Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base Stations

Base stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution. In such settings, sulfur-containing compounds, such as sulfur dioxide (SO₂) and hydrogen sulfide (H₂S), are commonly present. These compounds can penetrate the protective coatings of electronic components, leading to chemical reactions that cause corrosion and degradation. Sulfur-induced failures can result in increased maintenance costs, reduced operational efficiency, and potential network downtime.

| Environmental Factor | Impact on Base Station Components |

|---|---|

| High sulfur content | Accelerated corrosion of metal parts |

| Humidity | Enhanced sulfur penetration and reaction rates |

| Temperature fluctuations | Increased mechanical stress on components |

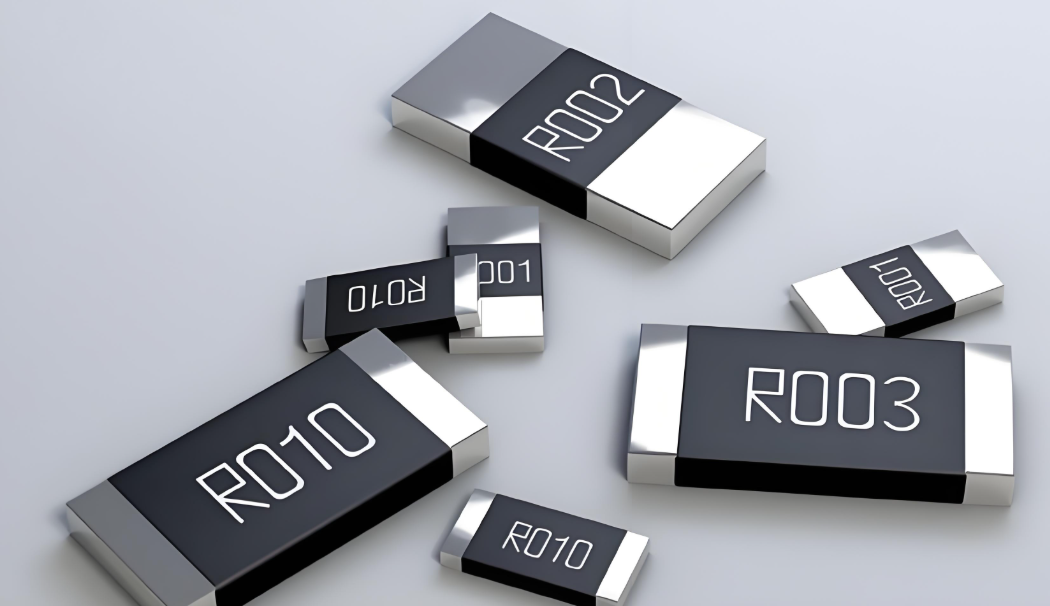

The Solution: Anti-Sulfur Resistors

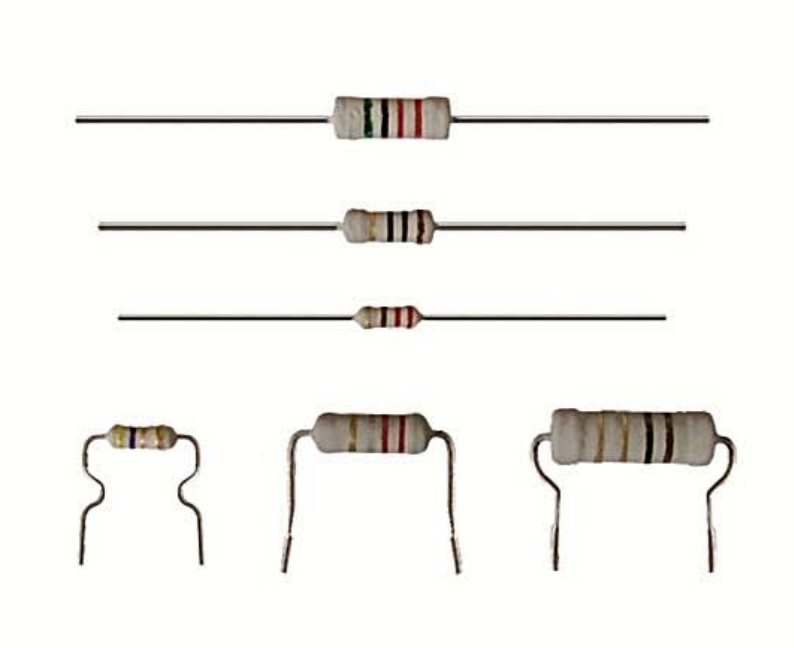

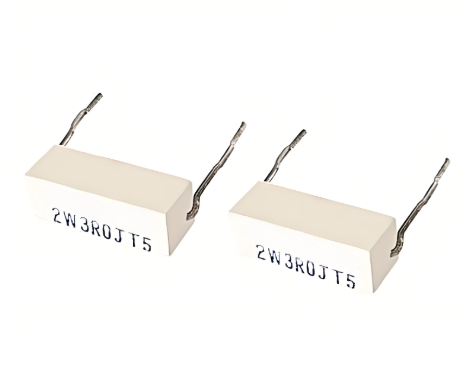

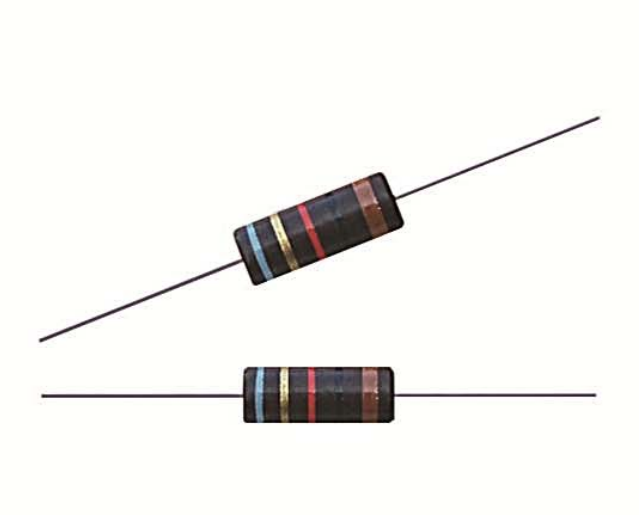

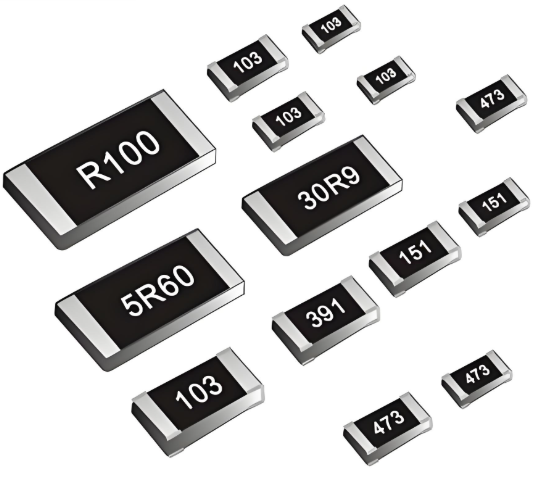

