High Temperature Power Resistors: Applications, Specifications & Selection Guide for Extreme Environments

Table of Contents

Introduction

High temperature power resistors are critical components in industries requiring operation under extreme thermal conditions. These resistors are engineered to withstand temperatures exceeding 200°C while maintaining stable electrical performance. Their applications span aerospace, industrial machinery, and renewable energy systems, where reliability in harsh environments is non-negotiable.

Key Applications in Extreme Environments

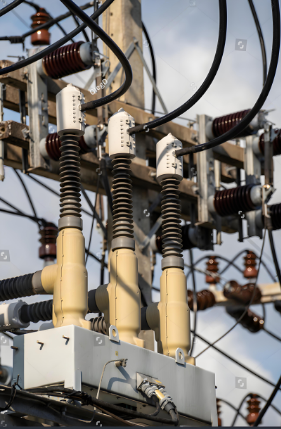

Industrial Power Systems

| Application | Temperature Range | Resistor Type | Key Requirement |

|---|---|---|---|

| Welding Equipment | 250°C–350°C | Wirewound Ceramic | High pulse energy handling |

| HVAC Systems | 180°C–220°C | Thick Film Aluminum | Moisture resistance |

Automotive & Aerospace

Electric Vehicle (EV) Batteries: Use high-voltage resistors for cell balancing, operating at 150°C–200°C.

Aircraft Engines: Require resistors rated for 300°C+ with vibration resistance.

Technical Specifications & Performance Metrics

Critical Parameters

| Parameter | Typical Value | Impact on Performance |

|---|---|---|

| Temperature Coefficient (TCR) | ±50 ppm/°C | Minimizes resistance drift at elevated temperatures |

| Max Operating Temperature | 350°C | Defines thermal endurance limits |

| Power Rating | 50W–500W | Determines heat dissipation capacity |

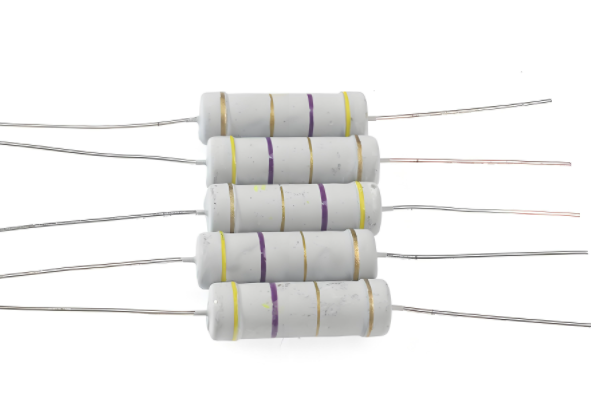

Material Innovations

Ceramic Substrates: Provide thermal conductivity up to 30 W/m·K.

Metal Alloy Films: Achieve TCR as low as 20 ppm/°C.

Selection Guide for High Temperature Resistors

Step-by-Step Criteria

Temperature Profile: Match resistor rating to maximum ambient + self-heating temperature.

Dissipation Requirements: Use derating curves to ensure safe operation (e.g., 70% of rated power at 250°C).

