Carbon Disc vs Carbon Composition Resistors: Noise, Power Handling & Which to Choose for Audio/Power Circuits

Carbon disc and carbon composition resistors are both legacy components valued for their low cost and organic material composition, but their differences in noise, power handling, and stability make them better suited for distinct applications. If you’re designing audio equipment or power supplies, choosing between them can mean the difference between a clean signal and unwanted distortion—or even component failure. This guide breaks down their technical specs, real-world performance, and how to pick the right one for your needs.

1. Construction: How They’re Made (and Why It Matters)

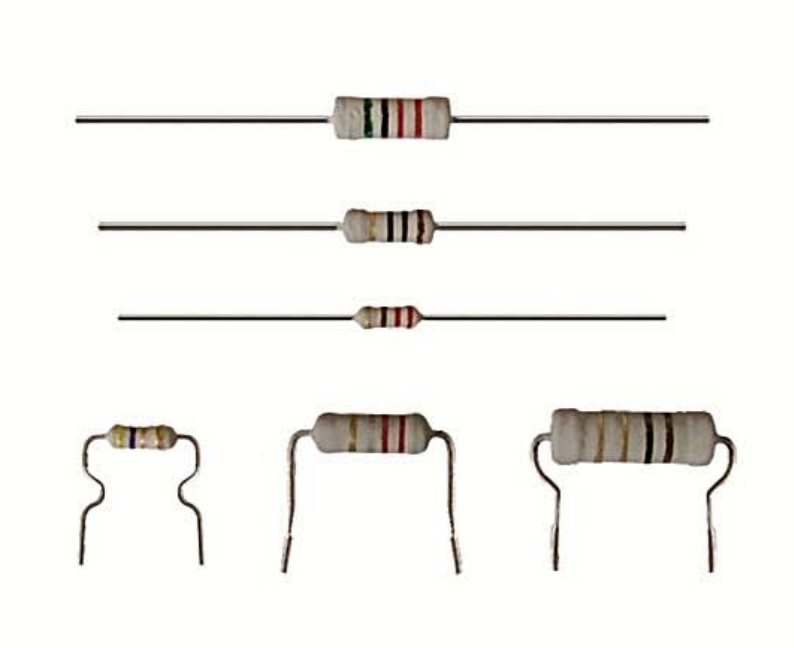

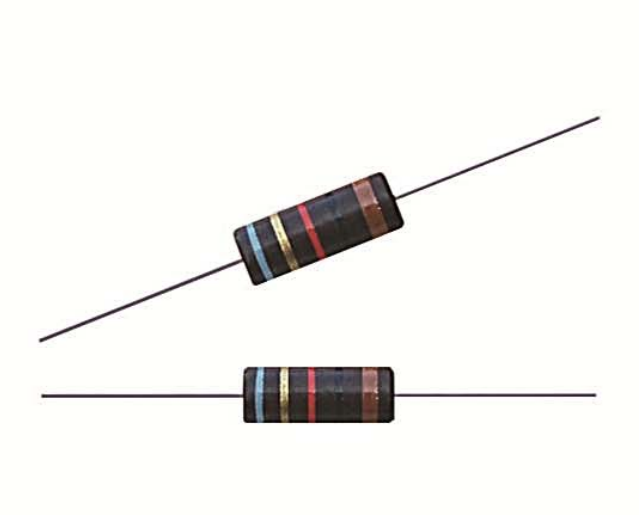

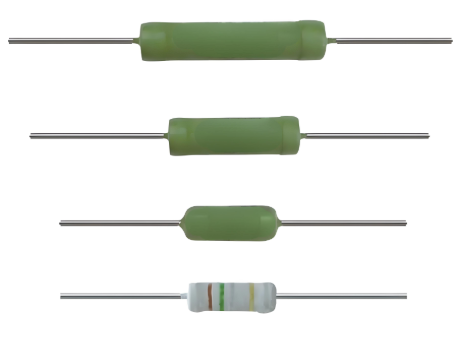

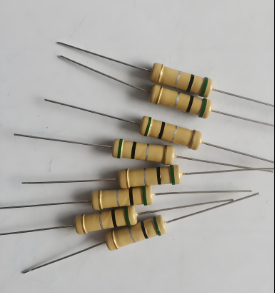

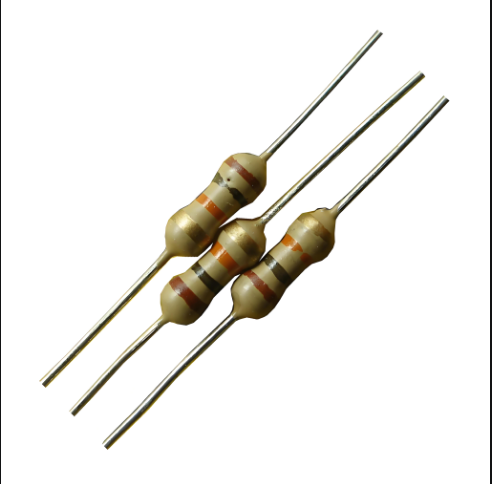

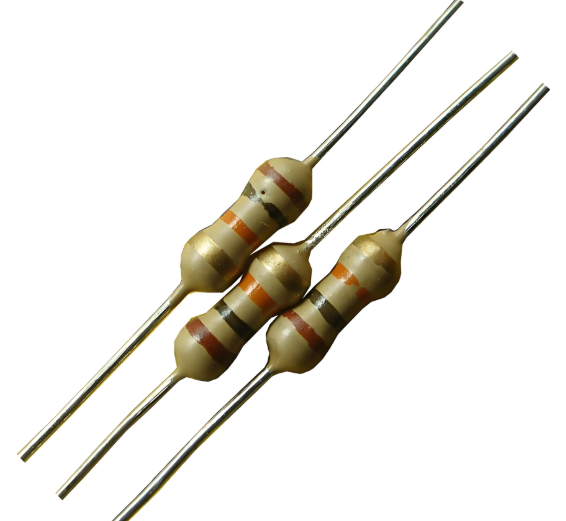

While both resistors use carbon-based materials, their internal structures directly impact performance:

