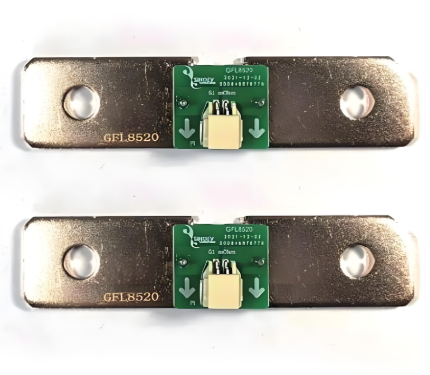

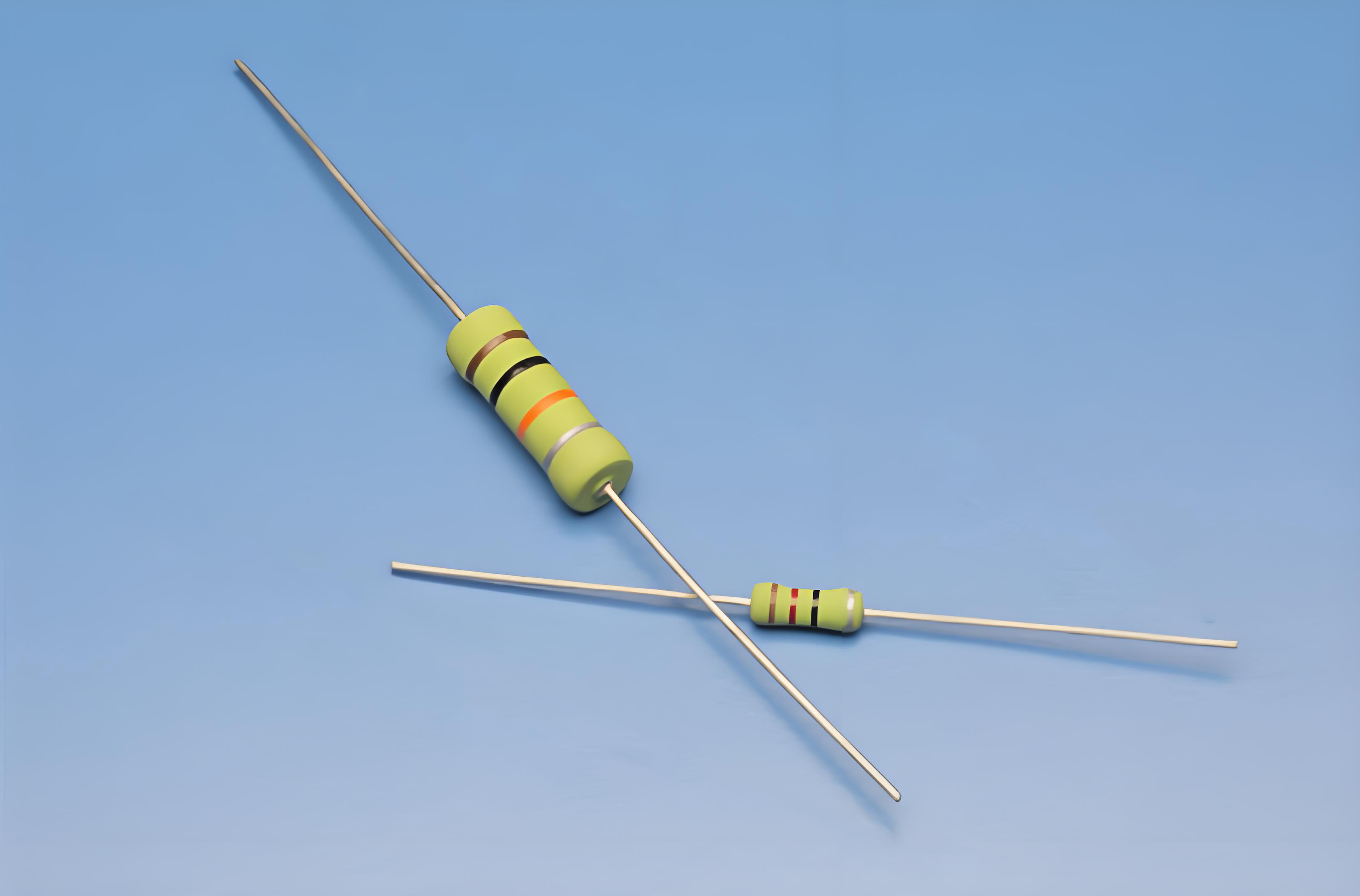

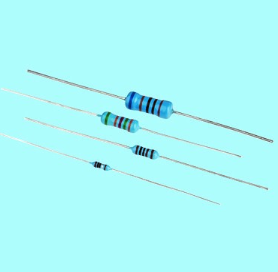

Title: Metal Film Precision Resistors for Medical Equipment – Reliable Components for Healthcare Electronics

Introduction

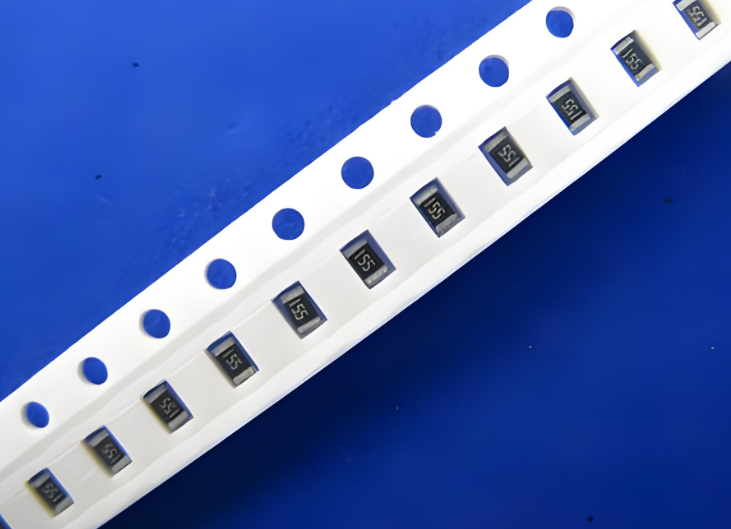

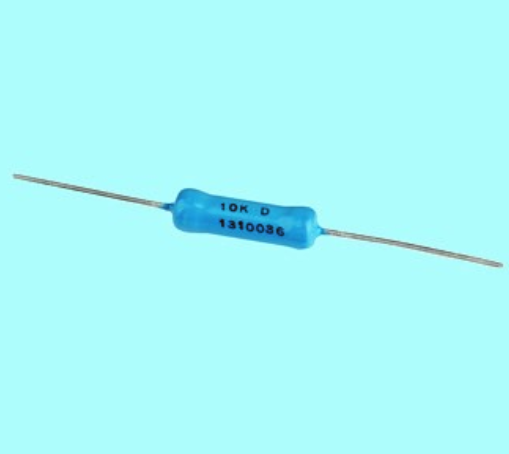

In healthcare electronics, reliability and accuracy are not just design goals but life-critical requirements. Metal film precision resistors for medical equipment provide the stability, low noise, and high tolerance control needed in sensitive diagnostic and monitoring devices. From ECG machines to infusion pumps, these resistors ensure that electrical signals are processed with consistency, safeguarding both patient safety and device reliability.

Table of Contents

Key Performance Parameters of Metal Film Precision Resistors

Comparison Table: Standard vs Metal Film Precision Resistors

Why Precision Resistors Are Vital in Healthcare Electronics

Medical devices operate under strict regulatory standards. Even a minor error in electrical measurement can affect diagnosis or therapy. Using precision metal film resistors in medical equipment ensures that circuits remain stable under varying conditions, minimizing drift, noise, and error rates. This makes them indispensable in life-support and diagnostic tools where accuracy cannot be compromised.

