Introduction

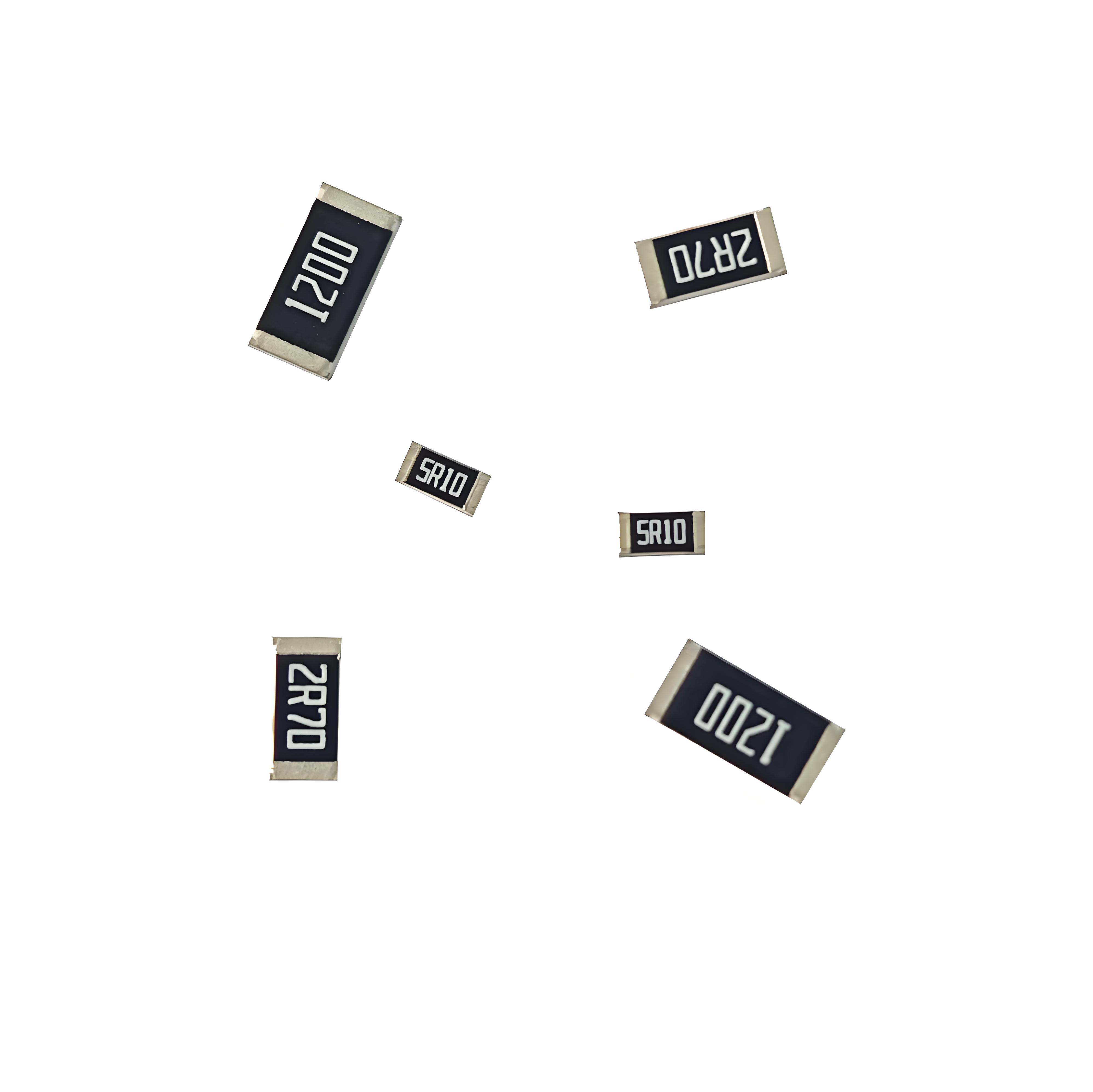

In the world of electronics, the precision and reliability of components are crucial for the performance of any device or system. Surface mount precision resistors are no exception. They are essential for applications ranging from high-precision analog circuits to advanced digital systems. Choosing the right surface mount precision resistor can significantly impact the accuracy and reliability of your design. This article will explore the top 10 factors you should consider when selecting surface mount precision resistors, ensuring you make the best choice for your specific application.

