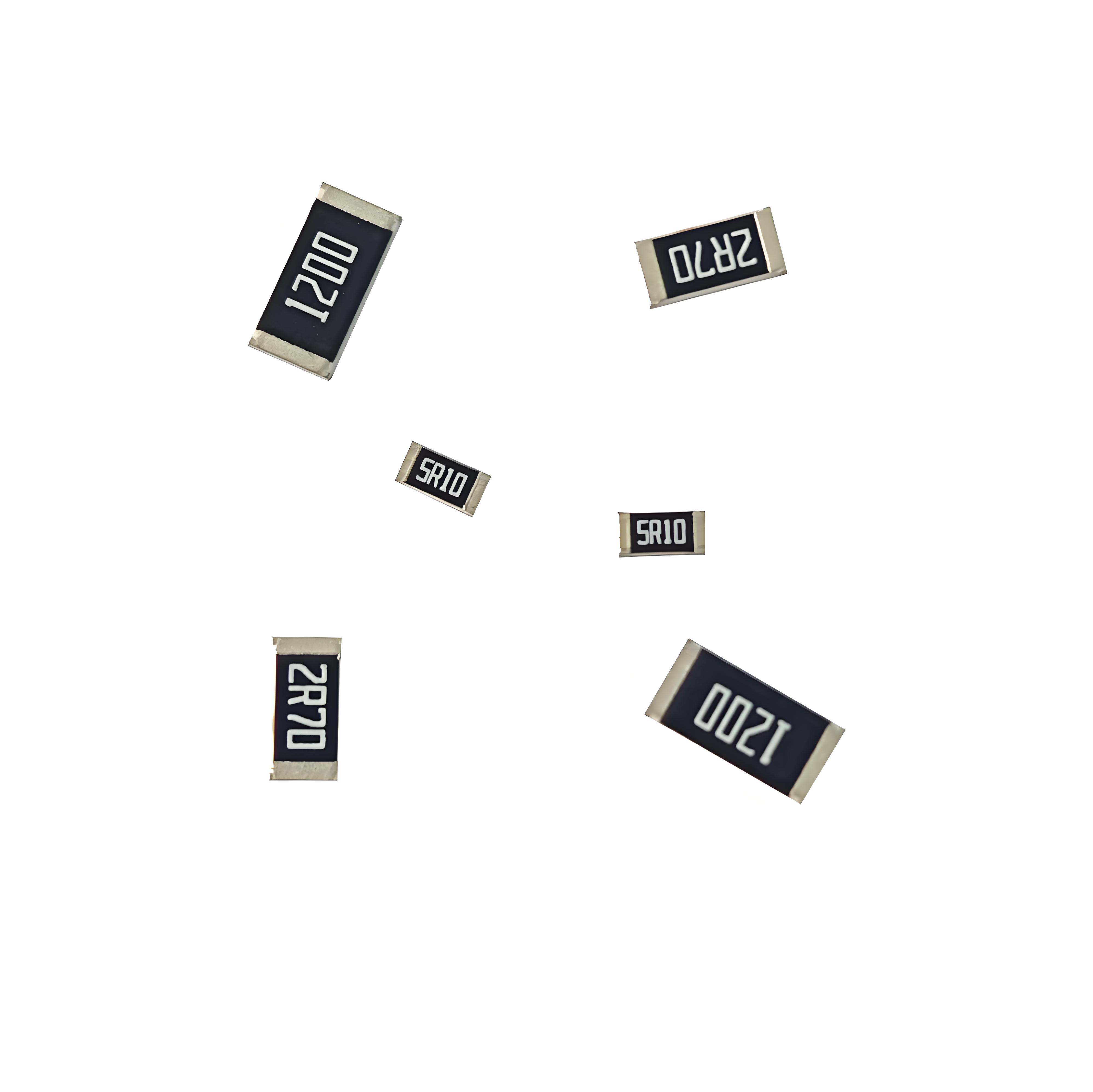

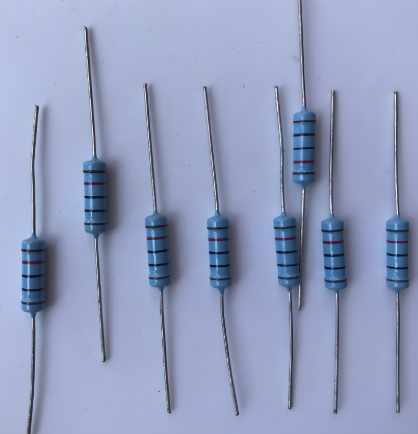

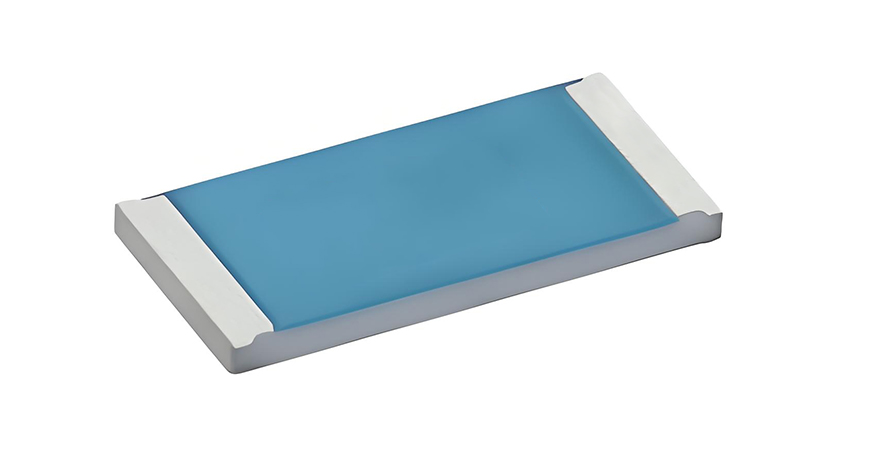

Exploring the Benefits and Applications of Surface Mount Lead-Free Resistors in Modern Electronics

As environmental awareness and regulatory requirements grow, lead-free electronics components are becoming increasingly important. Surface mount lead-free resistors offer numerous advantages for modern electronics manufacturing. This article explores their benefits, applications, and provides practical insights for engineers and designers.

Table of Contents

Introduction

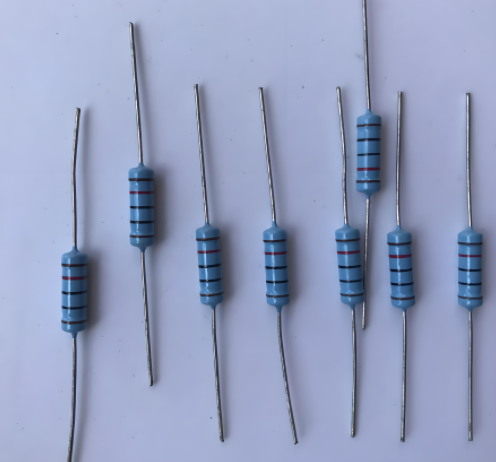

Surface mount lead-free resistors are essential components in contemporary electronics. They meet the growing demand for environmentally friendly components while offering technical advantages that enhance the performance and reliability of electronic devices. These resistors are free from lead, making them compliant with environmental regulations such as RoHS (Restriction of Hazardous Substances).

Benefits of Surface Mount Lead-Free Resistors

Surface mount lead-free resistors provide several key benefits that make them ideal for modern electronics manufacturing:

Environmental Compliance

Lead-free resistors help manufacturers meet environmental regulations and reduce the environmental impact of electronic products. This is crucial for companies aiming to be environmentally responsible and for products intended for markets with strict regulatory requirements.

Improved Reliability

Lead-free resistors often exhibit better thermal stability and mechanical strength, leading to improved reliability in electronic devices. They are less prone to failure due to temperature variations and mechanical stress.

Compatibility with High - Temperature Processes

Lead-free resistors can withstand higher soldering temperatures, making them suitable for use in advanced manufacturing processes that require higher reflow temperatures.

Consistent Performance

These resistors offer stable electrical performance over a wide temperature range, ensuring consistent operation in various environmental conditions.