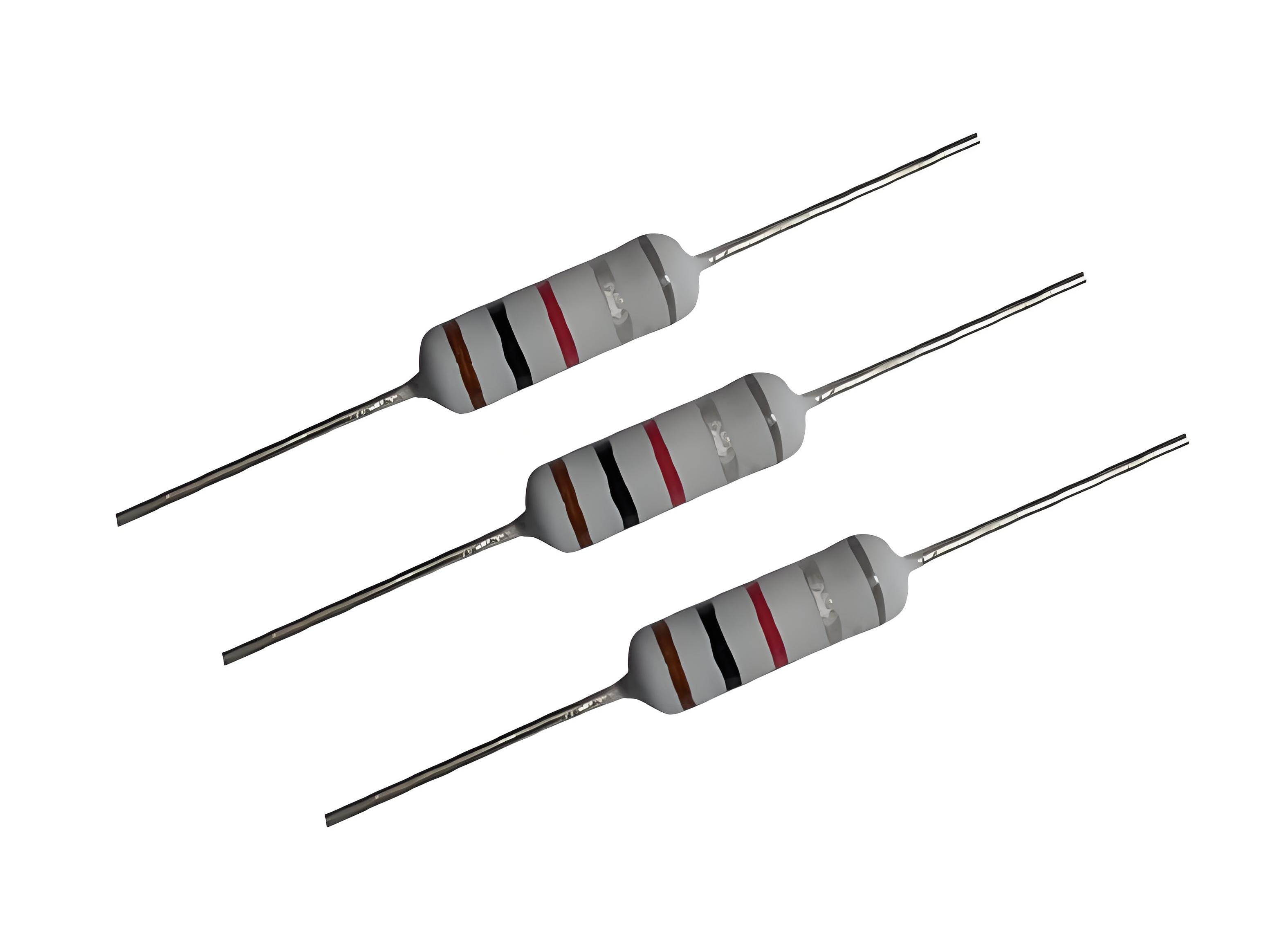

Key Performance Parameters of Metal Film Precision Resistors

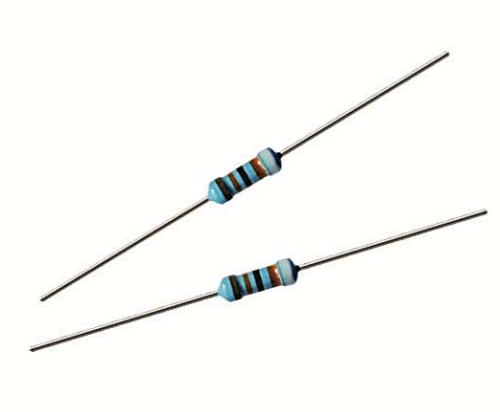