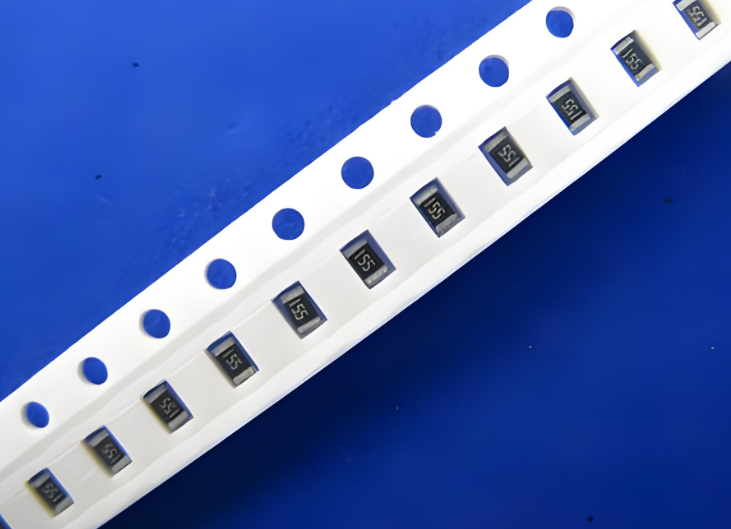

Anti-sulfur resistors are specifically designed to withstand the corrosive effects of sulfur-containing environments. These resistors are constructed using materials and manufacturing processes that prevent sulfur from reacting with the resistor's internal components, thereby maintaining their electrical characteristics and reliability over time. By incorporating anti-sulfur resistors into base station designs, operators can significantly reduce the risk of sulfur-induced failures and extend the lifespan of their equipment.

Applications of Anti-Sulfur Resistors in Base Stations

Anti-sulfur resistors find applications in various critical circuits within base stations, including power management, signal processing, and control systems. Their use ensures stable operation and accurate performance, even in the presence of high sulfur levels. Some specific applications include:

Power supply circuits: Anti-sulfur resistors help maintain stable voltage regulation and current sensing, preventing power fluctuations that could disrupt base station operations.

RF circuits: In radio frequency applications, anti-sulfur resistors ensure consistent signal transmission and reception, reducing the risk of signal degradation.

Control systems: These resistors provide precise resistance values in control circuits, enabling accurate monitoring and control of base station functions.

Benefits of Using Anti-Sulfur Resistors

The implementation of anti-sulfur resistors in base stations offers numerous benefits, enhancing both performance and reliability. Key advantages include:

| Benefit | Description |

|---|---|

| Enhanced reliability | Reduced risk of sulfur-induced failures, leading to increased uptime and lower maintenance costs. |

| Improved performance | Stable electrical characteristics ensure optimal performance of base station circuits. |

| Extended lifespan | Protection against sulfur corrosion extends the operational life of base station components. |

| Cost savings | Lower replacement and repair costs due to increased component durability. |

