Low Inductance High Voltage Resistor Design: Enhancing Precision and Performance

In high - frequency and high - voltage electronic applications, the design of resistors with low inductance is crucial for achieving precision and optimal performance. This article explores the importance of low inductance in high voltage resistors, design strategies to minimize inductance, and the benefits these resistors offer in various applications.

Table of Contents

Introduction

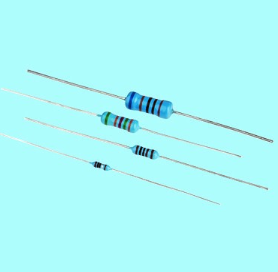

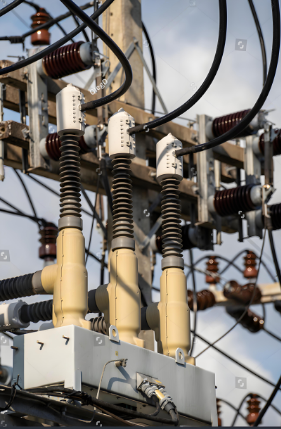

In electronic circuits, resistors are essential components that regulate voltage and current. However, in high - frequency applications, the inductance of resistors can lead to unwanted impedance effects, signal distortions, and energy losses. For high voltage applications, the challenge is to design resistors that can withstand high voltages while maintaining low inductance to ensure precision and performance. Low inductance high voltage resistors are critical in applications such as power electronics, telecommunications, medical equipment, and aerospace systems where high frequency operation and reliable voltage regulation are required.

Importance of Low Inductance in High Voltage Resistors

The inductance of a resistor becomes significant in high - frequency circuits as it contributes to the resistor's impedance, which affects the overall circuit performance. The impedance (Z) of a resistor is given by Z = √(R² + (XL - XC)²), where R is the resistance, XL is the inductive reactance, and XC is the capacitive reactance. At high frequencies, the inductive reactance (XL = 2πfL) can dominate, leading to increased impedance and phase shifts that can disrupt circuit performance. Low inductance design ensures that the resistor's impedance remains close to its DC resistance value over a wide frequency range, maintaining the intended circuit behavior and signal integrity.

Design Strategies for Low Inductance High Voltage Resistors

Several design strategies can be employed to minimize the inductance of high voltage resistors:

