Lead - Free Resistors Product Certification: Key Considerations for Buyers and Suppliers

Introduction

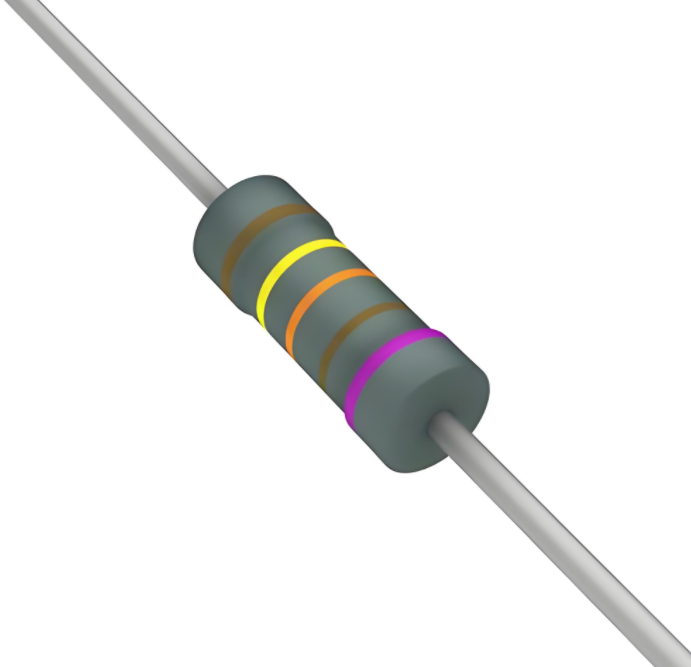

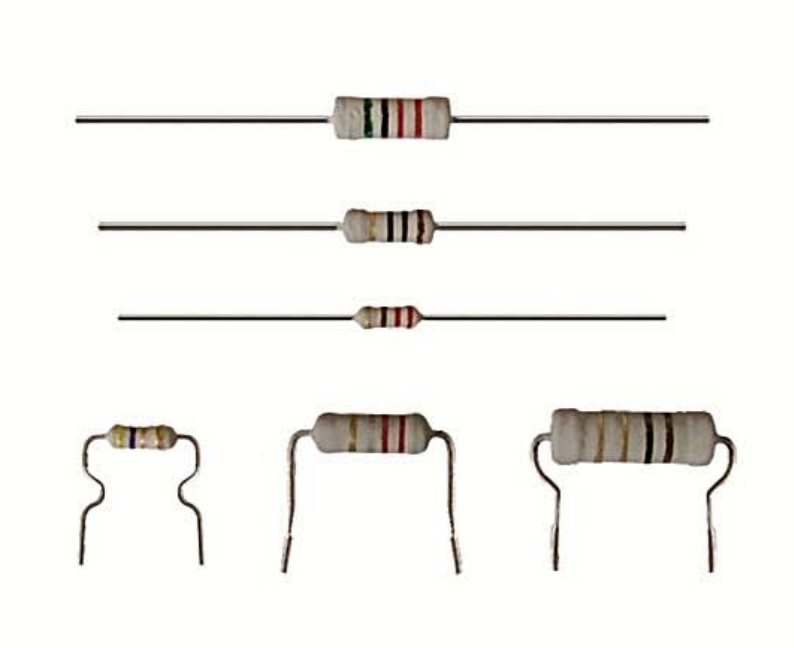

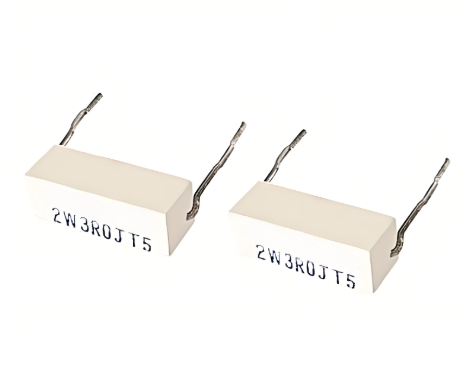

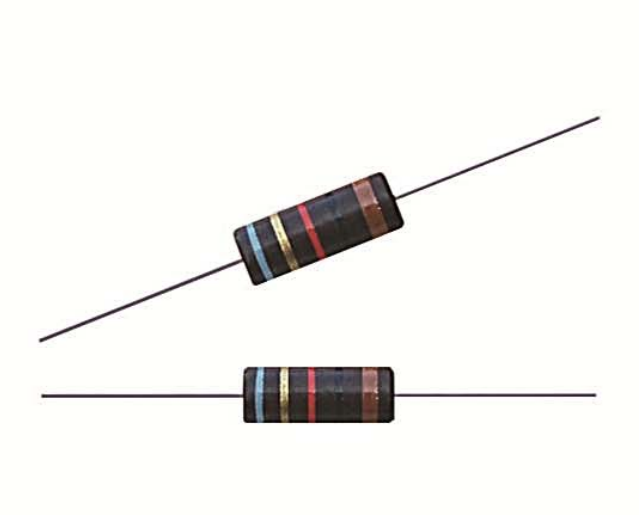

In the electronics industry, the shift towards lead-free resistors has become essential due to stringent environmental regulations and the growing demand for eco-friendly products. Lead-Free Resistors Product Certification plays a vital role in ensuring that these components meet high-quality standards and regulatory compliance. This article will delve into the key considerations for both buyers and suppliers when it comes to lead-free resistor certification, providing valuable insights to navigate this important aspect of the electronics supply chain.

Key Considerations for Buyers

When purchasing lead-free resistors, buyers need to consider several key factors to ensure they are acquiring certified and reliable products.

| Consideration | Description |

|---|---|

| Certification Compliance | Buyers must verify that the resistors comply with relevant certifications such as RoHS, REACH, and IPC standards. |

| Product Specifications | Ensure that the resistors meet specific requirements like resistance value, power rating, and tolerance. |

| Supplier Reputation | Choose suppliers with a proven track record of delivering high - quality, certified components. |

| Documentation | Request and review certification documents, test reports, and quality assurance records. |

For example, buyers should ensure that the resistors they purchase have proper documentation proving compliance with RoHS directive, which restricts the use of hazardous substances including lead.

Key Considerations for Suppliers

Suppliers, on the other hand, need to focus on maintaining certification standards and ensuring customer satisfaction.

| Consideration | Description |

|---|---|

| Ongoing Compliance | Suppliers must stay updated with the latest regulatory changes and ensure their products continually meet certification requirements. |

