Introduction

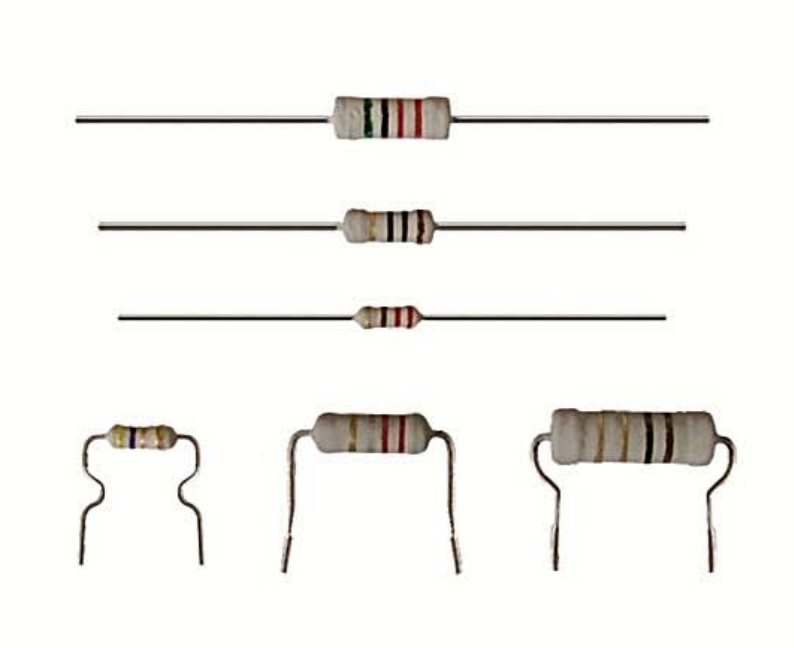

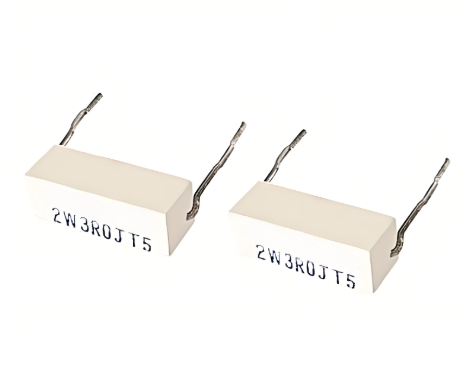

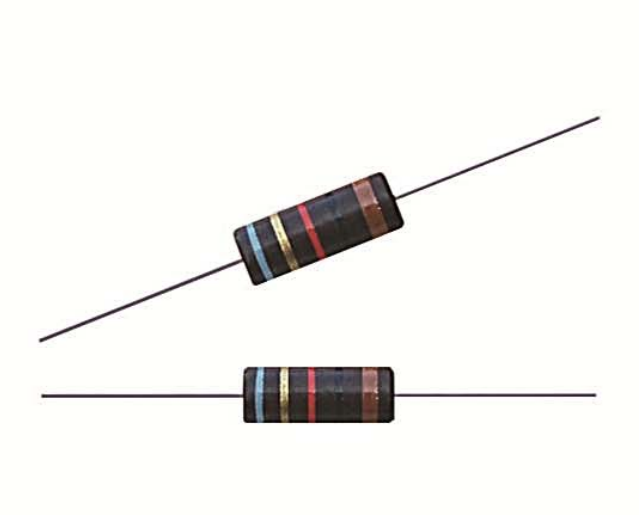

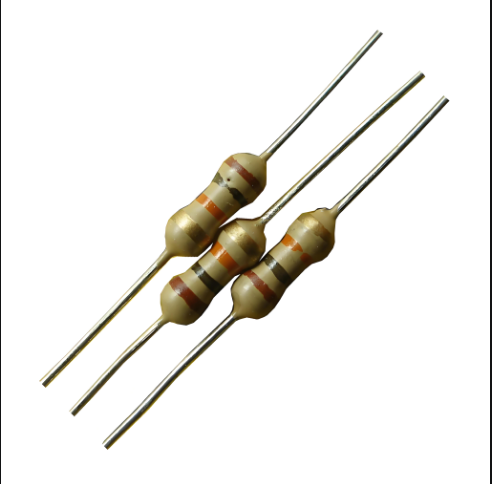

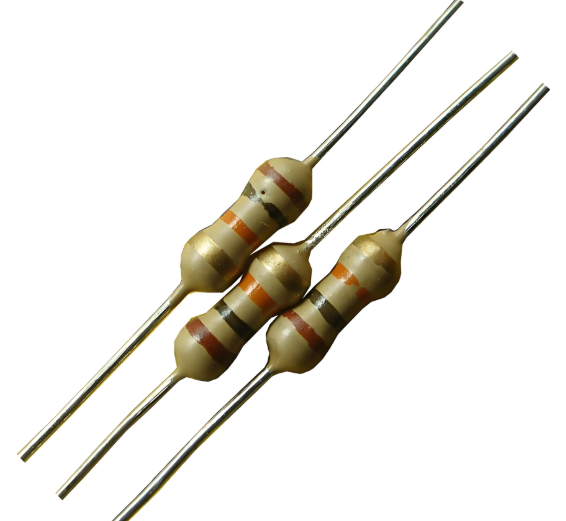

Carbon Disc Resistors have long been a staple in the world of electronics, and their unique properties make them particularly interesting for use in audio equipment. From vintage amplifiers to modern high-fidelity systems, understanding how to effectively utilize, maintain, and troubleshoot these components can significantly impact the overall performance and longevity of your audio gear. This comprehensive guide aims to delve into the usage, benefits, and maintenance of Carbon Disc Resistors in audio equipment, providing practical insights and solutions for enthusiasts and professionals alike.

One common problem audio enthusiasts face is the degradation of sound quality over time due to the aging of components. How can Carbon Disc Resistors be maintained to ensure optimal performance? We will explore this issue and provide effective solutions throughout the article.

