-

How to Choose a Milliohm Resistor for High-Accuracy Current Sensing

How to Choose a Milliohm Resistor for High-Accuracy Current SensingIn precision current sensing applications - from battery management systems (BMS) to motor control - milliohm shunt resistors play a ...

-

Unlocking the Potential of Milliohm Resistors: Precision Current Sensing and Power Conversion in Modern Telecommunications Infrastructure

IntroductionIn the rapidly evolving landscape of telecommunications, the need for efficient and reliable power management and signal processing has never been more critical. One often overlooked yet c...

-

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery Monitoring

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery MonitoringWhy Milliohm Resistors Matter in Li-Ion BMSIn lithium-ion battery management systems (BMS), milliohm resistors (typically 1m...

-

Precision Current Sensing Resistors: Enabling Accurate Current Measurement

Table of ContentsIntroductionKey Parameters and Performance MetricsApplications in Modern ElectronicsChallenges in High-Current ScenariosInnovative Solutions and Future TrendsIntroductionPrecision cur...

-

Low Inductance Shunt Resistor: Applications, Benefits, and Technical Specifications for High-Precision Current Sensing

IntroductionIn the realm of electrical engineering and electronics, precise current measurement is crucial for a wide range of applications, from power systems to sensitive electronic circuits. The lo...

-

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

How Alloy Resistors Enable Accurate Current Sensing in Power Electronics

<!-- Introduction -->Precision Current Measurement: The Critical Role of Alloy ResistorsIn power electronics systems, accurate current sensing directly impacts efficiency, safety, and performance. All...

-

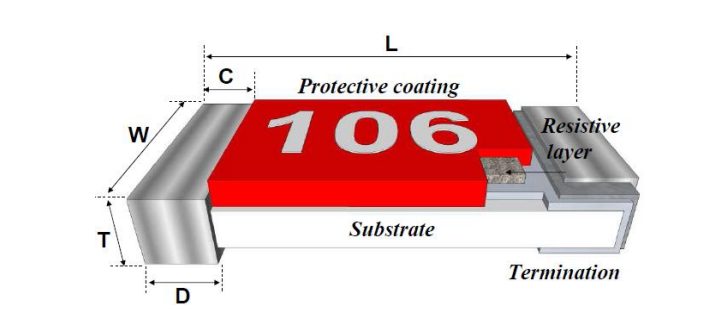

Precision Shunt Resistors: Key Components for Accurate Current Sensing

IntroductionIn the realm of electrical engineering and electronics, accurate current sensing is a cornerstone for numerous applications, ranging from power management in sophisticated electronic devic...