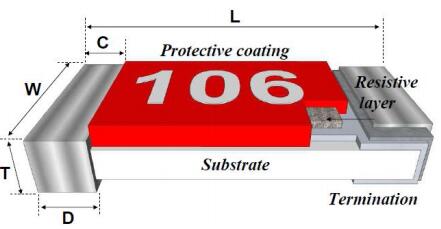

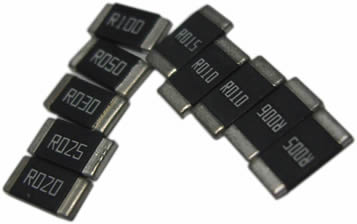

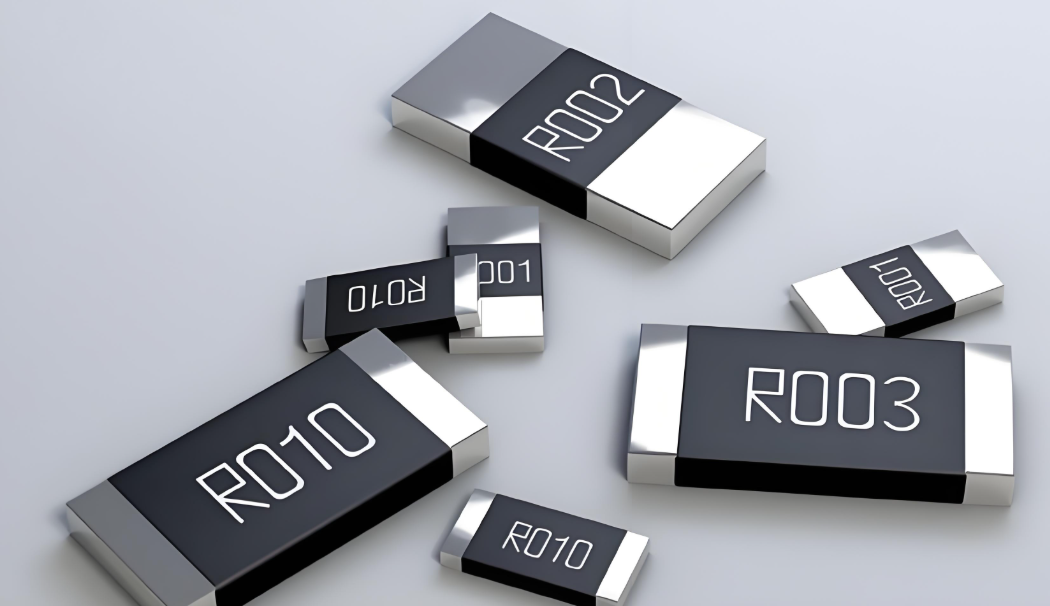

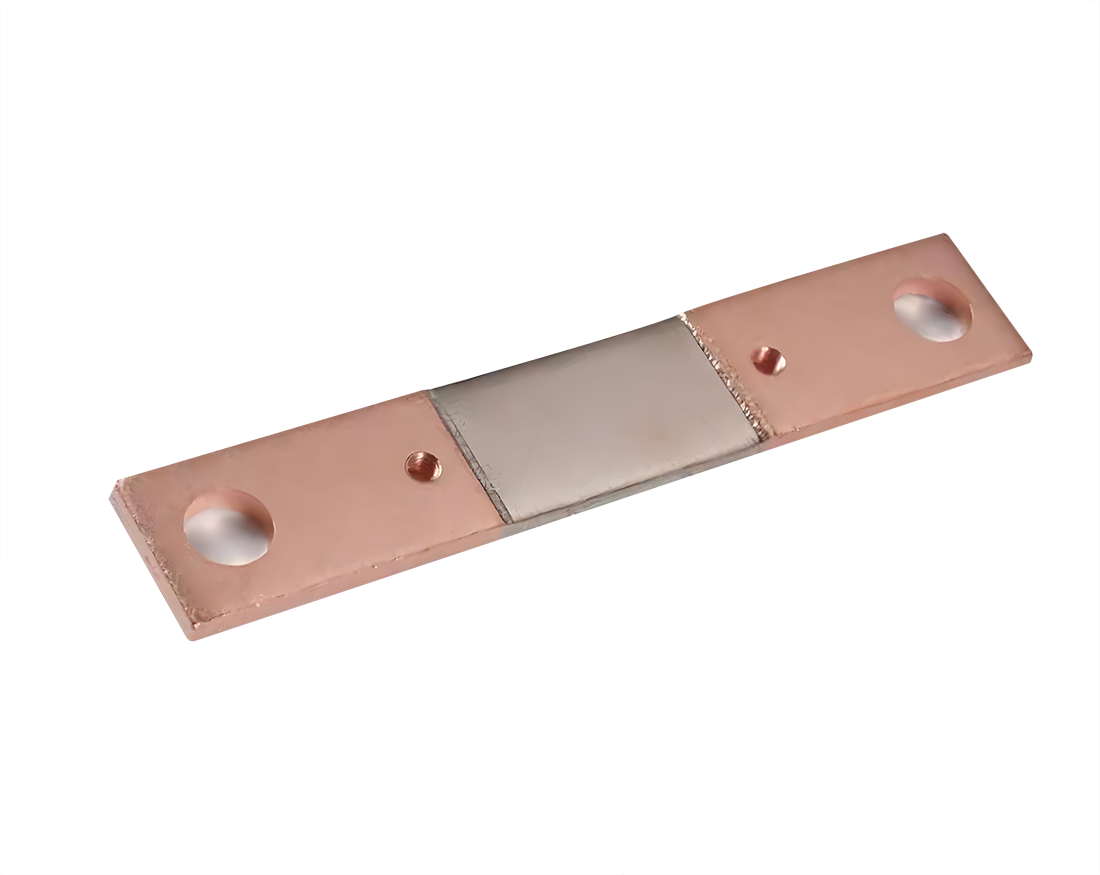

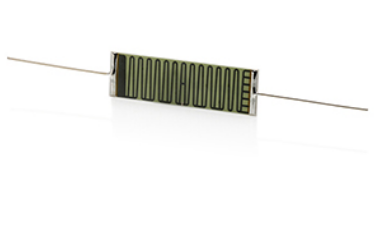

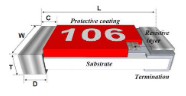

1. Flat and Thin Film Design

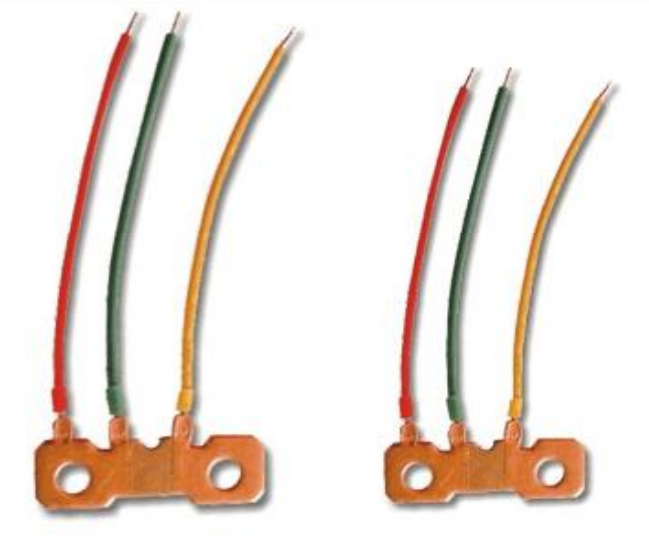

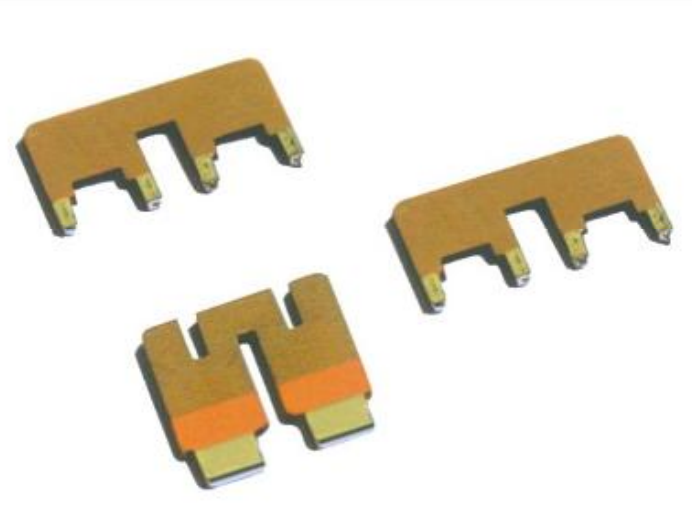

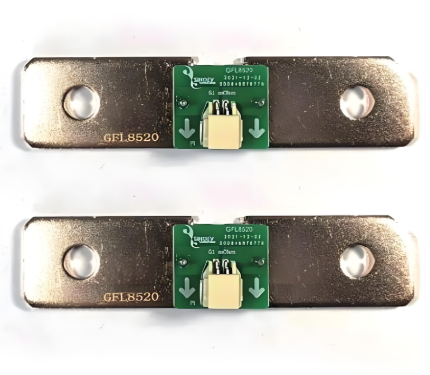

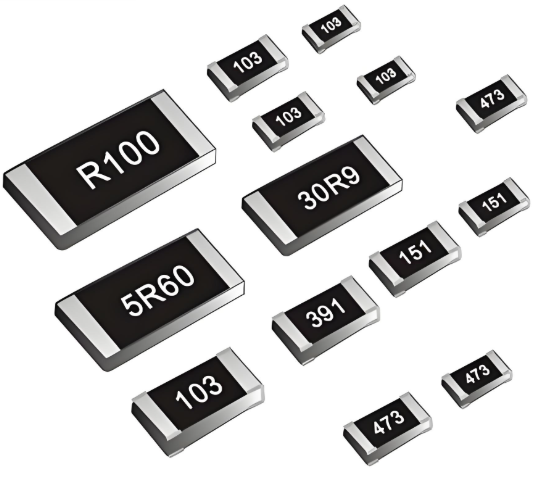

Using a flat or thin - film geometry reduces the physical length of the current path, thereby decreasing the inductance. Thin - film resistors are manufactured by depositing a thin layer of resistive material onto a substrate and then etching the desired pattern. This design reduces the loop area through which current flows, minimizing inductance.

