-

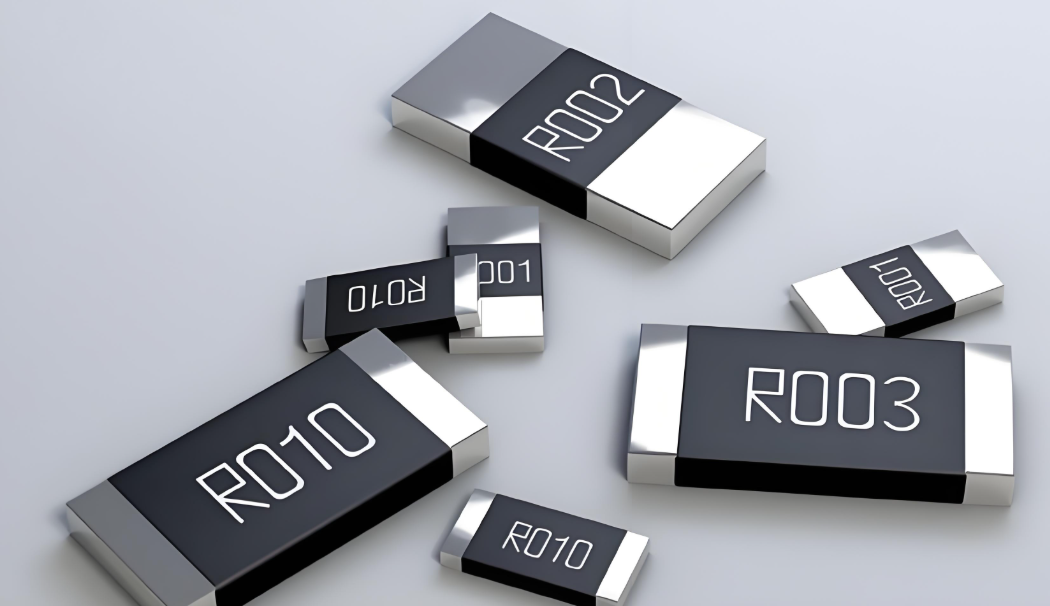

High-Precision Alloy Resistors for Battery Management Systems

<!-- Introduction -->Introduction: The Critical Role of Alloy Resistors in Battery ManagementAlloy resistors are indispensable components in modern battery management systems (BMS), ensuring accurate ...

-

How to Choose Alloy Resistors for High - Reliability Electronic Systems

IntroductionIn high-reliability electronic systems, the selection of components is critical to ensuring consistent performance and longevity. Alloy resistors, with their superior characteristics, are ...

-

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery Monitoring

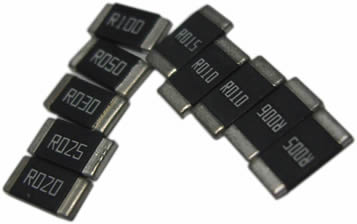

How to Choose the Right Milliohm Resistor for Lithium-Ion Battery MonitoringWhy Milliohm Resistors Matter in Li-Ion BMSIn lithium-ion battery management systems (BMS), milliohm resistors (typically 1m...

-

High Precision Alloy Resistors: Ensuring Long-Term Stability in Precision Circuits

IntroductionIn precision electronics, maintaining circuit stability over time is critical for reliable performance. High precision alloy resistors play a pivotal role in achieving this long-term stabi...