Table of Contents

Factor 1: Resistance Value and Tolerance

The resistance value and its tolerance are fundamental to selecting a precision resistor. The tolerance indicates the allowable deviation from the nominal value. For high-precision applications, such as precision voltage dividers or current sensing, a tight tolerance is crucial.

| Resistance Value | Tolerance | Typical Use |

|---|---|---|

| 1kΩ | ±0.1% | Precision Voltage Divider |

| 10kΩ | ±0.05% | High-Precision Current Sensing |

For example, a 10kΩ resistor with a ±0.05% tolerance will vary between 9,995Ω and 10,005Ω. This level of precision is essential for applications where accuracy is paramount.

Factor 2: Temperature Coefficient

The temperature coefficient (tempco) specifies how the resistance value changes with temperature. A low tempco ensures that the resistor's value remains stable across a wide range of operating temperatures.

| Temperature Coefficient | Change per °Cth</> |

|---|---|

| ±5ppm/°C | ±0.005% |

| ±10ppm/°C | ±0.01% |

A resistor with a ±5ppm/°C tempco will change by only ±0.005% for each degree Celsius change in temperature, making it suitable for applications with significant temperature variations.

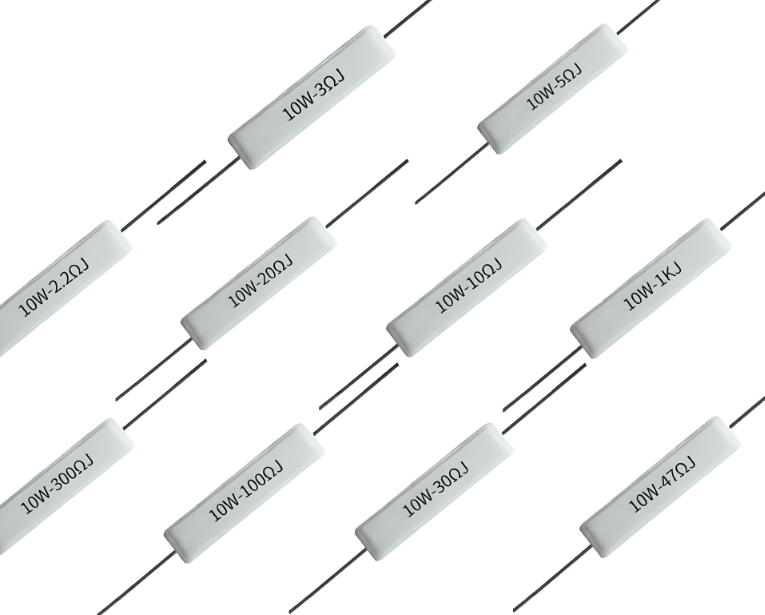

Factor 3: Power Rating

The power rating indicates the maximum power the resistor can dissipate without damage. It is crucial to select a resistor with a power rating that exceeds the expected power dissipation in your application.

| Power Rating | Typical Use |

|---|---|

| 0.1W | Low-Power Signal Routing |

| 1W | Power Management Circuits |

For example, a resistor used in a power management circuit might dissipate up to 1W of power, so selecting a 1W or higher-rated resistor is essential to avoid overheating and potential failure.