| Feature | Carbon Disc Resistor | Carbon Composition Resistor |

|---|---|---|

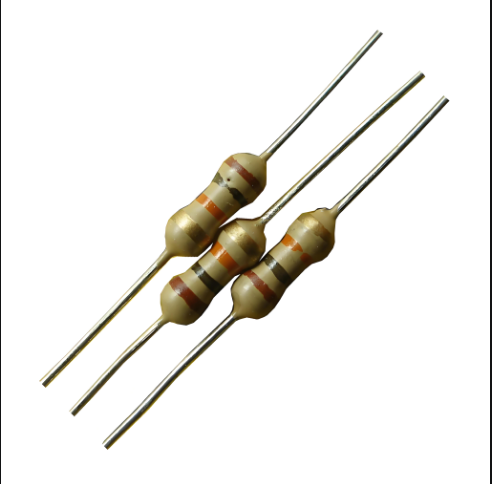

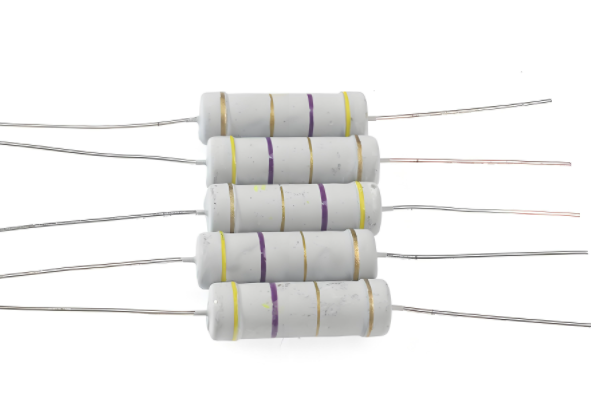

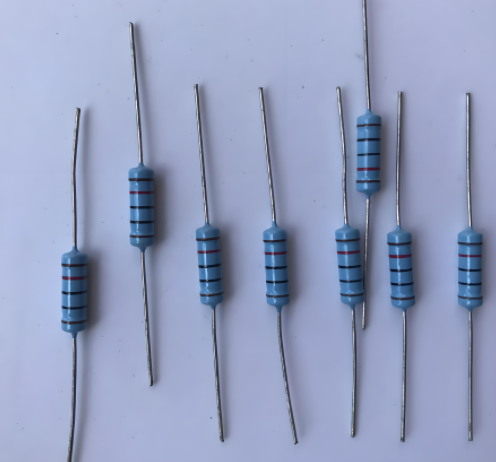

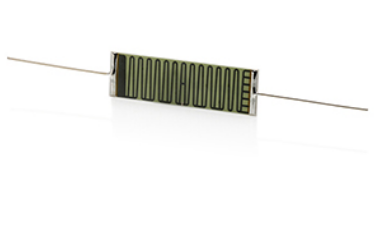

| Material Structure | Carbon granules mixed with clay, molded into a disc shape, and coated with epoxy. | Carbon particles suspended in a phenolic resin binder, extruded into a cylindrical rod with metal leads. |

| Typical Size | Small (e.g., 6mm diameter x 2mm thick for 1W variants). | Larger (e.g., 9mm diameter x 3mm thick for 1W variants). |

| Manufacturing Consistency | High (uniform granule distribution in modern production). | Lower (particle distribution varies, leading to wider tolerance ranges). |

This structural difference drives key performance variations: carbon disc resistors (modern versions) offer tighter tolerances (1%-5%) compared to carbon composition resistors (typically 5%-20%), making them better for precision circuits.

