Introduction

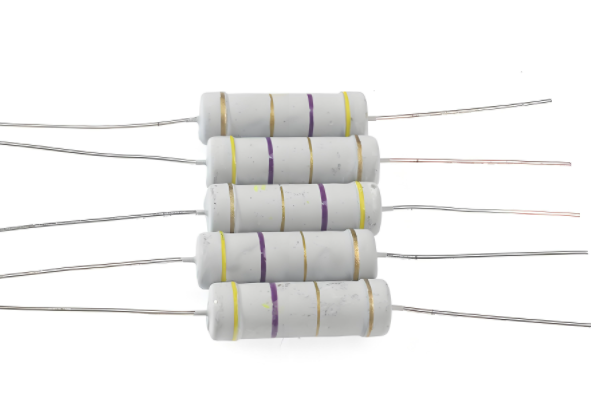

In the realm of electronics, the efficiency and reliability of components are paramount. Among these components, carbon disc resistors play a crucial role in various applications, from simple circuits to complex systems. One of the key aspects that engineers and hobbyists need to understand is how these resistors handle energy dissipation and power. This comprehensive guide aims to delve into the intricacies of carbon disc resistor energy dissipation and power handling, providing practical insights and solutions to maximize efficiency.

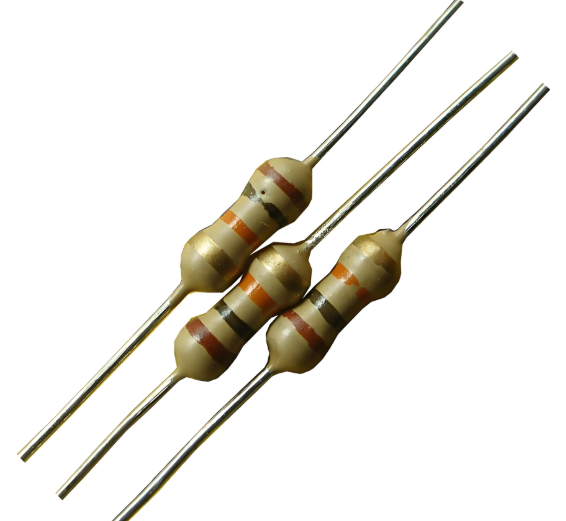

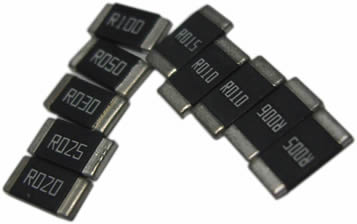

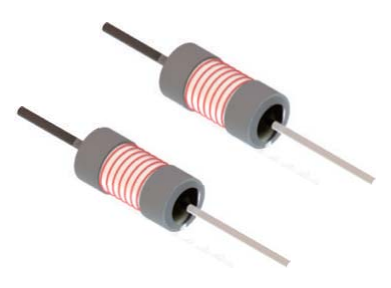

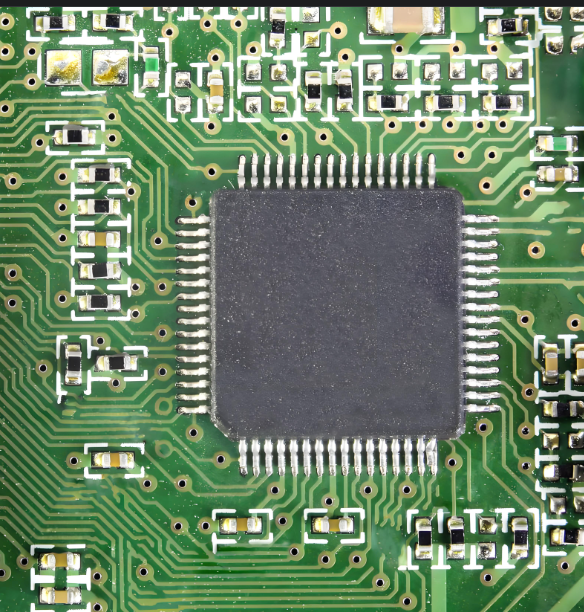

Carbon Disc Resistor Basics

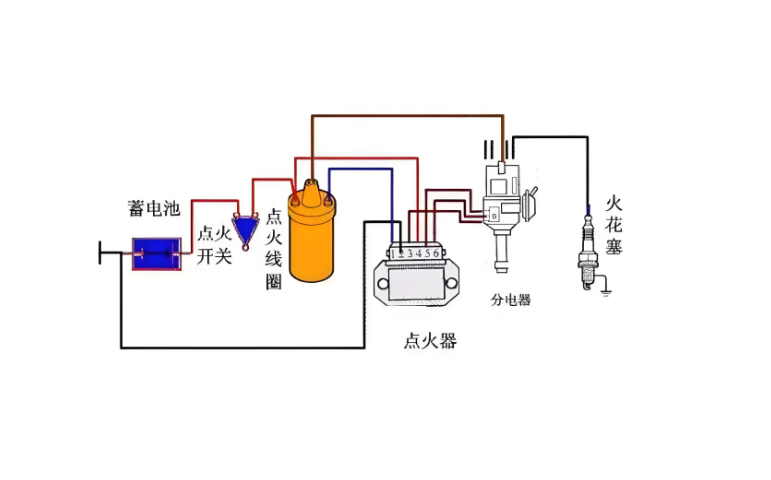

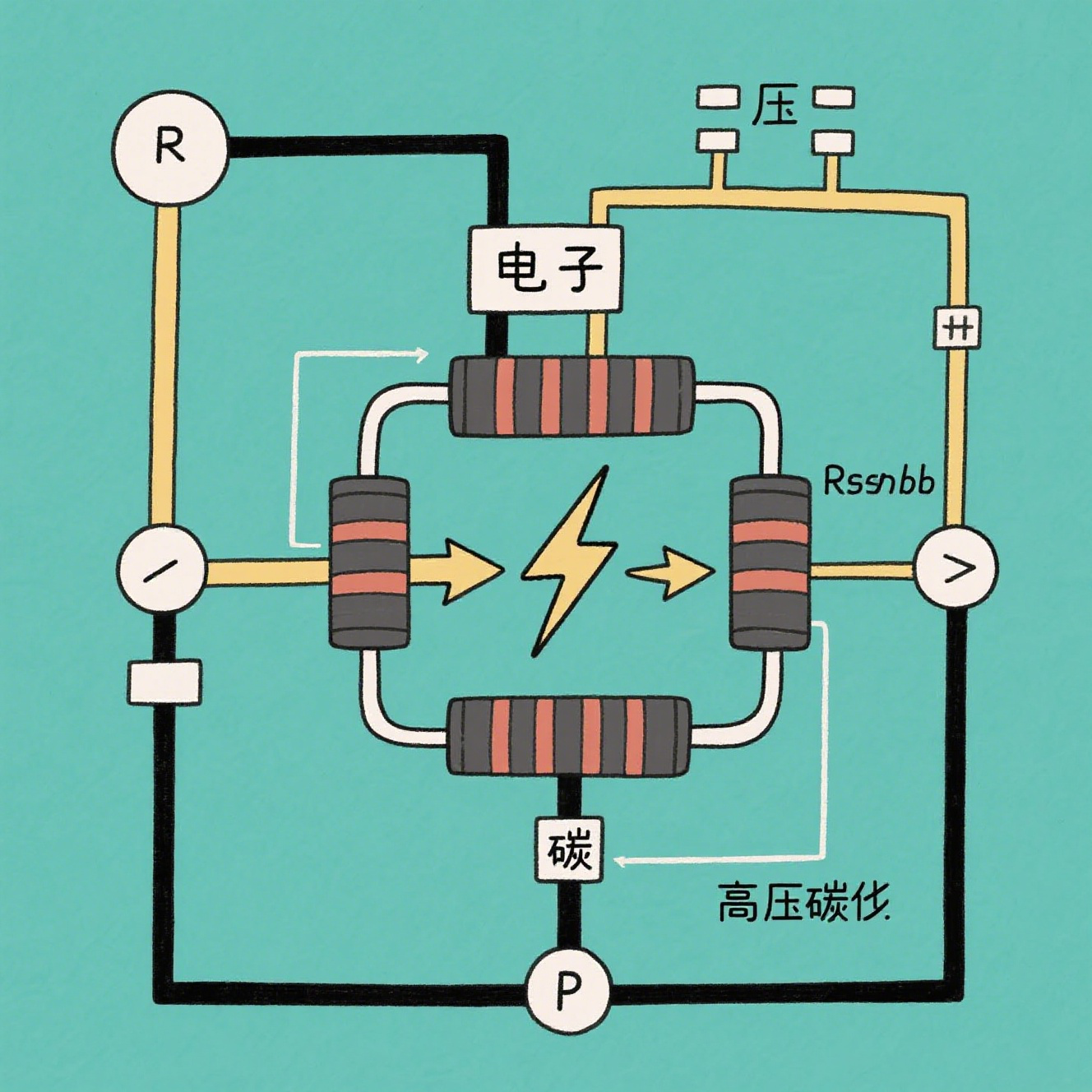

