Introduction

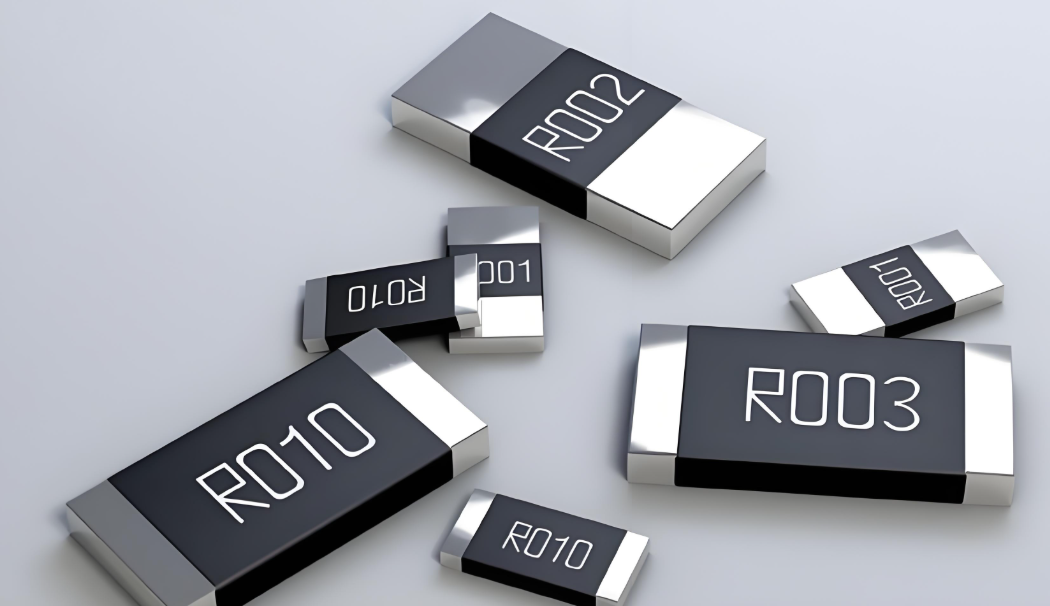

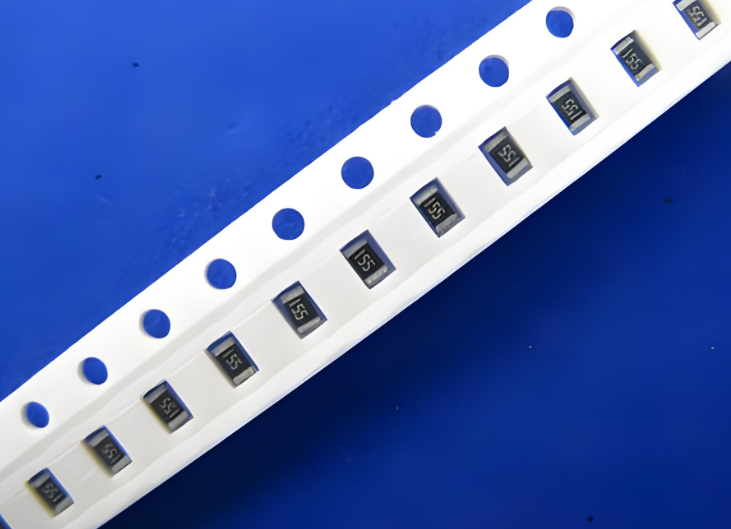

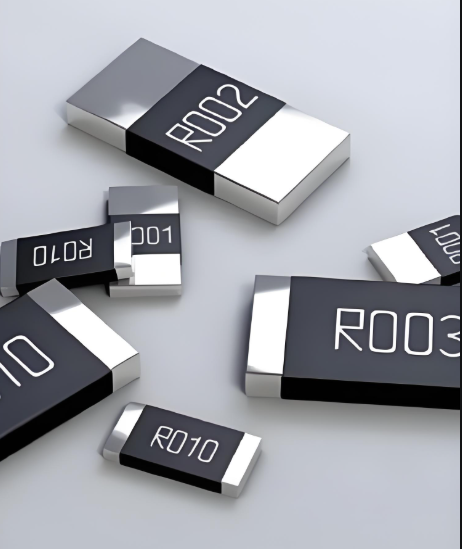

In the realm of electrical engineering and electronics, accurate current sensing is a cornerstone for numerous applications, ranging from power management in sophisticated electronic devices to the optimization of energy in large-scale industrial systems. Precision shunt resistors play a crucial role in achieving this accuracy. They offer a reliable method for measuring current flow by converting it into a voltage drop that can be easily measured. Despite their seemingly simple function, the selection and application of precision shunt resistors involve a complex interplay of factors including resistance value, power rating, temperature coefficient, and material quality. This article delves into the significance of precision shunt resistors, explores the challenges associated with their use, and provides effective solutions to ensure optimal performance in current sensing applications.

By understanding the intricacies of precision shunt resistors and addressing the issues that arise, engineers and designers can enhance the reliability and precision of their current sensing circuits. This in, turn, can lead to more efficient power management, better system performance, and ultimately, cost savings and increased longevity of electronic systems.