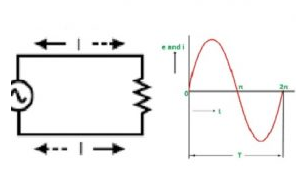

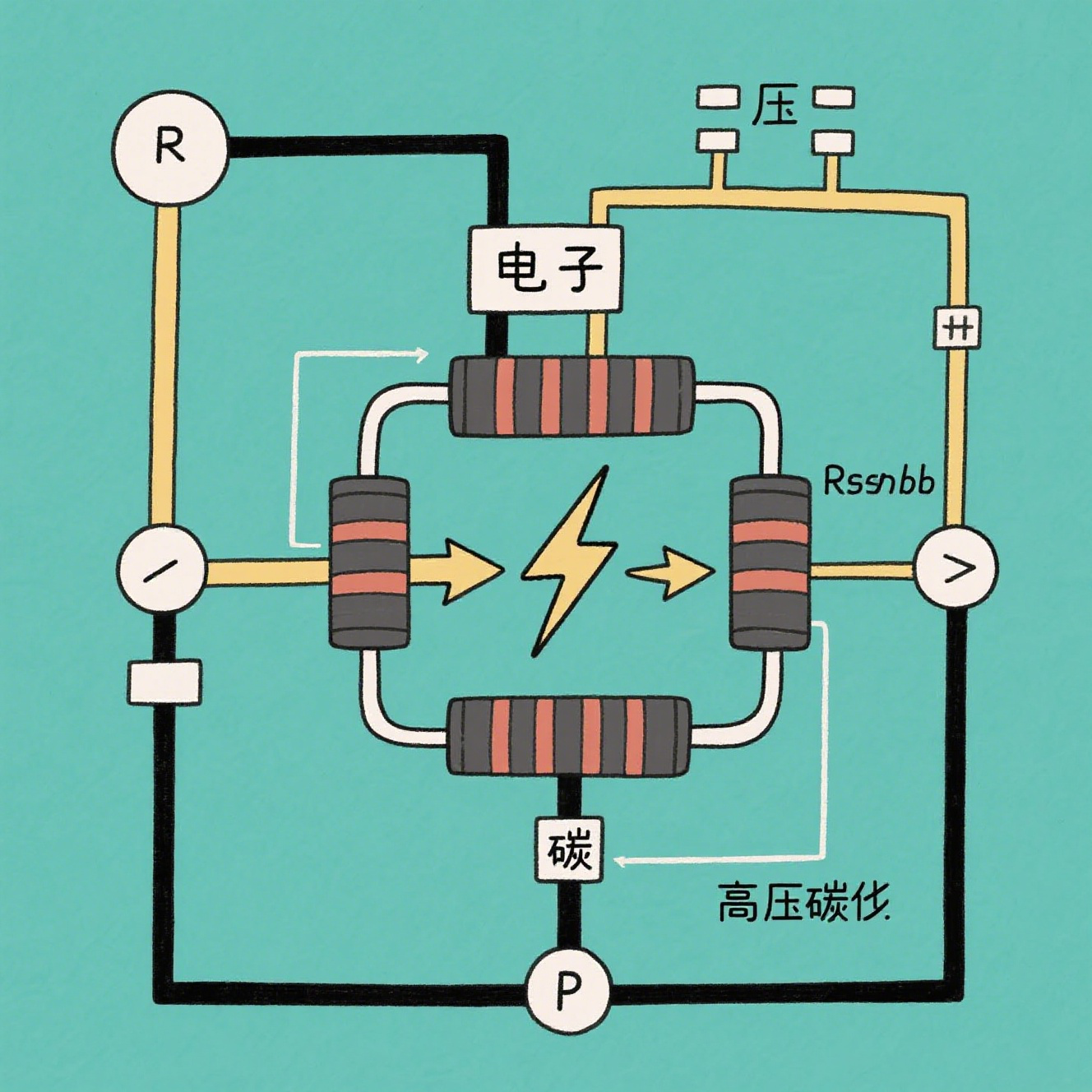

2. Noise Levels: Carbon Disc vs Carbon Composition

Noise is critical in audio and sensitive measurement circuits. Both resistors generate “thermal noise” (caused by electron movement), but their material structures affect noise levels differently.

| Parameter | Carbon Disc Resistor | Carbon Composition Resistor |

|---|---|---|

| Noise Voltage (1kHz, 25°C) | 0.05–0.15 µV/√Hz | 0.1–0.3 µV/√Hz |

| Noise Mechanism | Low granule-to-granule contact resistance reduces electron scattering. | Irregular particle distribution creates more electron “traps,” increasing noise. |

