The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right One

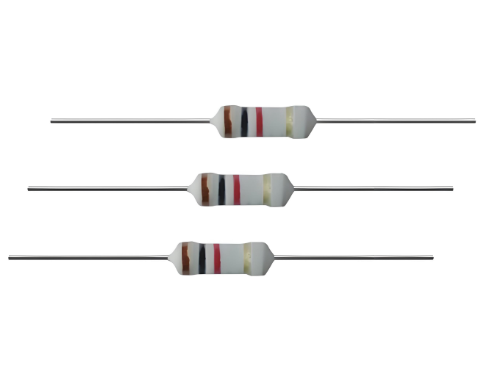

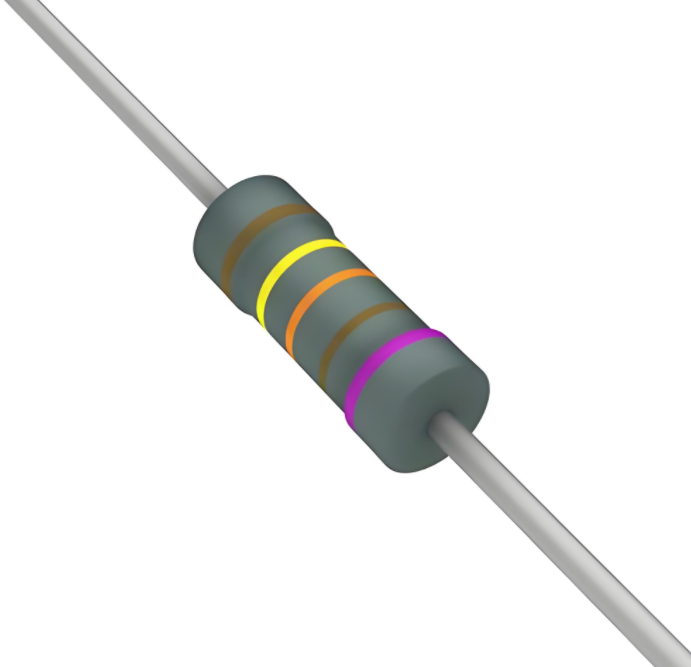

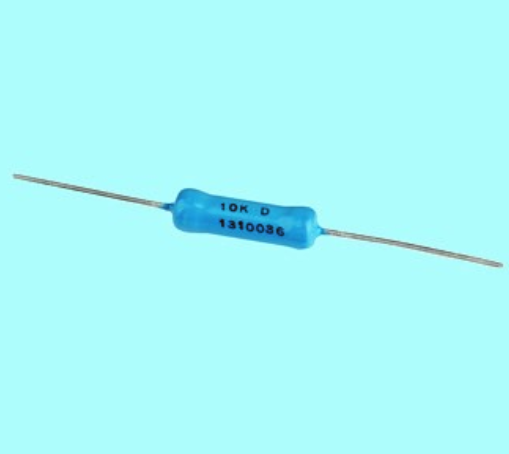

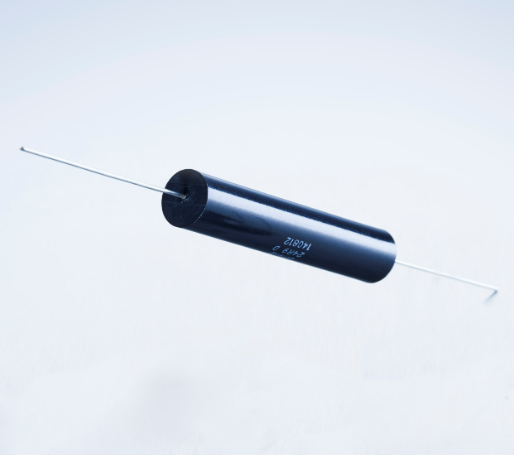

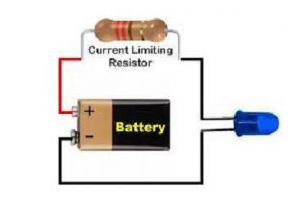

Resistors, often considered the workhorses of electronic circuits, are tasked with the critical job of managing and regulating electrical currents. With the advent of lead-free manufacturing practices, the tolerance of these resistors has become a significant factor in ensuring the reliability and performance of modern electronics. This article delves into the importance of lead-free resistor tolerance and provides a guide on selecting the appropriate resistor for various applications.

