Introduction

In the world of electronics, reliability is paramount, especially in harsh conditions. High moisture environments pose unique challenges for electronic components, particularly resistors. Moisture can lead to corrosion, increased resistance, and ultimately, component failure. This article explores the top high moisture resistant resistors available today, designed to withstand humid and challenging conditions. Whether you're working on automotive, industrial, or consumer electronics, finding the right resistor is crucial for ensuring long-term performance.

The Challenge of Moisture

Moisture is a common enemy of electronic components. In high humidity environments, such as automotive interiors, industrial plants, or marine applications, resistors can degrade quickly. The problem arises when moisture penetrates the resistor's coating, leading to oxidation and increased resistance. This not only affects the accuracy of the circuit but can also cause complete failure. Therefore, selecting high moisture resistant resistors is essential to ensure the reliability and longevity of electronic systems.

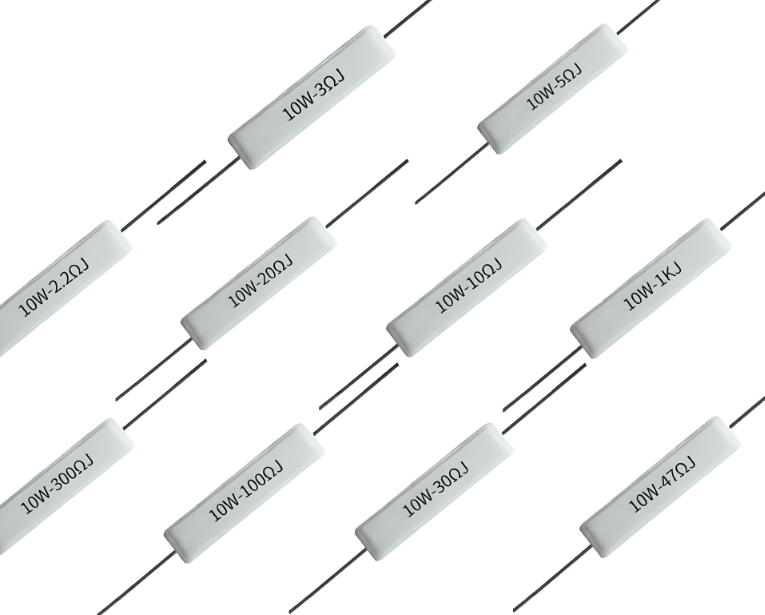

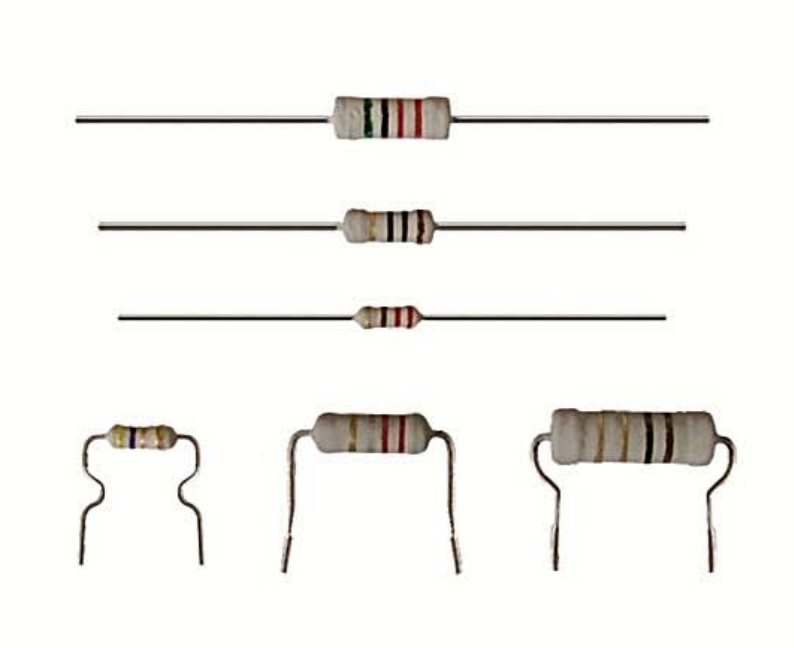

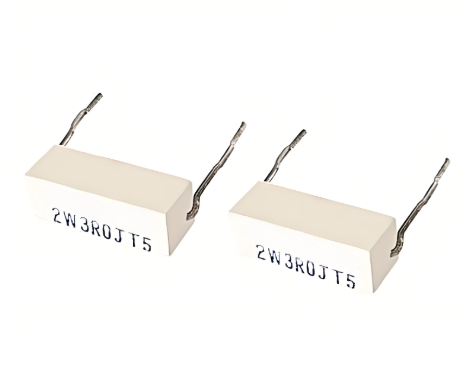

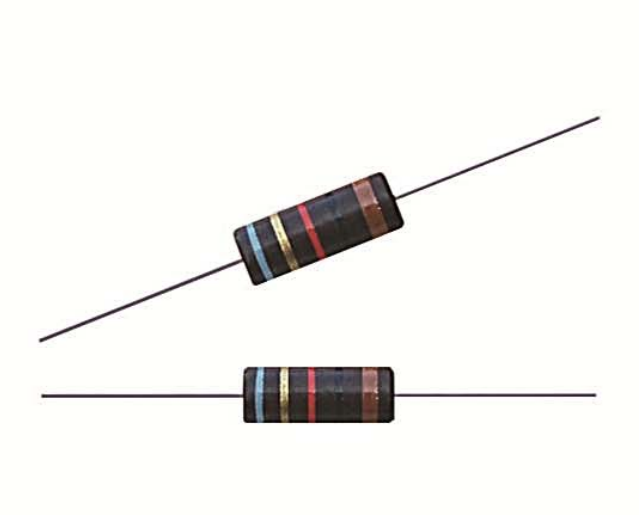

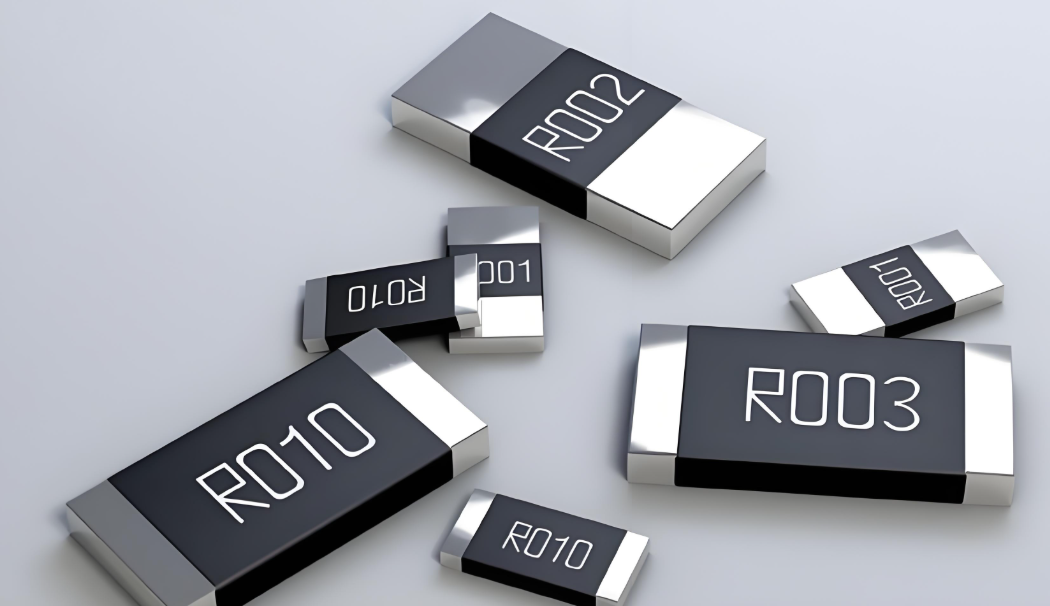

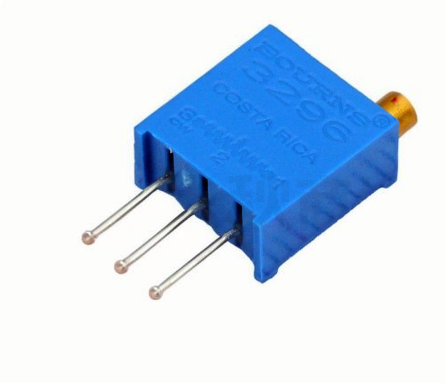

Top High Moisture Resistant Resistors

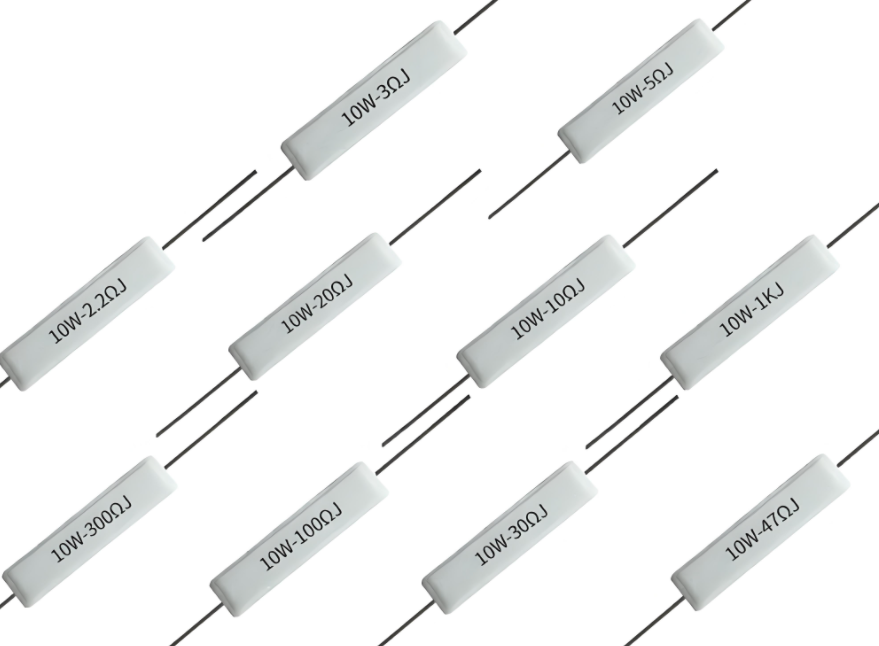

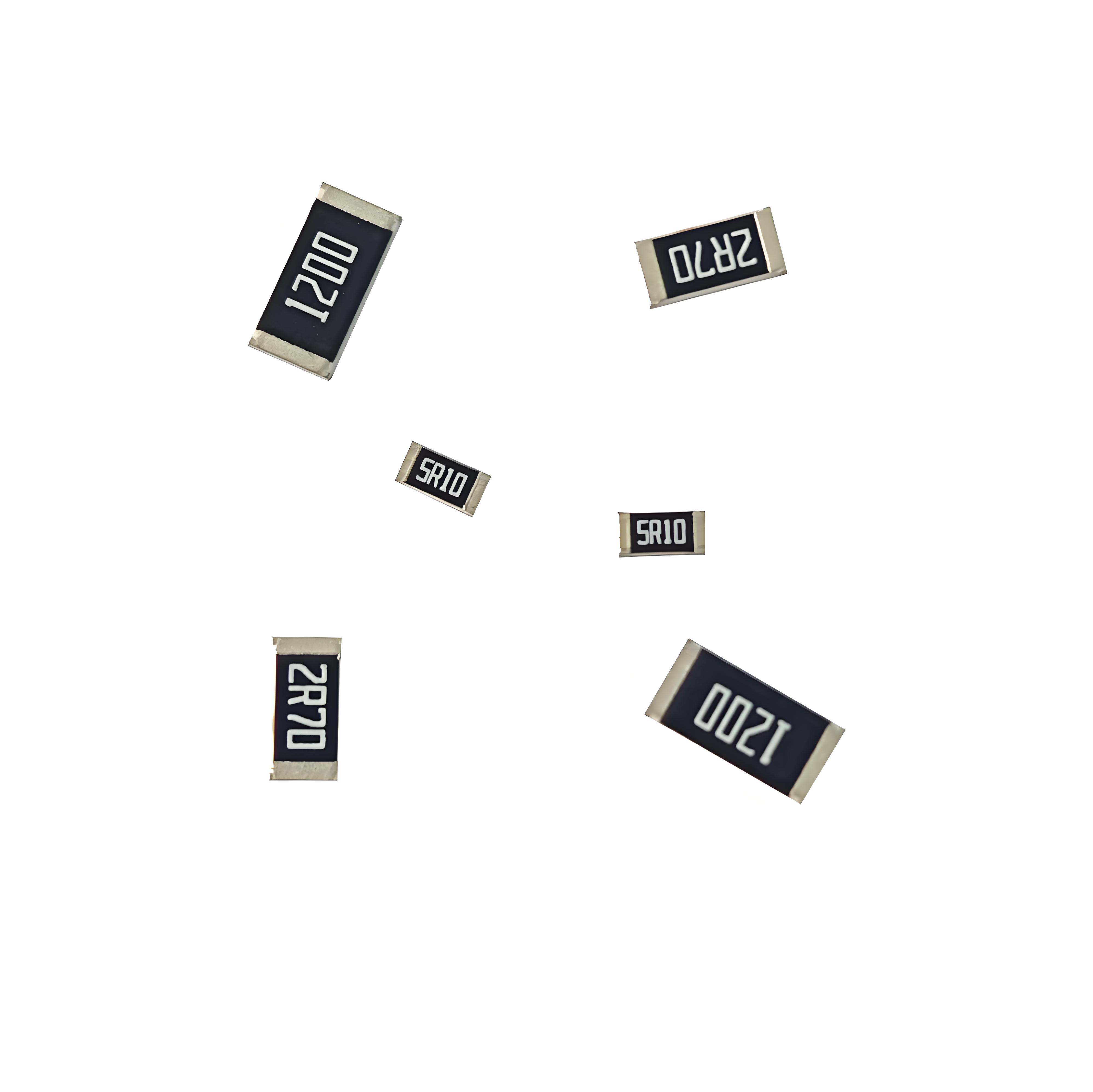

Several manufacturers have developed high moisture resistant resistors specifically designed to combat the challenges posed by humid conditions. These resistors use advanced materials and coatings to prevent moisture ingress and maintain stable resistance values. Here are some of the top options available in the market:

Comparison Table

| Resistor Type | Material | Resistance Range | Moisture Resistance | Temperature Range | Applications |

|---|---|---|---|---|---|

| Thin Film Chip Resistor | Nickel Phosphorus | 1Ω - 10MΩ | Excellent | -55°C to +155°C | Automotive, Industrial |