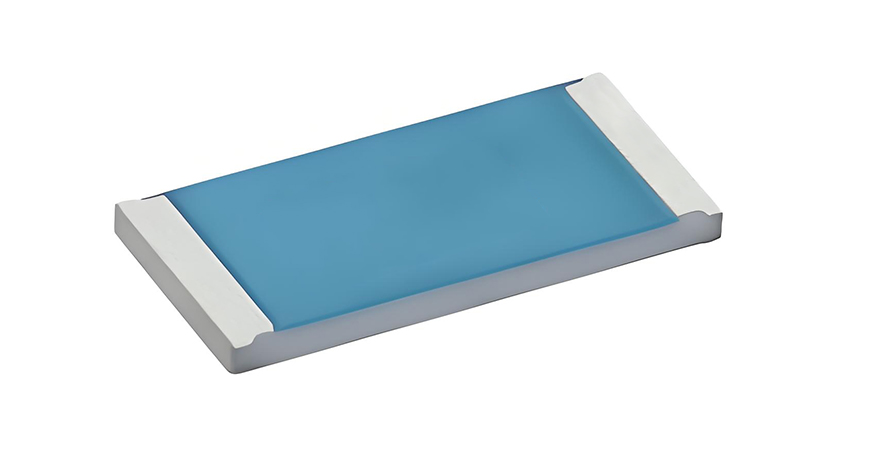

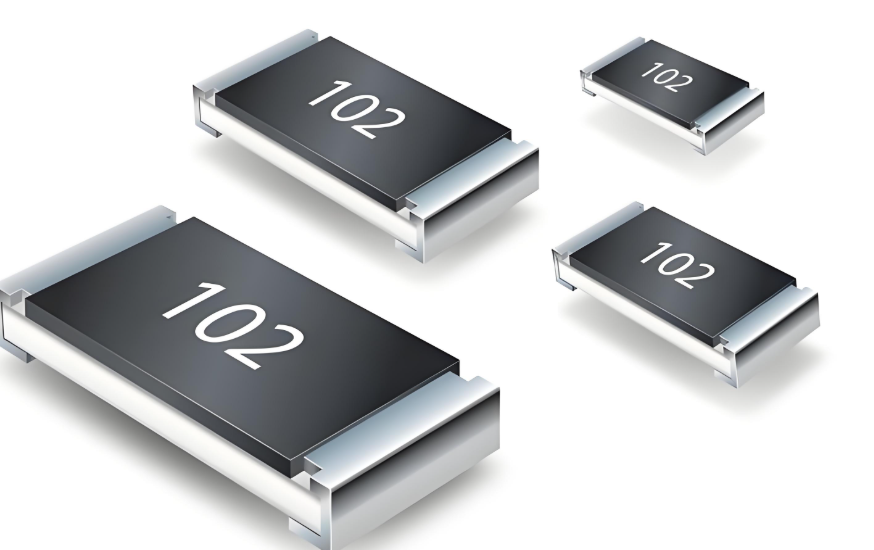

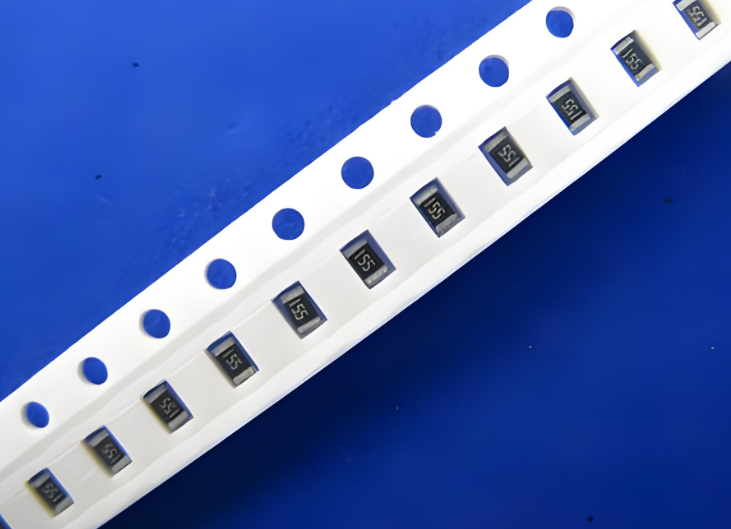

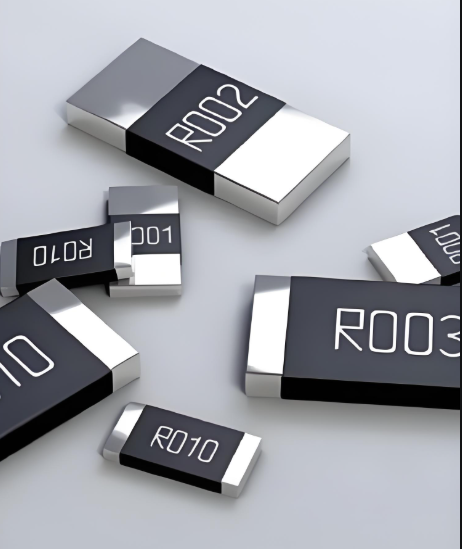

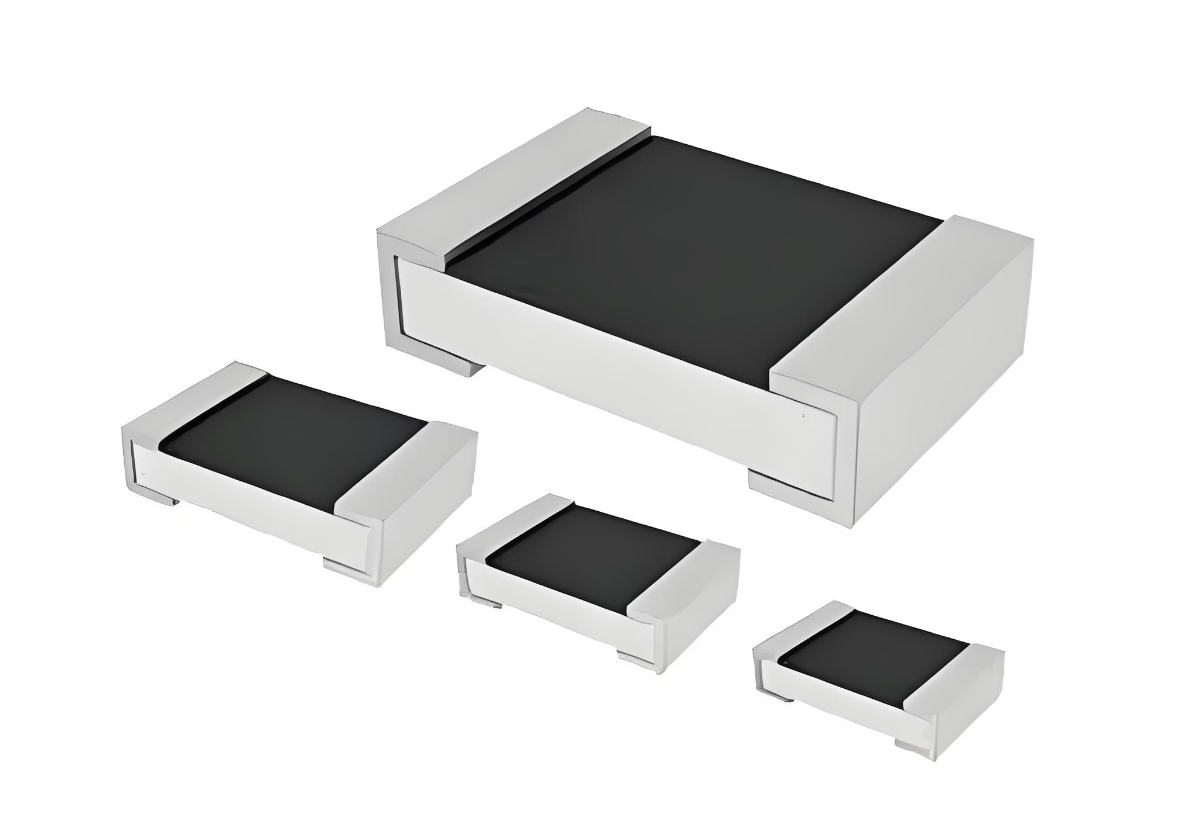

Factor 4: Package Size

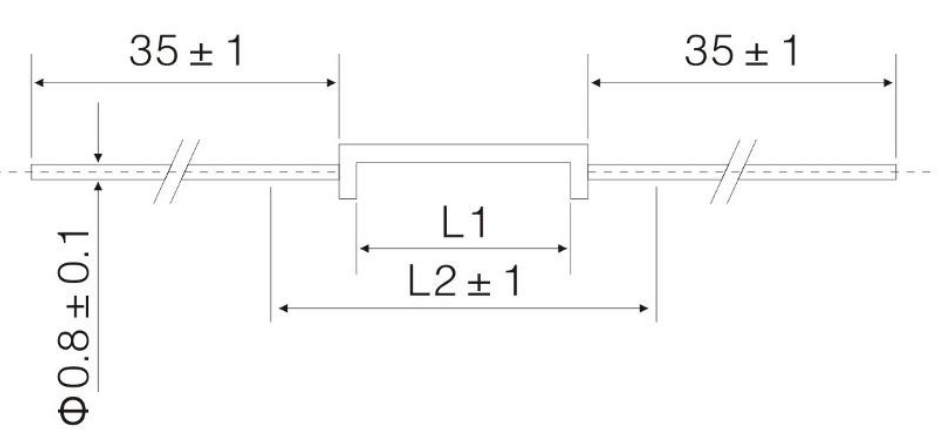

The physical size of the resistor can be a limiting factor, especially in compact designs. Common package sizes include 0805, 1206, and 2512, each with different footprints and power handling capabilities.

| Package Size | Dimensions (L x W) | Power Handling |

|---|---|---|

| 0805 | 2.0mm x 1.25mm | 0.125W |

| 1206 | 3.2mm x 1.6mm | 0.25W |

| 2512 | 6.4mm x 3.2mm | 1W |

For high-density designs, the 0805 package might be preferred, while for high-power applications, the 2512 package offers better power handling.