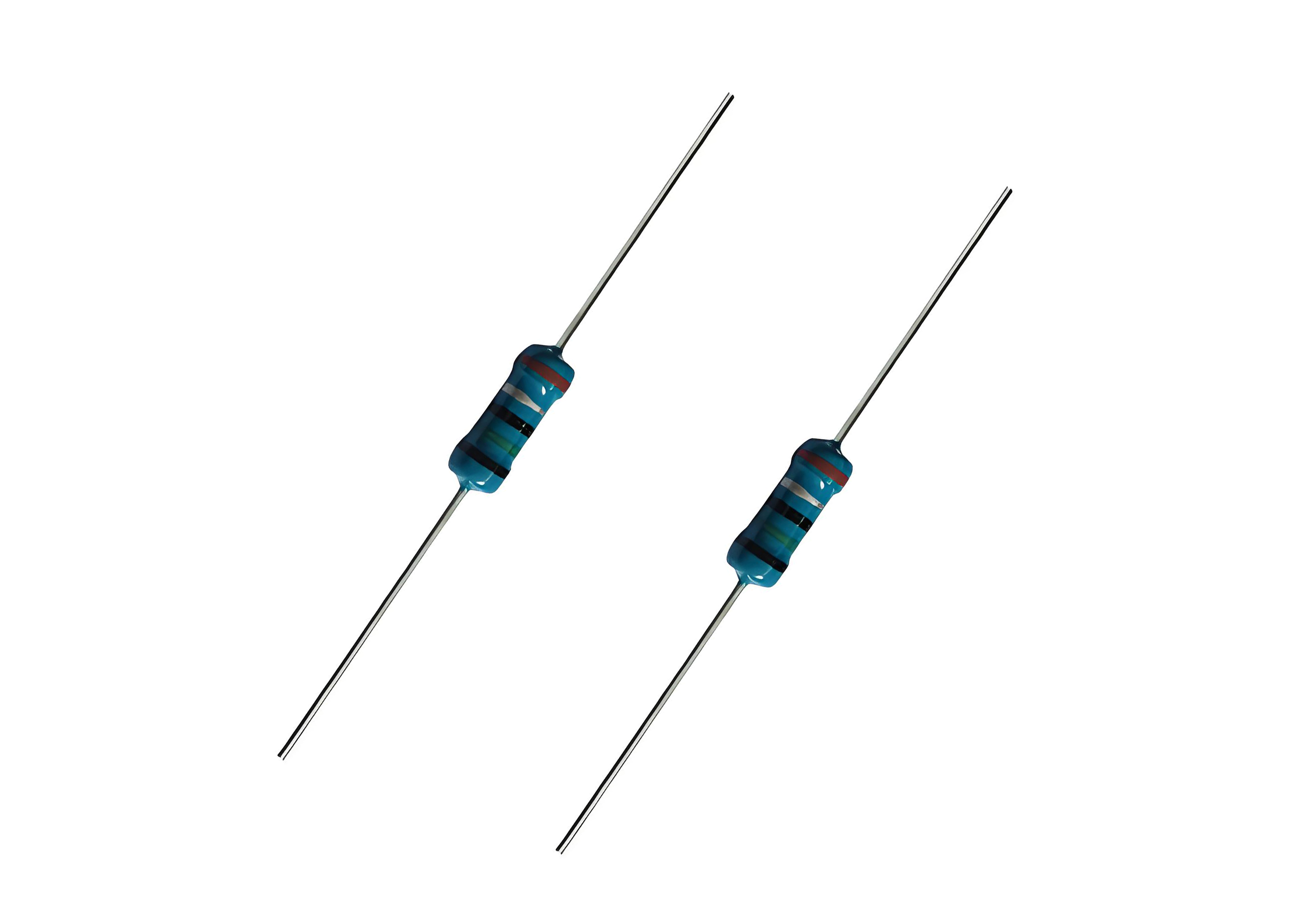

Tolerance: ±0.1% or better, ensuring consistent performance.