| Quality Control | Implement robust quality control measures to guarantee consistent product performance and compliance. |

| Customer Support | Provide detailed documentation and support to help buyers understand the certification status of the resistors. |

| Supply Chain Transparency | Ensure transparency in the supply chain, including the source of raw materials and manufacturing processes. |

For instance, suppliers should conduct regular internal audits to ensure their production processes remain compliant with IPC standards for lead-free resistors, thereby maintaining product quality and reliability.

Common Problems and Solutions

Both buyers and suppliers may face challenges related to lead-free resistor certification. Here are some common problems and their solutions:

| Problem | Solution |

|---|---|

| Non - Compliance Risks | Suppliers should invest in regular training for employees and update their manufacturing processes to meet the latest certification standards. |

| Documentation Issues | Buyers should request and verify complete documentation, while suppliers should maintain thorough records and provide them promptly. |

| Quality Fluctuations | Implement strict quality control measures, including incoming inspection, in - process testing, and final product verification. |

| Lead - Time for Certification | Suppliers should plan ahead and initiate the certification process early to avoid production delays. Buyers can work with suppliers to understand and manage lead times. |

One key problem suppliers face is ensuring consistent quality during mass production. This can be addressed by implementing a comprehensive quality management system that includes regular testing and statistical process control.

Case Study: Successful Certification

A leading electronics manufacturer, XYZ Corp, recently navigated the certification process for their new line of lead-free resistors. They faced initial challenges with material sourcing and process adjustments but overcame these by:

Partnering with a reliable material supplier certified under REACH standards.

Investing in advanced testing equipment to ensure compliance with IPC specifications.

