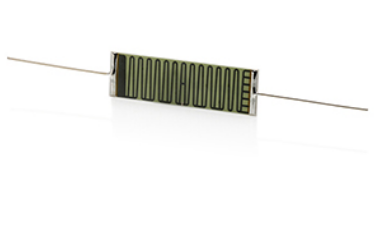

High Precision High Voltage Resistors: Reliable Performance for Industrial Applications

In industrial applications, high precision high voltage resistors play a crucial role in ensuring the accuracy and reliability of electrical systems. This article explores the characteristics, selection criteria, and applications of these precision components, providing valuable insights for engineers and technicians.

Table of Contents

Selection Criteria for High Precision High Voltage Resistors

Best Practices for Using High Precision High Voltage Resistors

Introduction

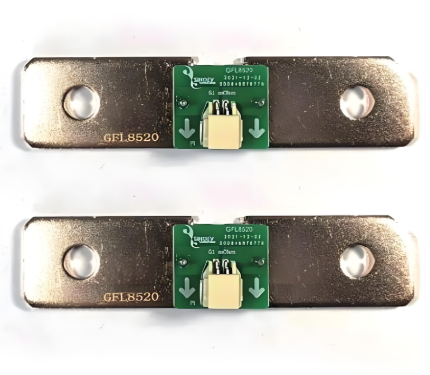

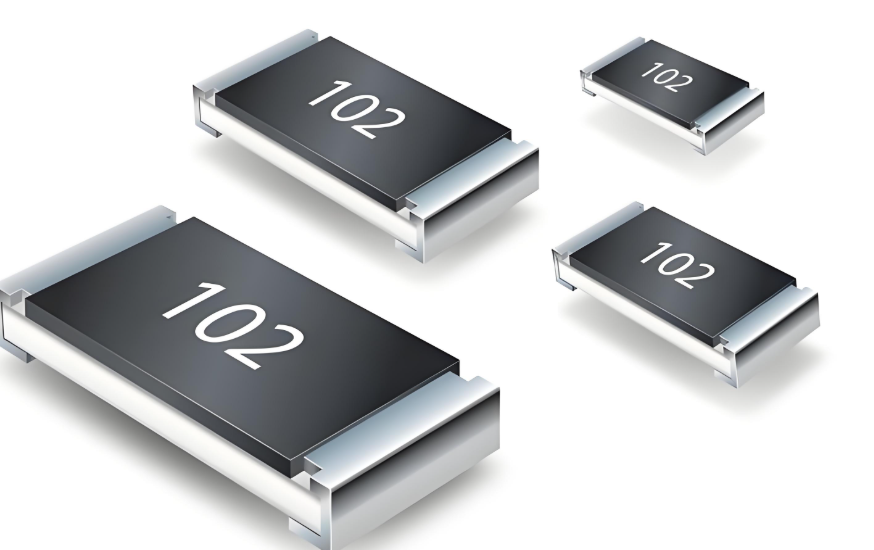

High precision high voltage resistors are specialized components designed to maintain tight resistance tolerances and stable performance under high voltage conditions. These resistors are essential in various industrial applications where precise voltage division, current limiting, and signal processing are required. Their ability to operate reliably in harsh environments makes them indispensable for ensuring the accuracy and longevity of industrial electrical systems.