Implementing Anti-Sulfur Resistors in Base Stations

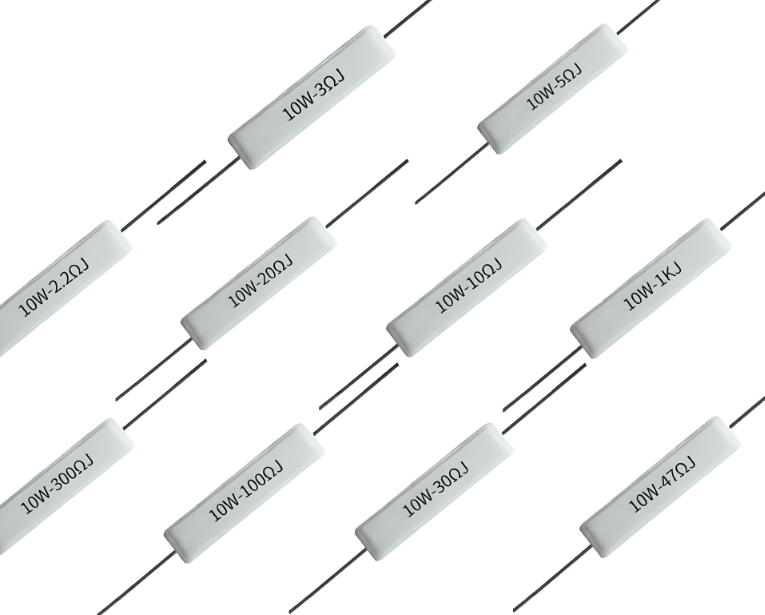

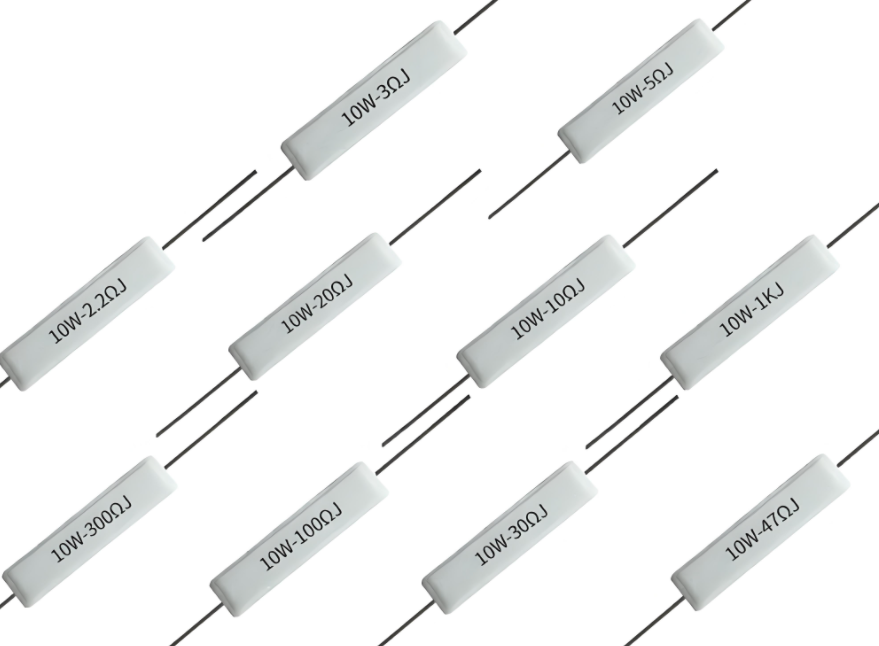

When integrating anti-sulfur resistors into base station designs, several factors should be considered to ensure optimal performance and reliability. These include selecting resistors with appropriate resistance values and power ratings, as well as ensuring proper installation and environmental sealing. Additionally, regular monitoring and maintenance can help identify potential issues before they lead to failures.

Long-tail keywords such as "anti-sulfur resistor base station applications" and "anti-sulfur resistor reliability in harsh environments" can be naturally integrated into the text to improve search engine visibility and attract targeted traffic.

Conclusion

Anti-sulfur resistors play a crucial role in enhancing the reliability and performance of base stations operating in harsh environments. By understanding the challenges posed by sulfur-containing compounds and implementing appropriate solutions, base station operators can ensure continuous and efficient network operations. The use of anti-sulfur resistors not only reduces maintenance costs but also extends the lifespan of critical components, making them an essential consideration in base station design and deployment.