Conducting regular training sessions for employees on the latest certification requirements.

This proactive approach enabled XYZ Corp to achieve certification within six months, significantly enhancing their market position and customer trust.

Future Trends in Lead-Free Resistor Certification

The future of lead-free resistor certification is likely to see increased complexity and stringency. Upcoming trends include:

Stricter Environmental Standards: As global environmental regulations tighten, lead-free resistors will need to meet more stringent criteria.

Smart Certification Processes: Leveraging IoT and AI to streamline the certification process and enhance transparency.

Full - Lifecycle Assessment: Certifications will increasingly consider the environmental impact of resistors from production to disposal.

Suppliers and buyers must stay informed about these trends to ensure ongoing compliance and market competitiveness.

Conclusion

Lead-Free Resistor Product Certification is a critical aspect for both buyers and suppliers in the electronics industry. By understanding and addressing key considerations, both parties can ensure high - quality, compliant products that meet market demands. Staying ahead of common problems and future trends will further enhance the reliability and sustainability of lead-free resistors in the market.

Email us

-

Moisture Resistant Resistors

Moisture Resistant Resistors

-

High Value Resistors

High Value Resistors

-

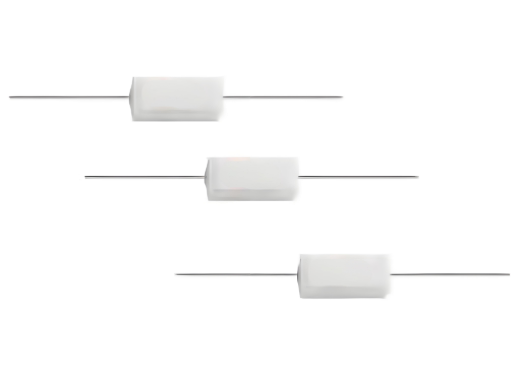

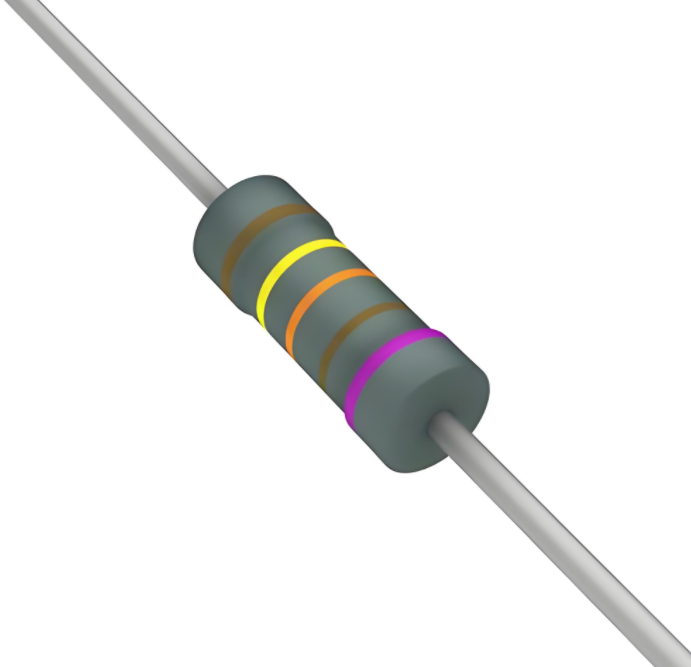

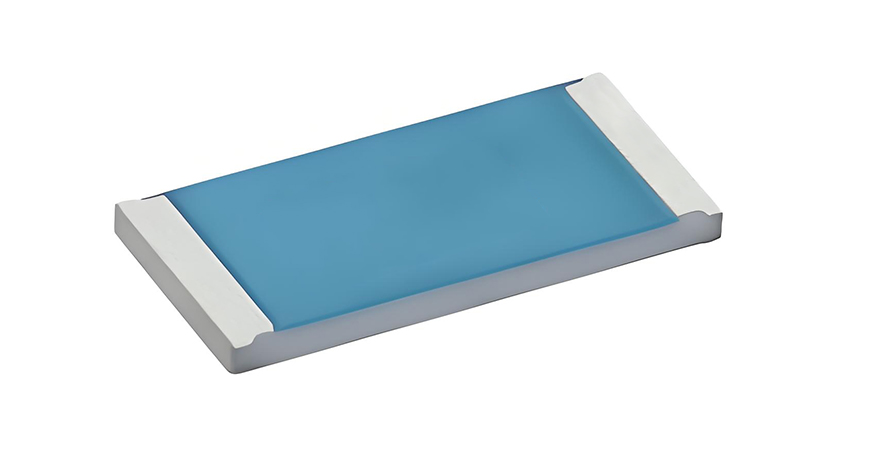

Lead-Free Resistors

Lead-Free Resistors

-

Anti-Sulfur Resistors

Anti-Sulfur Resistors

-

Low TCR Resistors

Low TCR Resistors

-

Precision Resistors

Precision Resistors

-

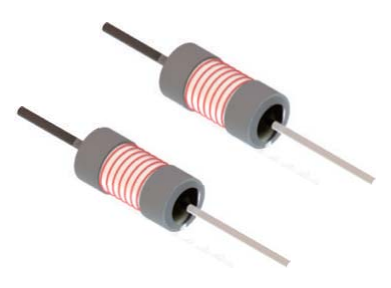

RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors

-

RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors

-

RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors

-

RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors

-

RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors

-

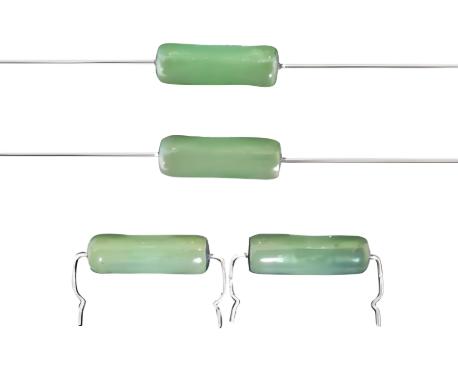

RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors

-

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

-

RXF21-TE power-type full-short-circuit temperature fuse resistors

RXF21-TE power-type full-short-circuit temperature fuse resistors

-

RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors

-

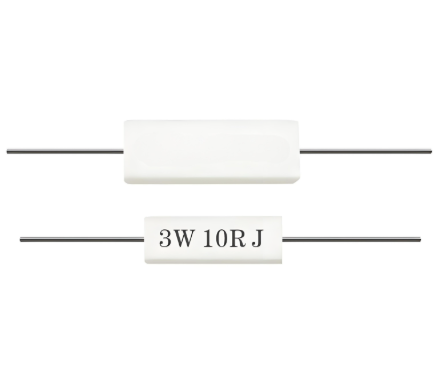

RX23 ceramic encased wire - wound resistors

RX23 ceramic encased wire - wound resistors

-

RX92 anti - interference wire - wound resistors

RX92 anti - interference wire - wound resistors

-

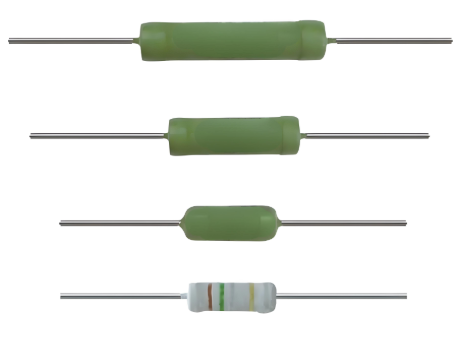

RX21 coated wire - wound resistors

RX21 coated wire - wound resistors

-

RXLG high power aluminum encased wire - wound resistors

RXLG high power aluminum encased wire - wound resistors

-

RX27 power ceramic encased wire - wound resistors

RX27 power ceramic encased wire - wound resistors

-

RXL power aluminum encased wire - wound resistors

RXL power aluminum encased wire - wound resistors

-

RXHGI high power wane ripple coated wire - wound resistors

RXHGI high power wane ripple coated wire - wound resistors

-

RX20 high power vitreous enameled wire - wound resistors

RX20 high power vitreous enameled wire - wound resistors

-

RX24 aluminum encased power wire - wound resistors

RX24 aluminum encased power wire - wound resistors

-

Lead - Free Resistors Product Certification: Key Considerations for Buyers and Suppliers

IntroductionIn the electronics industry, the shift towards lead-free resistors has become essential due to stringent environmental regulations and the growing demand for eco-friendly products. Lead-Fr...

