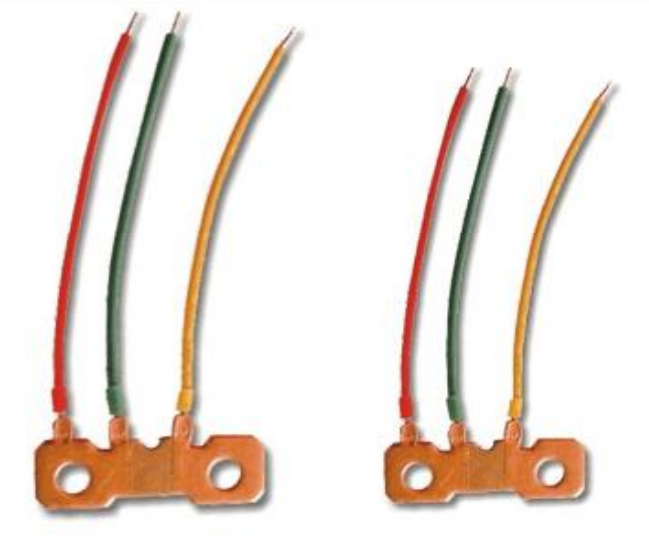

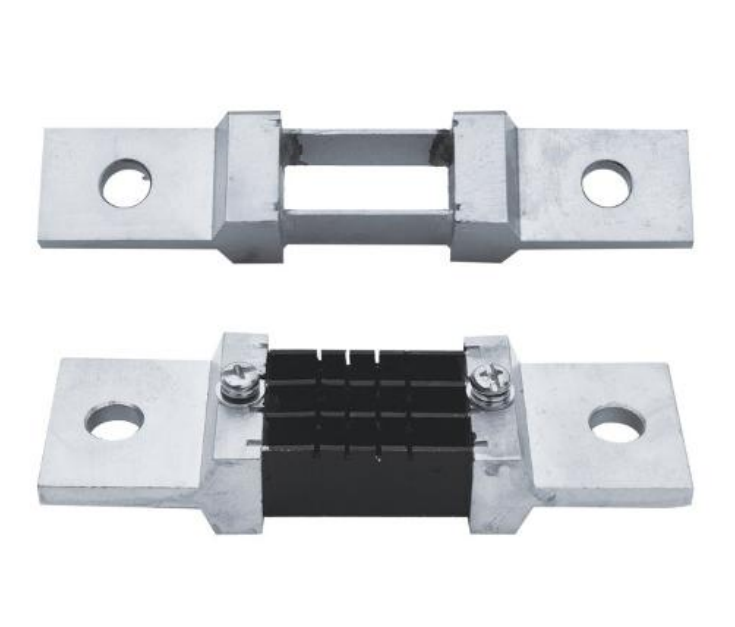

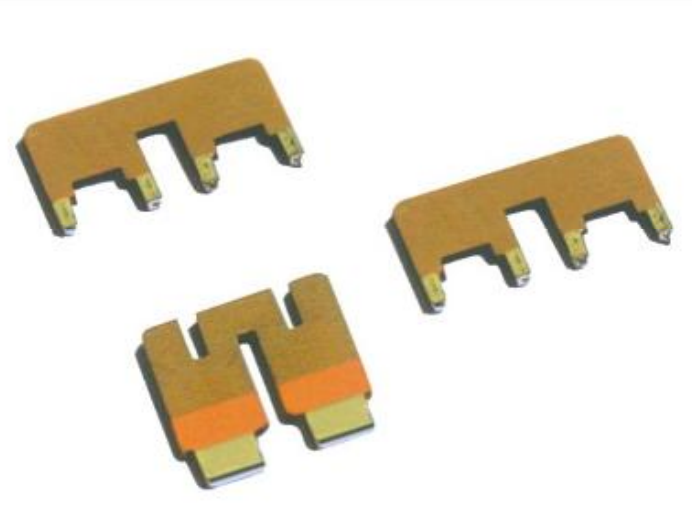

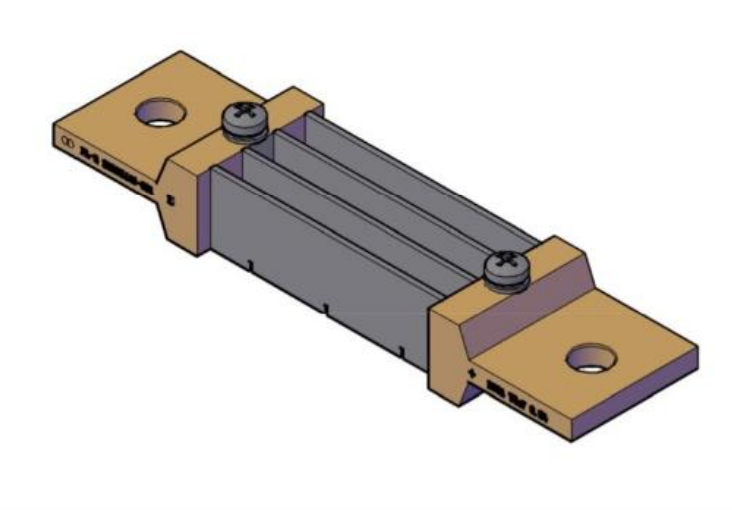

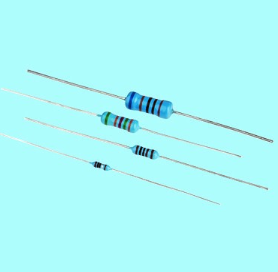

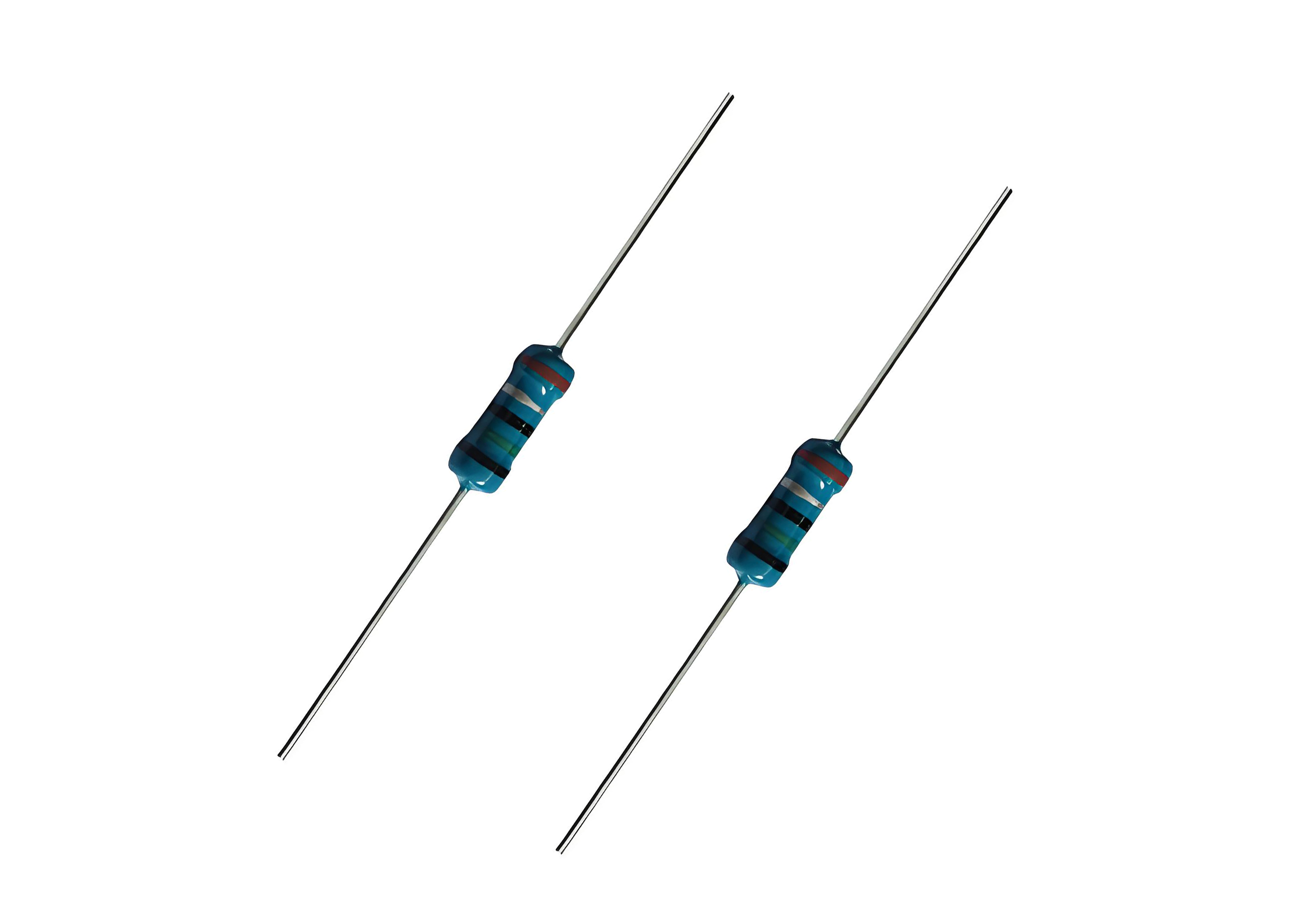

Title: High Precision Metal Film Resistors for Measuring Instruments and Test Equipment

Introduction

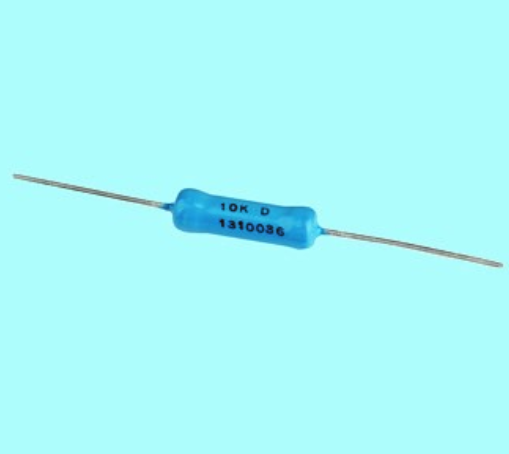

High precision metal film resistors are fundamental components in measuring instruments and test equipment where accuracy, stability, and reliability are mandatory. These resistors feature tight tolerance, low temperature coefficient of resistance (TCR), and excellent long-term stability, making them ideal for precision current sensing, voltage dividers, and calibration circuits. In