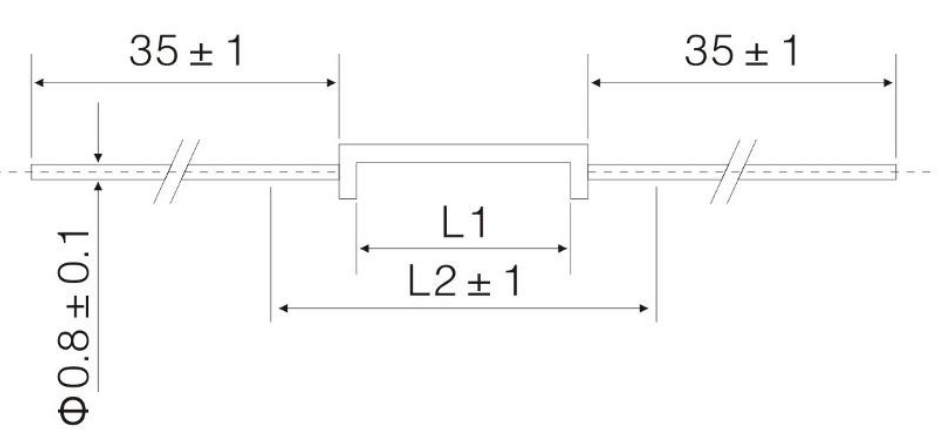

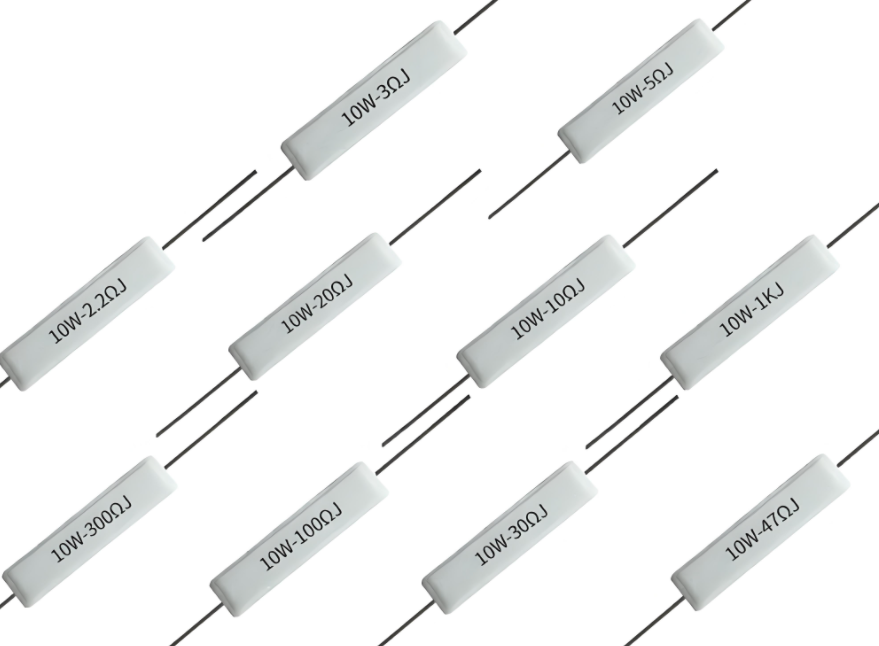

Characteristics of High Precision High Voltage Resistors

High precision high voltage resistors exhibit several key characteristics that make them suitable for demanding industrial applications:

1. Tight Tolerance

These resistors typically have resistance tolerances of ±0.1% or better, ensuring precise circuit performance. This level of precision is critical in applications such as voltage regulation and measurement.

2. High Voltage Rating

They are designed to withstand high voltages, often up to several kilovolts, without exhibiting significant resistance drift or electrical breakdown.

3. Low Temperature Coefficient

High precision high voltage resistors have a low temperature coefficient of resistance (TCR), typically in the range of ±5 ppm/°C or lower. This ensures minimal resistance variation with temperature changes, maintaining accuracy over a wide operating temperature range.