-

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right One

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right OneResistors, often considered the workhorses of electronic circuits, are tasked with the critical j...

-

Exploring the Benefits and Applications of Surface Mount Lead-Free Resistors in Modern Electronics

Exploring the Benefits and Applications of Surface Mount Lead-Free Resistors in Modern ElectronicsAs environmental awareness and regulatory requirements grow, lead-free electronics components are beco...

-

10kV High Voltage Resistors: Specifications, Applications & Top Suppliers for Industrial, Power Transmission & Test Equipment

Technical Specifications of 10kV High Voltage ResistorsTo ensure reliability in high-voltage environments, 10kV resistors must meet strict performance criteria. Below are critical parameters to evalua...

-

Key Aluminum Nitride Resistance Properties to Specify When Ordering Substrates

IntroductionAluminum Nitride (AlN) substrates are widely used in high-power electronic and optoelectronic applications due to their excellent thermal conductivity and electrical insulation properties....

-

Why Use Low TCR Resistors? The Key to Stable Circuit Performance

Why Use Low TCR Resistors The Key to Stable Circuit PerformanceIn electronic design, a resistor's value is often considered a constant. However, this is a simplification that can lead to significa...

-

Precision Shunt Resistors: Key Components for Accurate Current Sensing

IntroductionIn the realm of electrical engineering and electronics, accurate current sensing is a cornerstone for numerous applications, ranging from power management in sophisticated electronic devic...

-

Through-Hole Precision Resistors: Key Components for Reliable Circuit Design

IntroductionIn the intricate world of electronics, the reliability of a circuit design is paramount. Among the myriad components that contribute to this reliability, through-hole precision resistors s...

-

MELF Resistor Basics: Definition, Function, Applications & Key Specifications Explained

1. What Is a MELF Resistor Core DefinitionA MELF resistor is a leadless, surface-mountable resistor with a cylindrical metal electrode structure. Unlike traditional through-hole resistors (e.g., THT),...

-

Exploring the Diverse Applications of High Voltage Resistors in Power Generation: Key Roles and Advantages

Applications of High Voltage Resistors in Power GenerationIntroductionIn the intricate realm of power generation, high voltage resistors play a crucial role. They are essential components that help in...

-

Trimmable Thick Film Resistor Characteristics: Detailed Insights into Key Features, Applications, and Selection Criteria for Engineers

Trimmable Thick Film Resistor Characteristics: Detailed Insights into Key Features, Applications, and Selection Criteria for EngineersTrimmable thick film resistors are essential components in various...

-

Ultra-high Precision Resistor Stability: Key Factors, Optimization Techniques, and Industrial Applications for ±5ppm/°C Performance

IntroductionIn the realm of electronics and precision engineering, the stability of ultra-high precision resistors is of paramount importance. These resistors are crucial components in various applica...

-

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right One

The Critical Role of Lead-Free Resistor Tolerance in Modern Electronics and How to Choose the Right OneResistors, often considered the workhorses of electronic circuits, are tasked with the critical j...

-

Exploring the Benefits and Applications of Surface Mount Lead-Free Resistors in Modern Electronics

Exploring the Benefits and Applications of Surface Mount Lead-Free Resistors in Modern ElectronicsAs environmental awareness and regulatory requirements grow, lead-free electronics components are beco...

-

Lead - Free Resistors Product Certification: Key Considerations for Buyers and Suppliers

IntroductionIn the electronics industry, the shift towards lead-free resistors has become essential due to stringent environmental regulations and the growing demand for eco-friendly products. Lead-Fr...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000