-

Types of High Voltage Resistors: Wirewound vs. Thick Film, Medical vs. Industrial Uses, and How to Select (2024 Guide)

<!-- Introduction -->IntroductionHigh voltage resistors come in diverse types, each tailored for specific industrial, medical, or automotive applications. With advancements in materials like thick-fil...

-

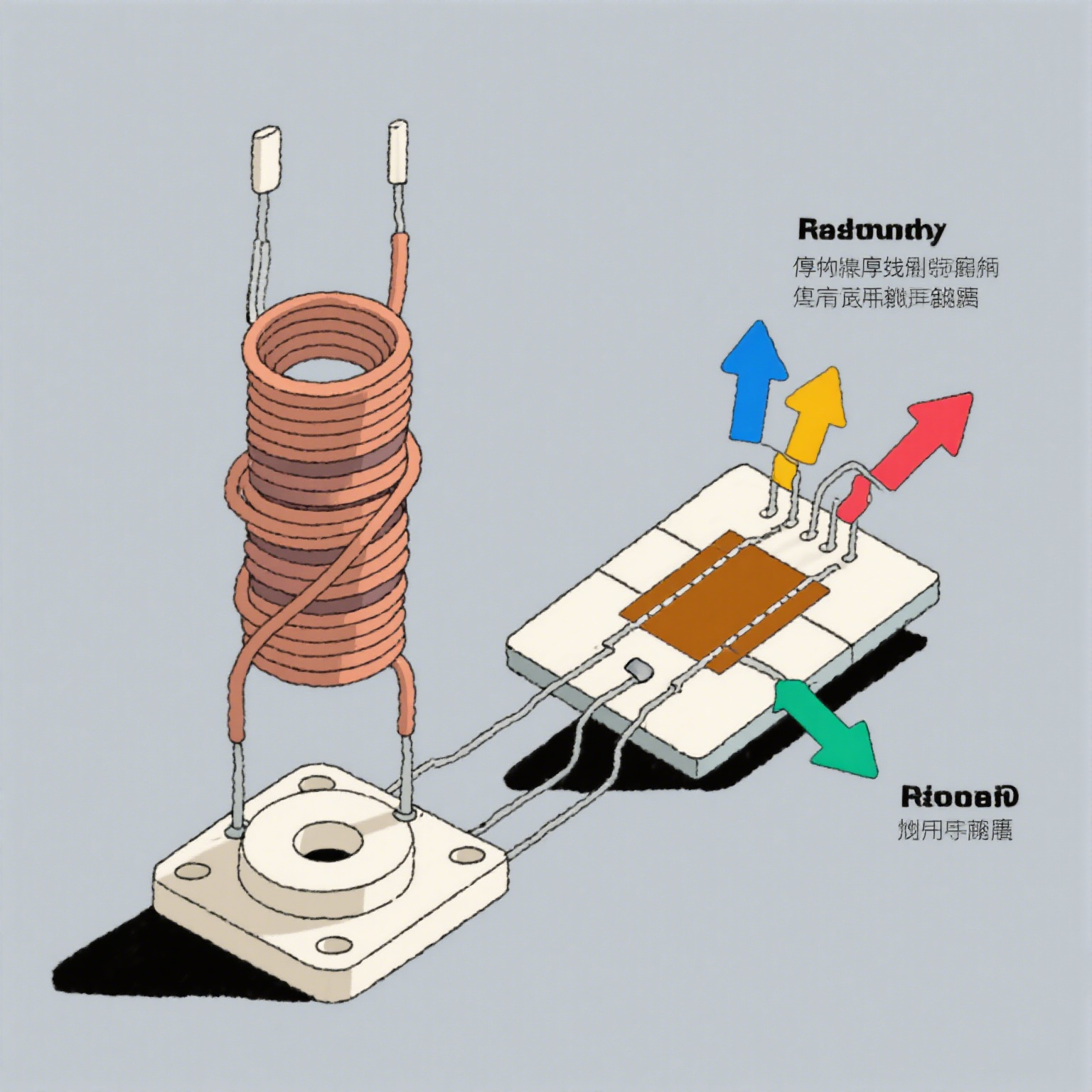

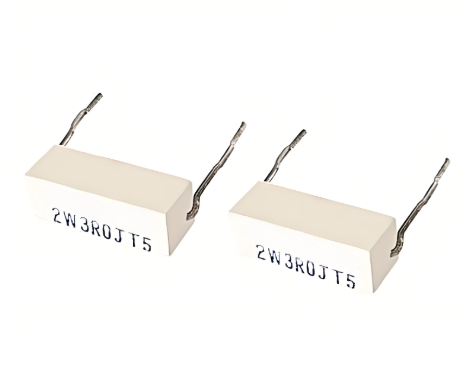