Email us

-

Moisture Resistant Resistors

Moisture Resistant Resistors

-

High Value Resistors

High Value Resistors

-

Lead-Free Resistors

Lead-Free Resistors

-

Anti-Sulfur Resistors

Anti-Sulfur Resistors

-

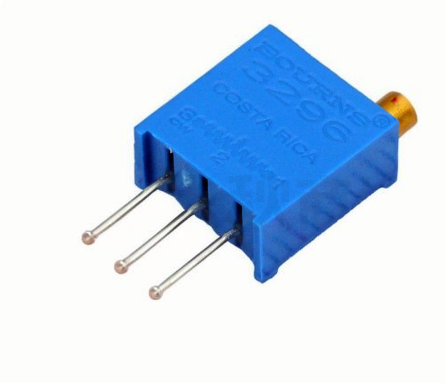

Low TCR Resistors

Low TCR Resistors

-

Precision Resistors

Precision Resistors

-

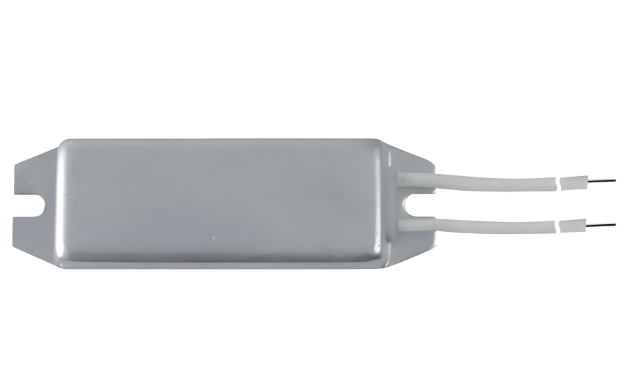

RXF21A/B/C (FRT) wire - wound fusing resistors

RXF21A/B/C (FRT) wire - wound fusing resistors

-

RFX21-T low-power full-short-circuit resistors

RFX21-T low-power full-short-circuit resistors

-

RFX21-D semi-short-circuit surge-resistant wirewound resistors

RFX21-D semi-short-circuit surge-resistant wirewound resistors

-

RF10 painted thin-film fuse resistors

RF10 painted thin-film fuse resistors

-

RF11 porcelain-cased thin-film fuse resistors

RF11 porcelain-cased thin-film fuse resistors

-

RWF molded wirewound fuse resistors

RWF molded wirewound fuse resistors

-

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

RXG21 (A/B/C/D) lightning surge-resistant wirewound resistors

-

RXF21-TE power-type full-short-circuit temperature fuse resistors

RXF21-TE power-type full-short-circuit temperature fuse resistors

-

RX22 Vitreous enameled wire - wound resistors

RX22 Vitreous enameled wire - wound resistors

-

RX23 ceramic encased wire - wound resistors

RX23 ceramic encased wire - wound resistors

-

RX92 anti - interference wire - wound resistors

RX92 anti - interference wire - wound resistors

-

RX21 coated wire - wound resistors

RX21 coated wire - wound resistors

-

RXLG high power aluminum encased wire - wound resistors

RXLG high power aluminum encased wire - wound resistors

-

RX27 power ceramic encased wire - wound resistors

RX27 power ceramic encased wire - wound resistors

-

RXL power aluminum encased wire - wound resistors

RXL power aluminum encased wire - wound resistors

-

RXHGI high power wane ripple coated wire - wound resistors

RXHGI high power wane ripple coated wire - wound resistors

-

RX20 high power vitreous enameled wire - wound resistors

RX20 high power vitreous enameled wire - wound resistors

-

RX24 aluminum encased power wire - wound resistors

RX24 aluminum encased power wire - wound resistors

-

Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base StationsBase stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution....

-

Standard vs. Sulfur Resistant Resistors: A Reliability Analysis

Standard vs. Sulfur Resistant Resistors: A Reliability AnalysisIntroductionIn the world of electronics design, component failure is often a silent and costly threat. Among the various failure modes, s...

-

Metal Alloy Resistor: High-Precision, Low-TCR Current Sensing Solutions for Harsh Environments

IntroductionMetal alloy resistors are critical components in modern electronic circuits, offering high precision and stability. These resistors are designed to provide accurate current sensing in a va...

-

French Blue Baseplate 180W Four Terminal Ultra Long Creepage Resistor | High Voltage Resistance, Non-Inductive Design for Industrial Power Supplies, Motor Control, and Harsh Environments

1. Key Technical Specifications of the French Blue Baseplate 180W Four Terminal Ultra Long Creepage ResistorTo evaluate its suitability for demanding applications, let’s examine its core parameters—...

-

Low Inductance High Voltage Resistor Design: Enhancing Precision and Performance

Low Inductance High Voltage Resistor Design: Enhancing Precision and PerformanceIn high - frequency and high - voltage electronic applications, the design of resistors with low inductance is crucial f...

-

Trimmable Thick Film Chip Resistor Stability: Enhancing Long-Term Performance in Electronics

IntroductionIn the realm of electronics, the stability of components is crucial for ensuring reliable and consistent performance over time. One such component that plays a vital role in various electr...

-

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics IntroductionIn the harsh operational environment of oil refineries and petrochemical plants, a silent a...

-

Top 10 Factors to Consider When Choosing Surface Mount Precision Resistors for Optimal Performance and Reliability

IntroductionIn the world of electronics, the precision and reliability of components are crucial for the performance of any device or system. Surface mount precision resistors are no exception. They a...