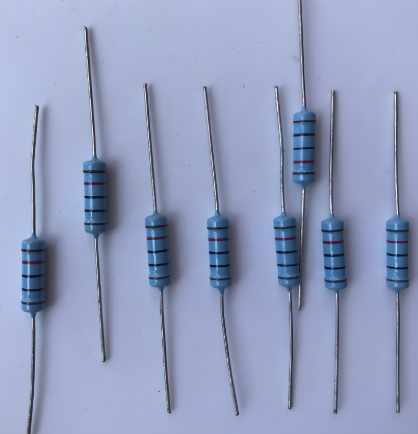

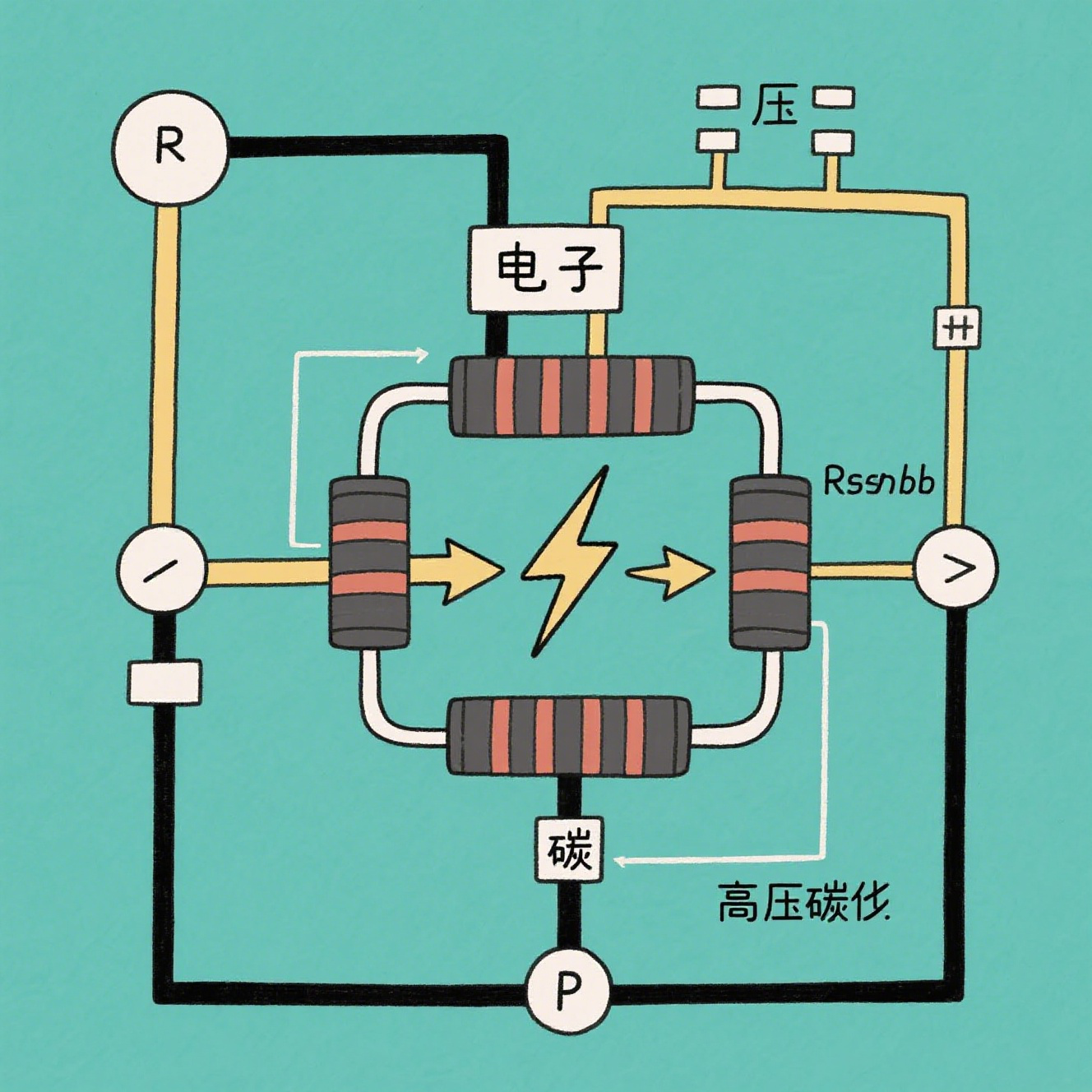

Usage of Carbon Disc Resistors in Audio Equipment

Carbon Disc Resistors are widely used in various components of audio equipment due to their distinct characteristics. The table below highlights some common applications:

| Component | Application | Typical Resistance Range |

|---|---|---|

| Amplifiers | Signal processing, power management | 1kΩ - 1MΩ |

| Preamps | Signal conditioning, impedance matching | 10kΩ - 100kΩ |

| Speaker Crossovers | Frequency filtering, impedance correction | 0.1Ω - 10Ω |

| Phono Stages | Signal amplification, tone control | 47kΩ - 220kΩ |

These applications leverage the robust and stable electrical properties of Carbon Disc Resistors, ensuring reliable performance across different audio equipment components.

Benefits of Using Carbon Disc Resistors in Audio Equipment