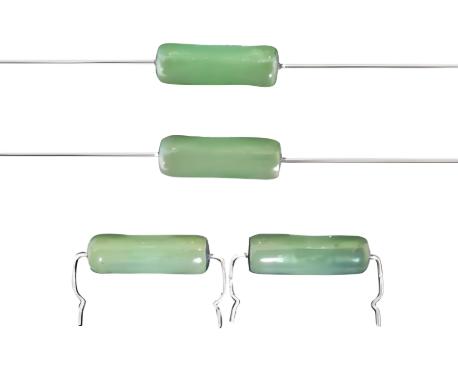

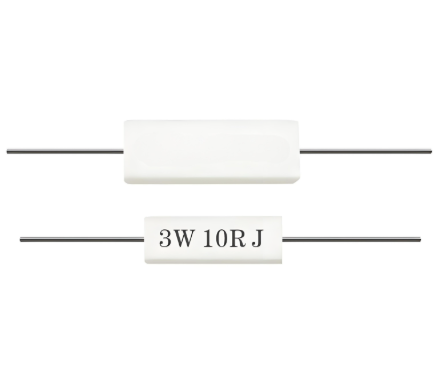

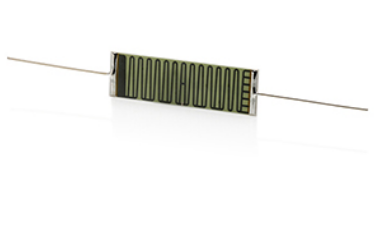

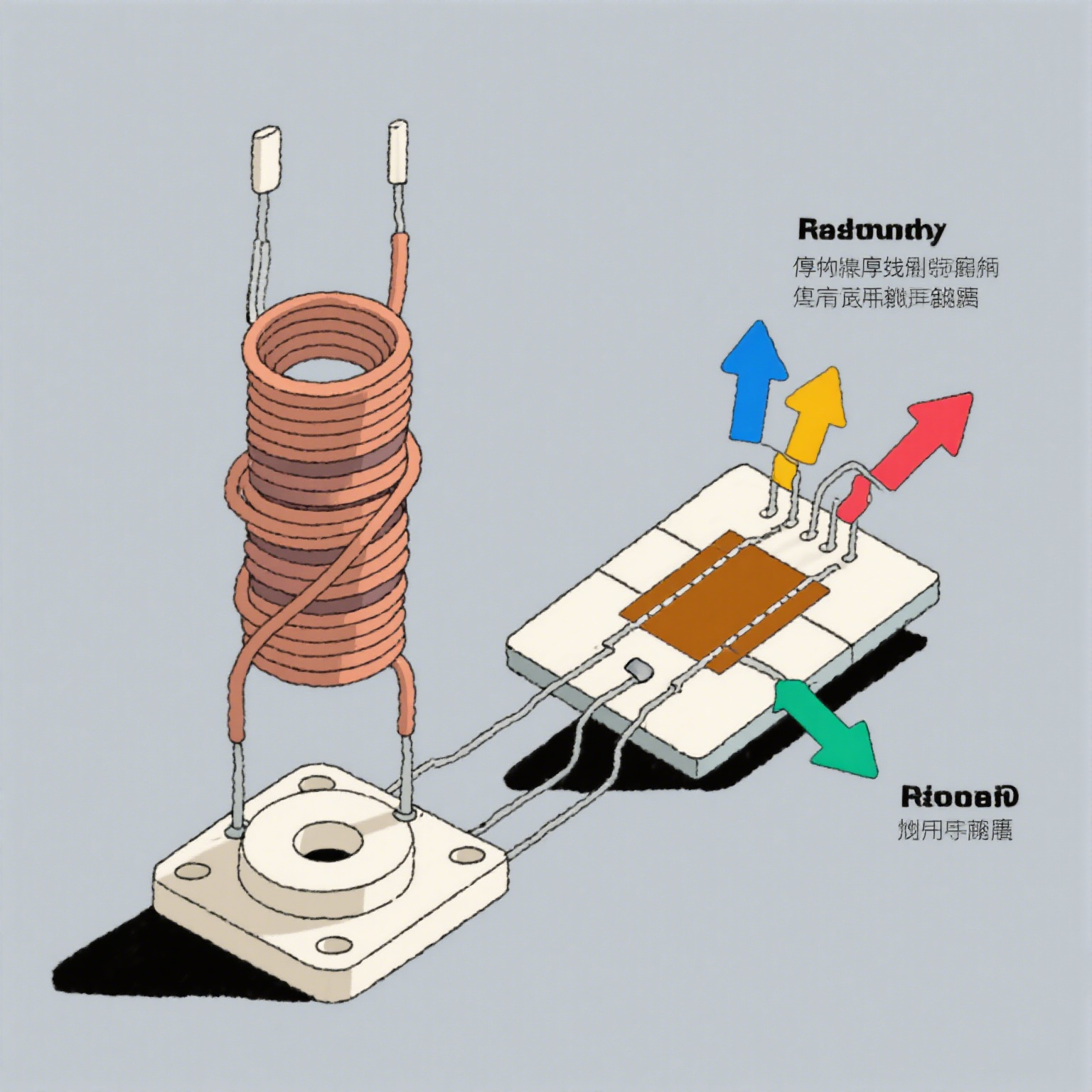

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial Applications

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial ApplicationsIn high - power industrial systems, the 600W wirewound power resistor is a cornerstone component...