Temperature Coefficient of Resistance (TCR): Typically 5–10 ppm/°C for stable readings across temperature ranges.

Noise: Very low, essential for sensitive medical signal processing.

Long-Term Stability: Minimal drift over years of operation.

Safety: Meets healthcare compliance for reliability and patient safety.

Comparison Table: Standard vs Metal Film Precision Resistors

| Parameter | Standard Resistors | Metal Film Precision Resistors |

|---|---|---|

| Tolerance | ±1% to ±5% | ±0.01% to ±0.1% |

| TCR | 50–200 ppm/°C | 5–10 ppm/°C |

| Noise | Moderate | Very low |

| Stability | Noticeable drift | Minimal drift over time |

| Suitability for Medical Equipment | Not recommended | Highly recommended |

Applications in Medical Equipment

Metal film precision resistors play a crucial role in:

ECG and EEG machines: Accurate signal processing for patient monitoring.

Infusion pumps: Reliable current control for drug delivery.

Defibrillators: Stable energy control in life-saving equipment.

Imaging devices (MRI, CT): Signal accuracy for image clarity.

Patient monitors: Consistent performance over long durations.

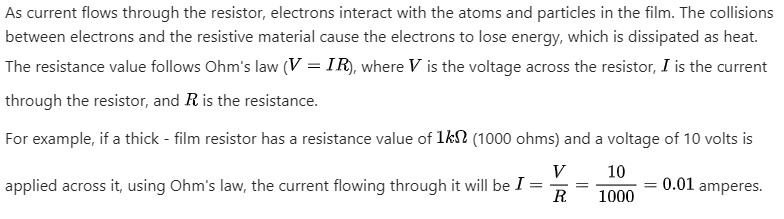

A Common Problem in Medical Devices

Many medical devices face challenges with signal drift due to environmental changes or component instability. For example, in ECG monitoring, a resistor with high TCR can cause the signal baseline to shift when temperature fluctuates. This creates difficulties in interpreting patient data accurately, potentially leading to false alarms or missed diagnoses.

Effective Solution

Implement metal film precision resistors with low TCR (<10 ppm/°C).

Choose resistors with tight tolerance (±0.1% or better) to maintain calibration accuracy.

Use resistors from certified suppliers that comply with medical standards.

Perform routine calibration checks to ensure resistor performance stability.

Adopt resistor networks designed for medical-grade circuit performance.

Buying and Selection Tips for Healthcare Applications

Look for resistors tested under medical device compliance standards.

Check for detailed datasheets specifying TCR, tolerance, and noise characteristics.

Select components with proven long-term stability for patient safety.

Ensure compatibility with sterilization and cleaning procedures in medical environments.

Conclusion

Metal film precision resistors for medical equipment ensure accuracy, stability, and reliability in healthcare electronics. By reducing noise, drift, and temperature-related errors, they support the safe and consistent performance of critical devices. Selecting the right resistor technology is therefore a cornerstone of designing reliable medical systems.

FAQ

Q: Why not use standard resistors in medical devices?

Standard resistors introduce drift and inaccuracies that can compromise patient safety, making them unsuitable for medical use.

Q: What tolerance level is recommended for medical equipment?

A tolerance of ±0.1% or better is typically required to meet the accuracy standards in healthcare electronics.

Q: Are metal film resistors safe for long-term use in medical applications?

Yes. Their stability, low noise, and compliance with healthcare standards make them ideal for continuous, long-term use in medical devices.

This article is a practical guide for selecting metal film precision resistors for medical equipment, highlighting their importance, applications, and role in reliable healthcare electronics.