-

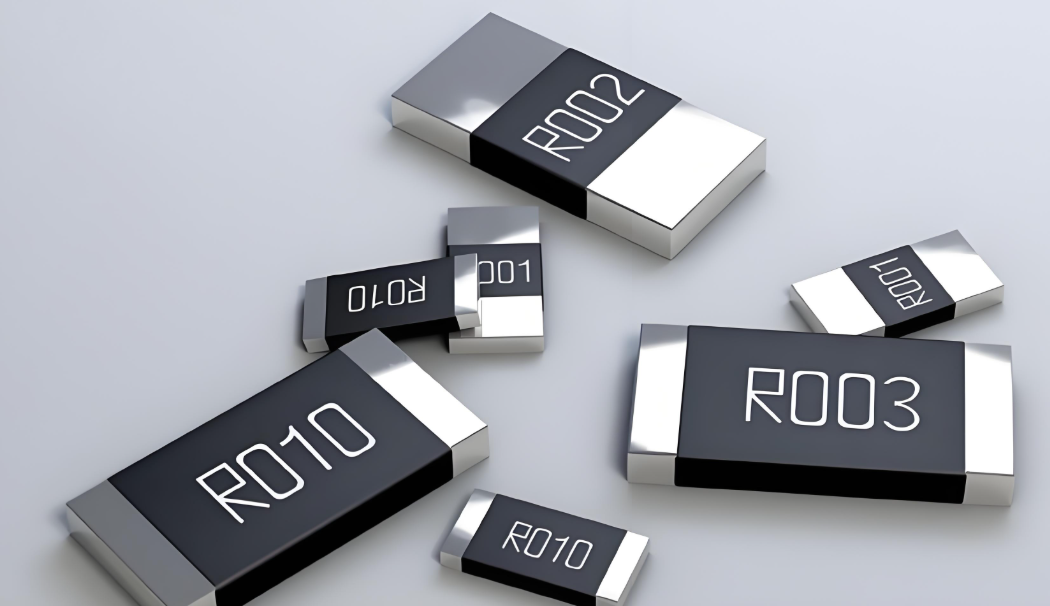

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...

-

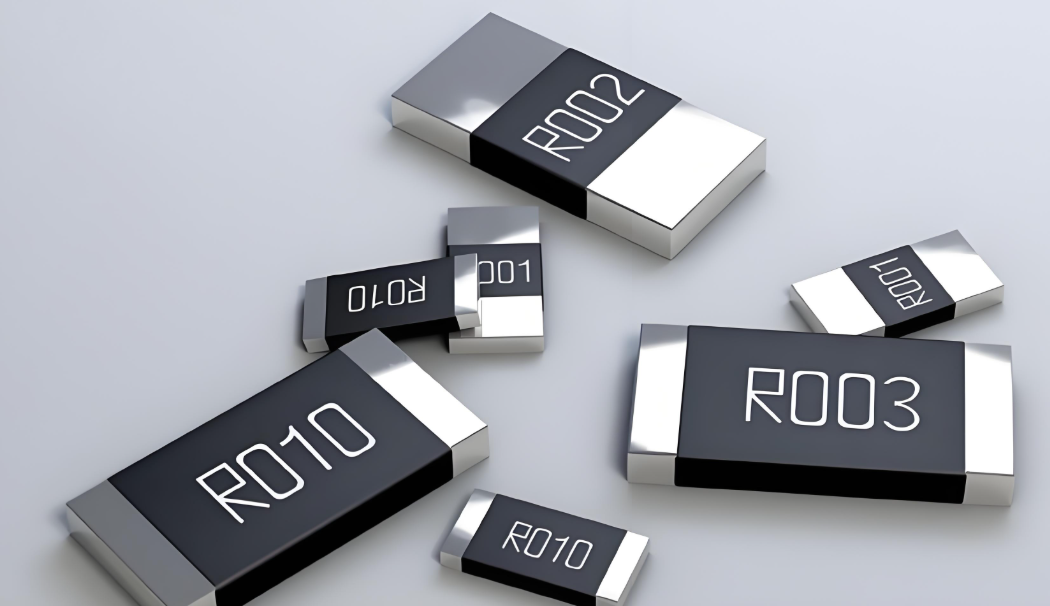

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

Low TCR Resistor Power Rating: Selection Guide, Applications & How to Avoid Overheating

1. What Is a Low TCR Resistor Power RatingThe power rating of a low TCR resistor specifies the maximum power ($P$) it can safely dissipate without exceeding its temperature limit (typically 125°C–1...