-

How Anti - surge Precision Resistors Can Stabilize Your Electronic Circuits

IntroductionIn today's complex electronic landscape, circuits are constantly exposed to voltage surges that can disrupt normal operations and damage sensitive components. Anti-surge precision resi...

-

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention Methods

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention MethodsSulfur-induced corrosion remains a leading cause of resistor failure in harsh environments like oil refine...

-

High Temperature Power Resistors: Applications, Specifications & Selection Guide for Extreme Environments

Table of ContentsIntroductionKey Applications in Extreme EnvironmentsTechnical Specifications & Performance MetricsSelection Guide for High Temperature ResistorsAddressing Thermal Stability Challe...

-

Top High Moisture Resistant Resistors for Harsh Conditions

IntroductionIn the world of electronics, reliability is paramount, especially in harsh conditions. High moisture environments pose unique challenges for electronic components, particularly resistors. ...

-

How to Choose Alloy Resistors for High - Reliability Electronic Systems

IntroductionIn high-reliability electronic systems, the selection of components is critical to ensuring consistent performance and longevity. Alloy resistors, with their superior characteristics, are ...

-

Precision Resistors in Medical Devices: Ensuring Accuracy and Reliability for Critical Applications

IntroductionIn the realm of medical devices, precision is not just a preference—it's a necessity. Precision resistors play a crucial role in ensuring the accuracy and reliability of medical equi...

-

Trimmable Thick Film Chip Resistor: Overcoming Trimming Challenges for Precision and Reliability

IntroductionTrimmable Thick Film Chip Resistors (TFCRs) are essential components in modern electronics, offering the flexibility to adjust resistance values to meet precise circuit requirements. Howev...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

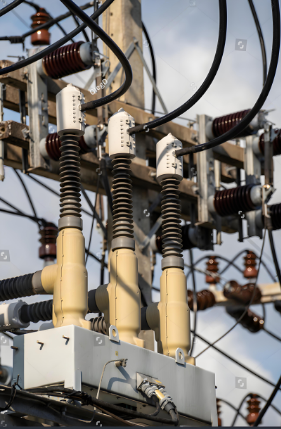

High Voltage Resistors for Power Transmission: Specifications, Reliability Standards, and Supplier Picks for Substations & Long-Distance Lines

Technical Specifications of High Voltage Resistors for Power TransmissionTo perform reliably in power transmission systems, resistors must meet strict performance criteria. Below are critical paramete...

-

Why Use Low TCR Resistors? The Key to Stable Circuit Performance

Why Use Low TCR Resistors The Key to Stable Circuit PerformanceIn electronic design, a resistor's value is often considered a constant. However, this is a simplification that can lead to significa...

-

Alloy Resistor: High - Precision Component for Stable Circuit Performance

IntroductionIn the pursuit of electronic circuit excellence, precision and stability are paramount. Alloy resistors, with their superior characteristics, have become indispensable in achieving these g...

-

High Performance Metal Film Resistors for Moisture-Prone Applications

Introduction to High Performance Metal Film ResistorsIn electronic circuit design, selecting appropriate resistors is crucial, especially for devices operating in challenging environments. This articl...

-

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics IntroductionIn the harsh operational environment of oil refineries and petrochemical plants, a silent a...

-

Standard vs. Sulfur Resistant Resistors: A Reliability Analysis

Standard vs. Sulfur Resistant Resistors: A Reliability AnalysisIntroductionIn the world of electronics design, component failure is often a silent and costly threat. Among the various failure modes, s...

-

Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base StationsBase stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution....

-

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention Methods

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention MethodsSulfur-induced corrosion remains a leading cause of resistor failure in harsh environments like oil refine...

Resistor Supplies - Jepsun Tech Corporation

JEPSUN INDUSTRIAL is committed to always being one of our customers' favorite suppliers.

+86755-29796190 +8615920026751 [email protected]

Huangjiazhongxin building Donghuan Road Longhua District SHENZHEN City, GUANGDONG Prov. CHINA 518000