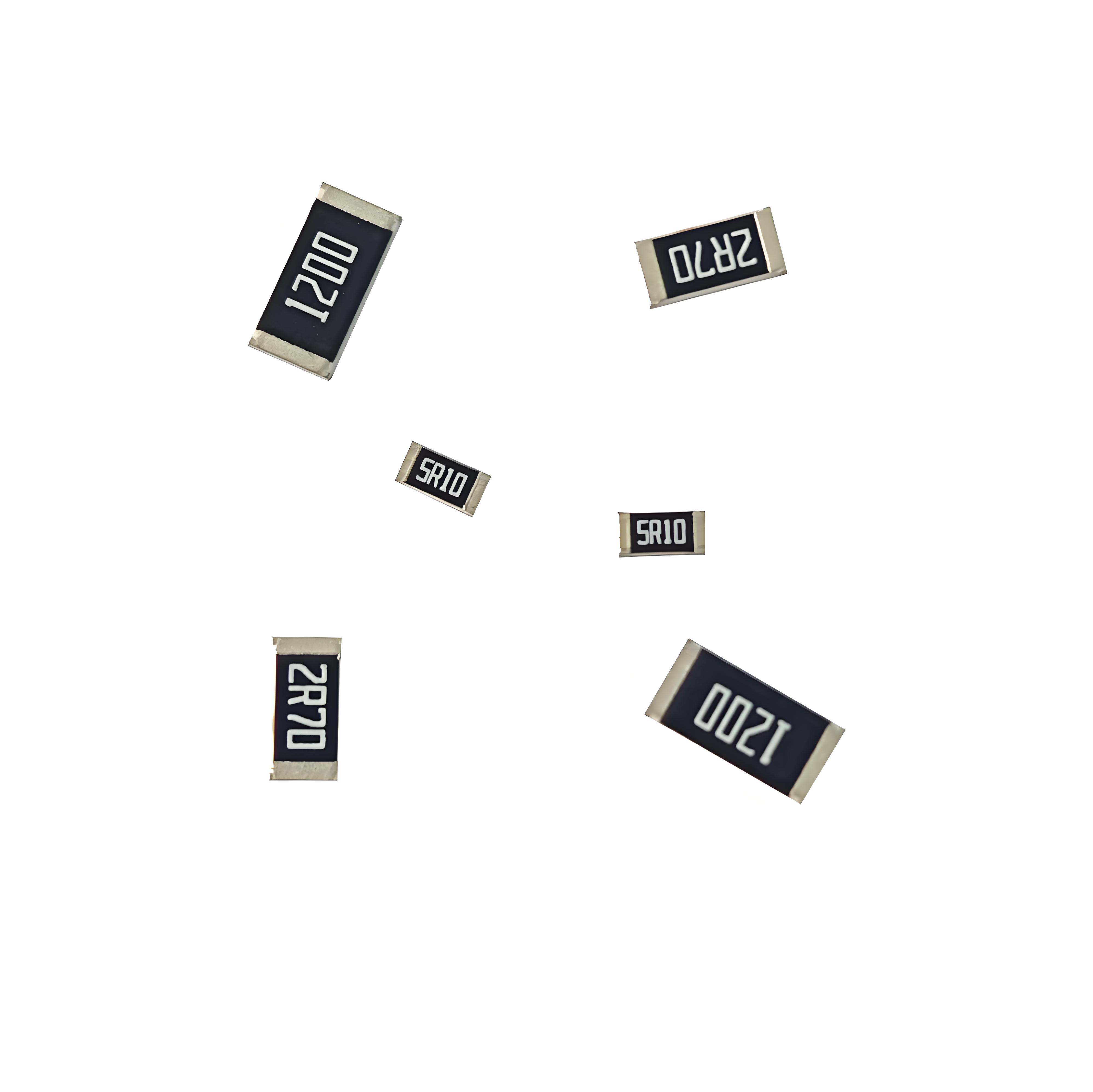

Bulk Metal Foil Resistors: Precision and Performance for High - Accuracy Applications

In the world of precision electronics, Bulk Metal Foil resistors have emerged as a gold standard for applications demanding the utmost accuracy and reliability. This article explores the unique properties of Bulk Metal Foil resistors, their manufacturing process, and why they are indispensable in high - accuracy applications across various industries.