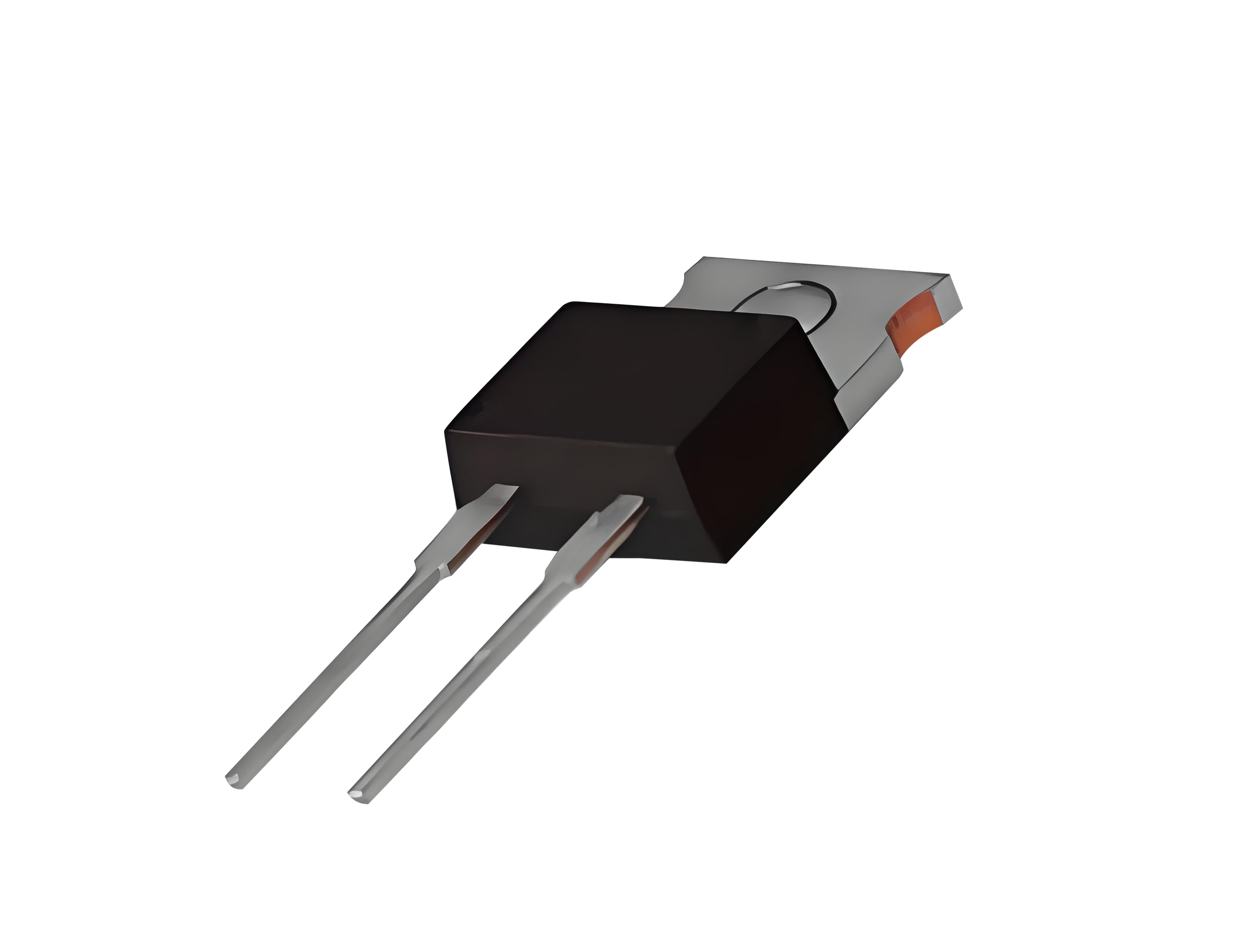

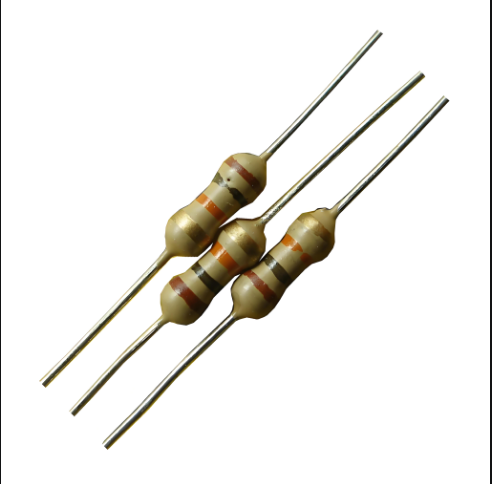

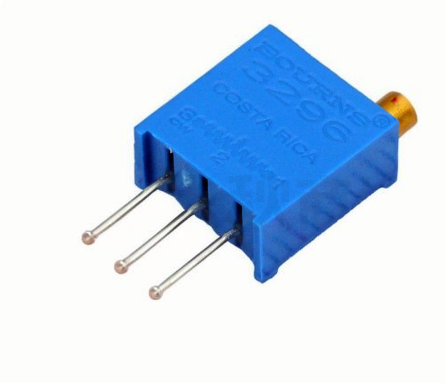

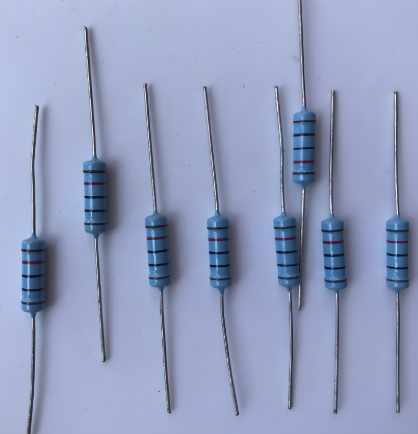

Mounting Method: Prioritize through-hole or chassis mounts for thermal expansion resistance.