-

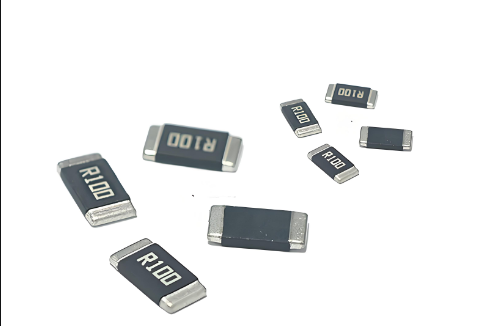

High Current Low TCR Thick Film Resistor for International Market - Long-term Stability

High Current Low TCR Thick Film Resistor for International Market - Long-term StabilityIn the global electronics market, high current low TCR thick film resistors have become increasingly important fo...

-

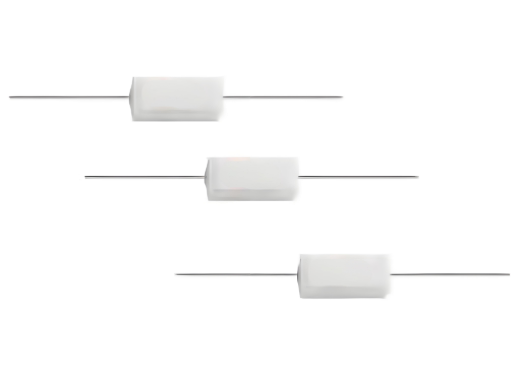

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial Applications

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial ApplicationsIn high - power industrial systems, the 600W wirewound power resistor is a cornerstone component...

-

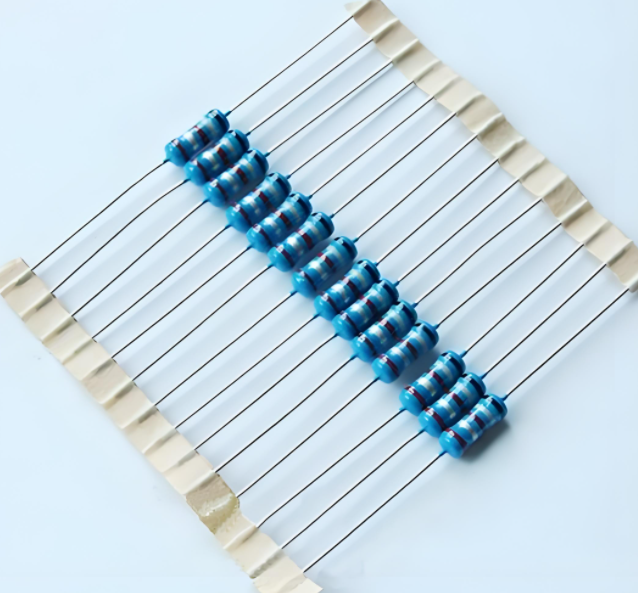

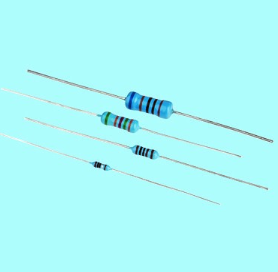

High Precision Metal Film Resistors: Low TCR for Maximum Stability

In the intricate landscape of modern electronics, high precision metal film resistors have emerged as a vital component, with their low Temperature Coefficient of Resistance (TCR) being a defining cha...

-

Low TCR Resistor Arrays: A Guide to Matched TCR, Precision, and Applications

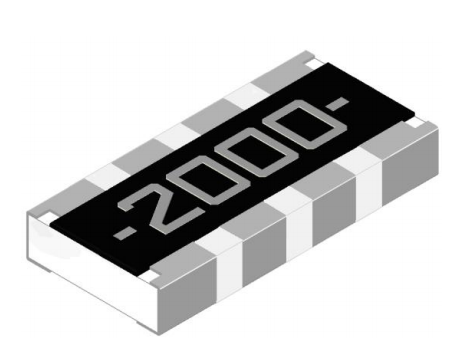

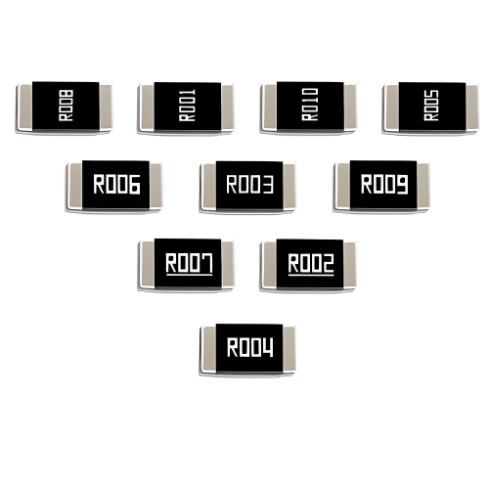

Low TCR Resistor Arrays: A Guide to Matched TCR, Precision, and ApplicationsIn precision circuit design, managing individual component drift is challenging enough. But what happens when you need multi...