-

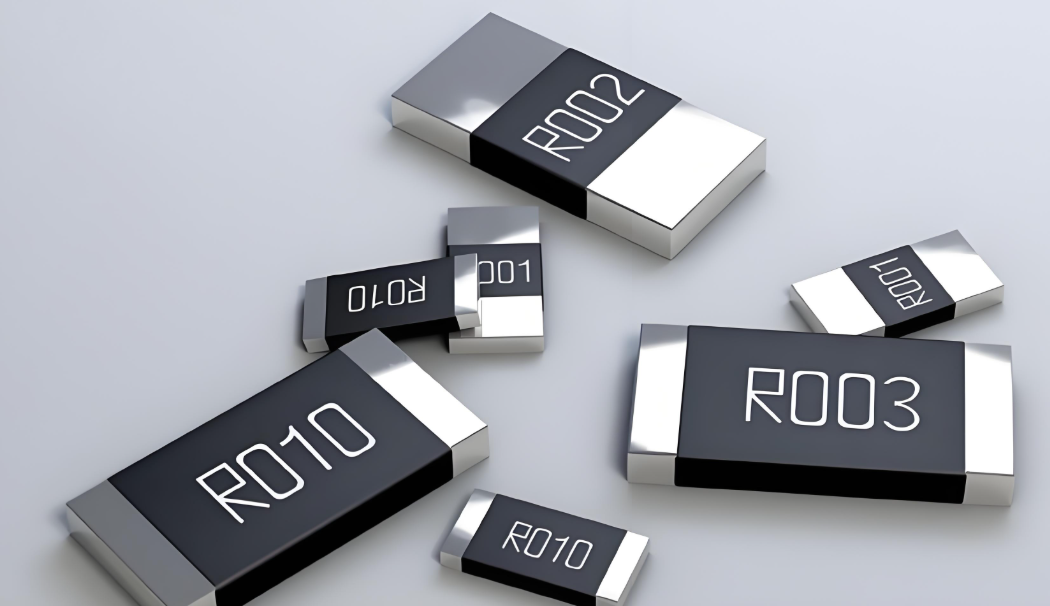

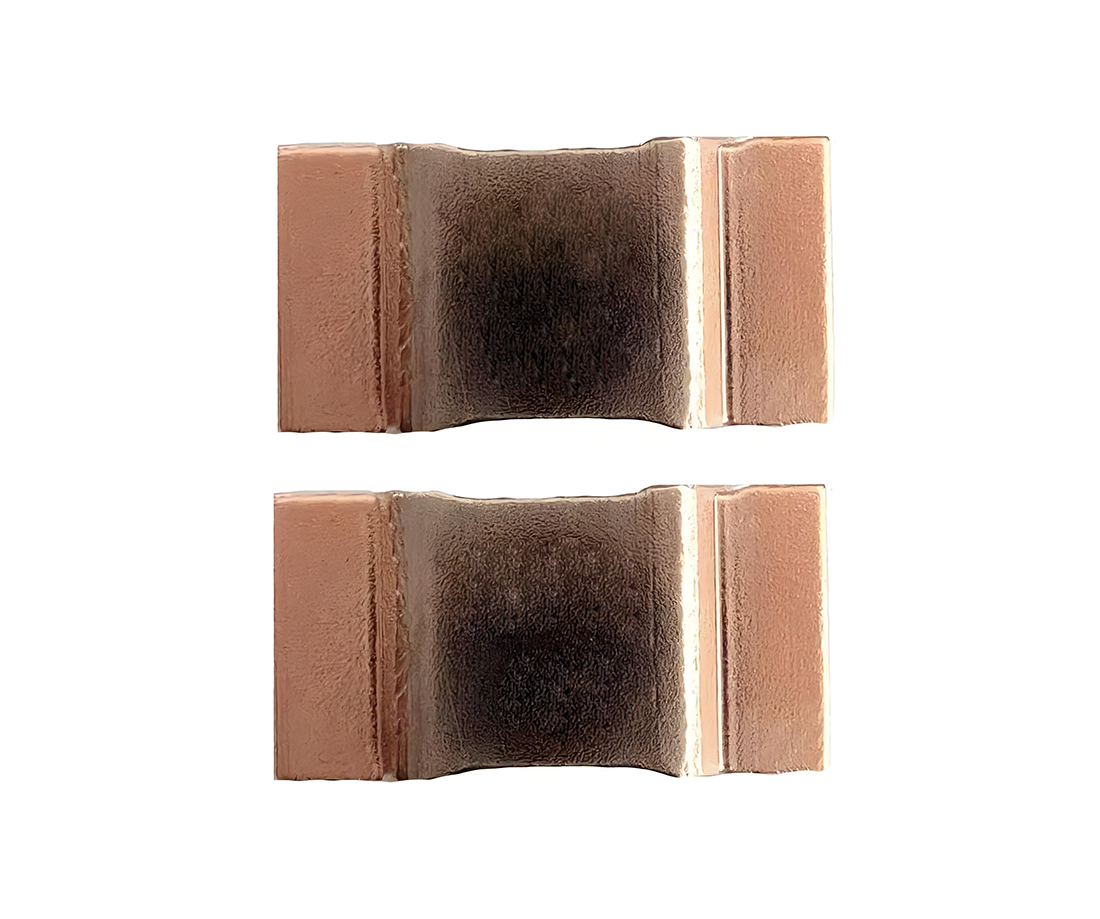

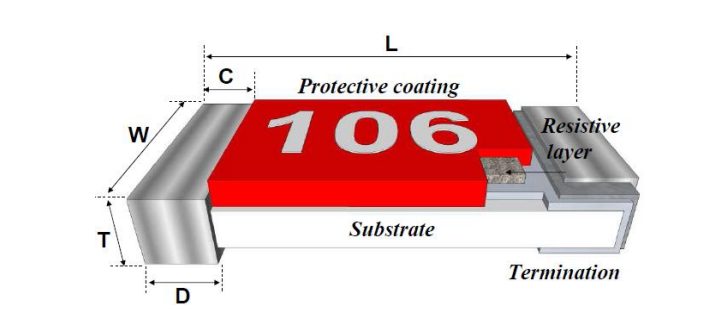

Exploring Alloy Shunt Chip Resistors Type J: High-Precision Solutions for Current Sensing Applications