-

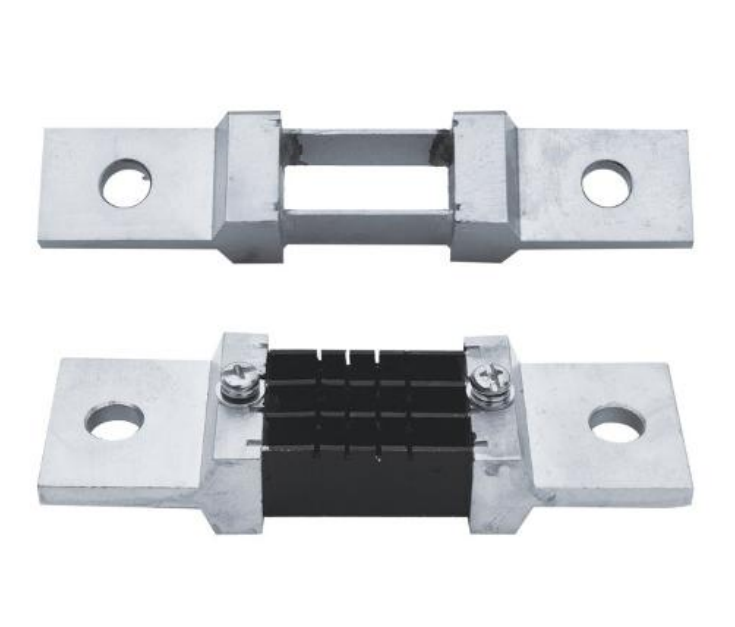

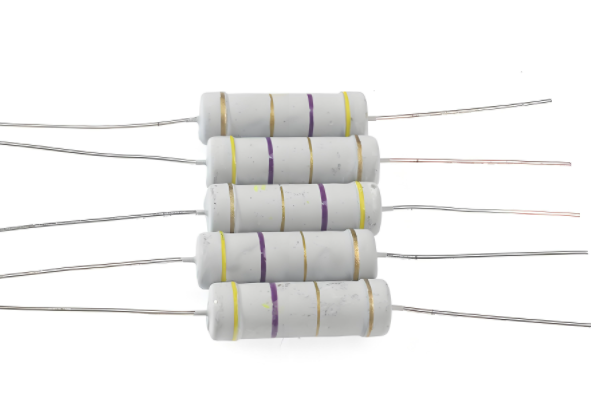

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal Management

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal ManagementIn high-power industrial circuits, 500W-600W resistors must handle both continuous load and sudden s...

-

Alloy Resistor: High - Precision Component for Stable Circuit Performance

IntroductionIn the pursuit of electronic circuit excellence, precision and stability are paramount. Alloy resistors, with their superior characteristics, have become indispensable in achieving these g...

-

High Performance Ceramic Energy Absorption Resistor PCB: Solutions for Efficient Energy Management in Electronics

Introduction: The Vital Role of Ceramic Energy Absorption Resistors in PCBsIn modern electronic systems, efficient energy management is crucial for reliable operation. Ceramic energy absorption resist...

