Standard vs. Sulfur Resistant Resistors: A Reliability Analysis

Introduction

In the world of electronics design, component failure is often a silent and costly threat. Among the various failure modes, sulfur-induced corrosion stands out for its stealthy and destructive nature. This analysis delves into the critical differences between standard and sulfur resistant resistors, providing a data-driven examination of their reliability in harsh environments. For engineers working in automotive, industrial, or other demanding sectors, understanding this distinction is not just a technicality—it's a necessity for ensuring product longevity and preventing catastrophic field failures.

The Hidden Problem: Sulfur's Attack on Electronics

Sulfur, present in the air as hydrogen sulfide (H₂S) or sulfur oxides (SOx) from pollution, industrial processes, or certain materials like rubber gaskets, creates a corrosive atmosphere. Standard resistors with silver-containing terminations are highly vulnerable. The sulfur reacts with the silver to form non-conductive silver sulfide (Ag₂S). This compound manifests as a dark, crusty layer that increases resistance, ultimately leading to an open circuit and catastrophic resistor failure. The problem is often only discovered after devices malfunction in the field, leading to expensive recalls and reputational damage.

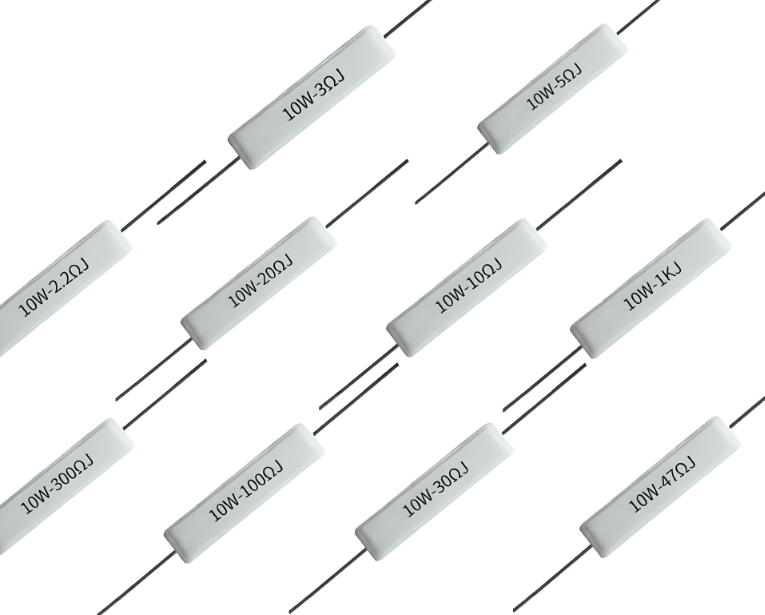

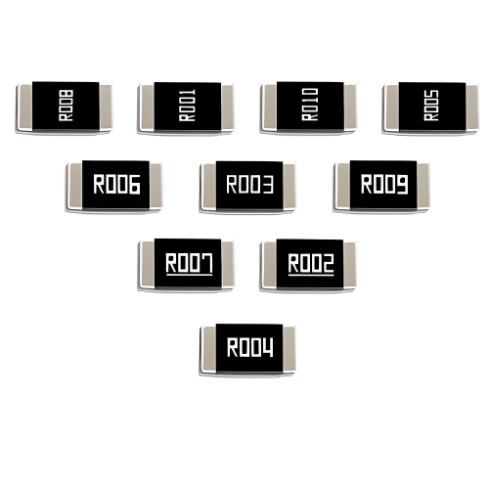

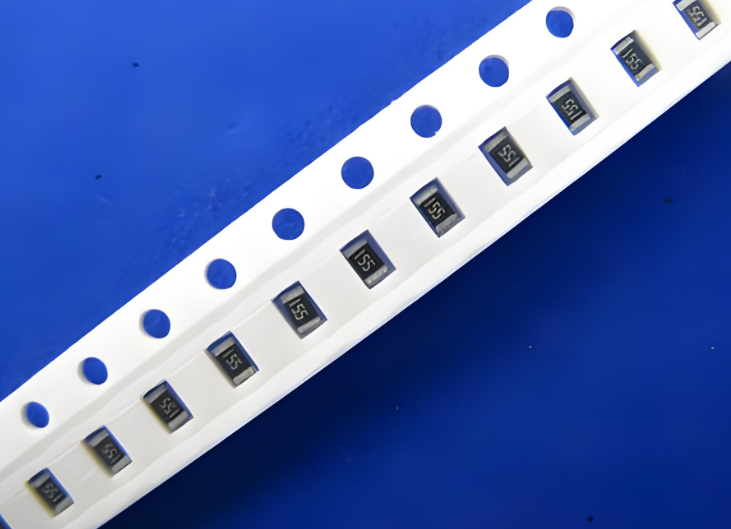

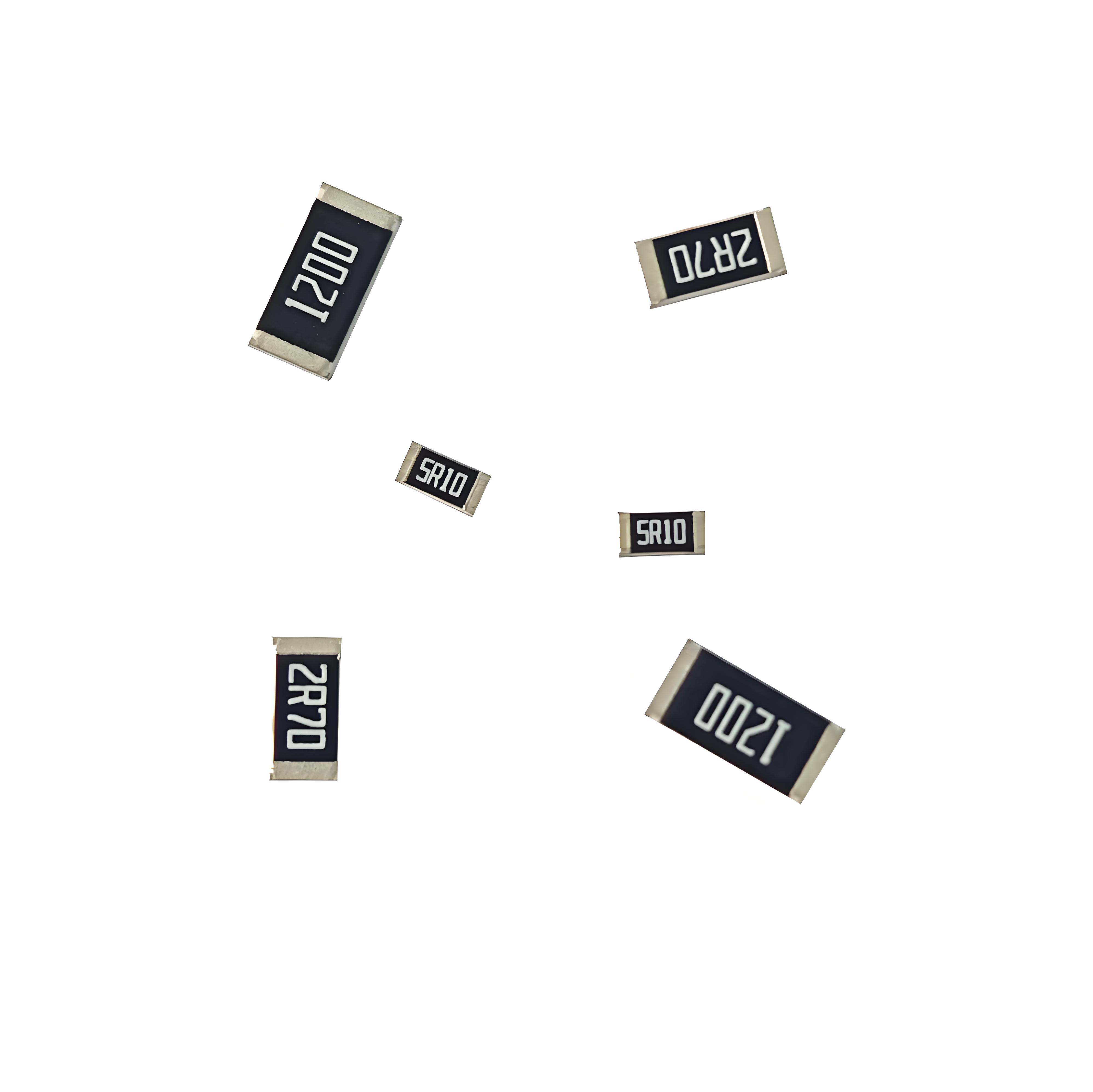

Key Differences in Construction and Materials

The fundamental difference lies in the materials used for the terminations (electrodes). This choice is the primary factor determining sulfur resistant resistor reliability.

| Feature | Standard Resistors | Sulfur Resistant Resistors |