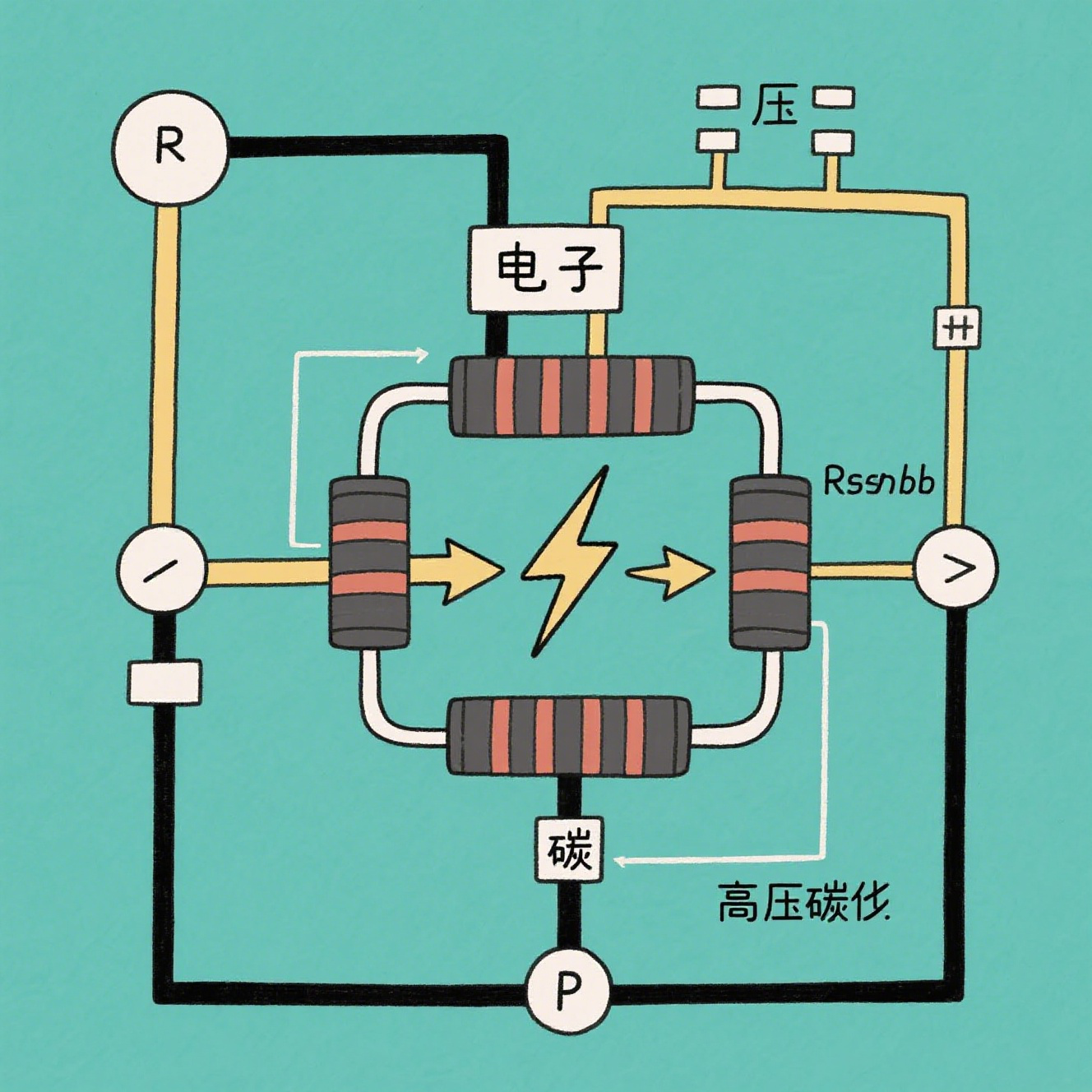

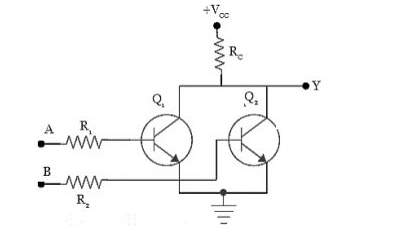

2. Multi - Layer Construction

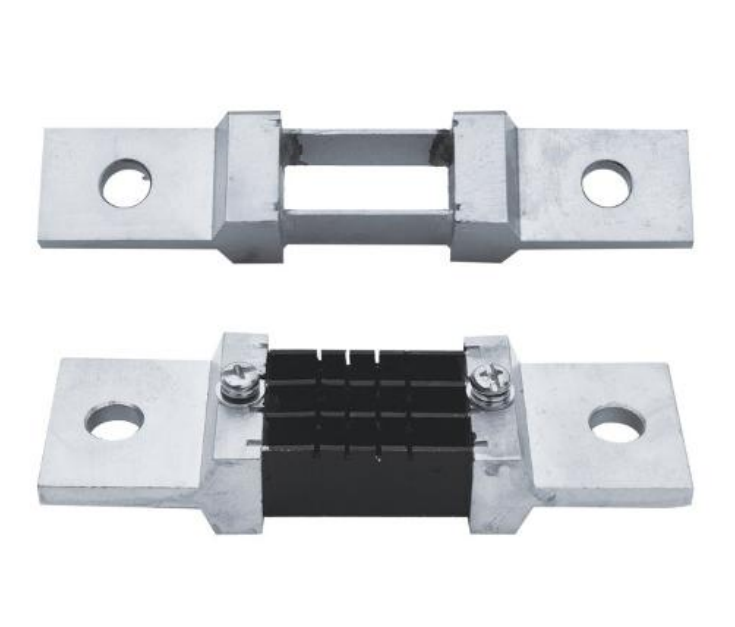

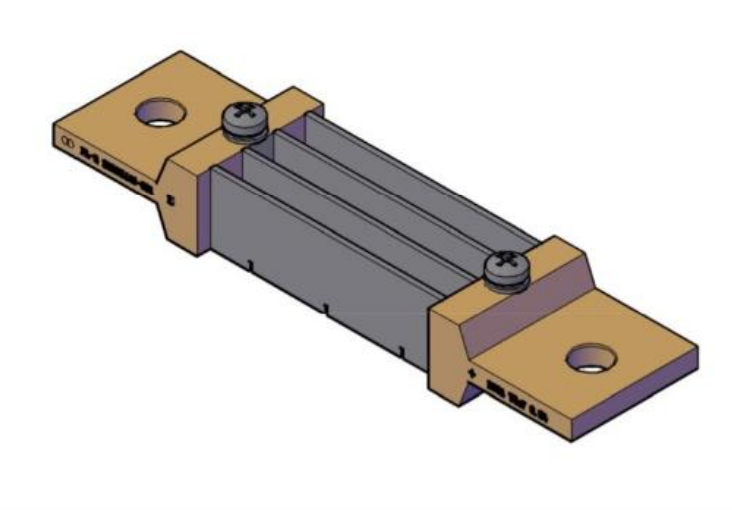

A multi - layer construction with interleaved electrodes can help cancel out the magnetic fields generated by the current, reducing overall inductance. This approach involves stacking multiple layers of resistive material with alternating electrodes to create a compact design with low inductance.