-

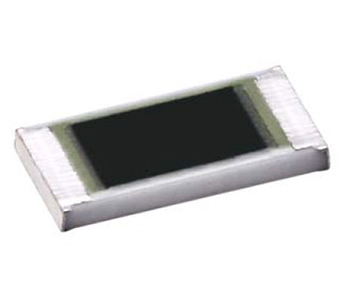

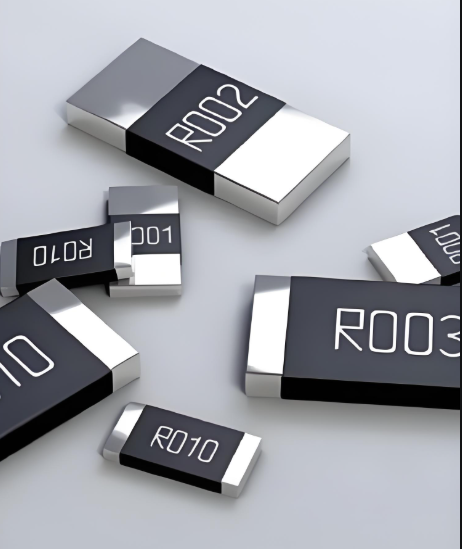

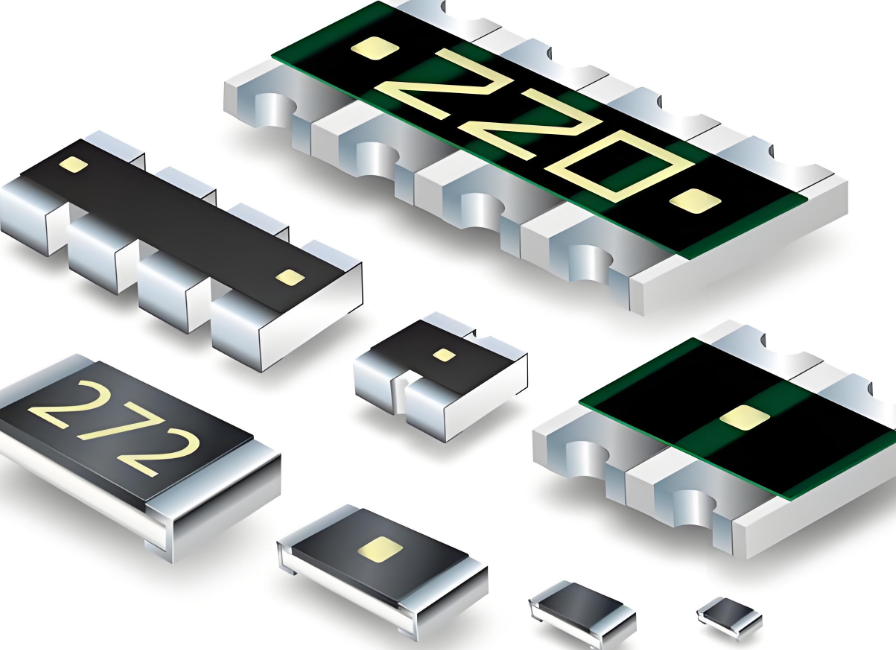

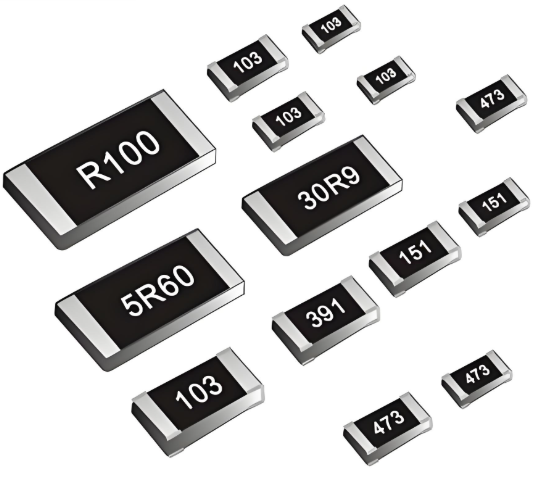

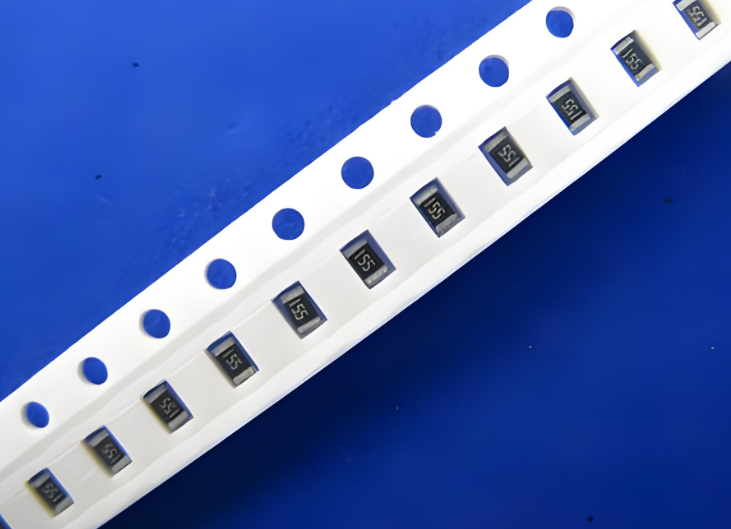

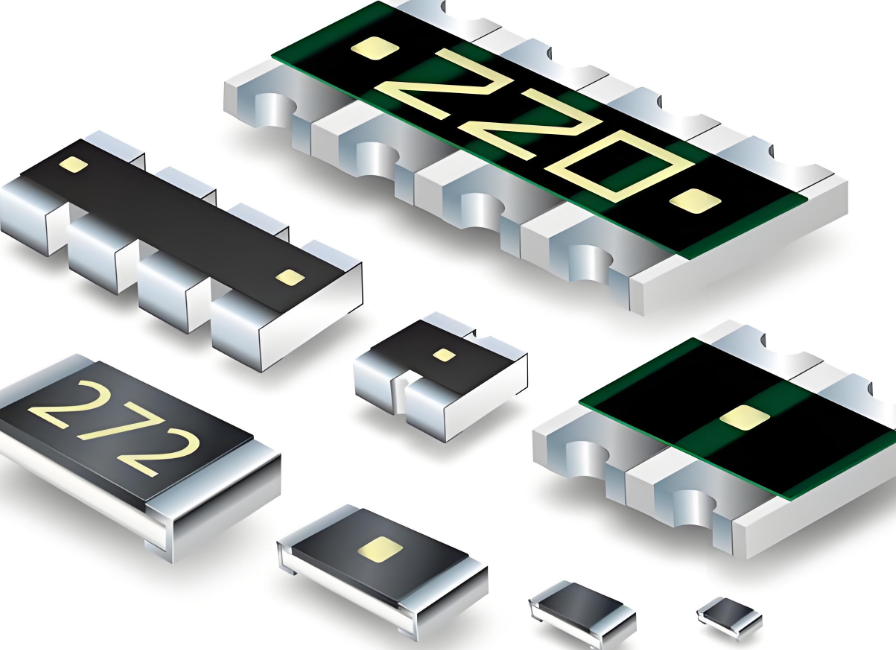

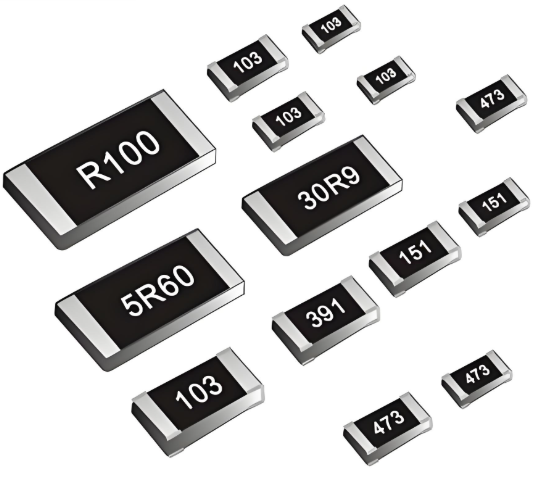

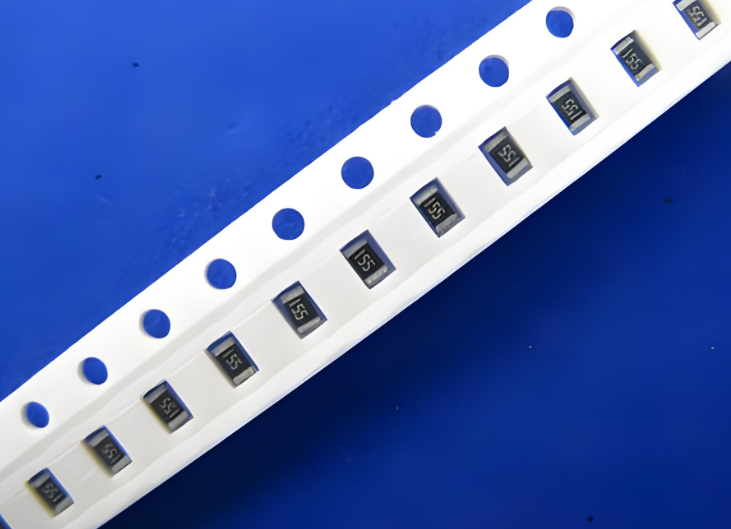

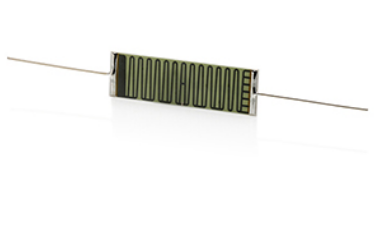

Thick Film Chip Resistors, High Voltage

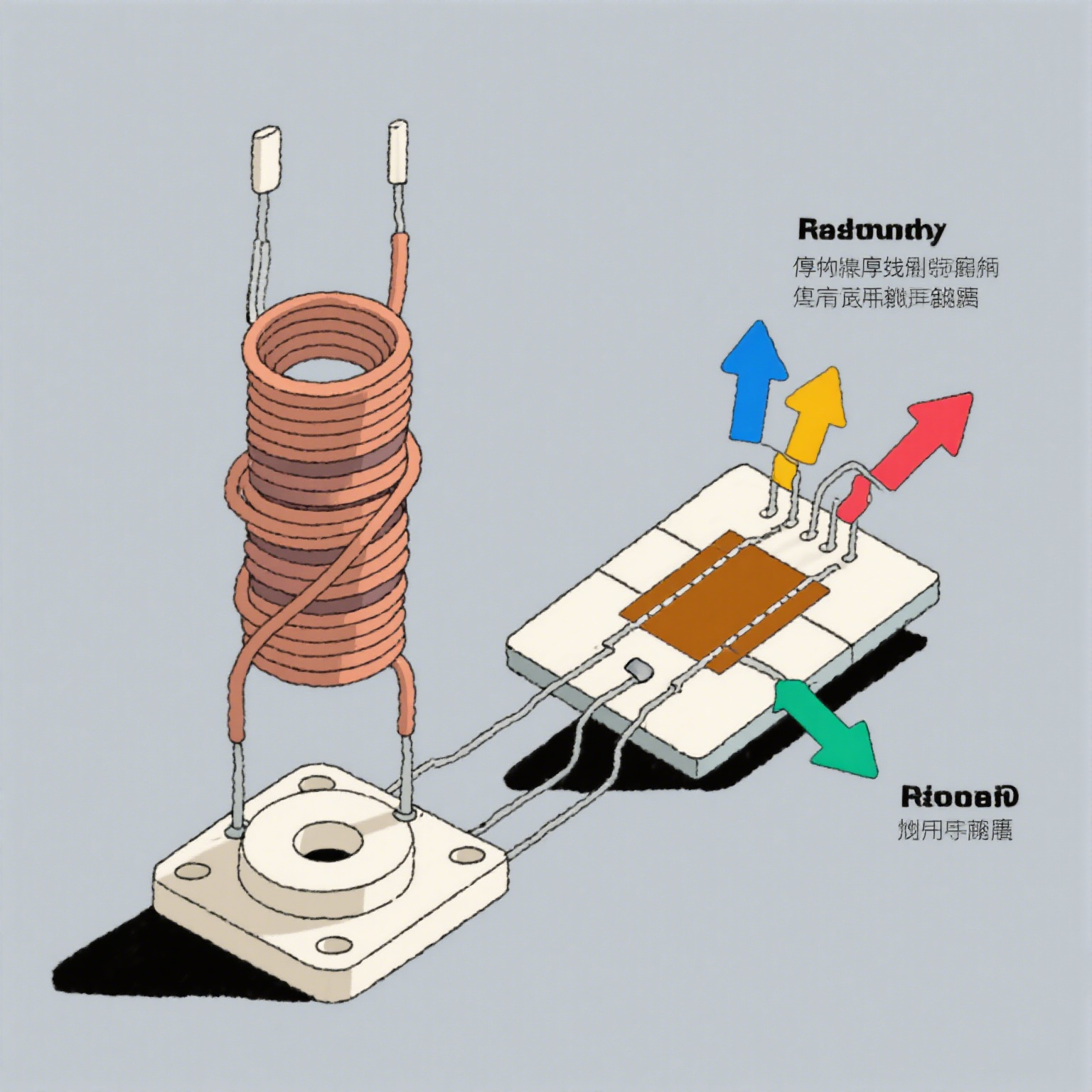

High Voltage Low VCR Thick Film Chip Resistor - HVRC SeriesDerating CurveHigh Voltage Low VCR resistor with the size from 1206 to 2512, resistance up to 500M ohm , offers Max overload to 4000V in 2512...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

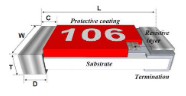

High Voltage (Up to 3 kV) Thick Film Chip Resistors

High Voltage (Up to 3 kV) Thick Film Chip Resistors are crucial electronic components in the modern electronics field. Below is a detailed overview of their key features and attributes:Key Characteris...