Table of Contents

orsFactors Affecting the Accuracy of Precision Shunt Resistors

Problems and Solutions in Precision Shunt Resistors Application

The Importance of Precision Shunt Resistors

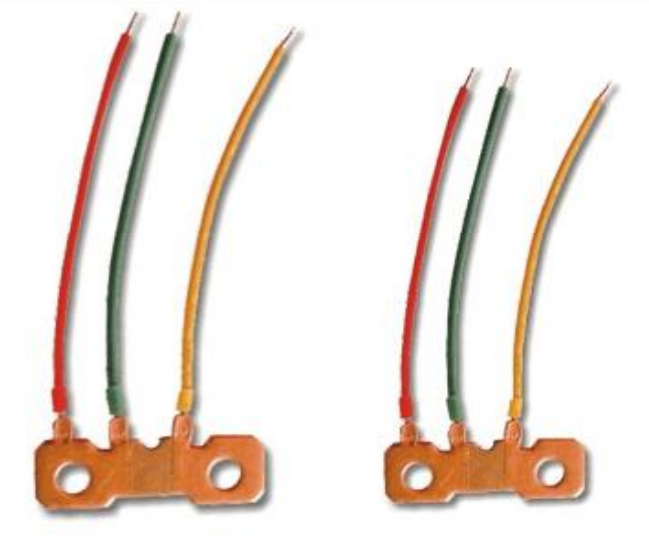

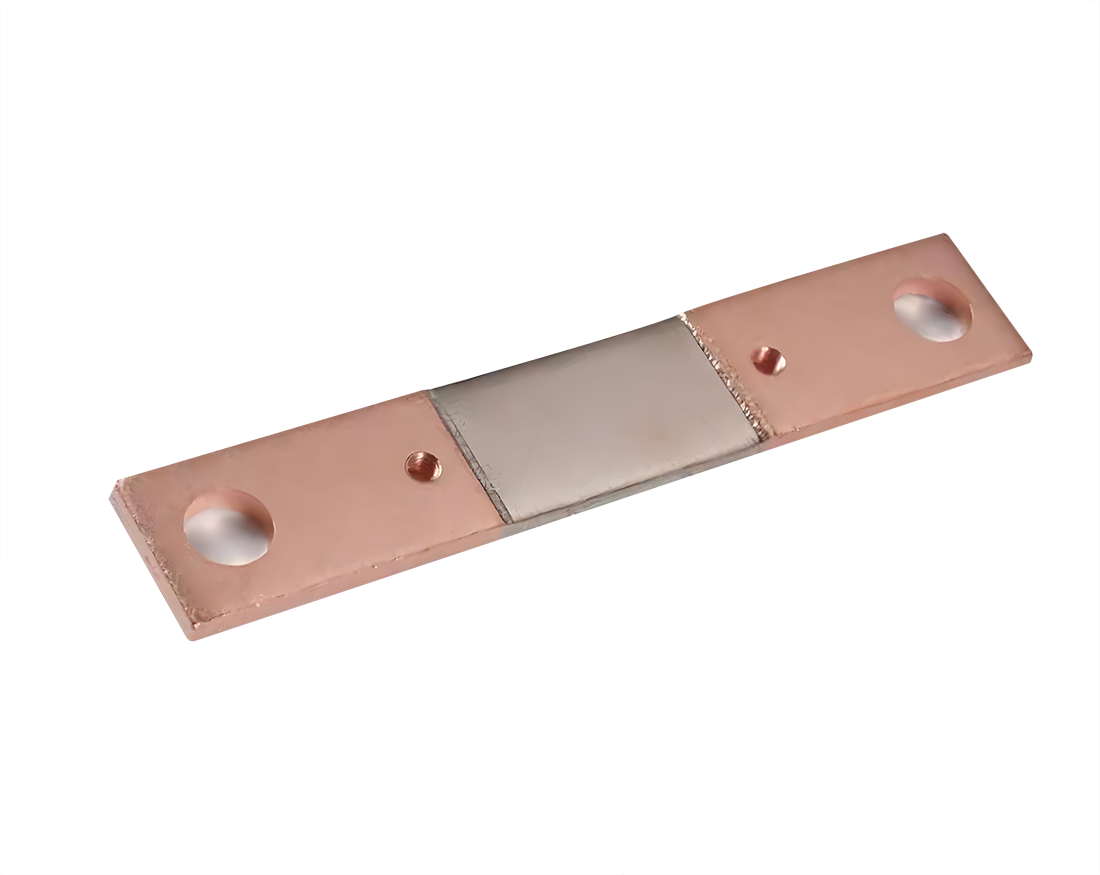

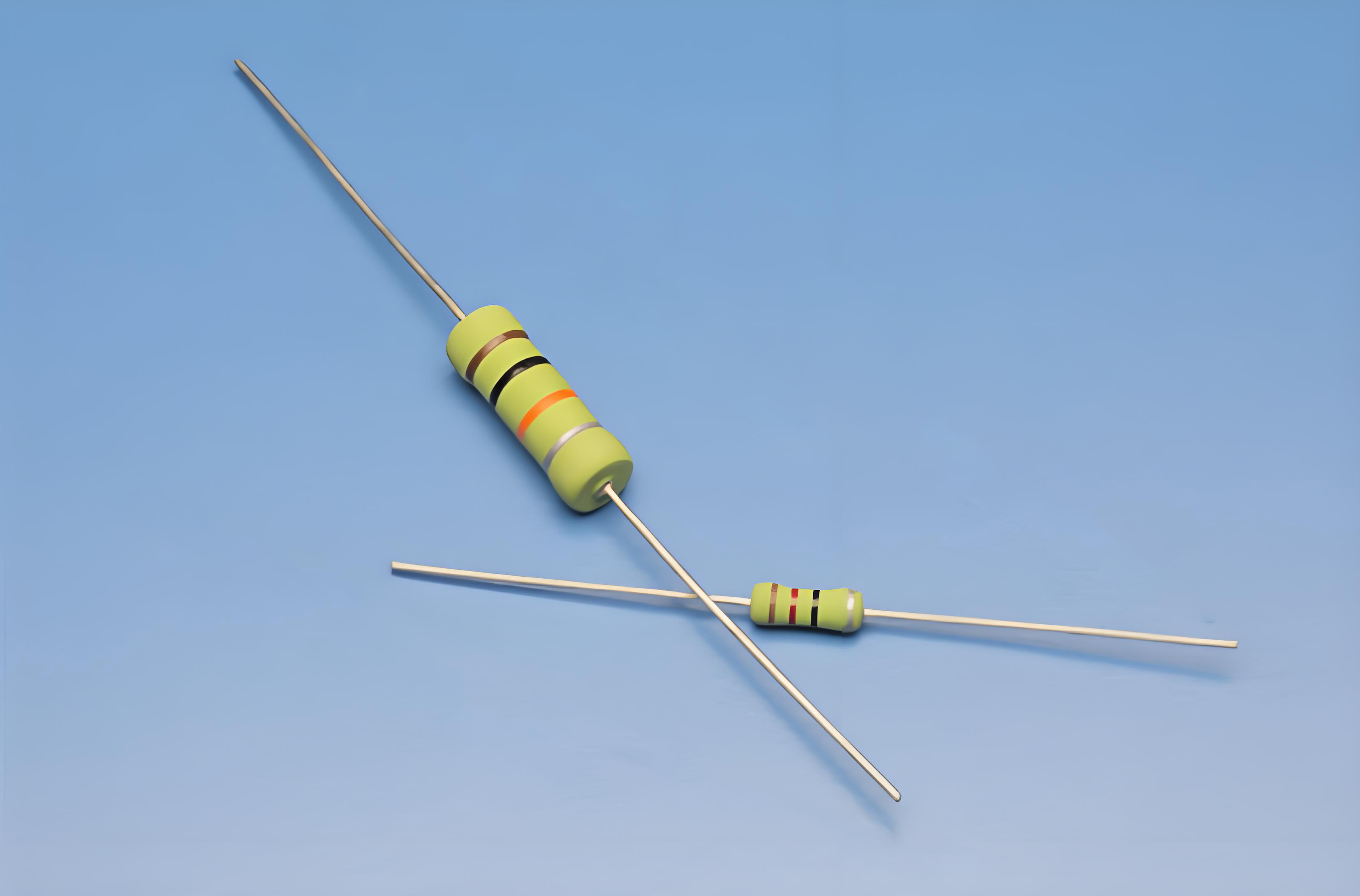

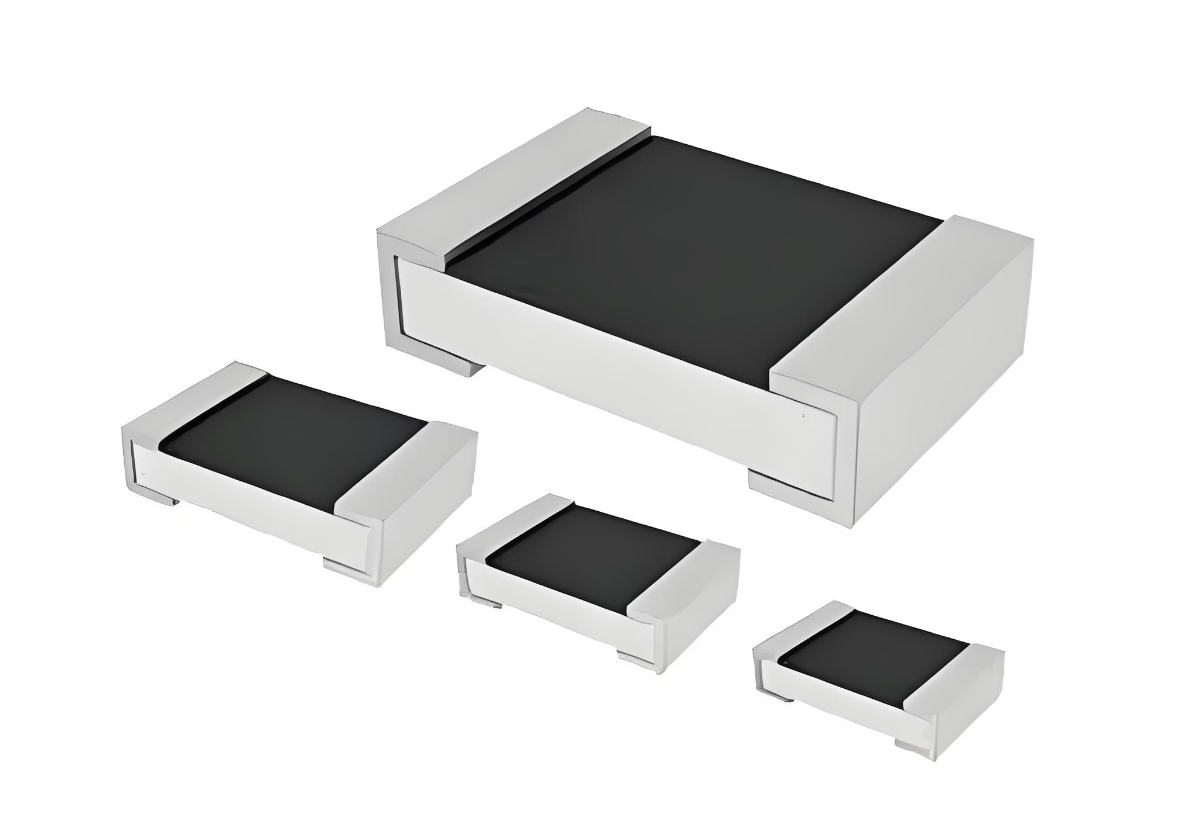

Precision shunt resistors are essential components in current sensing applications due to their ability to provide highly accurate measurements with minimal impact on the circuit. They