4. High Stability

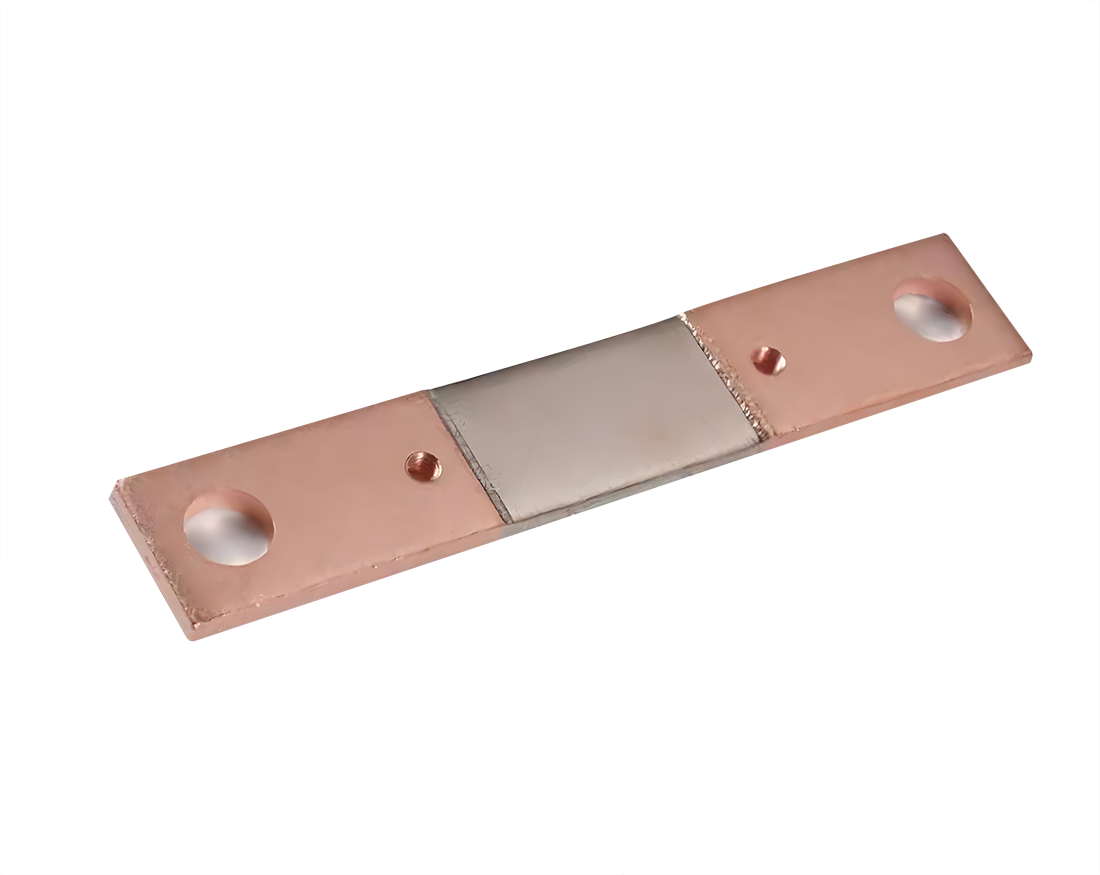

These resistors are manufactured using high - quality materials and advanced processes to ensure long - term stability. They resist changes in resistance due to factors such as voltage stress, humidity, and mechanical vibration.

5. High Power Rating

They can dissipate significant amounts of power without degradation in performance, making them suitable for high - power industrial applications.

Selection Criteria for High Precision High Voltage Resistors

Selecting the right high precision high voltage resistor involves several considerations:

1. Resistance Value and Tolerance

Determine the required resistance value and tolerance based on the specific application requirements. Tighter tolerances are necessary for applications requiring precise voltage division or current control.

2. Voltage Rating

Ensure the resistor's voltage rating exceeds the maximum voltage it will encounter in the application. This prevents electrical breakdown and resistance drift.

3. Power Rating

Select a resistor with a power rating sufficient to handle the expected power dissipation. This prevents overheating and maintains resistor stability.

4. Temperature Coefficient

Choose a resistor with a low TCR if the application involves temperature variations. This ensures minimal resistance change with temperature, maintaining accuracy.

5. Environmental Considerations

Consider the operating environment and select resistors with appropriate protection against factors such as moisture, dust, and chemicals.

6. Stability and Reliability

Select resistors known for their long - term stability and reliability, especially for applications in harsh or critical environments.

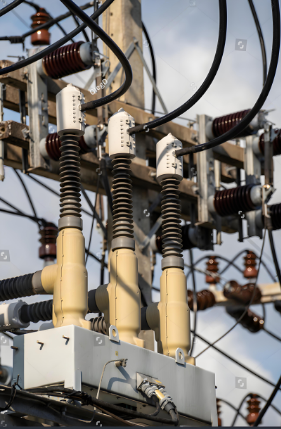

Applications of High Precision High Voltage Resistors

High precision high voltage resistors are used in a variety of industrial applications:

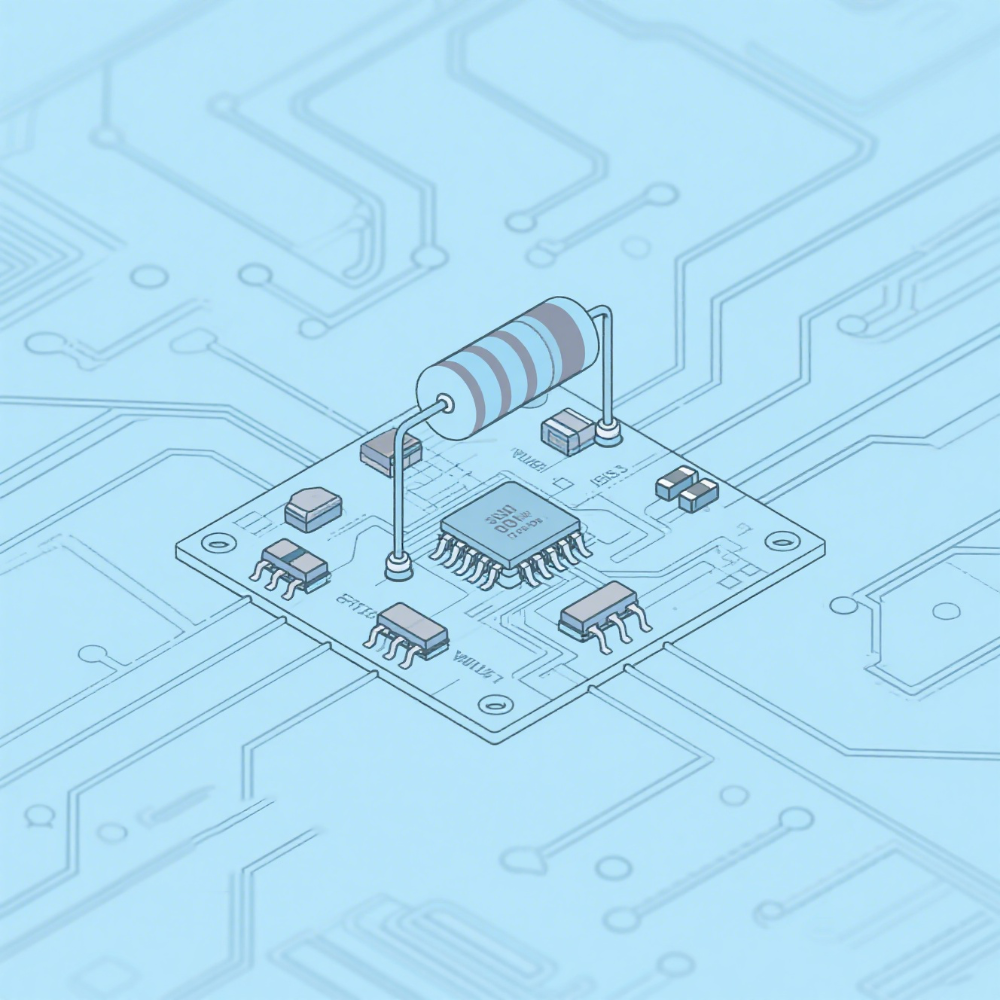

1. Power Supply Circuits

In high - voltage power supplies, these resistors are used for voltage division, biasing, and current limiting to ensure stable and precise voltage regulation.