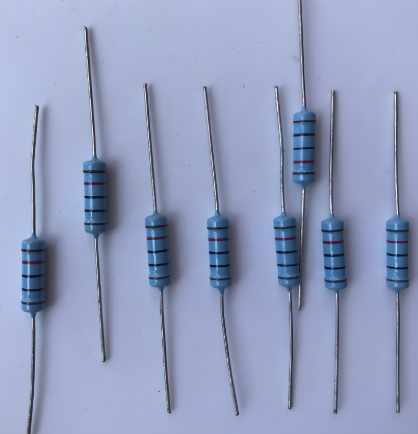

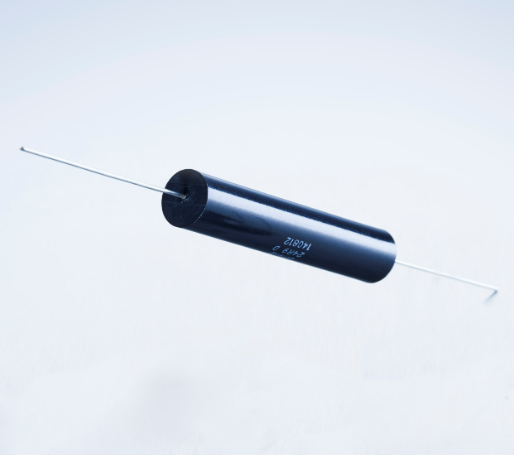

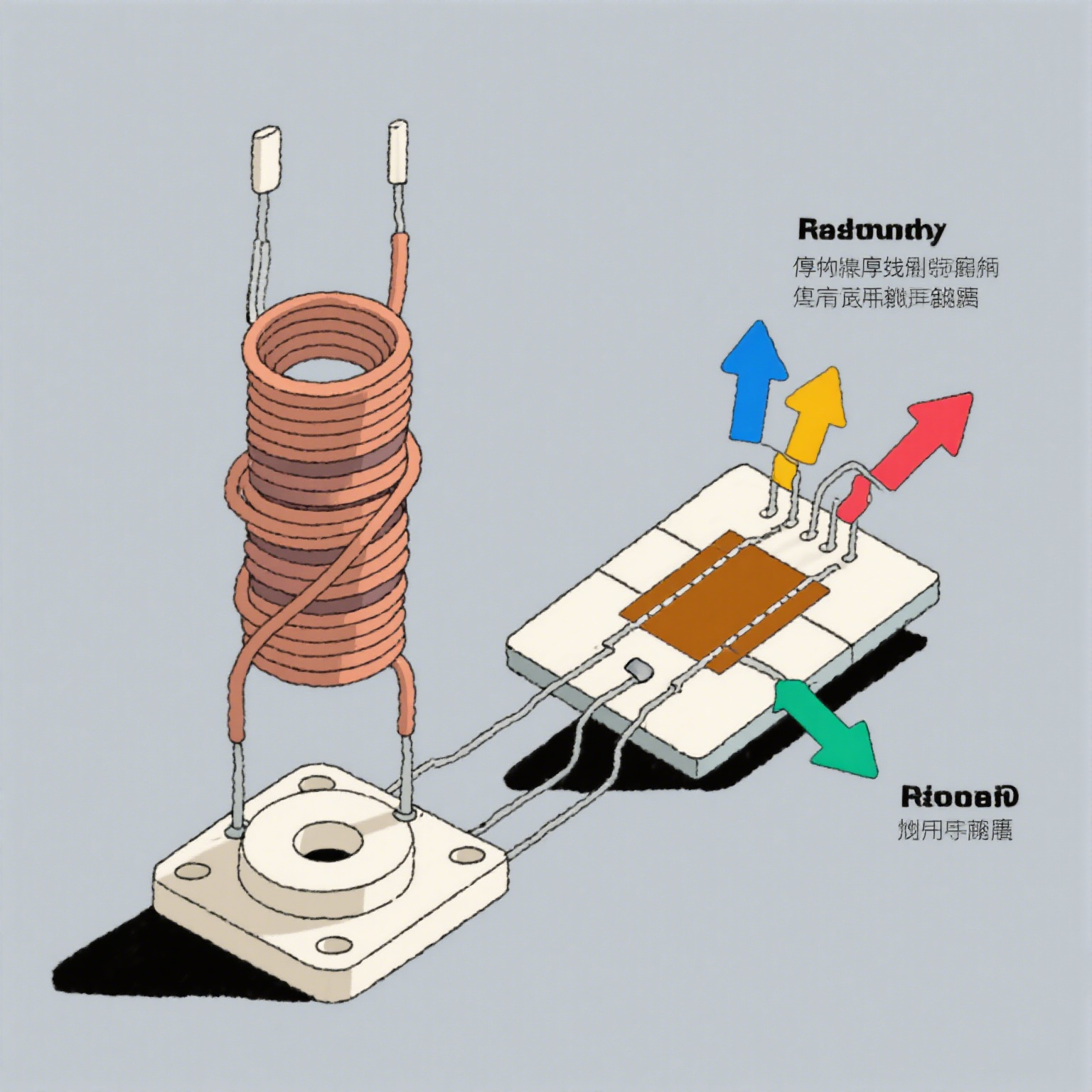

3. Non - Inductive Winding Techniques

For wire - wound resistors, non - inductive winding techniques such as bifilar or Ayrton - Perry winding can minimize inductance. Bifilar winding involves winding two wires side - by - side in opposite directions to cancel out the magnetic fields. The Ayrton - Perry winding uses a flat, multi - layer winding with alternate layers connected in opposite directions to achieve a similar effect.

4. Selection of Resistive Materials

Choosing resistive materials with high resistivity allows for thinner layers or smaller wire diameters to achieve the desired resistance, which can help reduce inductance. Materials such as nichrome, tantalum nitride, or specialized high - resistivity alloys are commonly used in low inductance resistor designs.

Performance Comparison

To illustrate the benefits of low inductance high voltage resistor design, the following table compares key performance metrics of low inductance high voltage resistors with traditional high voltage resistors:

| Parameter | Low Inductance High Voltage Resistor | Traditional High Voltage Resistor |

|---|---|---|

| Inductance | < 0.1 nH | 1 - 10 nH |

| Resistance Tolerance | ±0.01% - ±0.1% | ±0.1% - ±5% |

| Frequency Range | Up to several GHz | Up to several MHz |

| Voltage Rating | Up to 10 kV | Up to 10 kV |

| Power Rating | 0.1 W - 10 W | 0.1 W - 50 W |

| Temperature Coefficient | ±5 ppm/°C | ±20 - ±100 ppm/°C |

This data shows that low inductance high voltage resistors offer significantly lower inductance and better performance at high frequencies while maintaining tight resistance tolerance and low temperature coefficient. These characteristics make them suitable for precision applications where traditional high voltage resistors may not perform adequately.