| Typical Use Case | High-quality audio preamps, microphone preamps. | Non-critical circuits (e.g., LED drivers, simple switches). |

Example: In a phono preamp (where noise below 0.1 µV/√Hz is ideal), a carbon disc resistor (0.08 µV/√Hz) will outperform a carbon composition resistor (0.2 µV/√Hz), preserving subtle audio details like vinyl surface noise or instrument overtones.

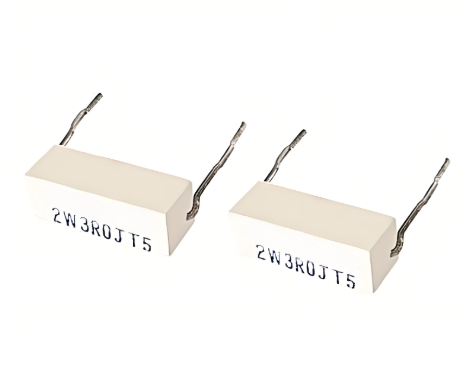

3. Power Handling: Which Resists Overheating Better?

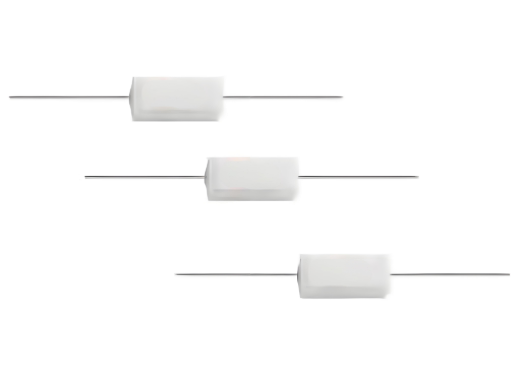

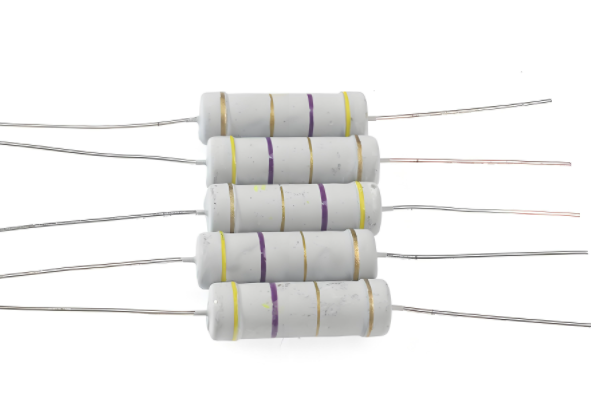

Power handling depends on material density, thermal conductivity, and size. Carbon disc resistors generally handle heat more efficiently due to their compact, uniform structure.