| Thick Film Chip Resistor | Tantalum Nitride | 0.1Ω - 100kΩ | Very Good | -55°C to +125°C | Consumer Electronics, Telecommunications |

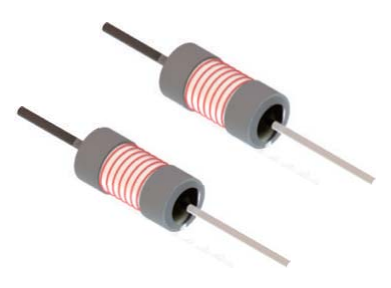

| Wirewound Resistor | Copper-Nickel Alloy | 1Ω - 1kΩ | Good | -40°C to +85°C | Power Electronics, Audio |

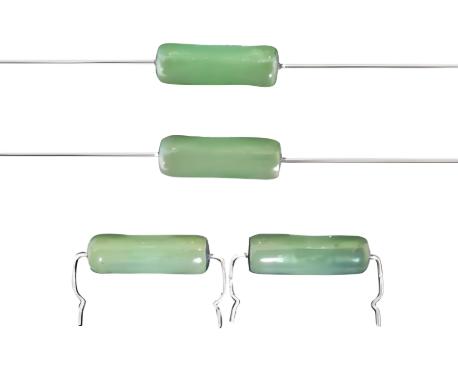

| Metal Oxide Film Resistor | Zinc Oxide | 10Ω - 1MΩ | Excellent | -55°C to +155°C | Automotive, Medical |

Selecting the Right Resistor

When choosing high moisture resistant resistors, several factors must be considered. The primary problem is ensuring that the resistor can withstand prolonged exposure to moisture without degrading. Here are some key points to consider:

Material: Different materials offer varying levels of moisture resistance. For example, nickel phosphorus and zinc oxide are known for their excellent moisture resistance.

Coating: Advanced coatings can significantly enhance moisture resistance. Look for resistors with specialized passivation layers.

Temperature Range: Ensure the resistor can operate within the temperature range of your application.

Resistance Range: Select a resistor with the appropriate resistance value for your circuit.

Application-Specific Requirements: Consider the specific needs of your application, such as automotive, industrial, or consumer electronics.

By carefully evaluating these factors, you can select a high moisture resistant resistor that will provide reliable performance in harsh conditions.

Conclusion

High moisture resistant resistors are essential for applications exposed to humid environments. By choosing the right resistor, you can ensure the stability and longevity of your electronic systems. Whether you opt for thin film chip resistors, thick film chip resistors, wirewound resistors, or metal oxide film resistors, understanding their characteristics and applications is crucial. Always consider the specific requirements of your project to make the best selection.