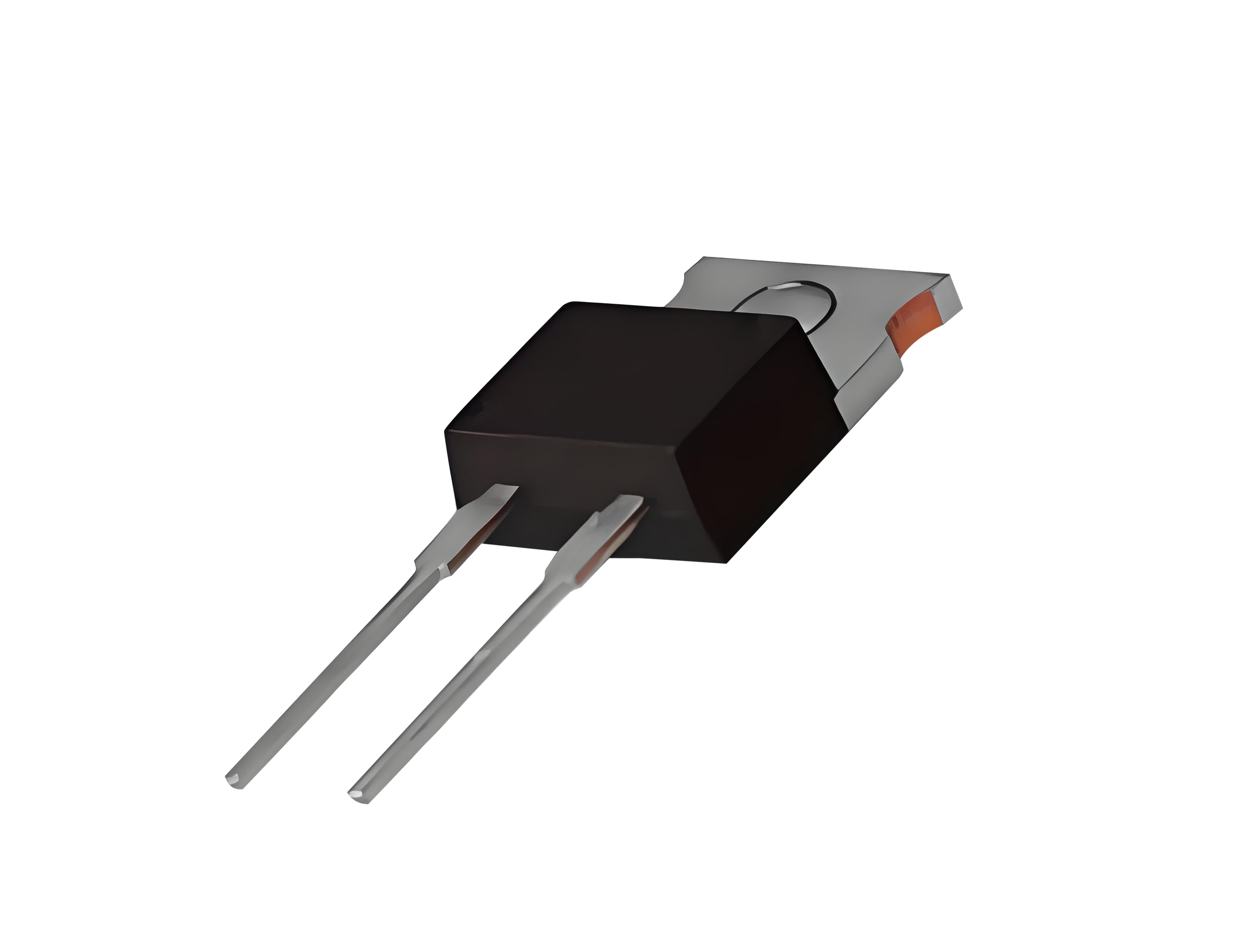

Problem and Solution

A common problem in the design of low inductance high voltage resistors is achieving a balance between low inductance and high - voltage withstand capability. High voltage resistors typically require a certain physical size and structure to distribute the voltage and prevent electrical breakdown. However, larger structures can lead to increased inductance. For example, a high voltage resistor designed with a long, thin resistive element may have good voltage withstand properties but higher inductance due to the longer current path.

Solution: To address this challenge, a combination of design strategies can be employed. Using a multi - layer thin - film design allows for a compact structure with low inductance while providing sufficient voltage distribution. Additionally, incorporating non - inductive winding techniques in wire - wound resistors can minimize inductance without significantly increasing the physical size. Selecting materials with high dielectric strength and excellent resistivity helps achieve the desired resistance and voltage rating without requiring excessive dimensions. By optimizing these factors, it is possible to create low inductance high voltage resistors that meet both the inductance and voltage requirements of the application.

Best Practices for Designing Low Inductance High Voltage Resistors

Use thin - film or flat designs to minimize the current path length and reduce inductance.

Implement multi - layer constructions with interleaved electrodes to counteract magnetic fields and lower inductance.

Employ non - inductive winding techniques such as bifilar or Ayrton - Perry winding for wire - wound resistors.

Select high - resistivity materials to achieve the desired resistance with thinner layers or smaller wire diameters.