Introduction

When it comes to precision electronics, accuracy is non - negotiable. Bulk Metal Foil resistors have carved out a niche for themselves by offering unparalleled precision and stability. Whether it's in aerospace, medical equipment, or industrial control systems, these resistors ensure that electronic components function reliably and accurately.

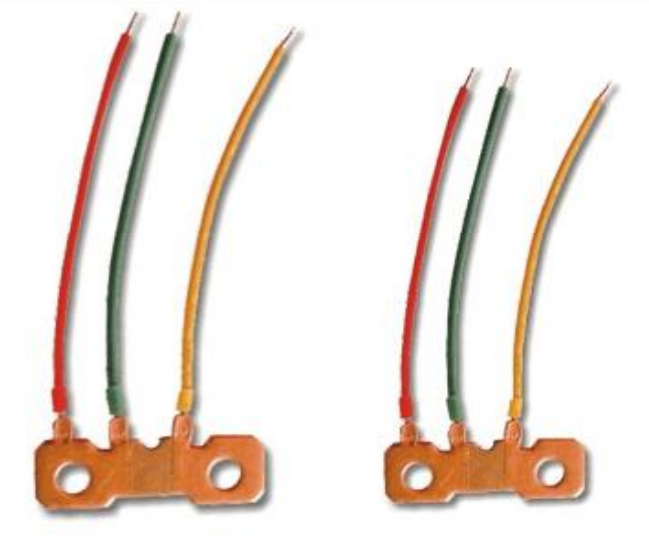

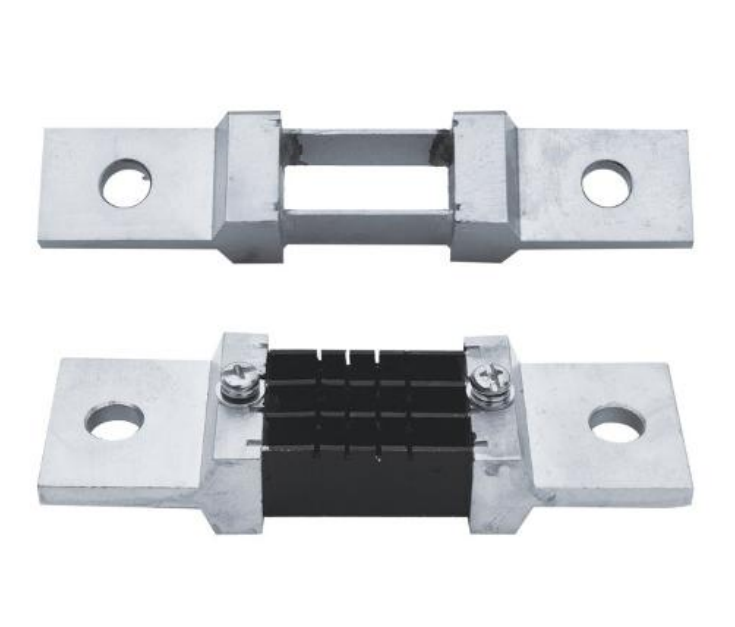

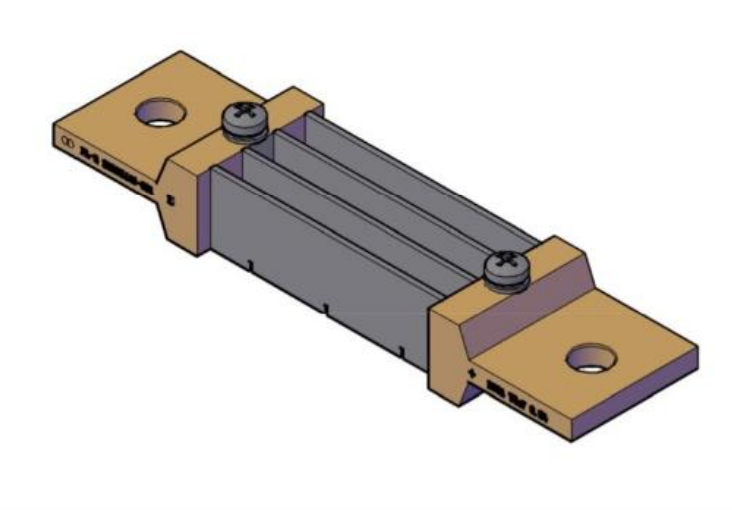

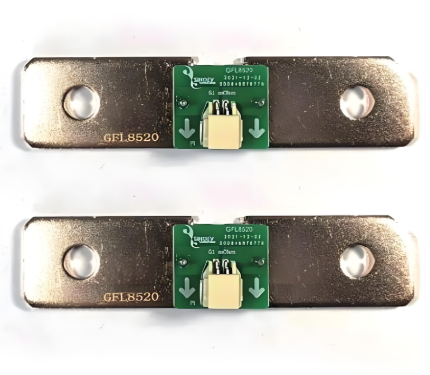

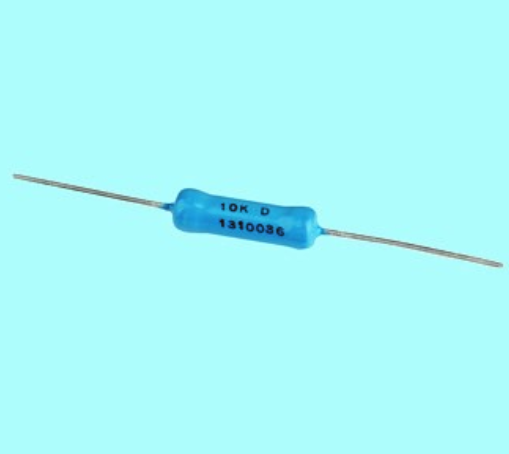

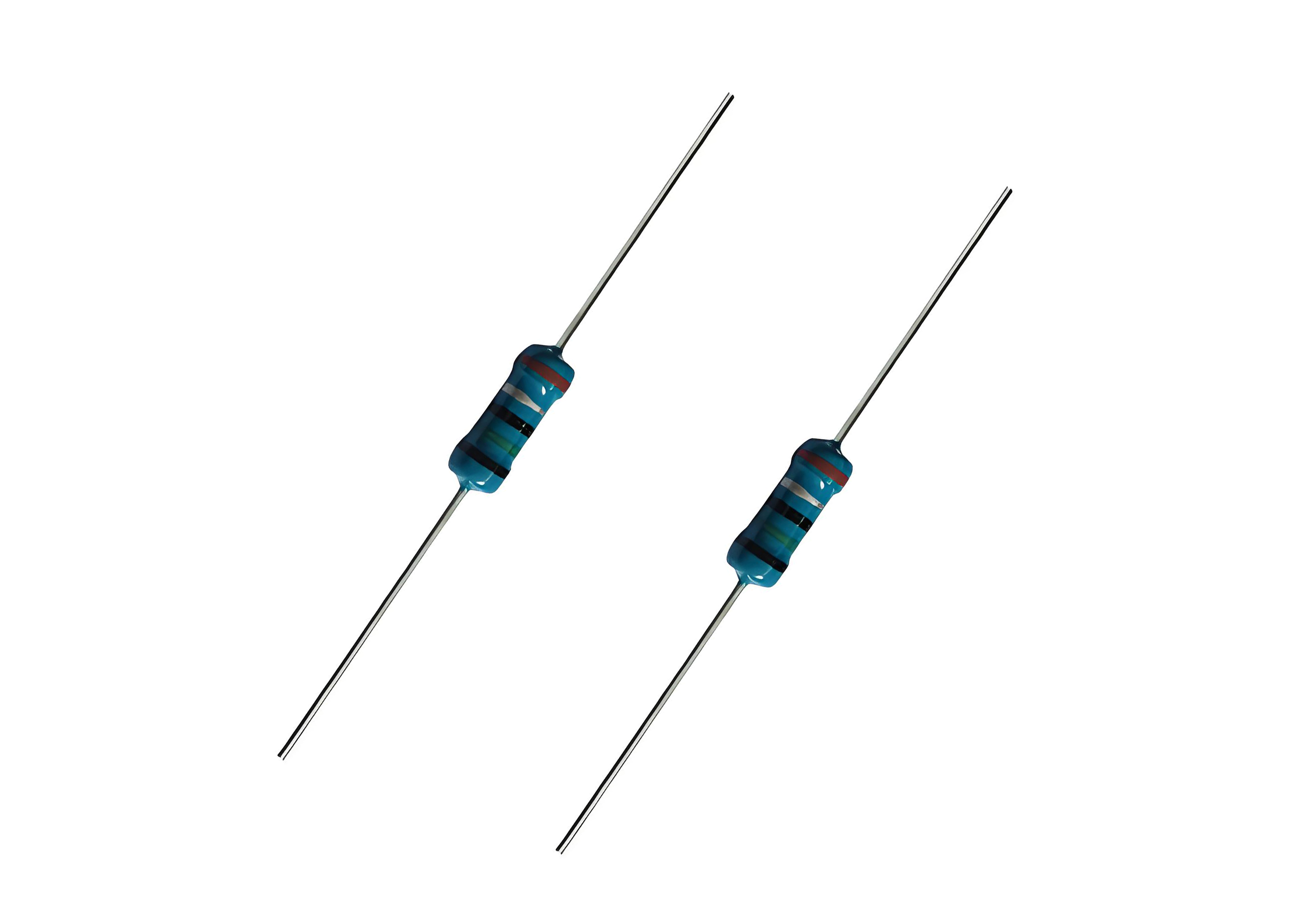