-

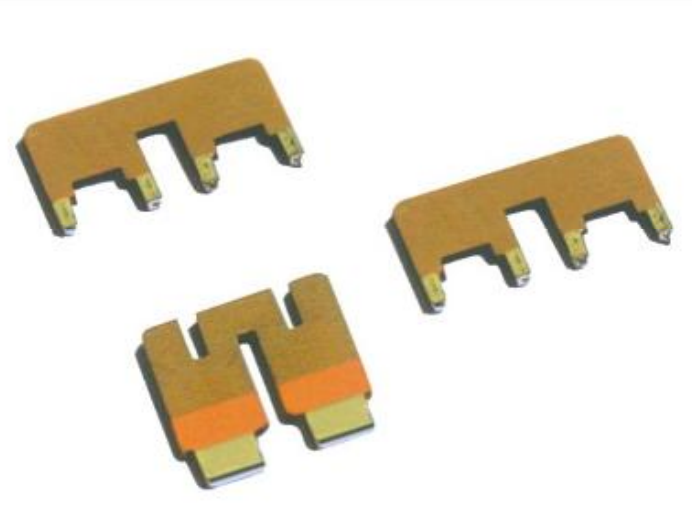

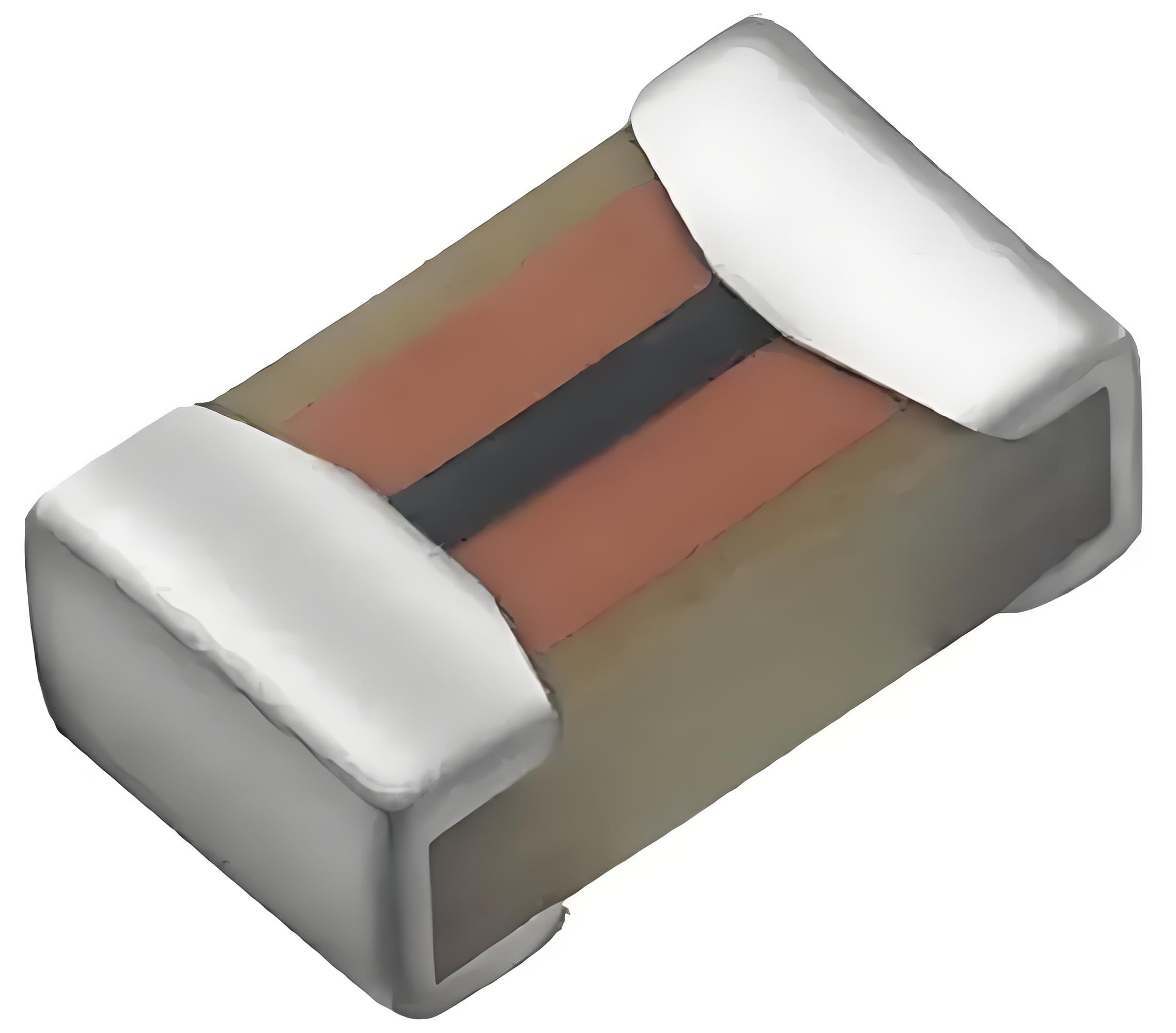

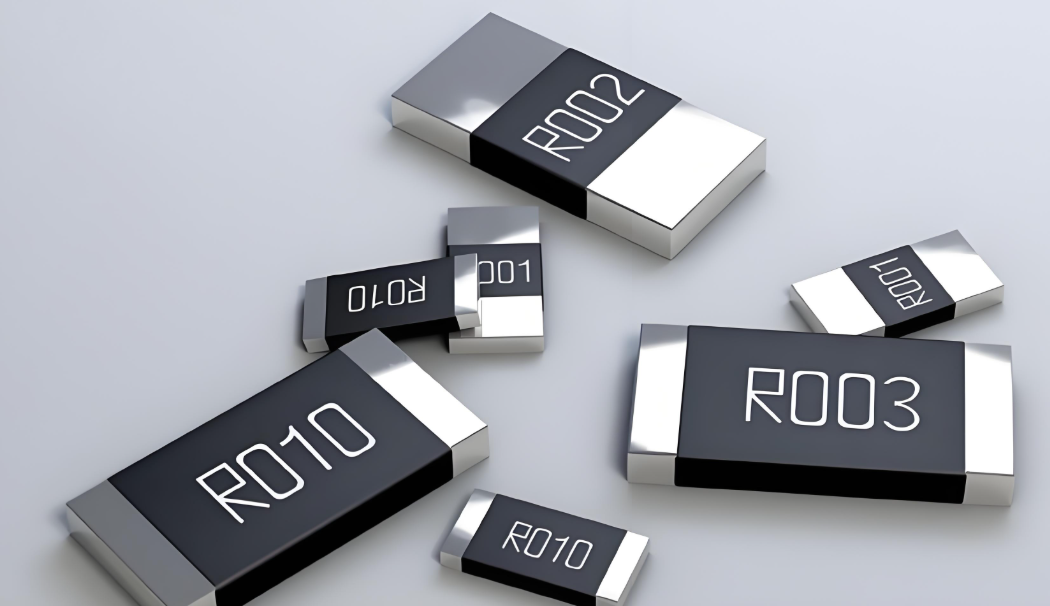

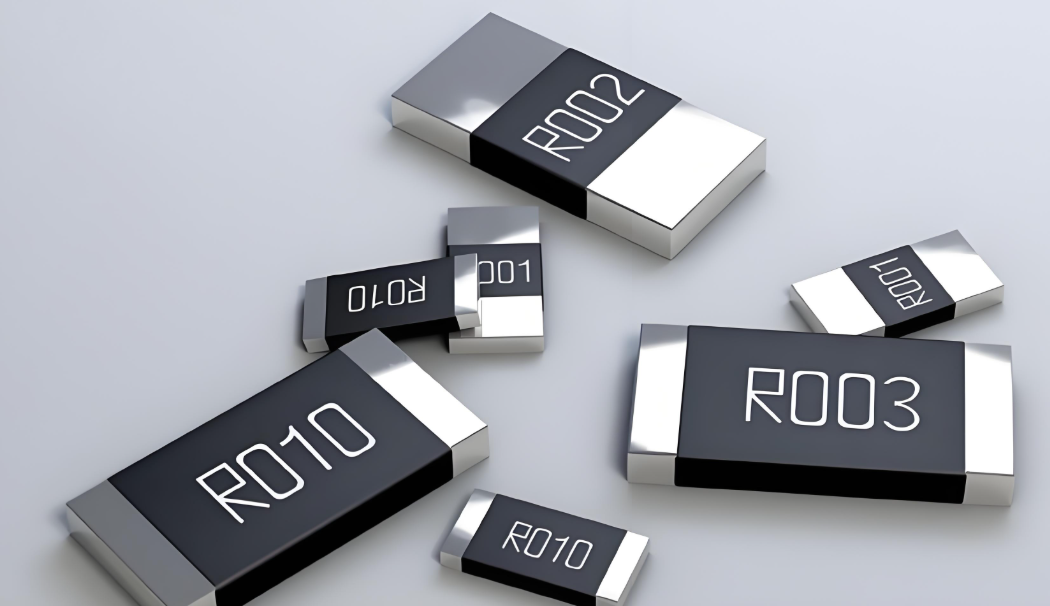

Exploring Alloy Shunt Chip Resistors Type J: High-Precision Solutions for Current Sensing Applications

<!-- Introduction -->IntroductionIn today's high-performance electronics, precision current sensing is critical across a wide range of industries—from power management systems to automotive cont...