| Parameter | Carbon Disc Resistor | Carbon Composition Resistor |

|---|---|---|

| Max Power Rating (Typical) | 1W–5W (small 1W discs are common in consumer electronics). | 0.5W–2W (larger physical size limits use in space-constrained designs). |

| Thermal Conductivity | Higher (clay binder conducts heat away from carbon granules). | Lower (phenolic resin traps heat, increasing internal temperature). |

| Derating at 70°C | 85% of rated power (e.g., 1W → 0.85W at 70°C). | 70% of rated power (e.g., 1W → 0.7W at 70°C). |

Problem: A user installs a 1W carbon composition resistor in a 12V power supply (calculating P=V 2 /R=(12) 2 /144=1Wfor a 144Ω resistor) but notices the resistor overheats after 30 minutes. Why? Carbon composition resistors derate more aggressively at high temperatures, so their effective power handling drops in warm environments.

Solution: Replace with a 1W carbon disc resistor (same 144Ω value). Its higher thermal conductivity and lower derating (85% at 70°C) keep it within safe operating limits, even in enclosed spaces. For sustained high-power use (>1W), upgrade to a 2W carbon disc resistor.

4. Audio & Power Circuits: Matching Resistors to Use Cases

Understanding their strengths helps select the right resistor for specific applications:

Audio Circuits

Audio systems demand low noise and stable performance. Carbon disc resistors are preferred here for two reasons:

Lower Noise: 0.05–0.15 µV/√Hz vs. 0.1–0.3 µV/√Hz for carbon composition.

Better Stability: Tighter tolerances (1%-5%) ensure consistent signal transfer in potentiometers and tone controls.

| Audio Stage | Recommended Resistor | Why |

|---|---|---|

| Microphone Preamp Input | 100kΩ, 1% Carbon Disc | Low noise preserves weak audio signals from microphones. |

| Tone Control Potentiometer | 10kΩ, 5% Carbon Disc | 5% tolerance is acceptable for user-adjustable controls; 1W rating handles small power loads. |

Power Circuits

Power supplies and motor controls require components that withstand heat and current surges. Carbon disc resistors excel here, but carbon composition resistors still have niche uses:

Carbon Disc: Best for 1W–5W loads, frequent current fluctuations, and enclosed spaces (due to better thermal management).

Carbon Composition: Suitable for low-power (<0.5W), non-critical circuits (e.g., indicator lights, simple timers) where cost is prioritized over longevity.

5. How to Choose: A Quick Decision Framework

Use this checklist to pick between carbon disc and carbon composition resistors:

Check Noise Requirements: If noise<0.1 µV/√Hz is critical (audio, sensors), choose carbon disc.

Calculate Power Load: For >0.5W sustained loads, use carbon disc (better thermal derating).

Evaluate Tolerance Needs: Need 1%-5% precision? Carbon disc is the only option.

Consider Cost: For non-critical, low-power circuits (<0.5W), carbon composition is cheaper.

By aligning your circuit’s needs with these factors, you’ll ensure reliable performance and avoid costly redesigns.