The use of Carbon Disc Resistors in audio equipment offers several advantages. Below are some key benefits:

<> tr| Benefit | Description | Impact on Audio Performance |

|---|---|---|

| Temperature Stability | Maintain consistent resistance over varying temperatures | Minimizes signal distortion and ensures stable frequency response |

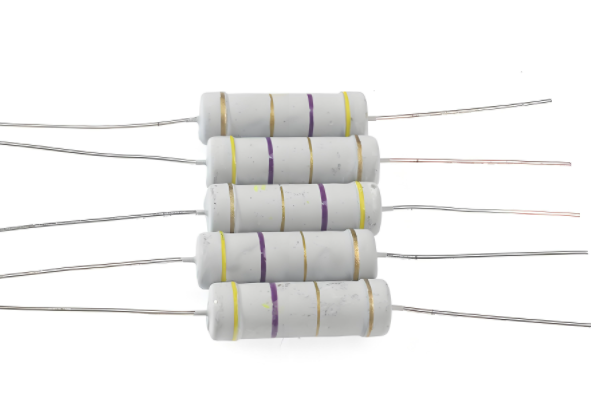

| High Power Handling | Can handle higher power levels without significant degradation | Ensures durability and reliability in high-power applications |

| Low Noise | Produces minimal electrical noise compared to other types | Contributes to cleaner and more accurate sound reproduction |

| Wide Resistance Range | Available in a broad range of resistance values | Offers flexibility in circuit design and tuning |

These benefits collectively enhance the overall performance and reliability of audio equipment, making Carbon Disc Resistors a preferred choice for many audio enthusiasts and professionals.