Carbon disc resistors are a type of fixed resistor that uses a carbon composition material to provide resistance. They are known for their durability and ability to handle high energy pulses. These resistors are commonly used in applications where high surge currents are expected, such as in braking circuits, electric traction, and high-voltage impulse circuits.

Energy Dissipation

Energy dissipation in carbon disc resistors is a critical factor that determines their performance and longevity. When current flows through a resistor, electrical energy is converted into heat. The ability of a resistor to dissipate this heat effectively is crucial to prevent overheating and potential damage.

| Parameter | Value | Unit |

|---|---|---|

| Typical Resistance Range | 1Ω to 1MΩ | Ohms |

| Power Rating | 0.5W to 5W | Watts |

| Temperature Coefficient | ±100 ppm/°C | ppm/°C |

| Operating Temperature | -55°C to +155°C | °C |

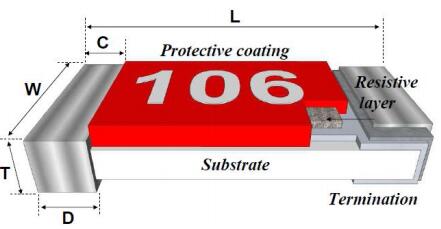

The table above provides a snapshot of typical specifications for carbon disc resistors. These parameters are essential for understanding how much energy the resistor can dissipate without overheating.