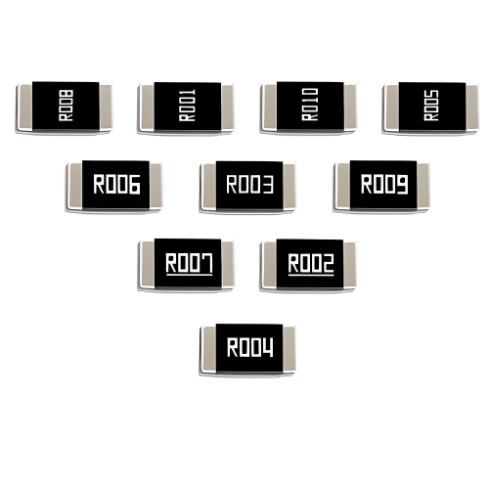

Example Product Comparison

| Model | Max Temp | TCR | Power Rating | Suitable For |

|---|---|---|---|---|

| TE Connectivity SBCHE15330RJ | 350°C | ±200 ppm/°C | 17W | Aerospace actuators |

| Stackpole KAL50FB50R0 | 275°C | ±50 ppm/°C | 50W | Industrial motor drives |

Addressing Thermal Stability Challenges

Common Issue: Resistance Drift at High Temperatures

Problem: Resistors may exhibit ±2% resistance variation beyond 200°C, causing circuit instability.

Solution: Select resistors with:

Low TCR (≤±50 ppm/°C)

Multi-layer ceramic construction

Pre-conditioning at 250°C for 1,000 hours

Case Study: Oil Exploration Equipment

A manufacturer reduced resistor failures by 85% by switching to KAL series resistors with 20 ppm/°C TCR, enabling operation at 230°C in downhole drilling tools.

Market Trends & Growth Projections

Global Market Dynamics

The global high temperature resistor market is projected to reach $1.2B by 2030 (CAGR: 6.8%).

Key growth drivers: EV adoption, 5G infrastructure, and renewable energy systems.

Regional Adoption Rates

| Region | 2024 Market Size (USD) | 2030 Forecast |

|---|---|---|

| Asia-Pacific | $420M | $780M |

| North America | $290M | $510M |

Conclusion

Selecting the optimal high temperature power resistor requires balancing thermal endurance, electrical stability, and application-specific demands. By prioritizing low TCR values, robust construction materials, and rigorous testing, engineers can ensure reliability in extreme environments. Continuous advancements in ceramic and metal alloy technologies will further expand these components' applicability in emerging sectors like electric aviation and deep-space exploration.

Email us

-

High Frequency Resistor

High Frequency Resistor

-

Moisture Resistant Resistors

Moisture Resistant Resistors

-

High Value Resistors

High Value Resistors

-

Lead-Free Resistors

Lead-Free Resistors

-

Anti-Sulfur Resistors

Anti-Sulfur Resistors

-

Low TCR Resistors

Low TCR Resistors

-

Precision Resistors

Precision Resistors

-

RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors

-

RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors

-

RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors

-

RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors

-

RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors

-

RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors

-

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

-

RXF21-TE power-type full-short-circuit temperature fuse resistors

RXF21-TE power-type full-short-circuit temperature fuse resistors

-

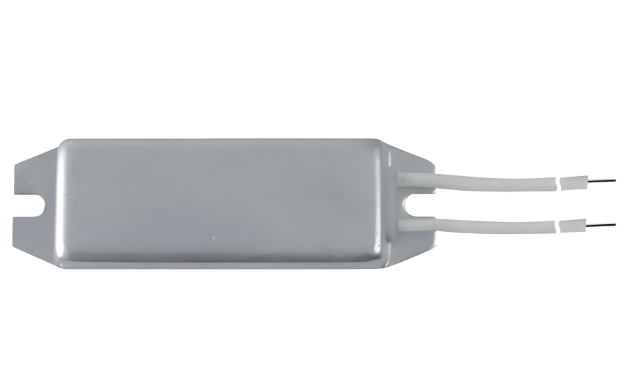

RE power aluminum case wound resistor

RE power aluminum case wound resistor

-

RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors

-

RX23 ceramic encased wire - wound resistors

RX23 ceramic encased wire - wound resistors

-

RX92 anti - interference wire - wound resistors

RX92 anti - interference wire - wound resistors

-

RX21 coated wire - wound resistors

RX21 coated wire - wound resistors

-

RXLG high power aluminum encased wire - wound resistors

RXLG high power aluminum encased wire - wound resistors

-

RX27 power ceramic encased wire - wound resistors

RX27 power ceramic encased wire - wound resistors

-

RXL power aluminum encased wire - wound resistors

RXL power aluminum encased wire - wound resistors

-

RXHGI high power wane ripple coated wire - wound resistors

RXHGI high power wane ripple coated wire - wound resistors

-

High Temperature Power Resistors: Applications, Specifications & Selection Guide for Extreme Environments