this article, we explore the role of precision metal film resistors, explain their parameters, provide data-driven examples, and present a real-world problem with a practical solution.

Table of Contents

Why Precision Metal Film Resistors Matter

Measuring instruments such as digital multimeters, oscilloscopes, and calibration devices require extreme accuracy. Even a small drift or high TCR in resistors can cause measurement errors that accumulate over time. By using high precision metal film resistors for measuring instruments, engineers ensure consistent performance under varying temperature and load conditions.

Key Performance Parameters

Tolerance: As low as ±0.01% for accurate readings.

TCR: Typically 1–10 ppm/°C for stability across temperature changes.

Noise level: Extremely low, critical for sensitive measurements.

Stability: Long-term drift minimized for calibration-grade equipment.

Voltage coefficient: Ensures linear response across applied voltages.

Comparison Table: Precision vs Standard Resistors

| Parameter | Standard Resistors | High Precision Metal Film Resistors |

|---|---|---|

| Tolerance | ±1% to ±5% | ±0.01% to ±0.1% |

| TCR | 50–200 ppm/°C | 1–10 ppm/°C |

| Noise | Moderate | Very low |

| Long-term stability | 0.5–1% drift/year | <0.01% drift/year |

| Cost | Low | Higher, but justified in precision systems |

Applications in Measuring Instruments & Test Equipment

Typical use cases of metal film resistors in test equipment include:

Reference voltage dividers for calibration standards.