Email us

-

Moisture Resistant Resistors

Moisture Resistant Resistors

-

High Value Resistors

High Value Resistors

-

Lead-Free Resistors

Lead-Free Resistors

-

Anti-Sulfur Resistors

Anti-Sulfur Resistors

-

Low TCR Resistors

Low TCR Resistors

-

Precision Resistors

Precision Resistors

-

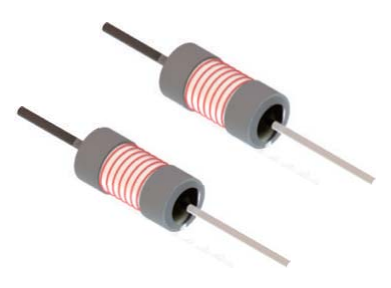

RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors

-

RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors

-

RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors

-

RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors

-

RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors

-

RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors

-

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

-

RXF21-TE power-type full-short-circuit temperature fuse resistors

RXF21-TE power-type full-short-circuit temperature fuse resistors

-

RE power aluminum case wound resistor

RE power aluminum case wound resistor

-

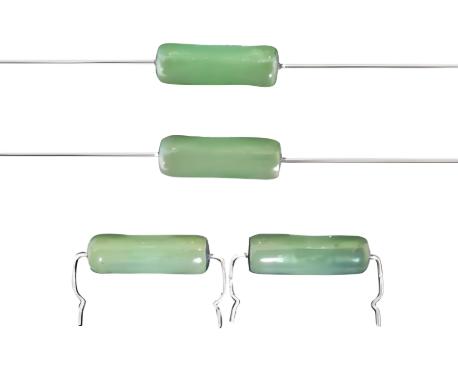

RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors

-

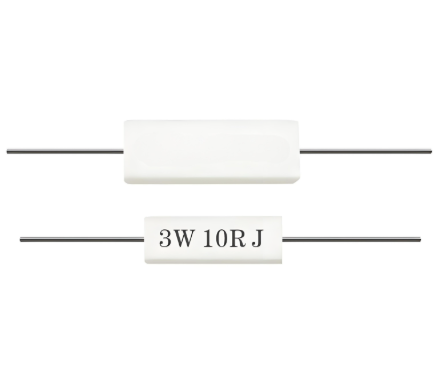

RX23 ceramic encased wire - wound resistors

RX23 ceramic encased wire - wound resistors

-

RX92 anti - interference wire - wound resistors

RX92 anti - interference wire - wound resistors

-

RX21 coated wire - wound resistors

RX21 coated wire - wound resistors

-

RXLG high power aluminum encased wire - wound resistors

RXLG high power aluminum encased wire - wound resistors

-

RX27 power ceramic encased wire - wound resistors

RX27 power ceramic encased wire - wound resistors

-

RXL power aluminum encased wire - wound resistors

RXL power aluminum encased wire - wound resistors

-

RXHGI high power wane ripple coated wire - wound resistors

RXHGI high power wane ripple coated wire - wound resistors

-

RX20 high power vitreous enameled wire - wound resistors

RX20 high power vitreous enameled wire - wound resistors

-

Carbon Disc vs Carbon Composition Resistors: Noise, Power Handling & Which to Choose for Audio/Power Circuits

Carbon disc and carbon composition resistors are both legacy components valued for their low cost and organic material composition, but their differences in noise, power handling, and stability make t...

-

Carbon Disc Resistors 1kΩ-100kΩ 5%-1% Tolerance: Specs, Audio/Power Supply Use & Supplier Guide

Carbon disc resistors remain a staple in electronics design, valued for their cost-effectiveness and stability in moderate-power applications. Among the most searched variants are those spanning 1kΩ ...

-

1 Watt Carbon Disc Resistors: Specs, Power Supply/Audio Use & Overheating Fixes (1kΩ-100kΩ)

1 Watt carbon disc resistors are a workhorse in electronics, balancing power handling with cost-effectiveness for moderate-load circuits. Whether you’re designing a power supply, audio amplifier, or...

-

Carbon Disc Resistor Current Rating: 1A-5A Charts, Power Supply/Audio Use & Overload Fixes

Carbon disc resistors are widely used in low-to-moderate power circuits, but their current rating—how much current they can safely carry without overheating—is a critical parameter often overlooke...

-

High Voltage Carbon Composition Resistors: The Ideal Choice for Power Electronics Circuits

High Voltage Carbon Composition Resistors: The Ideal Choice for Power Electronics CircuitsIntroductionIn the rapidly evolving field of power electronics, selecting the right components is crucial for ...

-

Maximizing Efficiency: A Comprehensive Guide to Carbon Disc Resistor Energy Dissipation and Power Handling

IntroductionIn the realm of electronics, the efficiency and reliability of components are paramount. Among these components, carbon disc resistors play a crucial role in various applications, from sim...

-

Carbon Disc Resistors in Audio Equipment: Usage, Benefits, and Maintenance Guide

IntroductionCarbon Disc Resistors have long been a staple in the world of electronics, and their unique properties make them particularly interesting for use in audio equipment. From vintage amplifier...

-

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips<nav></nav>IntroductionElectric traction systems are at the heart of modern...

-

Carbon Composition Resistor High Frequency Applications: Unveiling the Unique Advantages and Niche Uses in Modern Electronics

Carbon Composition Resistor High Frequency Applications: Unveiling the Unique Advantages and Niche Uses in Modern ElectronicsIntroductionCarbon composition resistors have been a cornerstone in the wor...