|---|---|---|

| Termination Material | Silver (Ag) or Silver-Palladium (AgPd) | Palladium-Silver (PdAg) with barriers, Nickel Barrier (Ni), or Tin (Sn) |

| Protection Mechanism | None; susceptible to corrosion | Special ceramic passivation or proprietary plating that prevents sulfur diffusion |

| Cost | Lower | Higher (typically 20-50% premium) |

| Primary Use Case | Benign environments (consumer electronics, office equipment) | Harsh sulfur environments (automotive, industrial controls, oil/gas) |

Reliability Showdown: A Data Comparison

Theoretical differences are best understood through empirical data. Accelerated life testing, following standards like ASTM B809, simulates years of sulfur exposure in a matter of days. The following table illustrates the stark contrast in long-term performance of anti-sulfur resistors compared to their standard counterparts.

| Resistor Type | Test Condition (ASTM B809) | Failure Rate after 500 hours | Average Resistance Shift (ΔR) |

|---|---|---|---|

| Standard Thick Film (Ag Termination) | 25°C, 75% RH, 100 ppb H₂S | > 85% | > +1000% (Open Circuit) |

| Basic Sulfur Resistant (Ni Barrier) | 25°C, 75% RH, 100 ppb H₂S | < 5% | < ±1% |

| High-Performance Anti-Sulfur (Special Passivation) | 25°C, 75% RH, 100 ppb H₂S | < 0.1% | < ±0.5% |

| Standard Resistor (Ag Termination) | Real-world harsh environment (e.g., automotive under-hood) | High failure rate within 2-3 years | Drastic increase leading to failure |

The data unequivocally shows that specifying sulfur resistant electronic components is the only effective way to mitigate this specific failure mode in susceptible environments.

Solutions and Best Practices for Design Engineers