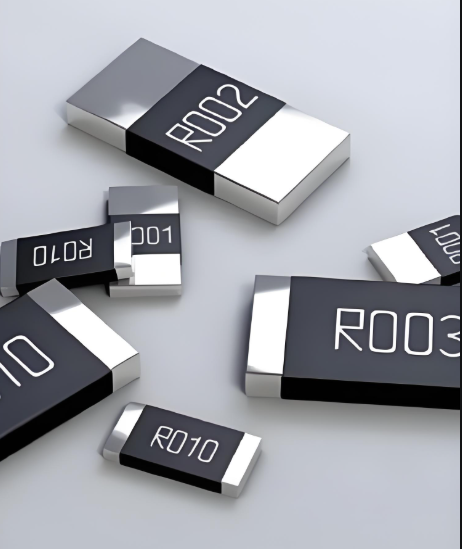

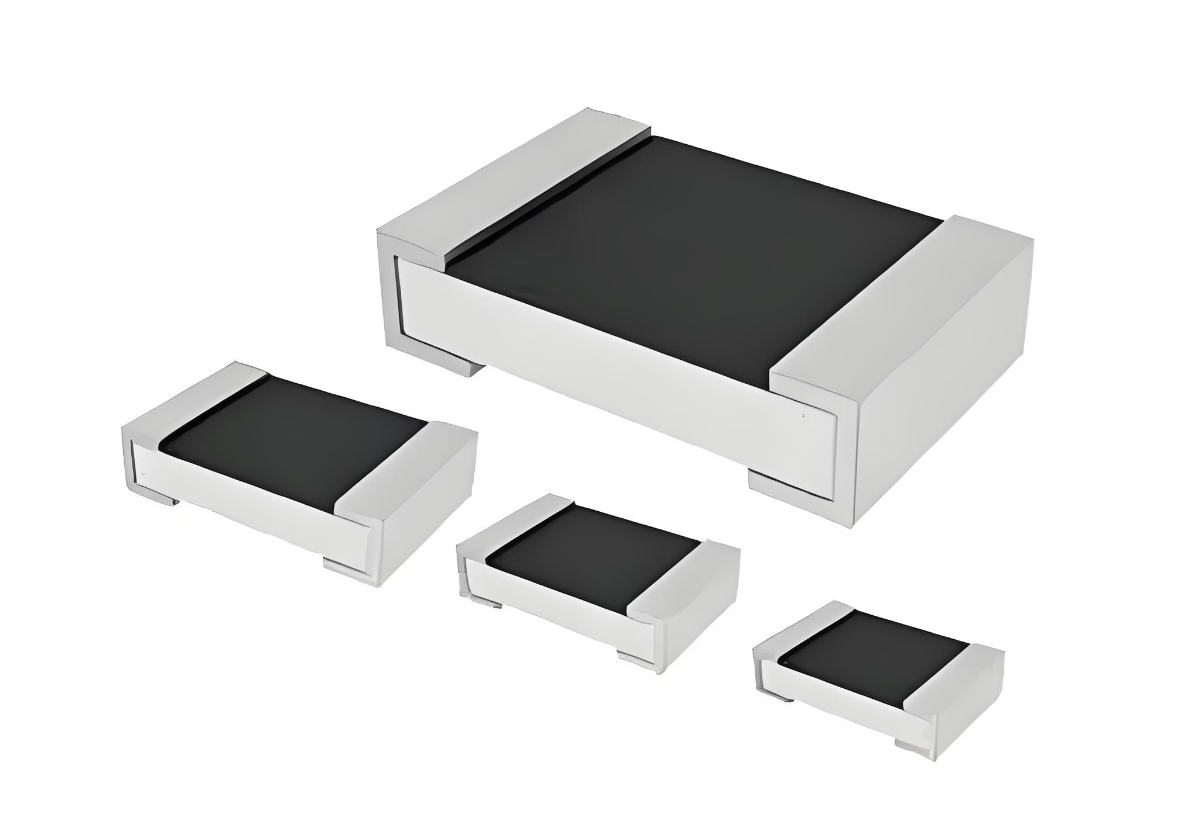

Bulk Metal Foil Resistor Design

Bulk Metal Foil resistors are designed to offer several key advantages over traditional resistors. Their unique design and manufacturing process contribute to their exceptional performance.

Resistance Material

The use of Bulk Metal Foil material allows for a high degree of precision and stability. This material exhibits low temperature coefficient of resistance (TCR) and minimal resistance drift over time, making it suitable for applications requiring high accuracy.