operate based on Ohm's Law, where the voltage drop across the resistor is directly proportional to the current flowing through it. This voltage drop can then be measured using a voltmeter or an analog-to-digital converter (ADC) in a microcontroller-based system.

| Feature | Importance |

|---|---|

| Low Resistance | Minimizes power loss and voltage drop across the resistor, maintaining high efficiency in the circuit. |

| High Power Rating | Ensures durability and reliability, especially in high-current applications. |

| Low Temperature Coefficient | Reduces measurement errors caused by temperature fluctuations. |

Given these features, precision shunt resistors are indispensable for applications such as motor control, power supplies, battery management systems, and industrial automation where accurate current monitoring is critical.

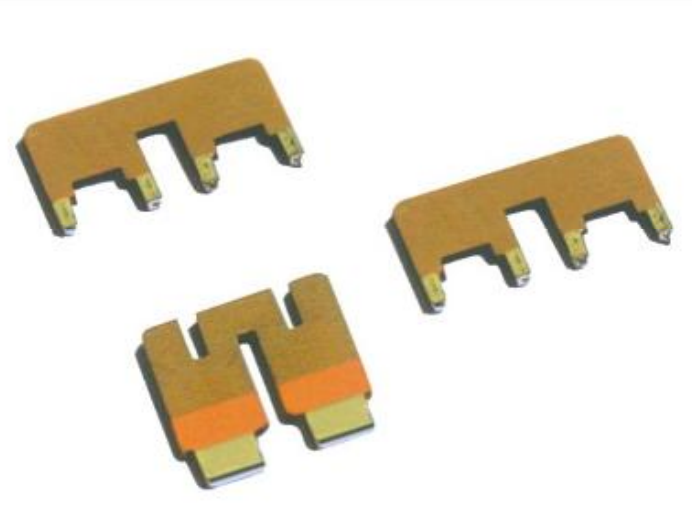

Factors Affecting the Accuracy of Precision Shunt Resistors

Several factors can influence the accuracy of precision shunt resistors, thereby affecting the reliability of current sensing. These factors include:

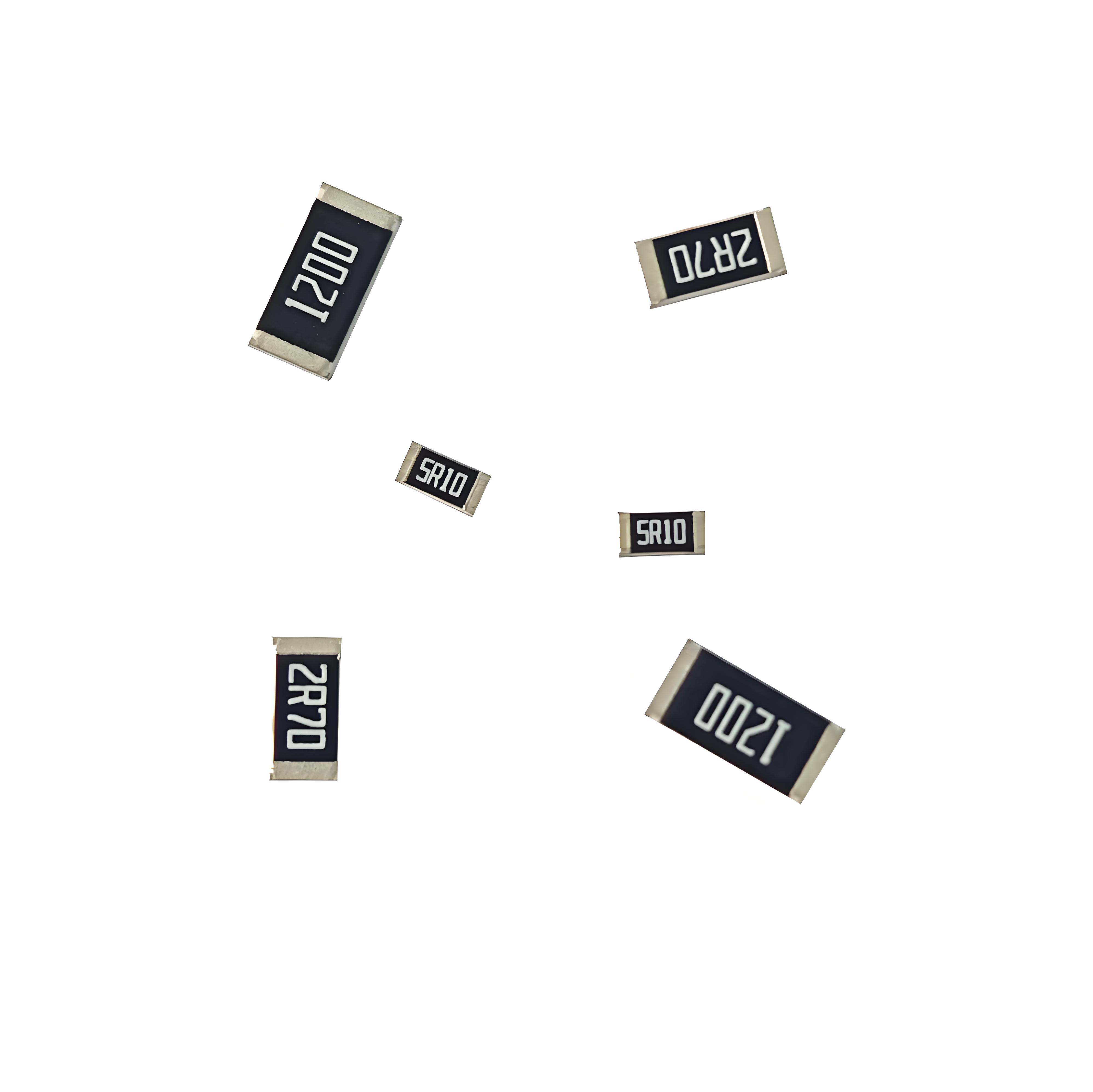

Resistance Tolerance: The precision of the resistance value is crucial. A resistor with a tighter tolerance will provide more accurate current measurements.

Temperature Coefficient: Changes in temperature can alter the resistance value. A resistor with a low temperature coefficient will exhibit less resistance variation over a range of temperatures.