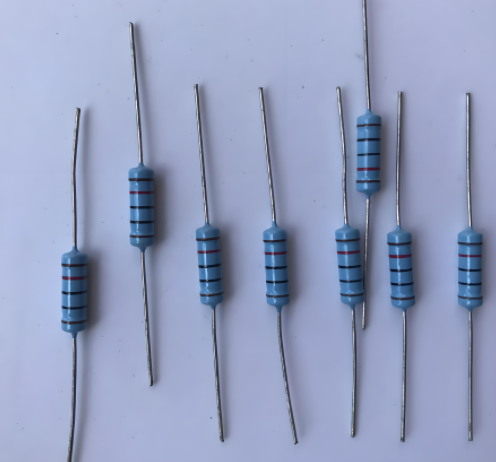

Maintenance Guide for Carbon Disc Resistors

To ensure the longevity and optimal performance of Carbon Disc Resistors in audio equipment, proper maintenance is essential. Here are some key maintenance tips:

| Maintenance Task | Frequency | Procedure |

|---|---|---|

| Visual Inspection | Annually | Check for physical damage, cracks, or signs of aging |

| Resistance Testing | Bi-annually | Use a multimeter to verify resistance within specified tolerance |

| Cleaning | As needed | Gently clean with a soft brush to remove dust and debris |

| Thermal Management | Ongoing | Ensure adequate ventilation around components to prevent overheating |

Regular maintenance can help prevent common issues such as resistance drift or thermal failures, ensuring your audio equipment remains in top condition.

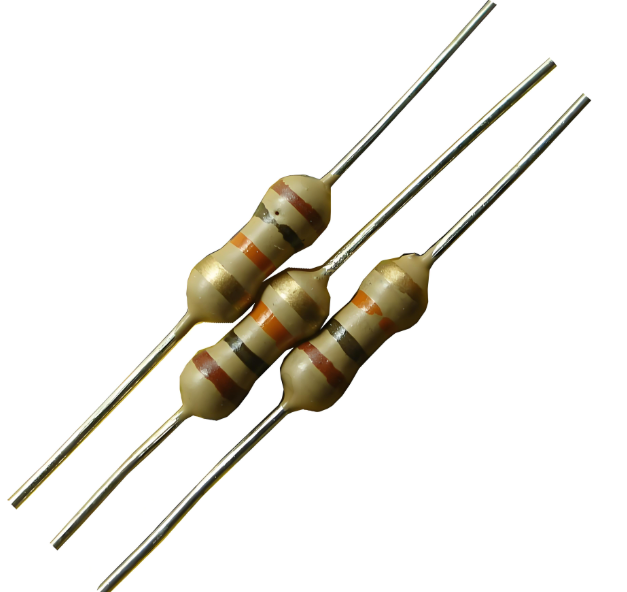

Problem and Solution: Addressing Sound Quality Degradation

One of the common problems audio enthusiasts face is the degradation of sound quality over time. This can be attributed to various factors, including aging components such as Carbon Disc Resistors. Here are some steps to identify and address this issue:

Identify symptoms: Listen for changes in frequency response, increased background noise, or distortion.

Test components: Use a multimeter to test the resistance of suspected resistors. Compare the measured values to the rated values to identify significant deviations.

Replace if necessary: If the resistance values are outside the acceptable tolerance range, consider replacing the resistors with new ones of the same or similar specifications.

Implement maintenance practices: Follow the maintenance guide provided earlier to prevent future degradation and ensure consistent performance.

By proactively addressing potential issues and maintaining your Carbon Disc Resistors, you can significantly improve the overall sound quality of your audio equipment and extend its lifespan.

Conclusion

Carbon Disc Resistors play a crucial role in the performance and reliability of audio equipment. By understanding their usage, recognizing the benefits they offer, and following a proper maintenance routine, you can ensure optimal performance and longevity. Addressing common problems such as sound quality degradation through proactive measures will help you get the most out of your audio gear. Whether you are an audiophile or a professional technician, this guide provides the essential information needed to effectively manage and maintain Carbon Disc Resistors in audio equipment.