Introduction

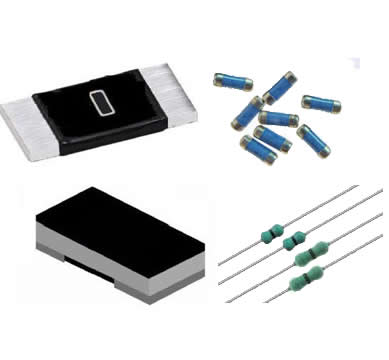

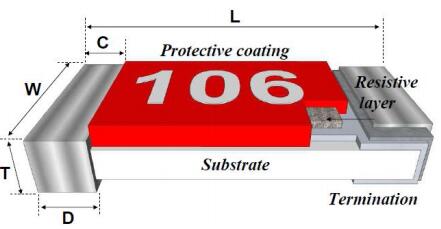

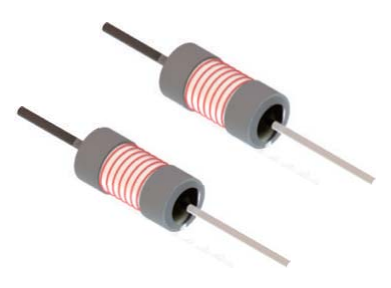

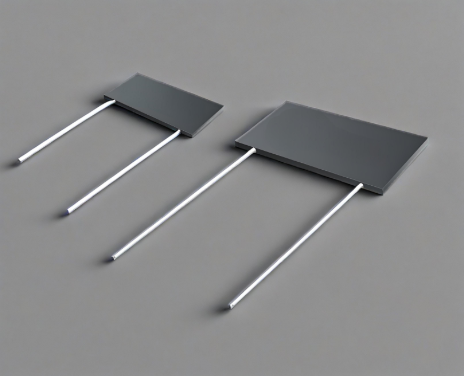

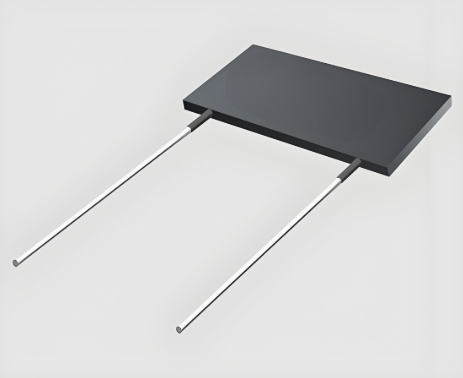

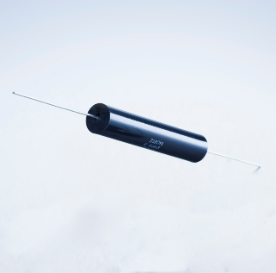

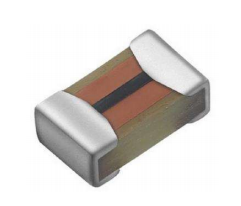

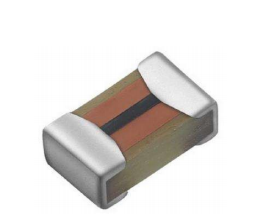

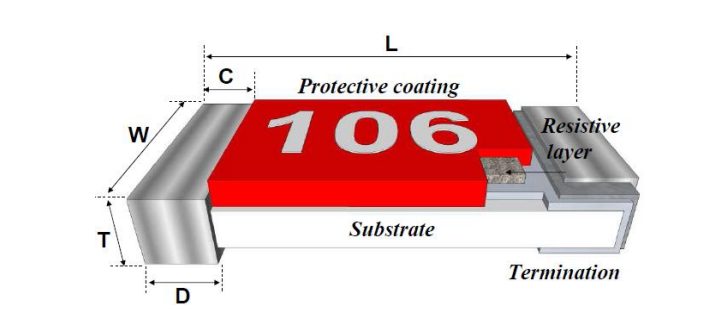

MELF (Metal Electrode Leadless Face) resistors are widely used in various electronic applications due to their superior characteristics. One of the key factors to consider when selecting a MELF resistor for a specific application is its temperature coefficient. This article aims to provide a comprehensive understanding of the MELF resistor temperature coefficient, its significance, and how to address potential issues related to it.

What is Temperature Coefficient

The temperature coefficient of a resistor describes how the resistance changes with temperature. It is typically expressed in parts per million per degree Celsius (ppm/°C). A positive temperature coefficient means the resistance increases with temperature, while a negative coefficient indicates a decrease in resistance.

The Importance of Temperature Coefficient in MELF Resistors

Understanding the temperature coefficient is crucial for ensuring the stability and reliability of electronic circuits. MELF resistors are often used in precision applications where temperature variations can significantly impact performance. By knowing the temperature coefficient, engineers can predict and compensate for resistance changes due to temperature fluctuations.

Common Temperature Coefficient Values for MELF Resistors

The following table provides typical temperature coefficient values for different types of MELF resistors:

| Resistor Type | Temperature Coefficient (ppm/°C) |

|---|---|

| MELF High Precision | ±10 |

| MELF General Purpose | ±200 |

| MELF Power | ±150 |

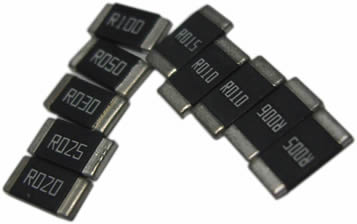

These values can help in selecting the appropriate MELF resistor for a given application based on the required precision and expected temperature range.

A Common Problem and Its Solution

Problem: In precision circuits, temperature-induced changes in resistance can lead to significant errors and instability. For example, a temperature variation of 30°C in a circuit using a MELF resistor with a temperature coefficient of ±200 ppm/°C can result in a 6% change in resistance.

Solution: To mitigate this issue, engineers can:

Select MELF resistors with lower temperature coefficients for precision applications.

Implement temperature compensation techniques to adjust for resistance changes.

Use temperature sensors to monitor and correct for temperature variations in real-time.

By addressing the temperature coefficient issue, the overall performance and accuracy of the circuit can be significantly improved.

Conclusion

The temperature coefficient of MELF resistors is a critical factor in determining their suitability for various applications. By understanding and carefully considering this parameter, engineers can design more reliable and accurate electronic circuits. This article has provided a detailed overview of the temperature coefficient in MELF resistors, its importance, and practical solutions to common problems.