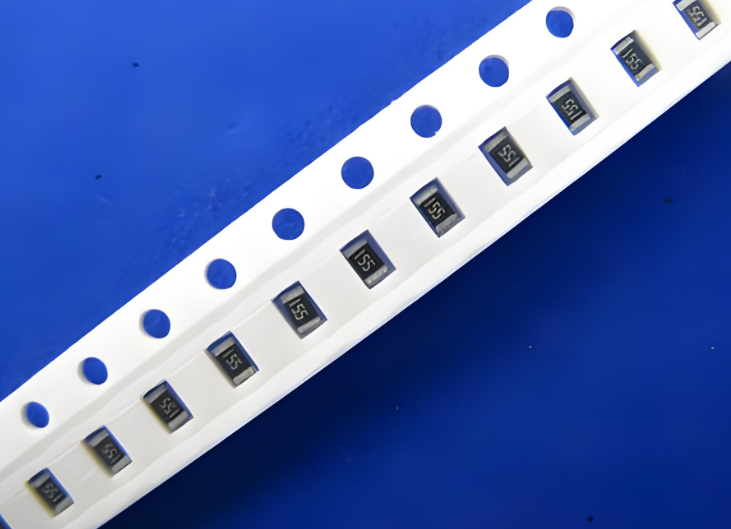

<!-- Introduction -->IntroductionIn today's high-performance electronics, precision current sensing is critical across a wide range of industries—from power management systems to automotive cont...

-

Top 10 Benefits of Using Power Shunt Resistors in Surface Mount Applications for Efficient Current Sensing and Precision Control in Electronics

Benefits of Power Shunt Resistors1. High Precision Current MeasurementPower shunt resistors are known for their exceptional precision in current measurement. With low resistance values and tight toler...

-

How to Choose the Right High-Voltage Safety Resistor for Your Circuit

<!-- Introduction -->IntroductionHigh-voltage safety resistors are critical components in electrical circuits, ensuring protection against overvoltage, surges, and potential failures. Choosing the rig...

-

Thin Film Precision Resistors: Benefits and Applications for High - Accuracy Electronics

Thin Film Precision Resistors: Benefits and Applications for High - Accuracy ElectronicsThin film precision resistors have become indispensable in high - accuracy electronic applications. This article...

-

Bulk Metal Foil Resistors: Precision and Performance for High - Accuracy Applications

Bulk Metal Foil Resistors: Precision and Performance for High - Accuracy ApplicationsIn the world of precision electronics, Bulk Metal Foil resistors have emerged as a gold standard for applications d...

-

Precision Resistors in Medical Devices: Ensuring Accuracy and Reliability for Critical Applications

IntroductionIn the realm of medical devices, precision is not just a preference—it's a necessity. Precision resistors play a crucial role in ensuring the accuracy and reliability of medical equi...

-

High Precision Metal Film Resistors: Ultimate Accuracy for Critical Circuits

High precision metal film resistors are applicable to fields such as analog signal acquisition and precision instruments and meters.● Products with military standard certification.● High stability...

-

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right One

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right OneResistors, often considered the workhorses of electronic circuits, are tasked with the critical j...

-

High Current Shunt Resistors for Accurate Current Measurement in EVs, Batteries, and Power Supplies – Selection Guide & Buying Tips

Title: High Current Shunt Resistors for Accurate Current Measurement in EVs, Batteries, and Power Supplies – Selection Guide & Buying TipsIntroductionHigh current shunt resistors are the unsung ...

-

How to Choose Alloy Resistors for High - Reliability Electronic Systems

IntroductionIn high-reliability electronic systems, the selection of components is critical to ensuring consistent performance and longevity. Alloy resistors, with their superior characteristics, are ...

-

High Voltage Resistors: Working Principle, Applications, Safety Tips & How to Choose the Right One

<!-- Introduction -->IntroductionHigh voltage resistors are critical components in circuits requiring precise voltage control under extreme electrical stress. Understanding their working principle, ap...

-

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial Applications

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial ApplicationsIn high - power industrial systems, the 600W wirewound power resistor is a cornerstone component...

-

Unlocking the Potential of Milliohm Resistors: Precision Current Sensing and Power Conversion in Modern Telecommunications Infrastructure

IntroductionIn the rapidly evolving landscape of telecommunications, the need for efficient and reliable power management and signal processing has never been more critical. One often overlooked yet c...

-

How to Choose a Milliohm Resistor for High-Accuracy Current Sensing

How to Choose a Milliohm Resistor for High-Accuracy Current SensingIn precision current sensing applications - from battery management systems (BMS) to motor control - milliohm shunt resistors play a ...

-

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery Monitoring

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery MonitoringWhy Milliohm Resistors Matter in Li-Ion BMSIn lithium-ion battery management systems (BMS), milliohm resistors (typically 1m...