-

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained<!-- 引言 -->IntroductionPower resistors up to 600W play pivotal roles in various industrial sectors like elec...

-

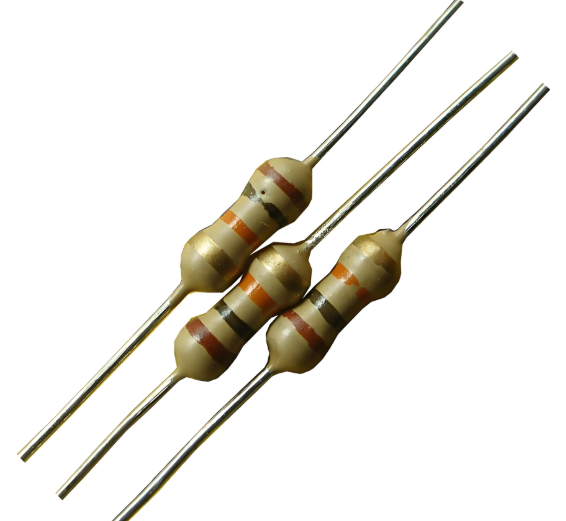

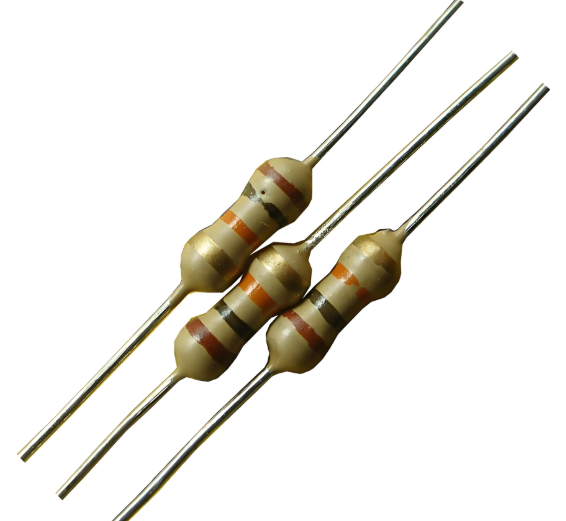

Carbon Disc vs Carbon Composition Resistors: Noise, Power Handling & Which to Choose for Audio/Power Circuits

Carbon disc and carbon composition resistors are both legacy components valued for their low cost and organic material composition, but their differences in noise, power handling, and stability make t...

-

High Ohmic Resistors: Precision, Stability & Low Leakage Solutions for HV Circuits

High Ohmic Resistors: Precision, Stability & Low Leakage Solutions for HV CircuitsHigh ohmic resistors (1MΩ to 10GΩ+) are critical components in high-voltage circuits where precision, long-term ...