The central question for a design engineer is: How to prevent sulfur corrosion in my application? The solution is a multi-faceted approach.

1. Component Selection: The most effective solution is to use certified sulfur resistant resistors from the start. Look for parts specifically tested against ASTM B809 or manufacturers' own stringent sulfur resistance testing standards. Brands like Vishay, Bourns, and KOA offer comprehensive product lines.

2. Environmental Control: If changing components is impossible, consider mitigating the environment. Using conformal coating (e.g., parylene) can create a physical barrier. However, this adds cost and process complexity and is not a guaranteed fix if the coating is imperfect.

3. Design and Layout: Avoid placing resistors near potential sulfur sources within an assembly, such as rubber gaskets or certain types of insulation.

The most reliable and cost-effective solution for corrosive environments is almost always the proactive selection of the right component, like a high reliability sulfur resistant resistor, during the design phase.

Conclusion: Making the Informed Choice

The choice between standard and sulfur resistant resistors is a clear trade-off between initial component cost and long-term system reliability. While standard resistors are suitable for most consumer applications, any device destined for an industrial, automotive, or other setting with airborne contaminants must consider the performance of anti-sulfur resistors. The data proves that the incremental investment in sulfur-resistant technology is a cheap insurance policy against premature failure, protecting the integrity of your product and your brand's reputation. Always consult your component supplier's datasheets and application notes to make the most informed decision for your specific use case.