-

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

Exploring Different Types of Alloy Resistors: Materials, Applications, and Characteristics

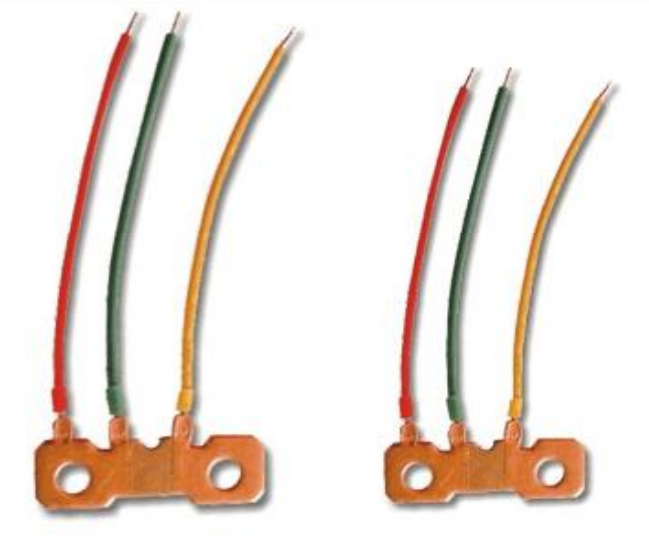

Exploring Different Types of Alloy Resistors: Materials, Applications, and CharacteristicsWelcome to this guide on alloy resistors. In this article, we will explore the different types of alloy resist...