Factor 5: Temperature Range

The operating temperature range of the resistor must match the expected environmental conditions of your application. A resistor with a wide temperature range ensures reliable performance in varying conditions.

| Temperature Range | Typical Use |

|---|---|

| -55°C to +125°C | Industrial and Automotive Applications |

| 0°C to +70°C | Consumer Electronics |

A resistor rated for -55°C to +125°C is suitable for industrial applications where the environment can be harsh and temperature extremes are common.

Factor 6: Material and Construction

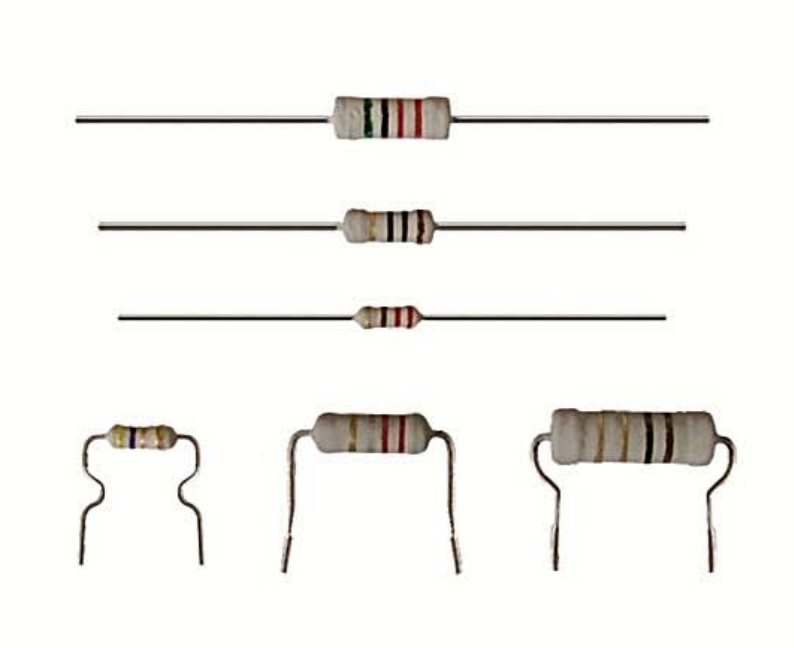

The material and construction of the resistor affect its durability, stability, and performance. Common materials include metal film, foil, and thick film, each with unique characteristics.

| Material | Characteristics |

|---|---|

| Metal Film | High Precision, Low Noise |

| Foil | High Stability, Low Temperature Coefficient |

| Thick Film | Cost-Effective, Wide Range of Values |

For high- applicationsprecision, metal film or foil resistors are preferred due to their superior performance.

Factor 7: Stability and Drift

The stability and drift of a resistor refer to how its value changes over time. A resistor with low long-term drift ensures consistent performance over its operational life.

| Drift | Change per Year |

|---|---|

| ±0.01% | ±0.01% per Year |

| ±0.1% | ±0.1% per Year |

A resistor with ±0.01% drift per year will maintain its value more consistently over time, making it ideal for applications requiring long-term reliability.

<h2 id="factor-8-noise