-

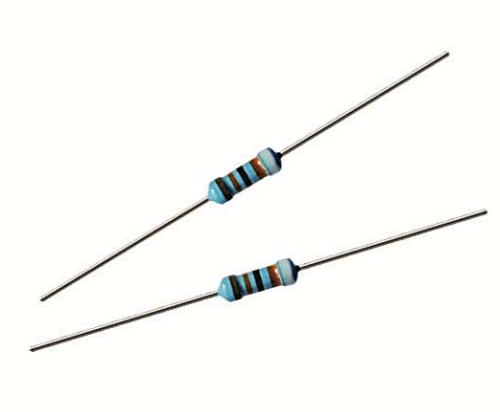

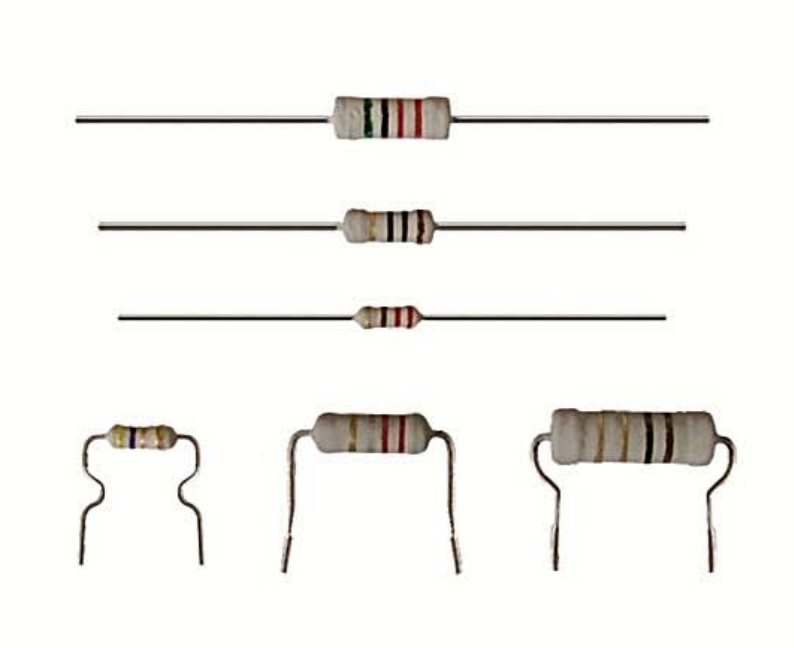

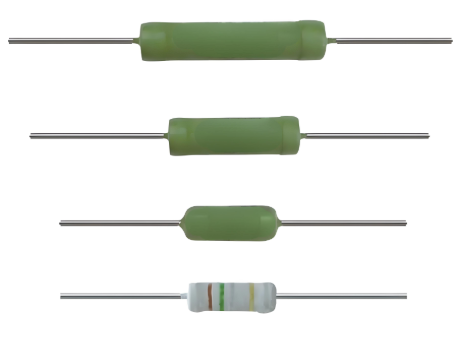

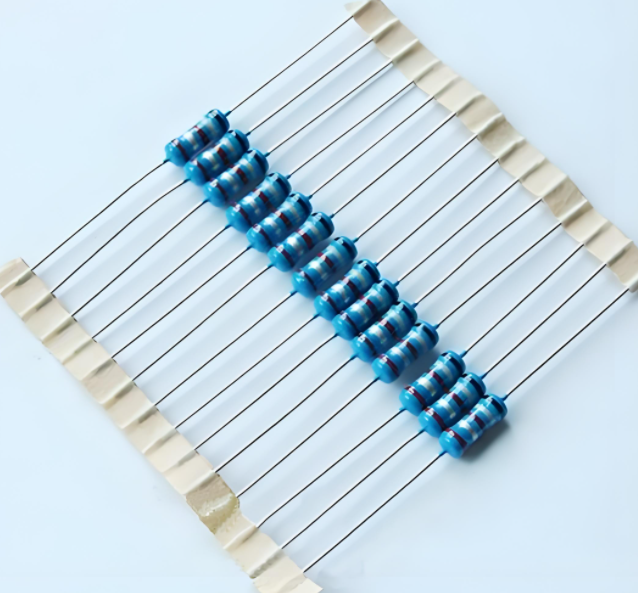

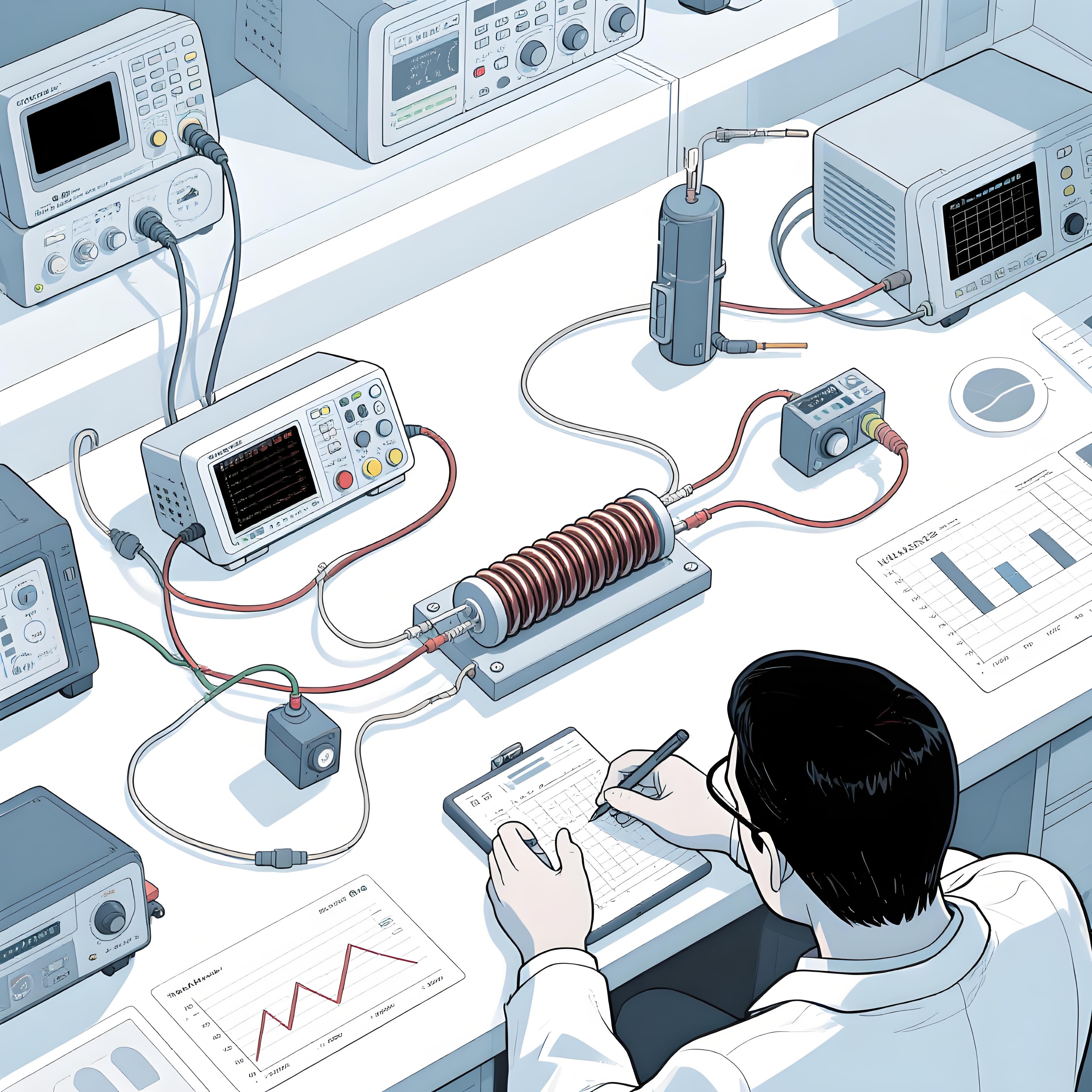

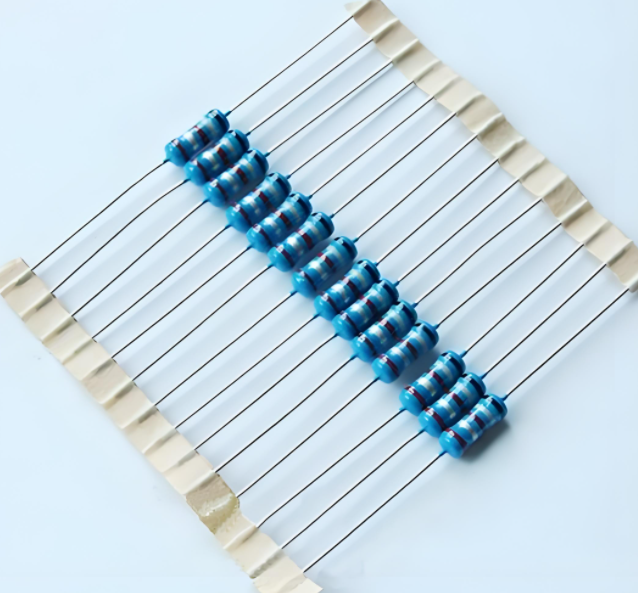

Carbon vs. Metal Film vs. Wirewound: Choosing a Resistor for High Pulse Loads

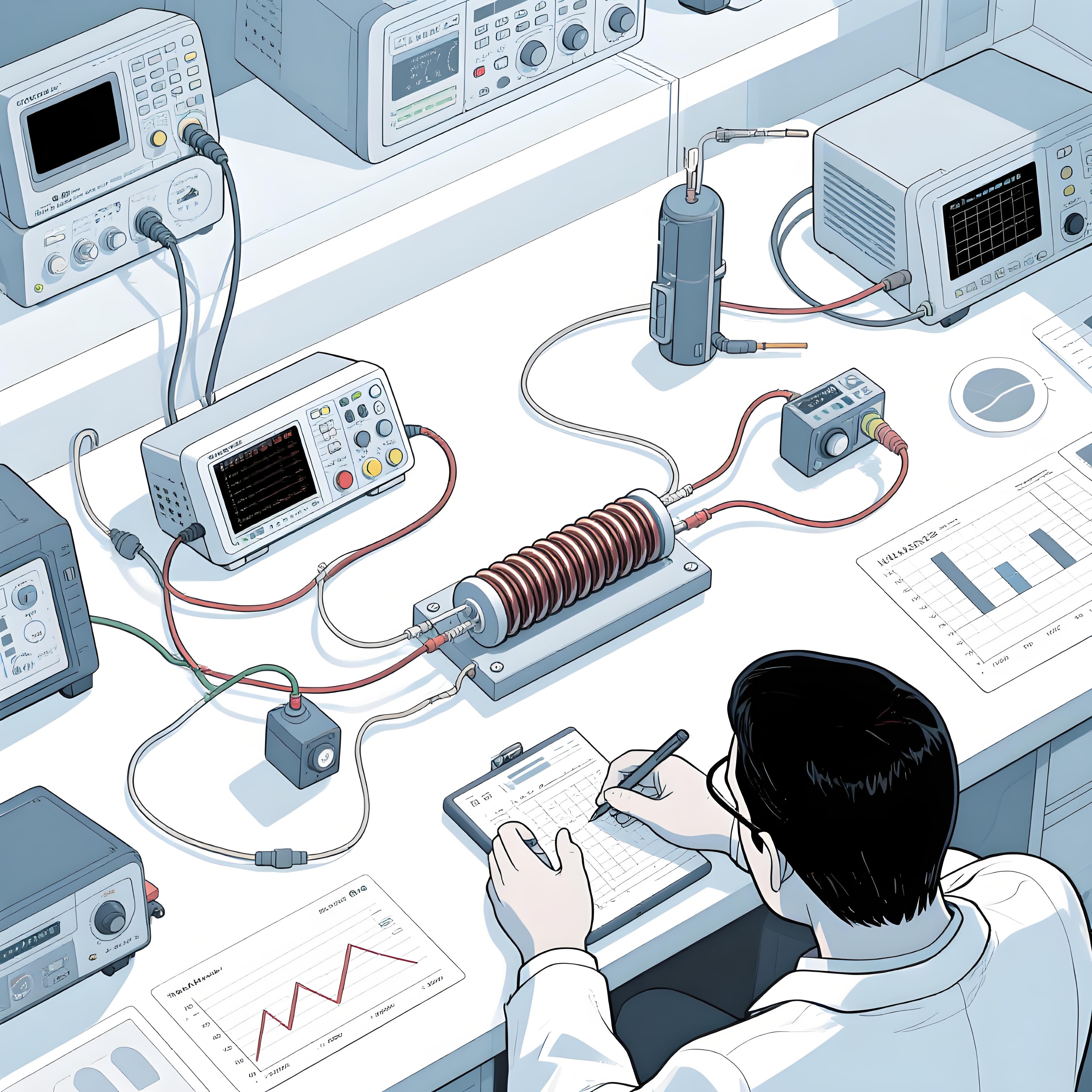

Carbon vs. Metal Film vs. Wirewound: Choosing a Resistor for High Pulse LoadsSelecting the right resistor for high pulse load applications is a critical decision that can make or break your circuit...

-

Metal Film Precision Resistors for Medical Equipment – Reliable Components for Healthcare Electronics

Title: Metal Film Precision Resistors for Medical Equipment – Reliable Components for Healthcare ElectronicsIntroductionIn healthcare electronics, reliability and accuracy are not just design goals ...

-

Molded Thick Film Divider, High Voltage, High Precision, Surface-Mount

Metal Film Precision High Voltage MELF Resistor (CSRP Series)500V-1000VCSRP±0.1%±0.25%±0.5%±1%MELF High Voltage Resistor (CSRH Series)1500V-2500VCSRH±1% ...

-

Exploring Different Types of Alloy Resistors: Materials, Applications, and Characteristics

Exploring Different Types of Alloy Resistors: Materials, Applications, and CharacteristicsWelcome to this guide on alloy resistors. In this article, we will explore the different types of alloy resist...

-

Thin Film vs. Thick Film: Which High-Frequency Resistor Technology is Best for Your 5G PCB?

Introduction: The Heart of the Matter in 5G DesignThe relentless drive for faster data rates, lower latency, and higher network density in 5G technology pushes every component on a PCB to its performa...

-

Trimmable Thick Film Chip Resisto

Trimmable Thick Film Chip Resistor: Unique Advantages and Application ScenariosResistors are fundamental components in electronic circuits, and selecting the right type can significantly impact the pe...

-

Precision Resistors: The Unsung Heroes in Medical Devices

Precision Resistors: The Unsung Heroes in Medical DevicesIn the world of medical technology, precision is not just a luxury—it's a necessity. Medical devices, from diagnostic equipment to life-s...

-

Trimmable Thick Film Chip Resistor: Overcoming Trimming Challenges for Precision and Reliability

IntroductionTrimmable Thick Film Chip Resistors (TFCRs) are essential components in modern electronics, offering the flexibility to adjust resistance values to meet precise circuit requirements. Howev...