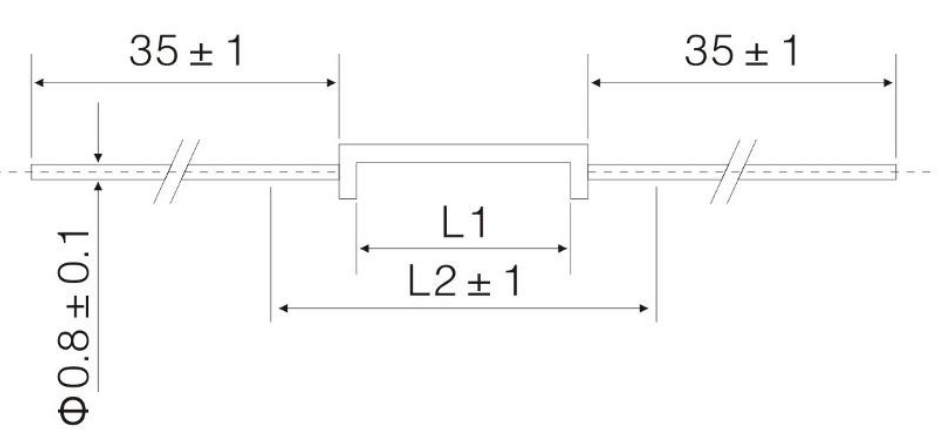

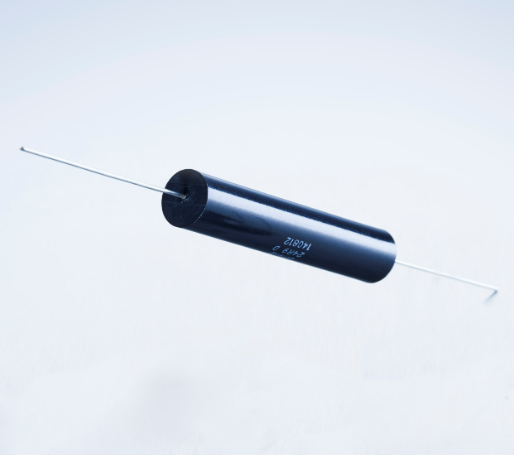

Geometry

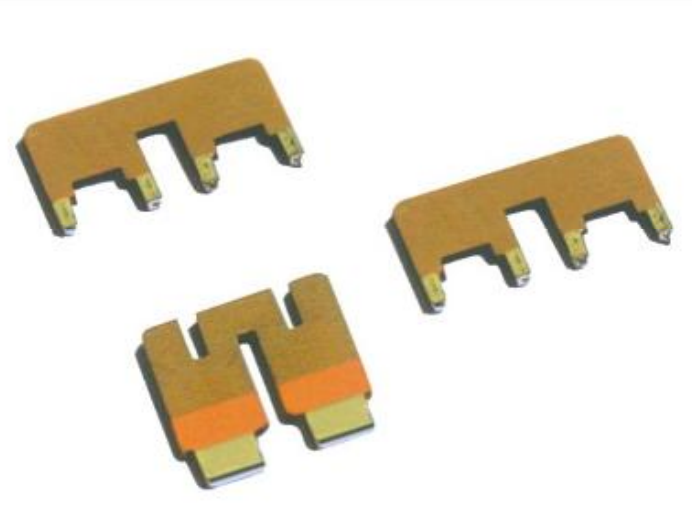

The thin - film design of Bulk Metal Foil resistors enables precise control over their resistance values. The resistive element is formed by etching a thin metal foil into a specific pattern, allowing for tight tolerance and consistent performance.

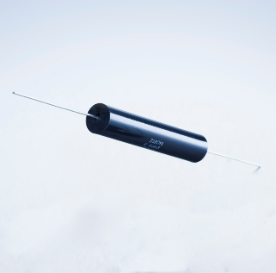

Manufacturing Process

The manufacturing process of Bulk Metal Foil resistors involves several precise steps to ensure their high - quality performance.

Substrate Preparation

A high - quality ceramic substrate is prepared to provide a stable base for the resistive element. The substrate's surface is carefully cleaned and polished to ensure a uniform and consistent deposition of the resistive material.

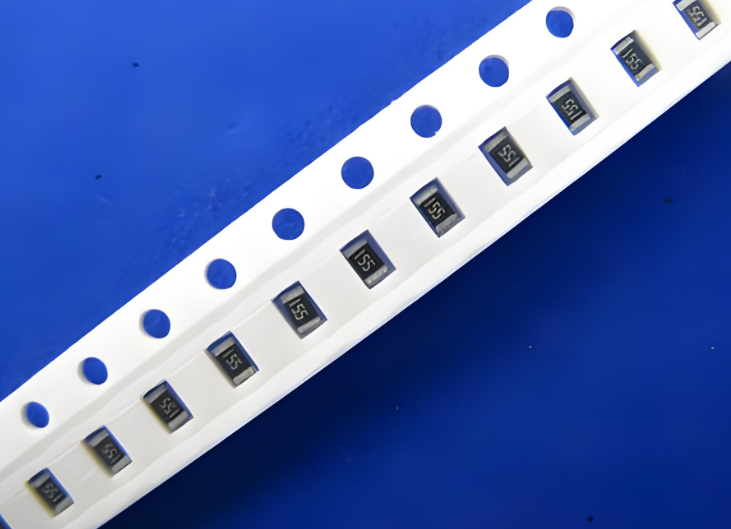

Resistive Element Deposition

A thin layer of metal foil, typically made of nickel - chromium alloy, is deposited onto the substrate. This process is carefully controlled to achieve the desired resistance value and tolerance.