Precision current measurement in multimeters.

Stable load resistors in oscilloscopes.

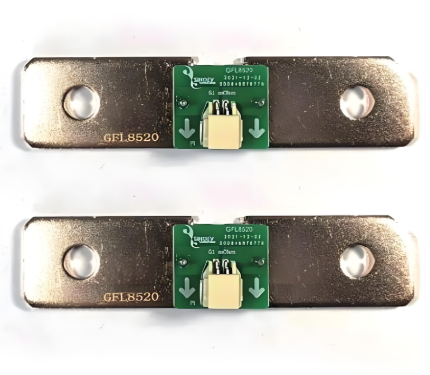

Bridge circuits in sensors and instrumentation amplifiers.

Data acquisition systems requiring long-term accuracy.

Common Measurement Problem

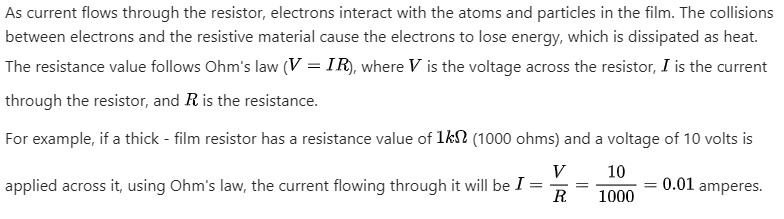

A frequent challenge occurs when standard resistors are used in measurement circuits: drift caused by temperature fluctuations leads to inaccuracies in readings. For example, a resistor with 100 ppm/°C TCR may shift by 0.1 Ω for every 10°C rise in temperature on a 1 kΩ nominal value. This translates into significant measurement error in sensitive test setups.

Practical Solution

Replace standard resistors with high precision metal film resistors with TCR <10 ppm/°C.

Select tolerance better than ±0.1% to ensure accuracy in calibration-grade equipment.

Use matched resistor networks for voltage dividers to ensure ratio stability.

Perform initial calibration after component integration to eliminate offset errors.

Regularly verify resistor stability as part of scheduled instrument maintenance.

Buying and Selection Tips

Choose manufacturers that publish detailed TCR, noise, and drift data.

For instruments requiring long service life, prioritize resistors with proven long-term stability data.

Check datasheet for voltage coefficient if the application involves high voltages.

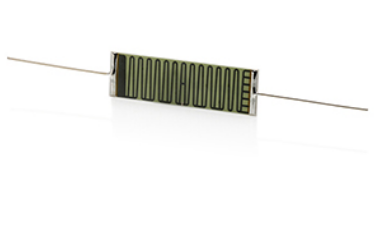

Evaluate whether bulk, thin-film, or foil precision resistors fit your budget and accuracy requirements.

Conclusion

High precision metal film resistors for measuring instruments and test equipment are critical to ensuring reliability, stability, and accuracy in sensitive measurement systems. By minimizing tolerance, TCR, and drift, these resistors directly contribute to the integrity of readings in calibration, testing, and long-term monitoring environments.

FAQ

Q: Can I use standard metal film resistors in precision test equipment?

Not recommended. Standard resistors may introduce unacceptable drift and tolerance errors in sensitive instruments.

Q: What tolerance should I target for high precision applications?

Preferably ±0.1% or better, with TCR below 10 ppm/°C for laboratory-grade accuracy.

Q: Are high precision resistors worth the cost?

Yes. The additional investment pays off in measurement accuracy, reduced recalibration, and long-term stability.

Note: This article serves as a practical selection and application guide for high precision metal film resistors in measuring instruments and test equipment, focusing on parameter evaluation, real-world problems, and actionable solutions.