Introduction

As 5G base stations, satellite transponders, and pulsed radar systems push into millimetre-wave bands, the once-obscure aluminum nitride substrate has become the decisive layer between a resistor and its ultimate RF performance. Engineers who once asked “Which thick-film paste should I use?” now start the conversation with “Which ceramic can keep the junction below 150 °C when 200 W pulses hit at 40 GHz?” This article explains in plain language why an AlN substrate is no longer optional for high-frequency, high-power resistors and how to integrate it without re-spinning the board.

The Emerging Challenge

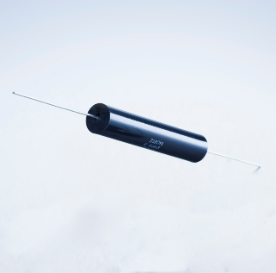

Modern resistive terminations for high-power RF amplifiers must simultaneously dissipate kilowatts of peak power and maintain return loss better than –20 dB at 40 GHz. The bottleneck is no longer the resistive film itself but the ceramic underneath it: if heat is not removed quickly, film temperature rises, resistance drifts, and the amplifier pulls back output power to protect the load. Traditional 96 % alumina (Al₂O₃) simply cannot keep up.

Why Aluminum Nitride Substrates Outperform Others

Three material properties matter most when the goal is low-loss, high-thermal-conductivity resistors:

Thermal conductivity: How fast heat leaves the resistive film.

Coefficient of thermal expansion (CTE): How closely the ceramic matches the adjoining copper or GaN die to avoid shear stress.

Loss tangent: How much RF energy is wasted as heat inside the ceramic itself.

AlN scores decisively on all three fronts, making it the preferred choice for wide-bandgap high-frequency resistive components.

Performance Data: AlN vs. Al₂O₃ vs. BeO

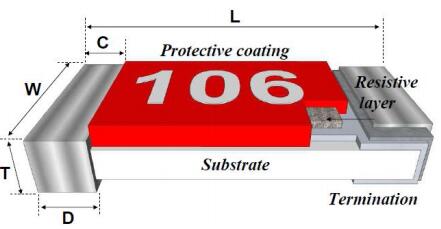

The table below normalises the critical parameters to 25 °C and 10 GHz. Values are typical for commercially available 0.635 mm (25 mil) substrates.

| Property | Units | AlN | Al₂O₃ (96 %) | BeO |

|---|---|---|---|---|

| Thermal conductivity | W·m⁻¹·K⁻¹ | 170–200 | 24–26 | 250–280 |

| CTE (25–400 °C) | ppm·K⁻¹ | 4.5 | 7.1 | 7.2 |

| Loss tangent @ 10 GHz | ×10⁻⁴ | 3–5 | 10–12 | 5–7 |

| Relative permittivity εᵣ | — | 8.8 | 9.8 | 6.7 |

| Max continuous surface temp. | °C | 350 | 250 | 350 |

| RoHS / REACH status | — | Compliant | Compliant | Toxic (restricted) |

Key takeaway: AlN offers 7× the thermal conductivity of alumina while remaining RoHS-compliant—something BeO cannot claim.

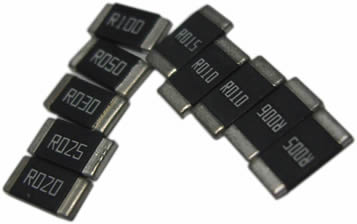

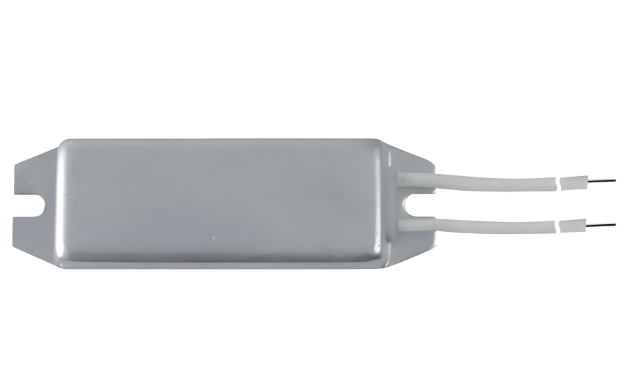

Problem Identified & Practical Solution

Problem

During a 48-hour DVT cycle at +85 °C ambient, an S-band 100 W flange resistor on 0.635 mm Al₂O₃ climbed to 240 °C surface temperature, triggering a 3 dB power fold-back in the GaN PA. Root-cause analysis showed the alumina spreading resistance dominated the thermal path.

Solution

By swapping to a 0.508 mm AlN substrate and adding a 50 µm silver-filled epoxy die-attach, the same resistor settled at 155 °C—well within the derating curve. Return loss at 3.5 GHz improved from –14 dB to –23 dB thanks to tighter film geometry allowed by lower thermal drift.

Actionable step: Replace alumina with AlN of 20 % thinner thickness to cut thermal resistance by ~6×.

Secondary benefit: Reduced dielectric loss (-0.03 dB) in the 3–6 GHz band.

Design Guide for High-Frequency, High-Power Resistors on AlN

Follow these checkpoints to avoid late-stage surprises:

Metallisation stack: Use Ti/W adhesion, Ni barrier, and 2–4 µm Au plating to survive 1000 temperature cycles (-55 °C↔+150 °C).

Via placement: Place 0.15 mm laser-drilled thermal vias under the resistive element at 0.4 mm pitch to pull heat downward.

Surface finish: Specify Ra < 0.2 µm to keep RF currents uniform above 30 GHz.

Edge plating: Wrap Cu/Au edge plating around the substrate to suppress parasitic modes in millimetre-wave high-power loads.

Storage: Vacuum-seal AlN substrates with desiccant; hydrolysis can raise loss tangent by 30 % if left at 60 % RH for a week.

Conclusion

Aluminum nitride substrates are no longer a boutique option—they are the linchpin for reliable high-frequency high-power resistor performance. The data above show that AlN simultaneously lowers junction temperature, shrinks form factor, and maintains RF fidelity up to Ka-band. By following the concise design guide, engineers can move from concept to field-qualified hardware without the thermal guesswork that plagued legacy alumina parts.