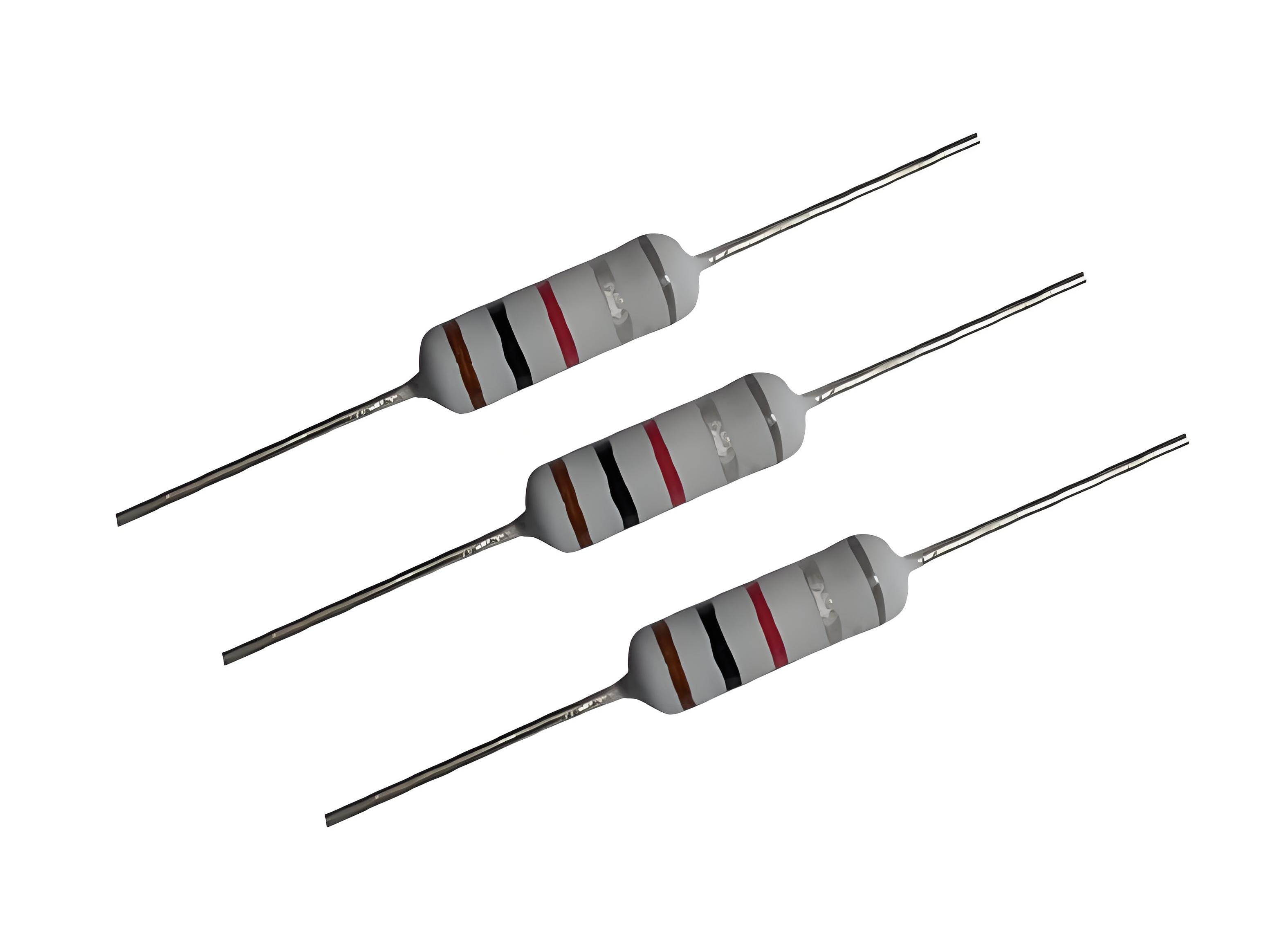

Power Rating: The ability of the resistor to dissipate power without changing its resistance value or burning out is essential for accurate and safe operation.

Material Quality: The type of material used in the resistor affects its stability, durability, and overall performance.

Understanding these factors is key to selecting the right precision shunt resistor for a specific application.