Table of ContentsIntroductionKey Applications in Extreme EnvironmentsTechnical Specifications & Performance MetricsSelection Guide for High Temperature ResistorsAddressing Thermal Stability Challe...

-

Low TCR Resistor Power Rating: Selection Guide, Applications & How to Avoid Overheating

1. What Is a Low TCR Resistor Power RatingThe power rating of a low TCR resistor specifies the maximum power ($P$) it can safely dissipate without exceeding its temperature limit (typically 125°C–1...

-

High Frequency Non-Inductive Resistors for RF, Microwave, and Power Electronics – Selection Guide & Applications

Title: High Frequency Non-Inductive Resistors for RF, Microwave, and Power Electronics – Selection Guide & ApplicationsIntroductionThis High Frequency Non-Inductive Resistors for RF, Microwave, ...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

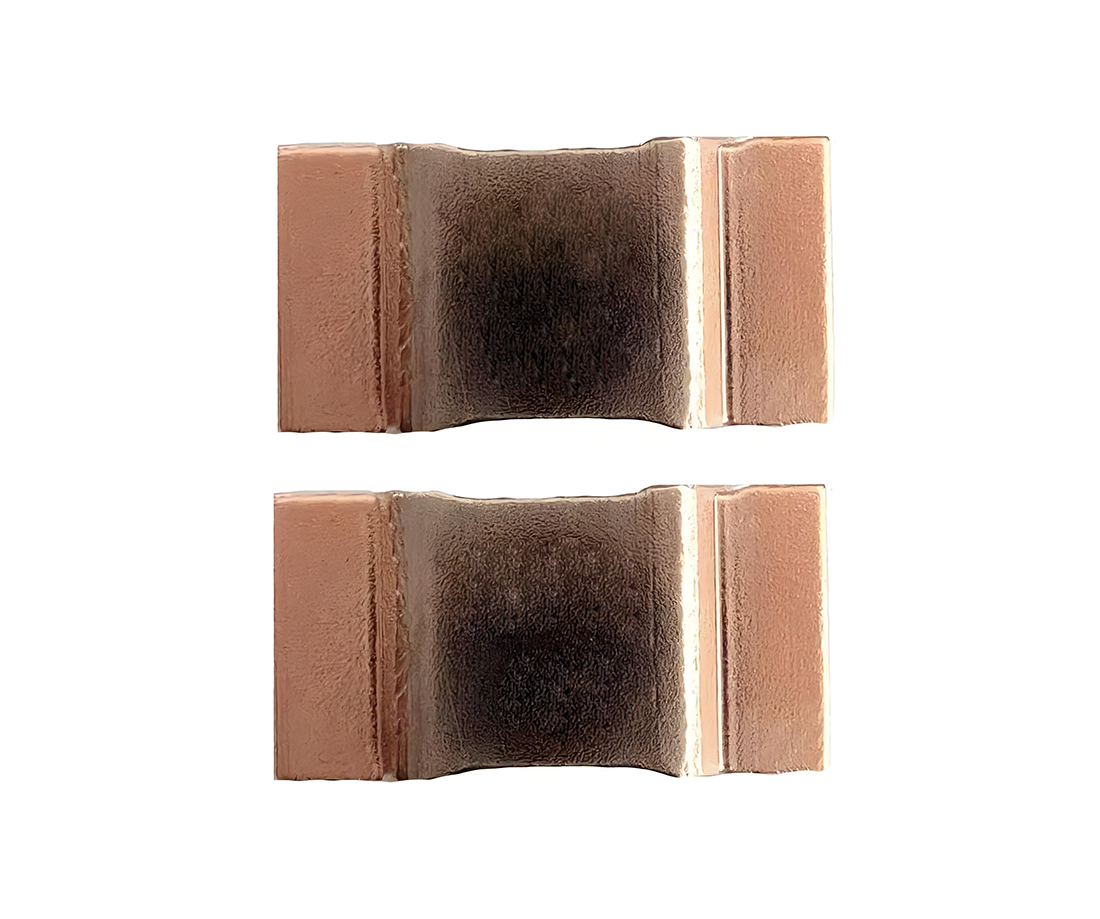

High Current Shunt Resistors for Accurate Current Measurement in EVs, Batteries, and Power Supplies – Selection Guide & Buying Tips

Title: High Current Shunt Resistors for Accurate Current Measurement in EVs, Batteries, and Power Supplies – Selection Guide & Buying TipsIntroductionHigh current shunt resistors are the unsung ...