Etching and Patterning

The resistive element is then patterned using photolithography and etching techniques. This step defines the shape and dimensions of the resistive element, which directly influences its electrical characteristics.

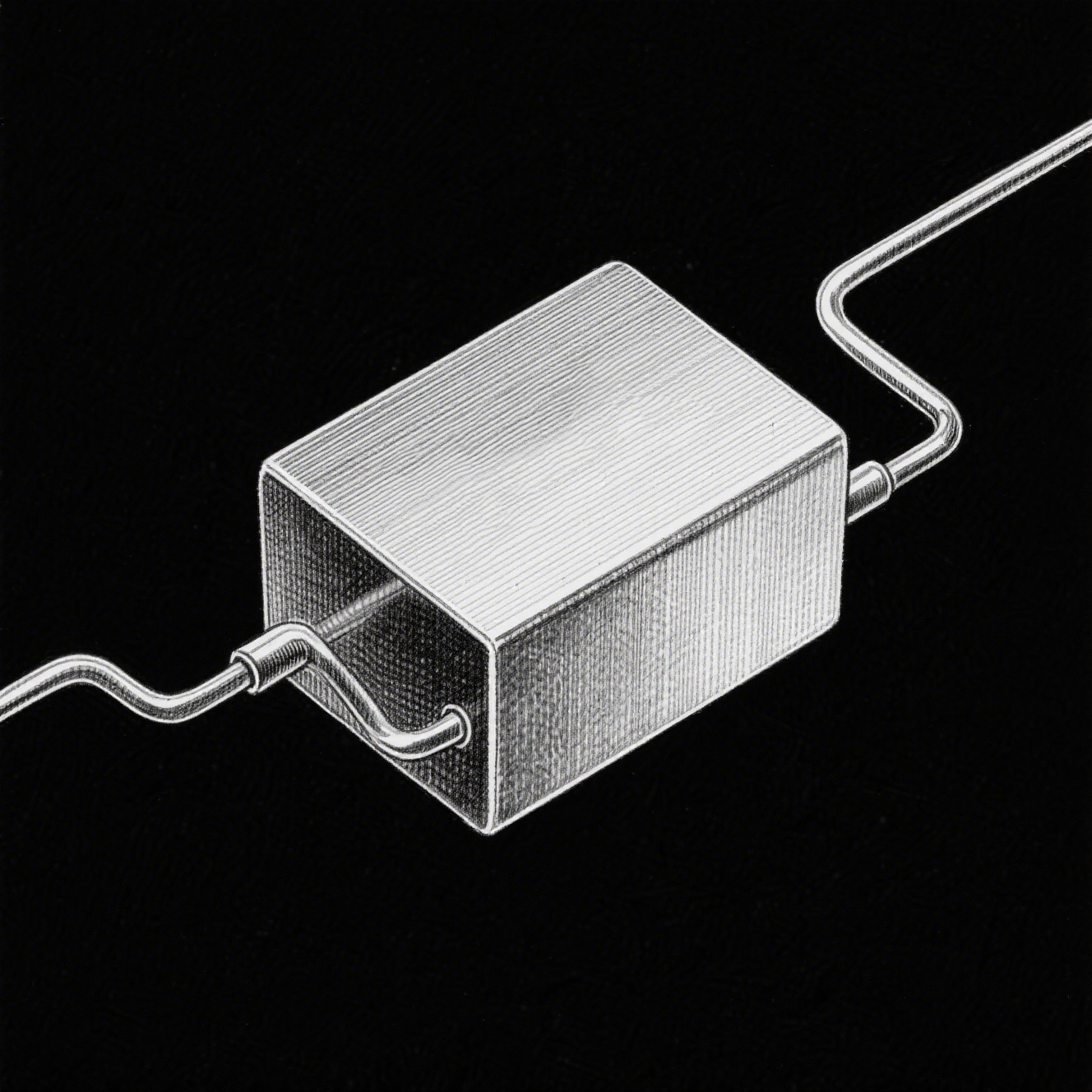

Final Assembly

After etching, the resistors are assembled with terminals and encapsulated to protect them from environmental factors. Each resistor is then tested to ensure it meets the specified performance criteria.