Problems and Solutions in Precision Shunt Resistors Application

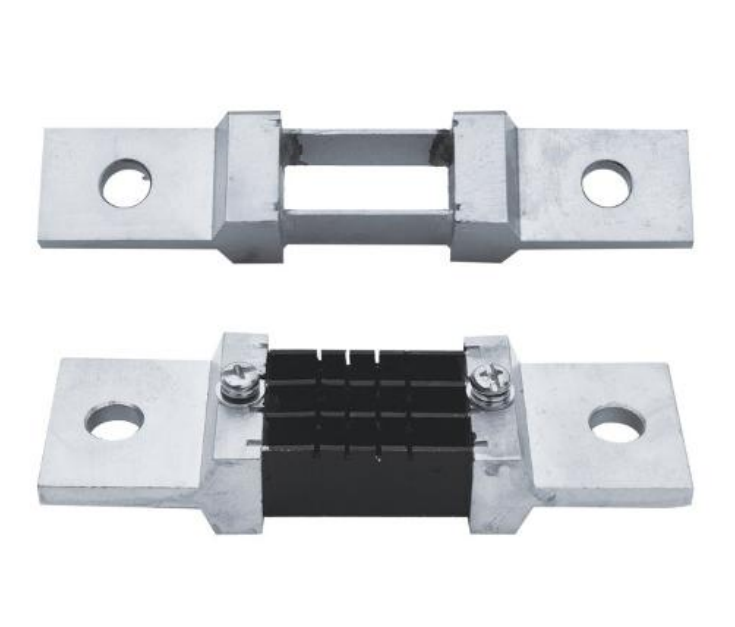

One common problem encountered when using precision shunt resistors is the issue of self-heating. As current flows through the resistor, it dissipates power as heat, which can increase the temperature of the resistor and, consequently, its resistance value. This can lead to inaccurate current readings and potential system malfunctions.