-

10kV High Voltage Resistors: Specifications, Applications & Top Suppliers for Industrial, Power Transmission & Test Equipment

Technical Specifications of 10kV High Voltage ResistorsTo ensure reliability in high-voltage environments, 10kV resistors must meet strict performance criteria. Below are critical parameters to evalua...

-

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained<!-- 引言 -->IntroductionPower resistors up to 600W play pivotal roles in various industrial sectors like elec...

-

High Frequency Resistor Selection Guide for RF, Microwave, and 5G Circuits – Design Tips, Datasheet Insights & Buying Advice

Title: High Frequency Resistor Selection Guide for RF, Microwave, and 5G Circuits – Design Tips, Datasheet Insights & Buying AdviceIntroductionThis High Frequency Resistor Selection Guide for RF...

-

What Is a KB Resistor? Definition, Function, Applications & Technical Specifications Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standardized nominal resistance value, most commonly 1kΩ (1,000Ω). Unlike variable resistors (e.g., pot...

-

THT Resistor Tolerance Specifications: A Comprehensive Guide

IntroductionThrough-Hole Technology (THT) resistors are a cornerstone in electronic circuit design, offering stability and reliability. One critical aspect that significantly influences their performa...

-

MELF Resistor Basics: Definition, Function, Applications & Key Specifications Explained

1. What Is a MELF Resistor Core DefinitionA MELF resistor is a leadless, surface-mountable resistor with a cylindrical metal electrode structure. Unlike traditional through-hole resistors (e.g., THT),...

-

High Voltage Resistors for Power Transmission: Specifications, Reliability Standards, and Supplier Picks for Substations & Long-Distance Lines

Technical Specifications of High Voltage Resistors for Power TransmissionTo perform reliably in power transmission systems, resistors must meet strict performance criteria. Below are critical paramete...

-

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips<nav></nav>IntroductionElectric traction systems are at the heart of modern...

-

KB Resistor Definition: 1kΩ Standard Value, Tolerance & Temperature Coefficient Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standard resistance value, typically used in low-to-moderate power circuits. Unlike variable resistors (e...

-

Carbon Disc Resistors 1kΩ-100kΩ 5%-1% Tolerance: Specs, Audio/Power Supply Use & Supplier Guide

Carbon disc resistors remain a staple in electronics design, valued for their cost-effectiveness and stability in moderate-power applications. Among the most searched variants are those spanning 1kΩ ...

-

French Blue Baseplate 180W Four Terminal Ultra Long Creepage Resistor | High Voltage Resistance, Non-Inductive Design for Industrial Power Supplies, Motor Control, and Harsh Environments

1. Key Technical Specifications of the French Blue Baseplate 180W Four Terminal Ultra Long Creepage ResistorTo evaluate its suitability for demanding applications, let’s examine its core parameters—...

-

How to Read Metal Film Resistor Specifications: Decoding Datasheets & Failure Analysis

<!-- Introduction -->How to Read Metal Film Resistor Specifications: Decoding Datasheets & Failure AnalysisMetal film resistors are widely used in precision electronics due to their stability, low...

-

Trimmable Thick Film Resistor Characteristics: Detailed Insights into Key Features, Applications, and Selection Criteria for Engineers

Trimmable Thick Film Resistor Characteristics: Detailed Insights into Key Features, Applications, and Selection Criteria for EngineersTrimmable thick film resistors are essential components in various...

-

Low Inductance Shunt Resistor: Applications, Benefits, and Technical Specifications for High-Precision Current Sensing

IntroductionIn the realm of electrical engineering and electronics, precise current measurement is crucial for a wide range of applications, from power systems to sensitive electronic circuits. The lo...

-

Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base StationsBase stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution....

-

High Temperature Power Resistors: Applications, Specifications & Selection Guide for Extreme Environments

Table of ContentsIntroductionKey Applications in Extreme EnvironmentsTechnical Specifications & Performance MetricsSelection Guide for High Temperature ResistorsAddressing Thermal Stability Challe...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000