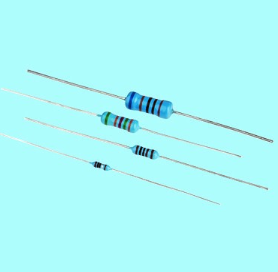

Performance Characteristics

Bulk Metal Foil resistors are known for their exceptional performance in various critical parameters. The following table compares their key performance metrics with those of traditional wire - wound and thin - film resistors.

| Parameter | Bulk Metal Foil Resistor | Wire - Wound Resistor | Thin - Film Resistor |

|---|---|---|---|

| Resistance Tolerance | ±0.01% to ±0.1% | ±0.1% to ±1% | ±1% to ±5% |

| Temperature Coefficient of Resistance (TCR) | ±0.2 ppm/°C to ±5 ppm/°C | ±5 ppm/°C to ±100 ppm/°C | ±20 ppm/°C to ±100 ppm/°C |

| Power Rating | 0.1W to 25W | 0.5W to 100W | 0.1W to 1W |

| Operating Temperature Range | -55°C to +125°C | -40°C to +150°C | -55°C to +125°C |

As shown in the table, Bulk Metal Foil resistors offer tighter resistance tolerance, lower TCR, and a wider operating temperature range compared to traditional resistors. These characteristics make them ideal for high - accuracy applications.

Applications

Owing to their superior performance, Bulk Metal Foil resistors are used in a wide range of high - accuracy applications.

Medical Devices

In medical equipment, such as imaging systems and diagnostic devices, the precision and stability of Bulk Metal Foil resistors ensure accurate readings and reliable performance.

Industrial Control Systems

For applications in industrial automation and control systems, these resistors provide the necessary accuracy and reliability to ensure precise control and monitoring.

Aerospace and Defense

The high - accuracy and stability of Bulk Metal Foil resistors make them suitable for use in aerospace and defense systems, where reliability and precision are crucial.

Measurement and Testing Equipment

They are also used in measurement and testing equipment, where their precision and low TCR ensure accurate and consistent results.

Problem and Solution

One of the problems often encountered in high - precision resistor applications is the need for both low TCR and high - power handling capability. Traditional resistors may offer high power ratings but often have higher TCRs, which can affect accuracy in temperature - sensitive environments.

Solution: Bulk Metal Foil resistors address this issue by combining low TCR with high - power handling capability. Their thin - film design allows for precise control over resistance and TCR, while their bulk metal construction provides the necessary power rating. This combination ensures that the resistor maintains its accuracy across a wide temperature range without compromising on power handling.

Best Practices

To maximize the benefits of Bulk Metal Foil resistors, certain best practices should be followed.

Proper Soldering Techniques

Use proper soldering techniques to avoid thermal stress on the resistors. Excessive heat during soldering can affect the resistor's performance and stability.

Thermal Management

Implement effective thermal management solutions to prevent overheating. This can include the use of heat sinks or proper ventilation.

Regular Testing and Calibration

Regularly test and calibrate the resistors to ensure their performance remains within the specified tolerance. This is especially important in high - accuracy applications.

Proper Storage and Handling

Store and handle the resistors in a controlled environment to prevent damage and contamination. This ensures that the resistor's performance is not affected by environmental factors.

Conclusion

Bulk Metal Foil resistors are essential for high - accuracy applications due to their exceptional performance characteristics. Their low TCR, high - power handling capability, and precise resistance control make them suitable for a wide range of critical applications. By following best practices in their use and handling, engineers can ensure that these resistors continue to provide reliable and accurate performance in high - precision electronic systems.