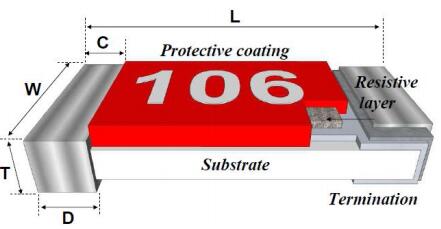

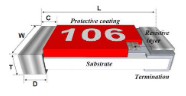

Moisture, humidity, dust, and corrosive gases in the environment can affect the resistor's performance and stability. Resistors with proper sealing and protective coatings are more resistant to environmental degradation.

5. Aging

Over time, all resistors will experience some degree of aging, which can lead to a gradual change in resistance. The quality of materials and manufacturing processes determines the resistor's aging rate.

Testing and Evaluating Stability

Various tests can be conducted to evaluate the stability of high voltage resistors:

1. Temperature Cycling Test

This test involves subjecting the resistor to repeated cycles of high and low temperatures to assess its resistance changes. The results are typically expressed as the percentage change in resistance after a specified number of cycles.

2. Voltage Endurance Test

The resistor is subjected to a rated voltage for an extended period (e.g., 1000 hours) to determine the long - term stability of its resistance. The resistance change after the test is measured to evaluate the resistor's voltage - withstand capability.

3. Mechanical Vibration and Shock Test

These tests simulate real - world mechanical stresses to see how the resistor's resistance changes. The resistance variation during and after the test indicates the resistor's mechanical stability.

4. Environmental Test

Tests such as humidity testing, salt spray testing, and dust testing evaluate the resistor's resistance to environmental factors. The results help determine the resistor's suitability for specific environmental conditions.

Problem and Solution

A common problem in high voltage resistor applications is the degradation of resistance over time due to voltage stress and temperature changes. For example, in a high - voltage power supply, if the resistor's resistance increases over time, it can lead to higher voltage drops and reduced efficiency. In severe cases, it may cause system failure.

Solution: To address this problem, selecting high - voltage resistors with low TCR and VCR values is essential. Additionally, using resistors made of high - quality, stable materials and employing proper heat dissipation techniques can help minimize temperature - related resistance changes. It's also important to ensure that the resistor is operated within its rated voltage and power specifications to avoid excessive stress. Regular monitoring and maintenance of the resistor's performance can help identify potential issues early and allow for timely replacement if needed.

Best Practices for Ensuring Stability

Choose high - voltage resistors with low TCR and VCR values for better temperature and voltage stability.

Select resistors made from high - quality, stable materials that are resistant to environmental factors.

Ensure proper heat dissipation and cooling for resistors in high - power applications.

Operate resistors within their rated voltage, power, and temperature ranges.

Use resistors with appropriate packaging and mounting methods to enhance mechanical stability.

Conduct regular testing and monitoring of resistor performance to detect stability issues early.

Conclusion

Ensuring the stability of high voltage resistors is crucial for the long - term performance and reliability of high - voltage applications. By understanding the factors that affect resistor stability and implementing the appropriate solutions and best practices, engineers can select and use high - voltage resistors that maintain their performance over time. Proper testing and evaluation of resistor stability help in choosing the right components for specific applications, ultimately contributing to safer and more efficient electrical systems.