-

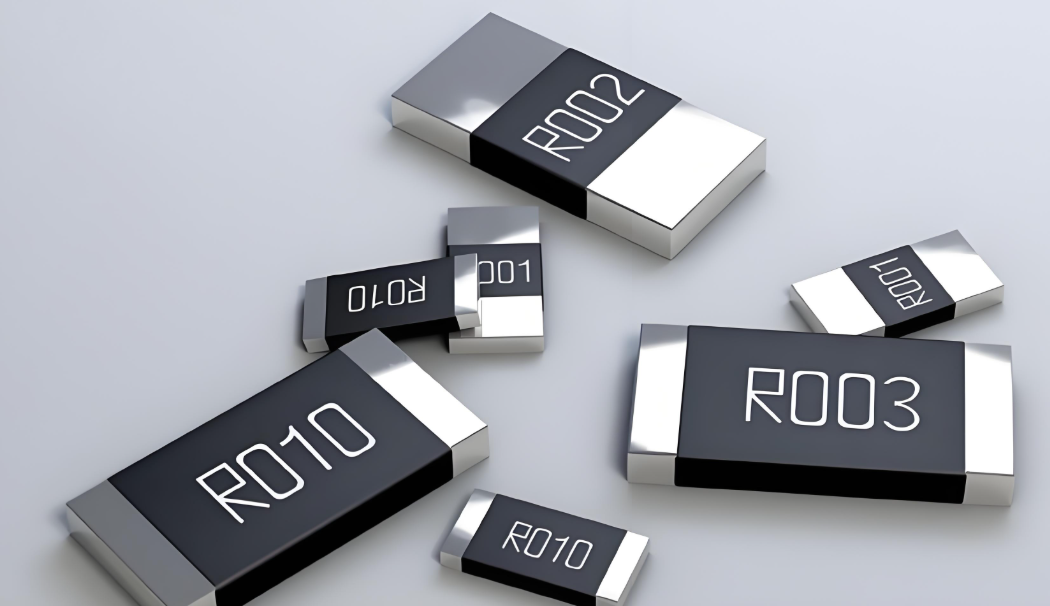

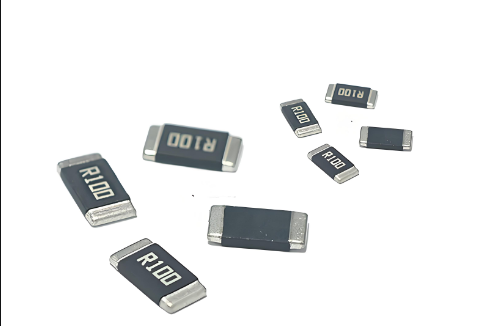

low TCR resistor vs standard chip resistor

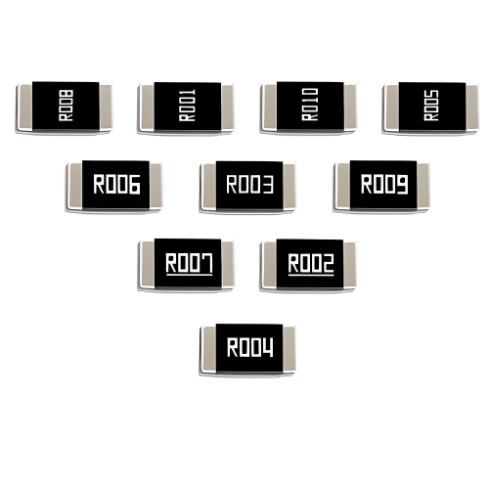

Low TCR Resistor vs Standard Chip Resistor: Key Differences & Best ApplicationsIntroductionWhen designing precision circuits, selecting the right resistor type is critical. Two common choices are ...

-

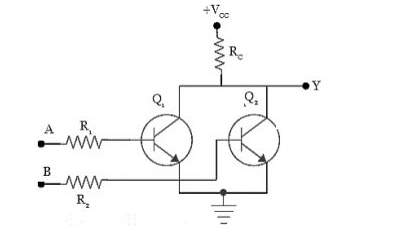

What Is a KB Resistor? Definition, Function, Applications & Technical Specifications Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standardized nominal resistance value, most commonly 1kΩ (1,000Ω). Unlike variable resistors (e.g., pot...

-

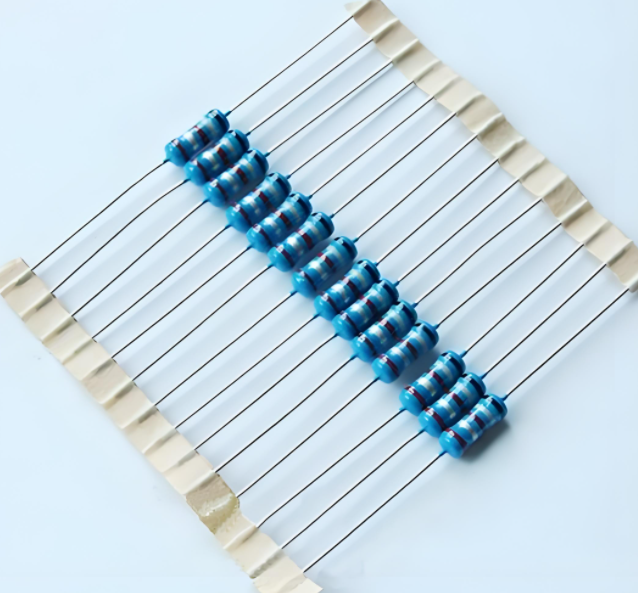

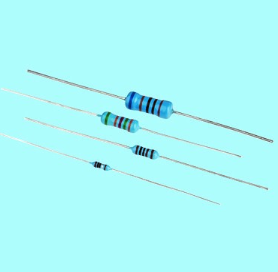

KB Resistor Definition: 1kΩ Standard Value, Tolerance & Temperature Coefficient Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standard resistance value, typically used in low-to-moderate power circuits. Unlike variable resistors (e...