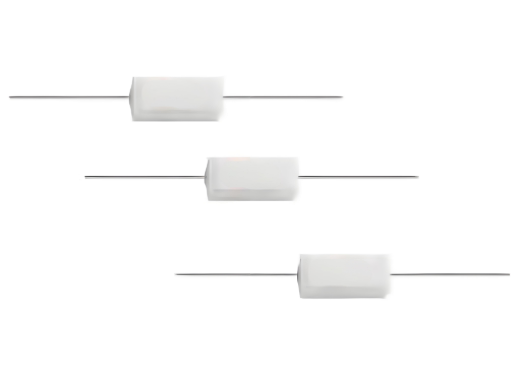

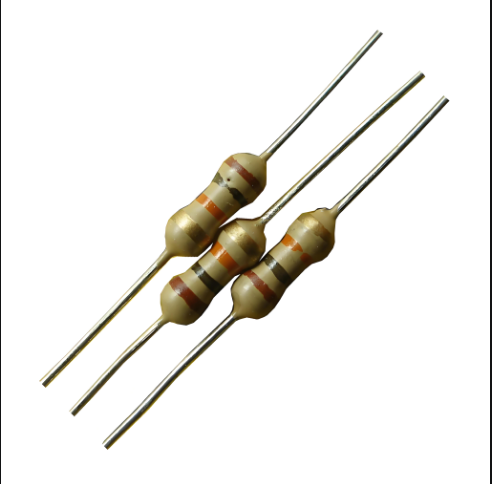

Power Handling

Power handling refers to the maximum amount of power a resistor can safely dissipate without damage. This is typically measured in watts (W). For carbon disc resistors, power handling is influenced by factors such as resistance value, operating temperature, and the physical size of the resistor.

| Resistance (Ω) | Power Rating (W) | Max Energy (Joules) |

|---|---|---|

| 100 | 1 | 10 |

| 1k | 0.5 | 5 |

| 10k | 0.25 | 2.5 |

| 100k | 0.1 | 1 |

The table above illustrates how power handling decreases with increasing resistance values. This is important to consider when selecting a resistor for a specific application.

Common Problems and Solutions

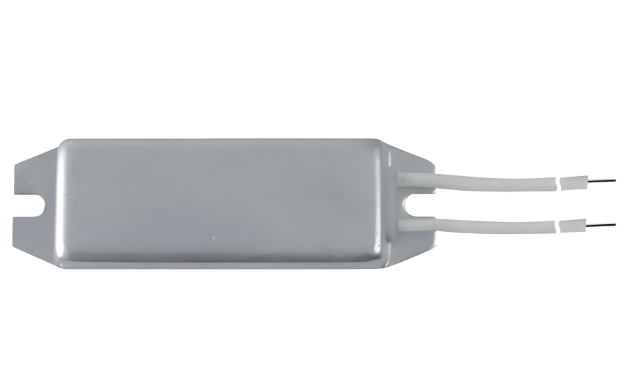

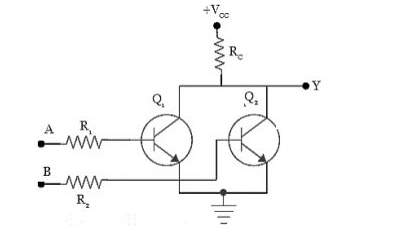

One common issue with carbon disc resistors is overheating, which can lead to reduced performance or failure. This problem often arises when the resistor is subjected to continuous high power dissipation beyond its rated capacity.

Solution

To address this issue, it is essential to select a resistor with an appropriate power rating for the application. Additionally, using heat sinks or ensuring adequate ventilation can help dissipate excess heat. For example, if a circuit requires a resistor to handle 2W of power, choosing a resistor rated for at least 2W or higher will prevent overheating.

Practical Tips for Maximizing Efficiency

Here are some practical tips to ensure optimal performance and longevity of carbon disc resistors:

Select the Right Power Rating: Always choose a resistor with a power rating that matches or exceeds the expected power dissipation in your circuit.

Monitor Temperature: Keep the operating temperature within the specified range to avoid thermal runaway.

Use Heat Sinks: For high-power applications, consider using heat sinks to improve thermal management.

Regular Maintenance: Periodically check for signs of wear or damage, especially in applications with frequent high-energy pulses.

Conclusion

Understanding the energy dissipation and power handling capabilities of carbon disc resistors is crucial for maximizing their efficiency and reliability. By selecting the right resistor for the job and implementing proper thermal management techniques, engineers and hobbyists can ensure that their circuits perform optimally. This guide provides a comprehensive overview of the key factors to consider, along with practical tips and solutions to common problems.