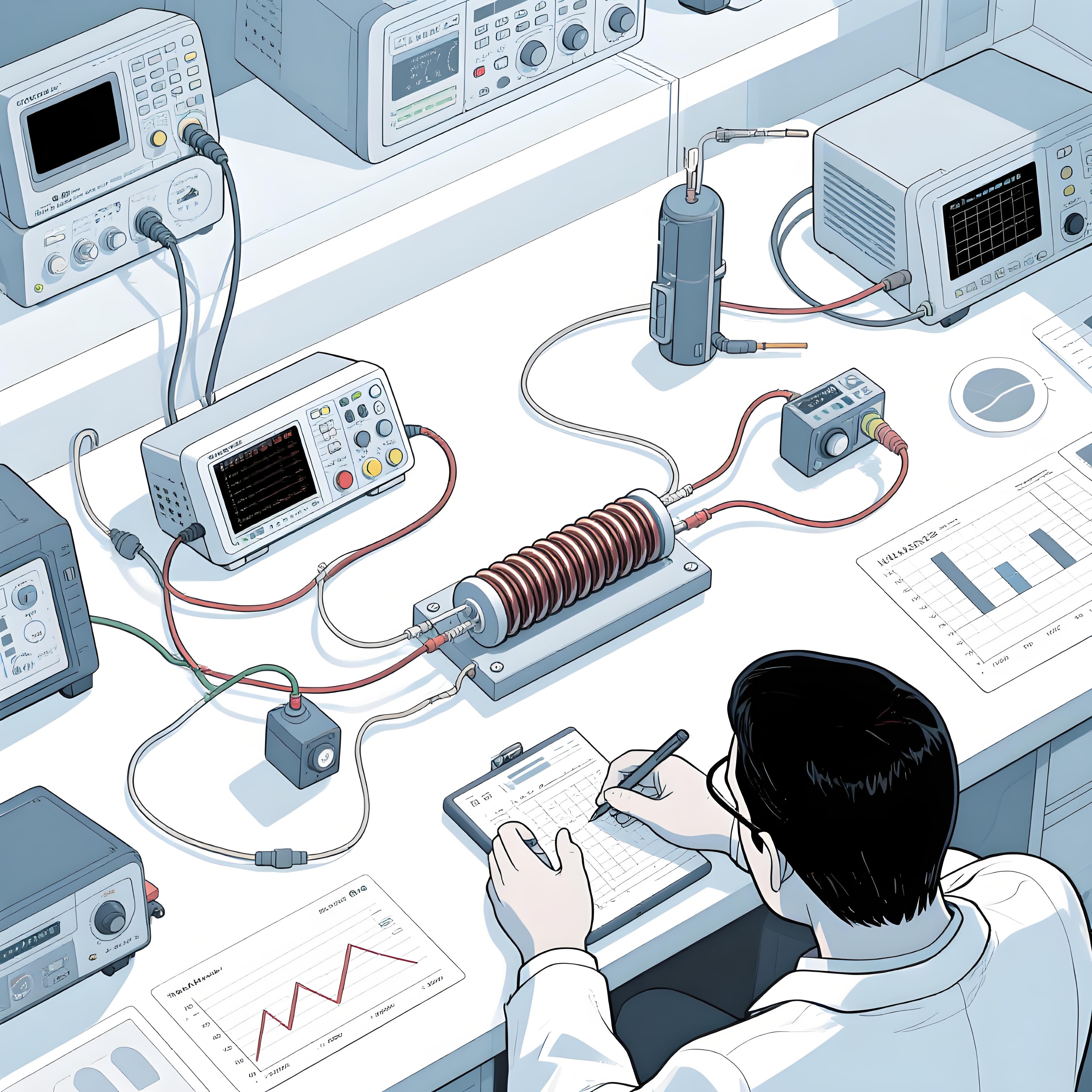

2. Measurement and Test Equipment

They are used in high - voltage test equipment for accurately measuring voltage, current, and other electrical parameters.

3. Industrial Control Systems

These resistors are used in control circuits for industrial machinery and processes, providing precise signal conditioning and processing.

4. High - Voltage Discharge Circuits

In applications such as lighting systems and laser equipment, high precision high voltage resistors are used to control discharge currents and voltages.

5. Motor Drive Systems

They are used in the control and feedback circuits of high - voltage motor drives to ensure precise speed and torque regulation.

Problem and Solution

A common problem in industrial applications is the degradation of resistor performance over time due to factors such as voltage stress, temperature changes, and environmental conditions. For example, in a high - voltage power supply, if the resistor's resistance increases over time, it can lead to higher voltage drops and reduced efficiency. In severe cases, it may cause system failure.

Solution: To address this problem, selecting high - voltage resistors with low TCR and VCR values is essential. Additionally, using resistors made of high - quality, stable materials and employing proper heat dissipation techniques can help minimize temperature - related resistance changes. It's also important to ensure that the resistor is operated within its rated voltage and power specifications to avoid excessive stress. Regular monitoring and maintenance of the resistor's performance can help identify potential issues early and allow for timely replacement if needed.

Best Practices for Using High Precision High Voltage Resistors

Choose resistors with tight tolerance and low TCR for applications requiring precise voltage division and stable performance.

Select resistors with appropriate voltage and power ratings to ensure reliable operation under all conditions.

Use resistors with proper insulation and packaging to protect against environmental factors.

Implement effective heat management solutions to prevent overheating and maintain resistor stability.

Conduct regular testing and inspection of resistors to detect any signs of degradation or failure.

Follow manufacturer guidelines for installation and operation to maximize resistor lifespan and performance.

Conclusion

High precision high voltage resistors are vital components in industrial applications where accuracy, reliability, and stability are paramount. By understanding their characteristics and selecting the right resistors based on application requirements, engineers can ensure optimal performance and long - term reliability of electrical systems. Proper usage and maintenance practices further contribute to the effective utilization of these precision components in demanding industrial environments.