-

MELF Resistor Basics: Definition, Function, Applications & Key Specifications Explained

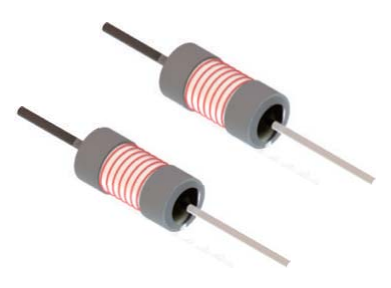

1. What Is a MELF Resistor Core DefinitionA MELF resistor is a leadless, surface-mountable resistor with a cylindrical metal electrode structure. Unlike traditional through-hole resistors (e.g., THT),...

-

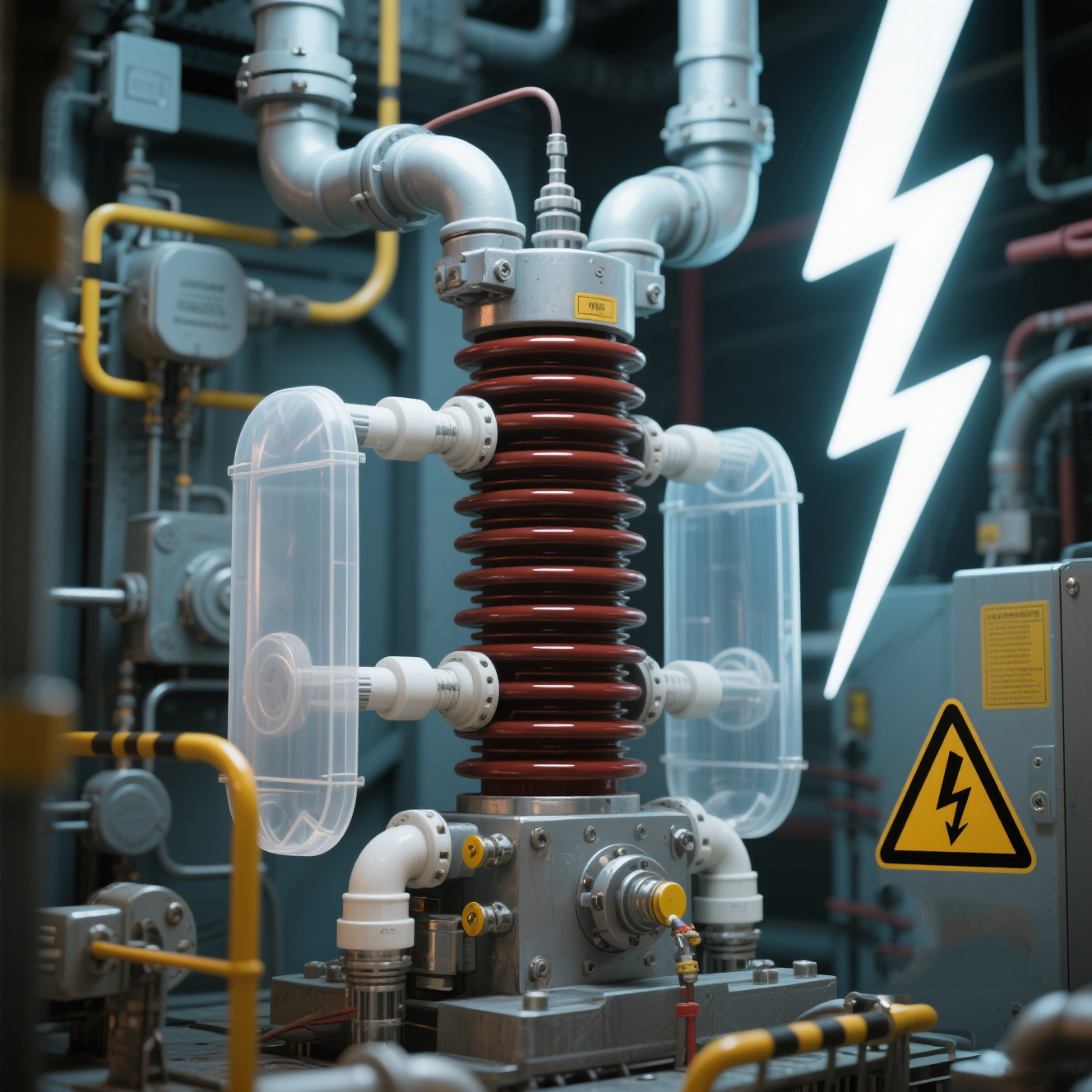

Exploring the Diverse Applications of High Voltage Resistors in Power Generation: Key Roles and Advantages