Optimize the resistor's geometry and layout to minimize the loop area and maximize the surface area for heat dissipation.

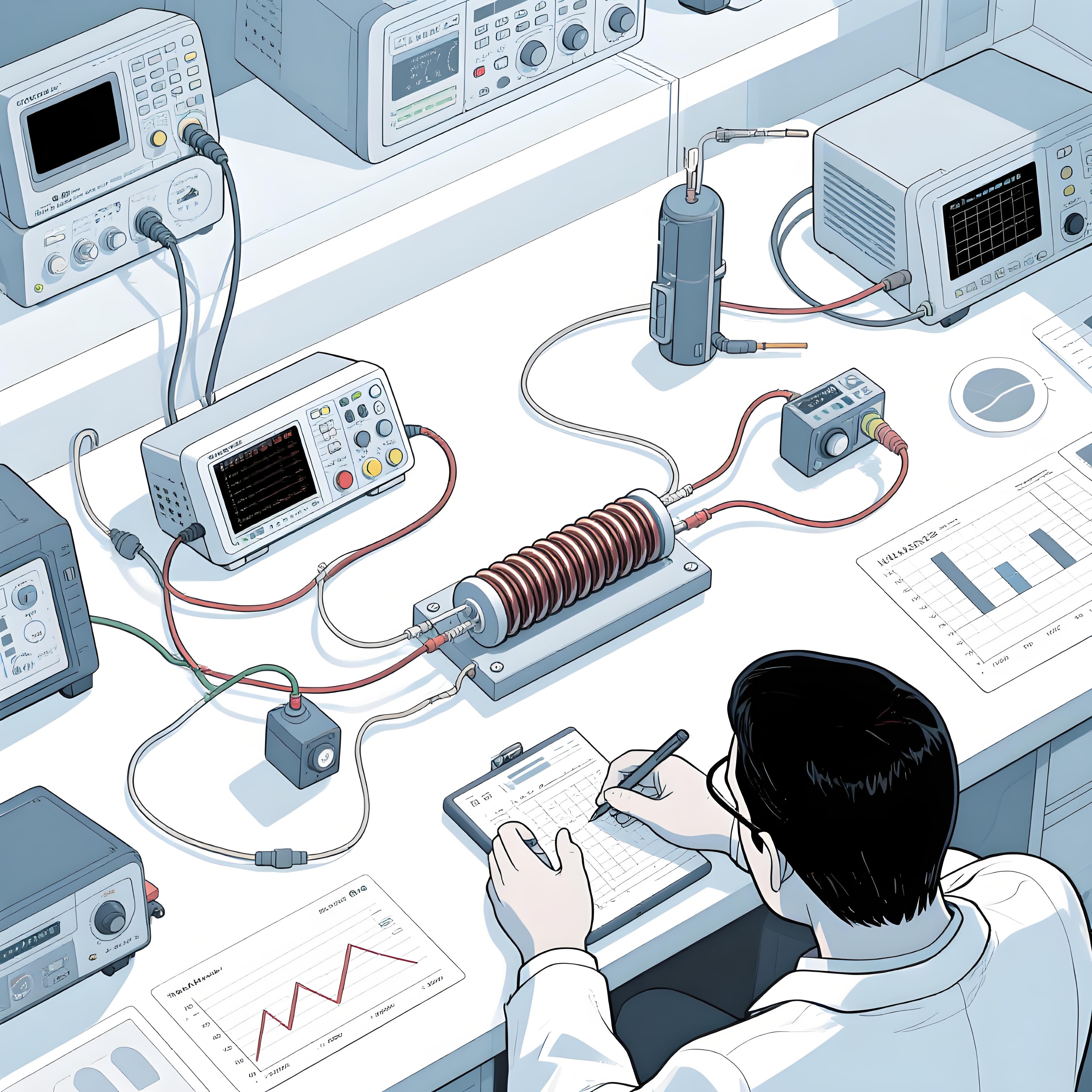

Conduct thorough testing and characterization of the resistor's performance across a wide range of frequencies and voltages to ensure it meets the application requirements.

Conclusion

Low inductance high voltage resistor design is essential for enhancing precision and performance in high - frequency and high - voltage electronic applications. By employing effective design strategies such as thin - film geometry, multi - layer construction, non - inductive winding techniques, and careful material selection, engineers can create resistors that maintain low inductance while withstanding high voltages. These design approaches help ensure accurate voltage regulation, signal integrity, and overall system reliability. Following best practices in the design and testing of low inductance high voltage resistors enables the development of advanced electronic systems for industries such as power electronics, telecommunications, medical equipment, and aerospace.