-

Unlocking the Potential of Thick Film Trimmable Chip Resistor: Comprehensive Insights for Engineers and Hobbyists

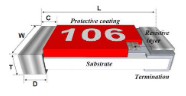

<nav></nav>What is a Thick Film Trimmable Chip ResistorA Thick Film Trimmable Chip Resistor is a specialized type of resistor that allows for post-manufacturing adjustment of its resistance value. Thi...

-

Thick Film Precision Chip Resistors: High - Performance Components for Reliable Electronics Manufacturing

Thick Film Precision Chip Resistors: High - Performance Components for Reliable Electronics ManufacturingIn the rapidly evolving landscape of electronics manufacturing, the need for high - performance...

-

Trimmable Thick Film Chip Resistor Stability: Enhancing Long-Term Performance in Electronics

IntroductionIn the realm of electronics, the stability of components is crucial for ensuring reliable and consistent performance over time. One such component that plays a vital role in various electr...

-

High Current Low TCR Thick Film Resistor for International Market - Long-term Stability

High Current Low TCR Thick Film Resistor for International Market - Long-term StabilityIn the global electronics market, high current low TCR thick film resistors have become increasingly important fo...

-

Precision Resistors in Medical Devices: Ensuring Accuracy and Reliability for Critical Applications

IntroductionIn the realm of medical devices, precision is not just a preference—it's a necessity. Precision resistors play a crucial role in ensuring the accuracy and reliability of medical equi...

-

High - Stability Golden Aluminum Case Wirewound Resistors for Precision Circuits

IntroductionIn the realm of precision electronics, the choice of components can make or break a circuit's performance. High-stability Golden Aluminum Case Wirewound Resistors have established them...

-

High Precision High Voltage Resistors: Reliable Performance for Industrial Applications

High Precision High Voltage Resistors: Reliable Performance for Industrial ApplicationsIn industrial applications, high precision high voltage resistors play a crucial role in ensuring the accuracy an...

-

High Voltage vs Standard Resistors: Voltage Ratings, Materials & Safety Compared

IntroductionWhen designing electronic circuits, engineers often face the critical choice between high voltage resistors and standard resistors. While both components regulate current flow, their diffe...

-

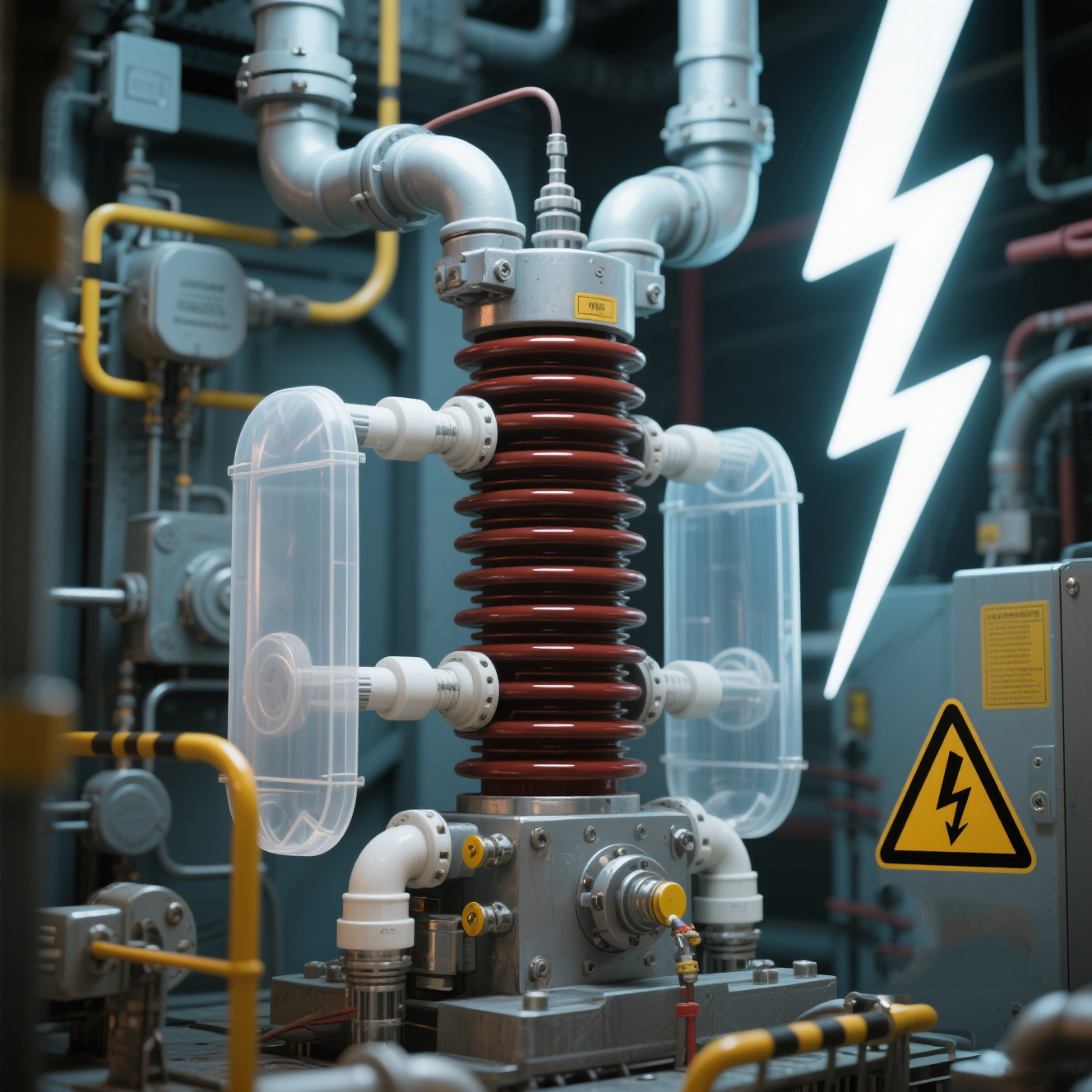

Maximizing High - Voltage Circuit Performance with High - Voltage Resistors

IntroductionHigh - voltage circuits are crucial in various applications such as power grids, industrial machinery, and advanced electronics. However, these circuits often face challenges like voltage ...

-

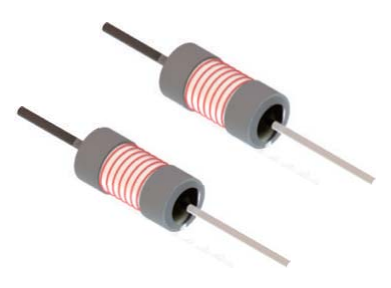

Low Inductance High Voltage Resistor Design: Enhancing Precision and Performance

Low Inductance High Voltage Resistor Design: Enhancing Precision and PerformanceIn high - frequency and high - voltage electronic applications, the design of resistors with low inductance is crucial f...