-

How Alloy Resistors Enable Accurate Current Sensing in Power Electronics

<!-- Introduction -->Precision Current Measurement: The Critical Role of Alloy ResistorsIn power electronics systems, accurate current sensing directly impacts efficiency, safety, and performance. All...

-

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...

-

Ignition Resistor for Fuel Injection Systems: Troubleshooting No Spark, Misfire & High Resistance Issues in Gasoline Engines

1. How Ignition Resistors Work in Fuel Injection SystemsIgnition resistors in fuel injection systems limit the primary current flowing to the ignition coil, preventing overheating and ensuring the coi...

-

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips<nav></nav>IntroductionElectric traction systems are at the heart of modern...

-

Ensuring Charger Safety: The Critical Role of Safety Resistors in Modern Power Systems

![]()

IntroductionIn today's fast-paced world, the safety and reliability of electronic devices are paramount. Chargers, as essential components of modern power systems, play a crucial role in ensuring ...

-

Ignition Suppression Resistor – Resistors designed to reduce electromagnetic interference in ignition systems

Ignition Suppression Resistor – Resistors Designed to Reduce Electromagnetic Interference in Ignition SystemsEvery spark in an automotive ignition system is a miniature lightning bolt radiating elec...

-

50kV High Voltage Resistors: Technical Specs, Industrial Use Cases & How to Choose the Right One for Power Grids, Test Labs & Renewable Systems

Technical Specifications of 50kV High Voltage Resistors50kV resistors must withstand high electrical stress while maintaining precision. Below are critical parameters to evaluate for reliability in de...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

180W Four Terminal Ultra Long Creepage Distance Power Resistor | High Voltage Resistance, Non-Inductive Design for Industrial Power Supplies, Motor Control, and Renewable Energy Systems

1. Key Technical Specifications of the 180W Four Terminal Ultra Long Creepage Distance Power ResistorTo understand why this resistor stands out, let’s break down its core parameters—critical for e...

-

High precision resistor applications

<!-- Introduction -->High Precision Resistor Applications: A 2024 Technical GuideHigh precision resistors are critical components in electronics where stability, accuracy, and low temperature coeffici...

-

High Precision Alloy Resistors: Ensuring Long-Term Stability in Precision Circuits

IntroductionIn precision electronics, maintaining circuit stability over time is critical for reliable performance. High precision alloy resistors play a pivotal role in achieving this long-term stabi...

-

How to Choose Alloy Resistors for High - Reliability Electronic Systems

IntroductionIn high-reliability electronic systems, the selection of components is critical to ensuring consistent performance and longevity. Alloy resistors, with their superior characteristics, are ...

-

How Alloy Resistors Enable Accurate Current Sensing in Power Electronics

<!-- Introduction -->Precision Current Measurement: The Critical Role of Alloy ResistorsIn power electronics systems, accurate current sensing directly impacts efficiency, safety, and performance. All...

-

High-Precision Alloy Resistors for Battery Management Systems

<!-- Introduction -->Introduction: The Critical Role of Alloy Resistors in Battery ManagementAlloy resistors are indispensable components in modern battery management systems (BMS), ensuring accurate ...

-

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

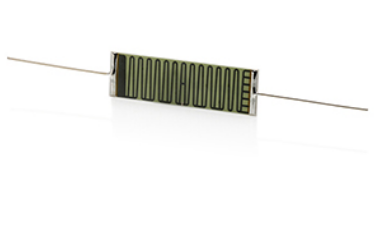

High - Stability Golden Aluminum Case Wirewound Resistors for Precision Circuits

IntroductionIn the realm of precision electronics, the choice of components can make or break a circuit's performance. High-stability Golden Aluminum Case Wirewound Resistors have established them...

-

Alloy Resistor: High - Precision Component for Stable Circuit Performance

IntroductionIn the pursuit of electronic circuit excellence, precision and stability are paramount. Alloy resistors, with their superior characteristics, have become indispensable in achieving these g...

-

Exploring Different Types of Alloy Resistors: Materials, Applications, and Characteristics

Exploring Different Types of Alloy Resistors: Materials, Applications, and CharacteristicsWelcome to this guide on alloy resistors. In this article, we will explore the different types of alloy resist...

-

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...