Table of Contents

Introduction

Electronic components must meet exacting standards to function within the narrow operational parameters of modern devices. Lead-free resistors, free from the toxic effects of lead, are now a standard in electronic parts due to global environmental regulations. Their tolerance—the variation allowed from the stated resistance value—is crucial for their performance in precise applications.

Importance of Tolerance in Lead-Free Resistors

Tolerance is a key specification for resistors as it determines the precision with which a resistor can control electrical current. The tighter the tolerance, the more accurately the resistor can perform its function within a circuit. This is particularly important in sensitive electronics such as medical devices, military equipment, and precision measurement instruments.

Factors Influencing Tolerance

Several factors influence the tolerance of lead-free resistors:

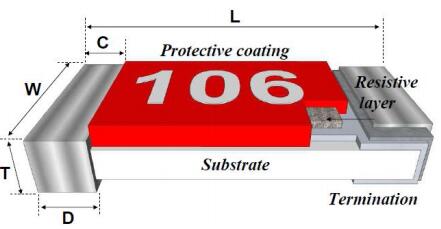

Manufacturing Process: The precision of the production methods can significantly affect tolerance.

Materials Used: The composition of the resistive element and its stability under various conditions.

Environmental Conditions: Temperature, humidity, and exposure to chemicals can cause resistance to vary.

Choosing the Right Lead-Free Resistor

Choosing the right resistor involves considering several key factors:

Required Precision: Determine the necessary tolerance based on circuit requirements.

Operating Temperatures: Consider the temperature range the resistor will be exposed to.

Long-Term Stability: Look for resistors with minimal drift over time.

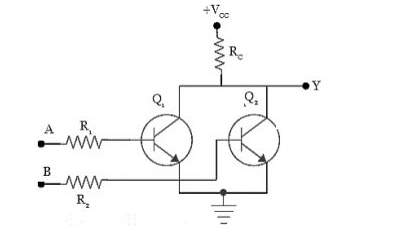

Performance Comparison

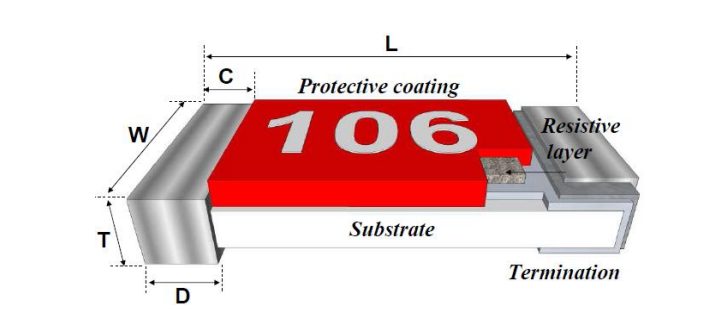

Below is a table comparing different types of lead-free resistors based on their tolerance and other performance criteria:

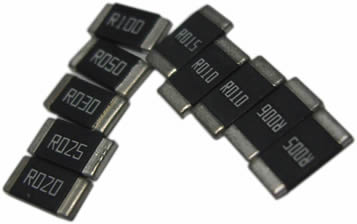

| Type of Resistor | Tolerance | Temperature Coefficient | Cost |

|---|---|---|---|

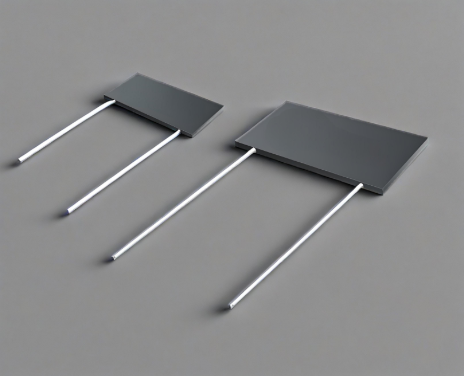

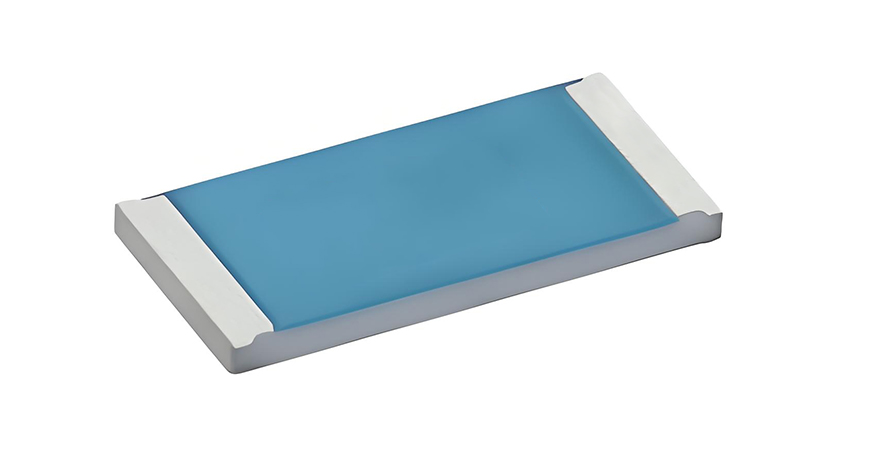

| 薄膜 resistor (Thin Film) | ±0.05% to ±0.1% | ±5 ppm/°C | High |

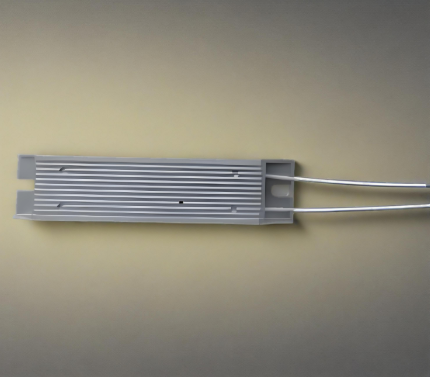

| 厚膜 resistor (Thick Film) | ±0.5% to ±1% | ±100 ppm/°C | Medium |

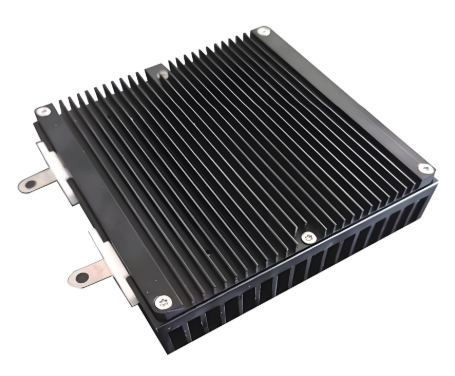

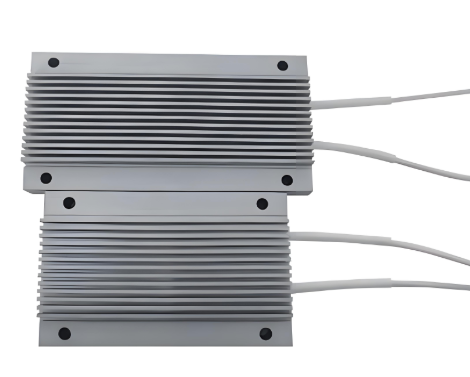

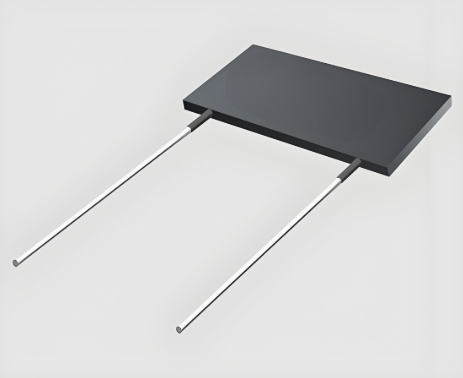

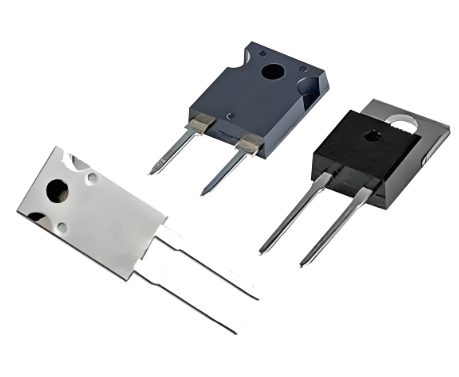

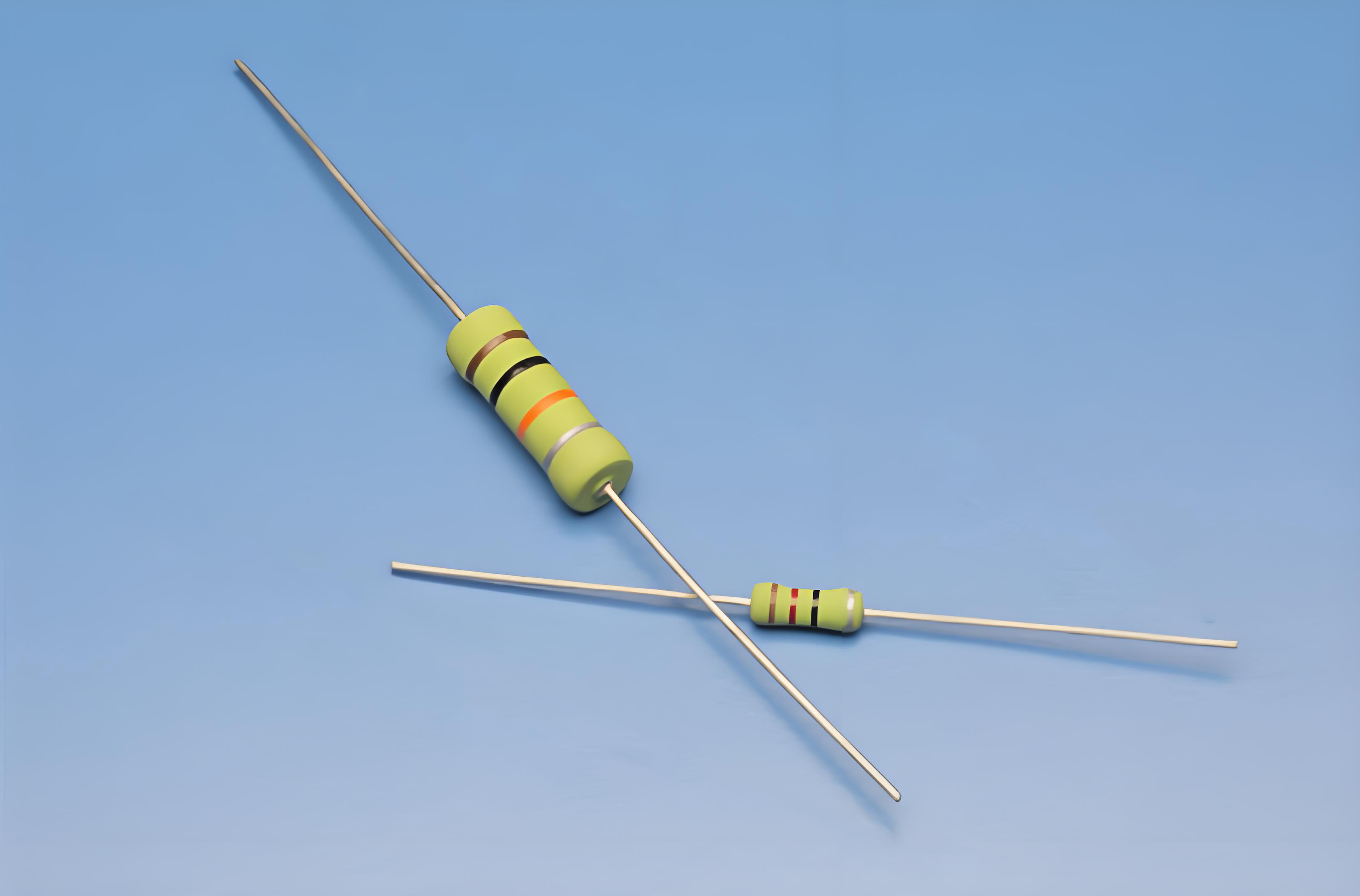

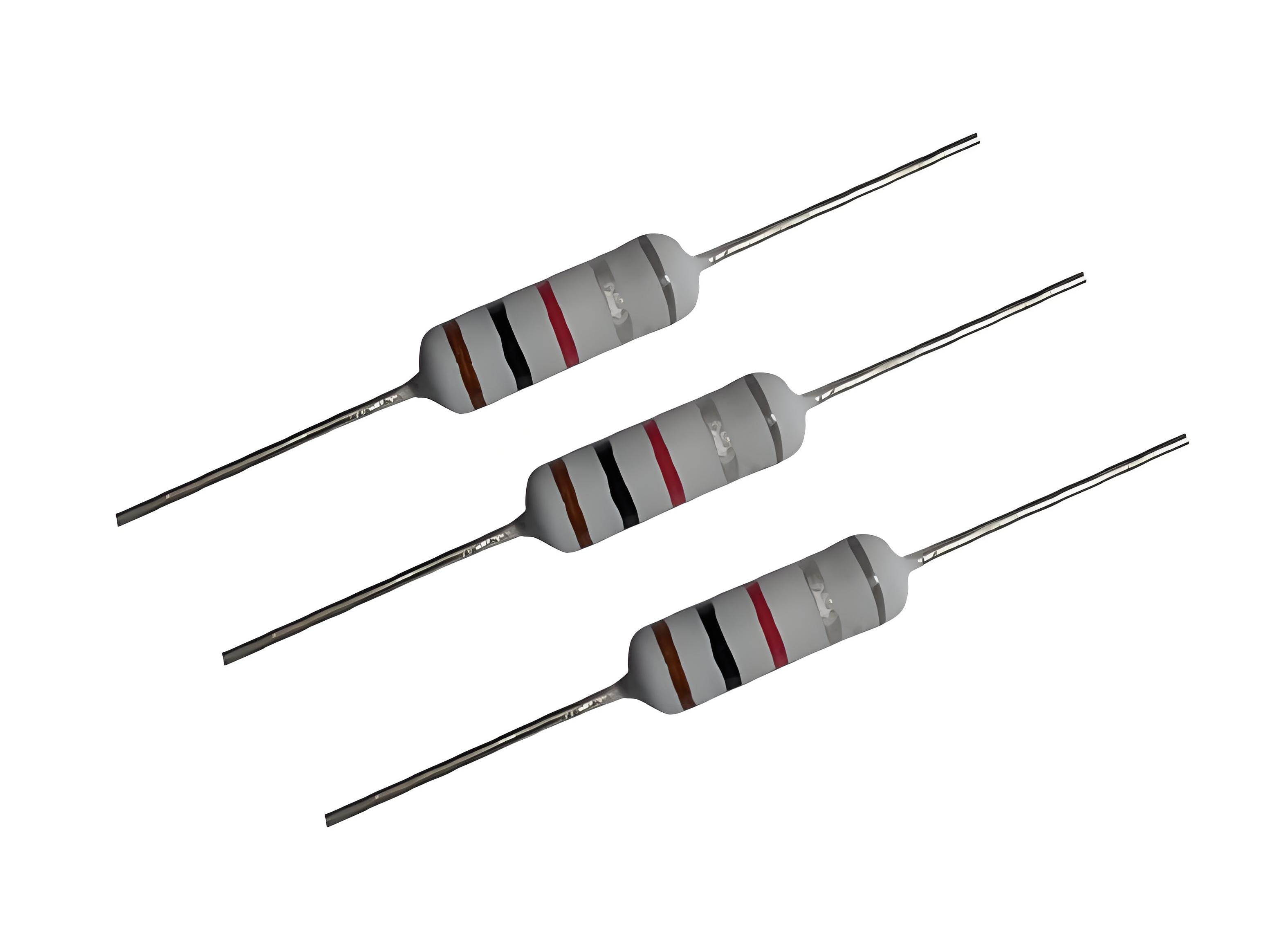

| 功率 resistor (Power Resistor) | ±1% to ±5% | ±200 ppm/°C | Low to Medium |

Common Problem and Solution

A common problem when using lead-free resistors is the risk of exceeding the resistance tolerance due to environmental factors such as temperature changes.

Solution: Implement temperature compensation circuits or select resistors with a low temperature coefficient. Calibrate the resistors regularly to ensure they remain within the specified tolerance after prolonged use.

Best Practices

For optimal performance and longevity of lead-free resistors:

Store components in controlled environments to prevent contamination.

Use resistors with a tolerance that meets the application requirements.

Monitor the environmental conditions around the resistors to prevent exceeding operational limits.

Perform regular maintenance and checks to ensure resistors are functioning within their specified tolerances.

Conclusion

Lead-free resistors play a critical role in the precision and reliability of modern electronic devices. Understanding the importance of tolerance and knowing how to choose the right resistor for your application is essential. By following best practices, engineers can ensure the long-term stability and performance of their electronic designs.