Solution: To mitigate the impact of self-heating, it is recommended to:

Select a precision shunt resistor with a higher power rating than the maximum expected power dissipation in the application.

Ensure proper heat dissipation by providing adequate ventilation or using a heatsink if necessary.

Choose a resistor with a low temperature coefficient to minimize resistance changes due to temperature variations.

For instance, in a high-current motor control application where the maximum current is 100A and the voltage drop across the shunt resistor is 50mV, the power dissipation can be calculated as follows:

P = IV = 100A * 0.05V = 5W

In this case, selecting a precision shunt resistor with a power rating of at least 10W and a low temperature coefficient would ensure accurate current measurements and reliable operation.

Case Study

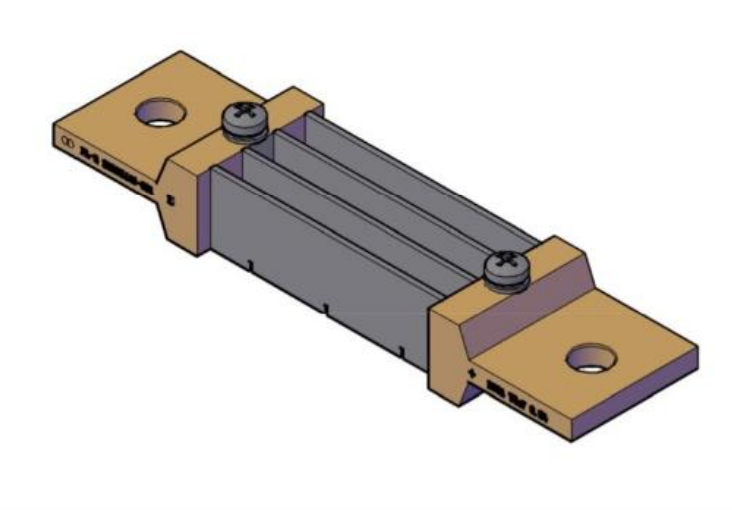

A manufacturing company was experiencing issues with the accuracy of its motor control system's current sensing. The motor was drawing more current than expected, leading to frequent system shutdowns and reduced efficiency. Upon investigation, it was discovered that the precision shunt resistor in use had a high temperature coefficient and was not adequately rated for the power dissipation.

Action Taken:

Replaced the existing shunt resistor with a precision shunt resistor from a reputable manufacturer with a low temperature coefficient (±10ppm/°C) and a higher power rating (20W).

Installed a heatsink to improve heat dissipation.

Results:

| Parameter | Before Replacement | After Replacement |

|---|---|---|

| Current Measurement Accuracy | ±5% | ±0.5% |

| System Efficiency | 80% | 95% |

| System Shutdowns | 5 per week | 0 per week |

The replacement of the precision shunt resistor significantly improved the accuracy of current sensing, increased system efficiency, and eliminated system shutdowns, resulting in a more reliable and efficient motor control system.

Conclusion

Precision shunt resistors are indispensable for accurate current sensing in a variety of applications. Their accuracy is influenced by several factors, including resistance tolerance, temperature coefficient, power rating, and material quality. By addressing potential issues such as self-heating through careful selection and proper installation, the reliability and precision of current sensing can be greatly enhanced. The case study highlighted in this article demonstrates the significant improvements that can be achieved by using the right precision shunt resistor. As technology advances and demands for precise current measurements continue to grow, understanding and effectively utilizing precision shunt resistors will remain a vital skill for engineers and designers in the field of electronics and electrical engineering.