Applications of High Voltage Resistors in Power GenerationIntroductionIn the intricate realm of power generation, high voltage resistors play a crucial role. They are essential components that help in...

-

Why Use Low TCR Resistors? The Key to Stable Circuit Performance

Why Use Low TCR Resistors The Key to Stable Circuit PerformanceIn electronic design, a resistor's value is often considered a constant. However, this is a simplification that can lead to significa...

-

Maximizing Efficiency: A Comprehensive Guide to Carbon Disc Resistor Energy Dissipation and Power Handling

IntroductionIn the realm of electronics, the efficiency and reliability of components are paramount. Among these components, carbon disc resistors play a crucial role in various applications, from sim...

-

High Precision Metal Film Resistors | 0.1% Tolerance, Low TCR (5ppm/°C), Military-Grade

High Precision Metal Film Resistors | 0.1% Tolerance, Low TCR (5ppm/°C), Military-Grade<!-- Introduction -->IntroductionHigh precision metal film resistors are critical components in advanced electro...

-

High Precision Alloy Resistors: Ensuring Long-Term Stability in Precision Circuits

IntroductionIn precision electronics, maintaining circuit stability over time is critical for reliable performance. High precision alloy resistors play a pivotal role in achieving this long-term stabi...

-

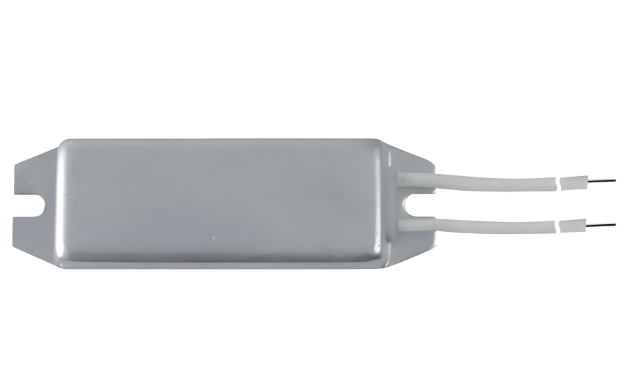

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal Management

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal ManagementIn high-power industrial circuits, 500W-600W resistors must handle both continuous load and sudden s...

-

High Precision Alloy Resistors: Ensuring Long-Term Stability in Precision Circuits

IntroductionIn precision electronics, maintaining circuit stability over time is critical for reliable performance. High precision alloy resistors play a pivotal role in achieving this long-term stabi...

-

How to Choose Alloy Resistors for High - Reliability Electronic Systems

IntroductionIn high-reliability electronic systems, the selection of components is critical to ensuring consistent performance and longevity. Alloy resistors, with their superior characteristics, are ...

-

How Alloy Resistors Enable Accurate Current Sensing in Power Electronics

<!-- Introduction -->Precision Current Measurement: The Critical Role of Alloy ResistorsIn power electronics systems, accurate current sensing directly impacts efficiency, safety, and performance. All...

-

High-Precision Alloy Resistors for Battery Management Systems

<!-- Introduction -->Introduction: The Critical Role of Alloy Resistors in Battery ManagementAlloy resistors are indispensable components in modern battery management systems (BMS), ensuring accurate ...

-

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

High - Stability Golden Aluminum Case Wirewound Resistors for Precision Circuits

IntroductionIn the realm of precision electronics, the choice of components can make or break a circuit's performance. High-stability Golden Aluminum Case Wirewound Resistors have established them...

-

Alloy Resistor: High - Precision Component for Stable Circuit Performance

IntroductionIn the pursuit of electronic circuit excellence, precision and stability are paramount. Alloy resistors, with their superior characteristics, have become indispensable in achieving these g...

-

Exploring Different Types of Alloy Resistors: Materials, Applications, and Characteristics

Exploring Different Types of Alloy Resistors: Materials, Applications, and CharacteristicsWelcome to this guide on alloy resistors. In this article, we will explore the different types of alloy resist...

-

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...