-

High Voltage Resistors in Consumer Electronics: Applications and Benefits

High Voltage Resistors in Consumer Electronics: Applications and BenefitsHigh voltage resistors play a crucial role in various consumer electronics applications, ensuring the safe and efficient operat...

-

High Precision High Voltage Resistors: Reliable Performance for Industrial Applications

High Precision High Voltage Resistors: Reliable Performance for Industrial ApplicationsIn industrial applications, high precision high voltage resistors play a crucial role in ensuring the accuracy an...

-

High Voltage Resistor Stability: Ensuring Long - Term Performance in High - Voltage Applications

High Voltage Resistor Stability: Ensuring Long - Term Performance in High - Voltage ApplicationsIn high - voltage applications, the stability of resistors is crucial for the reliable operation of elec...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

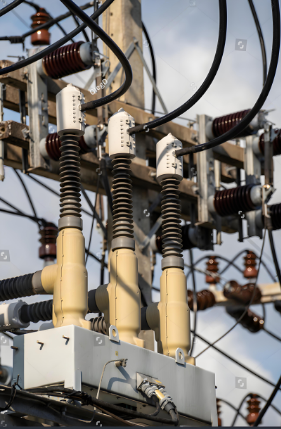

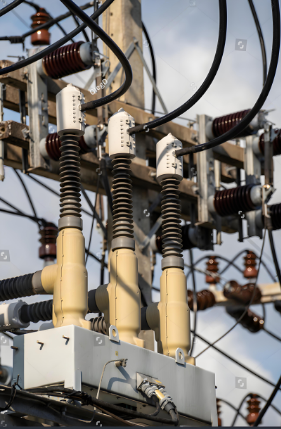

High Voltage Resistors for Power Transmission: Specifications, Reliability Standards, and Supplier Picks for Substations & Long-Distance Lines

Technical Specifications of High Voltage Resistors for Power TransmissionTo perform reliably in power transmission systems, resistors must meet strict performance criteria. Below are critical paramete...

-

50kV High Voltage Resistors: Technical Specs, Industrial Use Cases & How to Choose the Right One for Power Grids, Test Labs & Renewable Systems

Technical Specifications of 50kV High Voltage Resistors50kV resistors must withstand high electrical stress while maintaining precision. Below are critical parameters to evaluate for reliability in de...

-

10kV High Voltage Resistors: Specifications, Applications & Top Suppliers for Industrial, Power Transmission & Test Equipment

Technical Specifications of 10kV High Voltage ResistorsTo ensure reliability in high-voltage environments, 10kV resistors must meet strict performance criteria. Below are critical parameters to evalua...

-

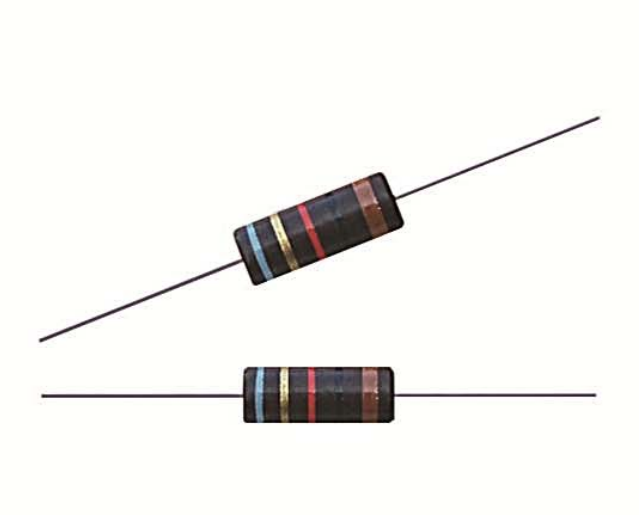

High Voltage Carbon Composition Resistors: The Ideal Choice for Power Electronics Circuits

High Voltage Carbon Composition Resistors: The Ideal Choice for Power Electronics CircuitsIntroductionIn the rapidly evolving field of power electronics, selecting the right components is crucial for ...

-

Exploring the Diverse Applications of High Voltage Resistors in Power Generation: Key Roles and Advantages

Applications of High Voltage Resistors in Power GenerationIntroductionIn the intricate realm of power generation, high voltage resistors play a crucial role. They are essential components that help in...

-

Types of High Voltage Resistors: Wirewound vs. Thick Film, Medical vs. Industrial Uses, and How to Select (2024 Guide)

<!-- Introduction -->IntroductionHigh voltage resistors come in diverse types, each tailored for specific industrial, medical, or automotive applications. With advancements in materials like thick-fil...

-

High Voltage Resistors: Working Principle, Applications, Safety Tips & How to Choose the Right One

<!-- Introduction -->IntroductionHigh voltage resistors are critical components in circuits requiring precise voltage control under extreme electrical stress. Understanding their working principle, ap...

-

Professional High Voltage Thin Film MELF Resistors

High Voltage resistor with the size from 0402 to 2512, resistance up to 100M ohm , offers Max overload to 4000V in 2512, 3000V in 2010.Thick Film special design to achieve high working voltage and sta...

-

Thick Film Chip Resistors, High Voltage

High Voltage Low VCR Thick Film Chip Resistor - HVRC SeriesDerating CurveHigh Voltage Low VCR resistor with the size from 1206 to 2512, resistance up to 500M ohm , offers Max overload to 4000V in 2512...

-

High Ohmic (up to 10 MΩ) / High Voltage (up to 3.5 kV) Metal Film Leaded Resistors

These metal film leaded resistors with high ohmic values (up to 10 MΩ) and high voltage ratings (up to 3.5 kV) possess excellent electrical characteristics. They are suitable for applications where p...

-

Precision Automotive High Voltage Thin Film MELF Resistors

Metal Film Precision High VoltageMELF Resistor (CSRP Series)500V-1000VCSRP±0.1%±0.25%±0.5%±1%0204 0207MELF High Voltage Resistor(CSRH Series)1500V-2500VCSRH±1 ±5%0207 0309ESD Surge ...

-

High Ohmic / High Voltage Metal Glaze Leaded Resistors

Thick Film High Voltage Chip ResistorUL Safety Certification3000VFVS±1%±5%0603 ~ 2512High Voltage Thick Film Chip Resistor10KV(10000V)HVR±1%±5%0402/0603/08051206/2010/2512Here is an overview of Hi...

-

Molded Thick Film Divider, High Voltage, High Precision, Surface-Mount

Metal Film Precision High Voltage MELF Resistor (CSRP Series)500V-1000VCSRP±0.1%±0.25%±0.5%±1%MELF High Voltage Resistor (CSRH Series)1500V-2500VCSRH±1% ...