-

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...

-

50kV High Voltage Resistors: Technical Specs, Industrial Use Cases & How to Choose the Right One for Power Grids, Test Labs & Renewable Systems

Technical Specifications of 50kV High Voltage Resistors50kV resistors must withstand high electrical stress while maintaining precision. Below are critical parameters to evaluate for reliability in de...

-

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial Applications

600W Wirewound Power Resistor: High - Current Handling and Thermal Stability for Industrial ApplicationsIn high - power industrial systems, the 600W wirewound power resistor is a cornerstone component...

-

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal Management

500W-600W High-Power Resistors: Industrial Grade Solutions for Surge Handling and Thermal ManagementIn high-power industrial circuits, 500W-600W resistors must handle both continuous load and sudden s...

-

Carbon vs. Metal Film vs. Wirewound: Choosing a Resistor for High Pulse Loads

Carbon vs. Metal Film vs. Wirewound: Choosing a Resistor for High Pulse LoadsSelecting the right resistor for high pulse load applications is a critical decision that can make or break your circuit...

-

Advanced Noise Reduction with High Precision Metal Film Resistors

In the realm of modern electronics, noise is an ever-present adversary that can compromise the performance and integrity of circuits. High precision metal film resistors have emerged as a powerful sol...

-

10kV High Voltage Resistors: Specifications, Applications & Top Suppliers for Industrial, Power Transmission & Test Equipment

Technical Specifications of 10kV High Voltage ResistorsTo ensure reliability in high-voltage environments, 10kV resistors must meet strict performance criteria. Below are critical parameters to evalua...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

High Voltage Resistors: Working Principle, Applications, Safety Tips & How to Choose the Right One

<!-- Introduction -->IntroductionHigh voltage resistors are critical components in circuits requiring precise voltage control under extreme electrical stress. Understanding their working principle, ap...

-

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained<!-- 引言 -->IntroductionPower resistors up to 600W play pivotal roles in various industrial sectors like elec...

-

100W TO-247 Resistor: High-Power, Non-Inductive & Pulse-Load Resistant Solutions

The Powerhouse Resistor: 100W TO-247 Solutions for Demanding ApplicationsIn high-power electronics, the 100W TO-247 resistor has become a critical component for engineers dealing with pulse loads, the...

-

Carbon Disc Resistor Current Rating: 1A-5A Charts, Power Supply/Audio Use & Overload Fixes

Carbon disc resistors are widely used in low-to-moderate power circuits, but their current rating—how much current they can safely carry without overheating—is a critical parameter often overlooke...

-

Carbon Disc vs Carbon Composition Resistors: Noise, Power Handling & Which to Choose for Audio/Power Circuits

Carbon disc and carbon composition resistors are both legacy components valued for their low cost and organic material composition, but their differences in noise, power handling, and stability make t...

-

1 Watt Carbon Disc Resistors: Specs, Power Supply/Audio Use & Overheating Fixes (1kΩ-100kΩ)

1 Watt carbon disc resistors are a workhorse in electronics, balancing power handling with cost-effectiveness for moderate-load circuits. Whether you’re designing a power supply, audio amplifier, or...

-

Carbon Disc Resistors 1kΩ-100kΩ 5%-1% Tolerance: Specs, Audio/Power Supply Use & Supplier Guide

Carbon disc resistors remain a staple in electronics design, valued for their cost-effectiveness and stability in moderate-power applications. Among the most searched variants are those spanning 1kΩ ...

-

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips

Optimizing Electric Traction Systems with High-Performance Carbon Disc Resistors: Applications, Benefits & Selection Tips<nav></nav>IntroductionElectric traction systems are at the heart of modern...

-

Maximizing Efficiency: A Comprehensive Guide to Carbon Disc Resistor Energy Dissipation and Power Handling

IntroductionIn the realm of electronics, the efficiency and reliability of components are paramount. Among these components, carbon disc resistors play a crucial role in various applications, from sim...

-

Carbon Disc Resistors in Audio Equipment: Usage, Benefits, and Maintenance Guide

IntroductionCarbon Disc Resistors have long been a staple in the world of electronics, and their unique properties make them particularly interesting for use in audio equipment. From vintage amplifier...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000