Applications in Modern Electronics

Surface mount lead-free resistors are used in a wide range of applications due to their numerous advantages:

Consumer Electronics

In devices such as smartphones, laptops, and tablets, lead-free resistors are used in power management circuits, signal processing, and voltage regulation. Their small size and compatibility with high - density assembly make them ideal for these compact devices.

Industrial Automation

In industrial control systems and automation equipment, lead-free resistors are used in sensor interfaces, power supplies, and control circuits. Their reliability and ability to withstand harsh environments make them suitable for industrial applications.

Automotive Electronics

Lead-free resistors are used in various automotive systems, including engine control units, infotainment systems, and advanced driver - assistance systems (ADAS). They meet the high - reliability requirements of automotive applications while complying with environmental regulations.

Medical Devices

In medical equipment such as imaging systems, monitoring devices, and diagnostic tools, lead-free resistors ensure accurate and reliable performance. Their environmental compliance is also crucial for medical devices that must meet strict safety and regulatory standards.

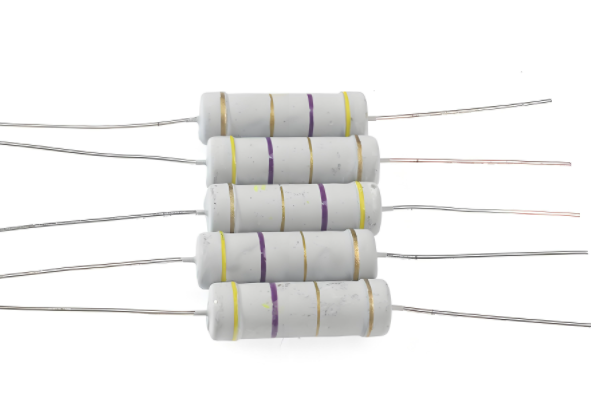

Performance Comparison

The following table compares the performance of surface mount lead-free resistors with traditional resistors:

| Parameter | Lead-Free Surface Mount Resistor | Traditional Resistor |

|---|---|---|

| Resistance Tolerance | ±0.01% - ±1% | ±0.1% - ±5% |

| Temperature Coefficient of Resistance (TCR) | ±5 ppm/°C - ±20 ppm/°C | ±20 ppm/°C - ±100 ppm/°C |

| Maximum Operating Temperature | 260°C | 240°C |

| Reliability | High | Moderate |

| Environmental Compliance | RoHS Compliant | Non - Compliant |

Problem and Solution

A common problem encountered in the use of surface mount lead-free resistors is the potential for solder joint issues due to the higher soldering temperatures required. This can lead to problems such as poor wetting and solder voids if not properly managed.

Solution: To address this issue, manufacturers and engineers can implement the following solutions:

Use optimized solder paste formulations specifically designed for lead-free soldering.

Employ advanced reflow soldering profiles that ensure proper melting and wetting of the solder.

Implement proper board design and layout techniques to facilitate effective heat transfer during soldering.

Use high - quality soldering equipment and ensure proper maintenance to achieve consistent soldering results.

Best Practices

Proper Storage: Store lead-free resistors in appropriate conditions to prevent moisture absorption and oxidation, which can affect solderability.

Handling and Assembly: Use proper handling techniques during assembly to avoid damaging the resistors. Follow recommended reflow temperature profiles to ensure reliable solder joints.

Testing and Inspection: Conduct thorough testing and inspection of the resistors after assembly to identify and correct any soldering - related issues. This includes visual inspection, electrical testing, and X - ray inspection for solder joint quality.

Documentation and Compliance: Maintain proper documentation of the manufacturing process and ensure compliance with relevant standards and regulations. This helps in traceability and quality control.

Conclusion

Surface mount lead-free resistors offer significant benefits for modern electronics manufacturing, including environmental compliance, improved reliability, and compatibility with high - temperature processes. Their applications span across various industries, from consumer electronics to automotive and medical devices. By understanding their benefits and following best practices in their use, engineers and manufacturers can leverage these components to create more sustainable and reliable electronic products.