Thin Film Precision Resistors: Benefits and Applications for High - Accuracy Electronics

Thin film precision resistors have become indispensable in high - accuracy electronic applications. This article explores the benefits and applications of thin film precision resistors and explains why they are essential for achieving precision and reliability in modern electronics.

Introduction

In modern electronics, precision is critical. Thin film precision resistors play a crucial role in ensuring accuracy and reliability in electronic circuits. These resistors are widely used in applications where tight resistance tolerance and low temperature coefficient are required, such as in medical devices, test equipment, and aerospace systems.

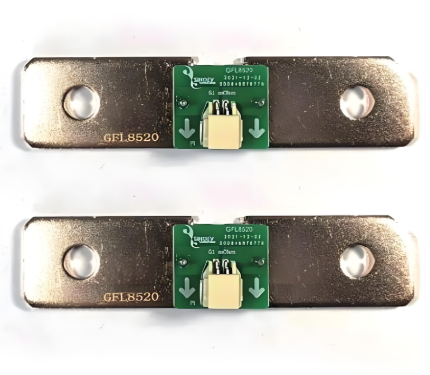

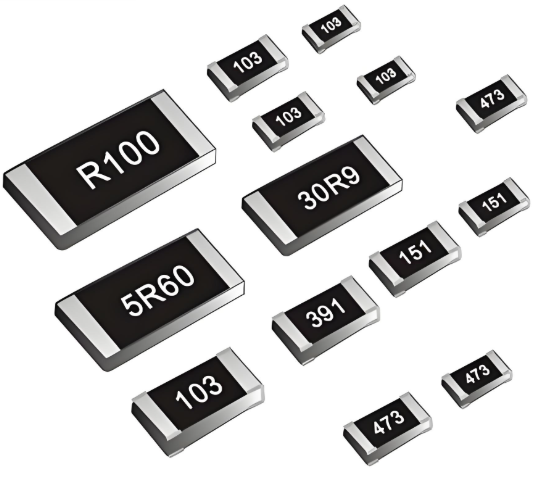

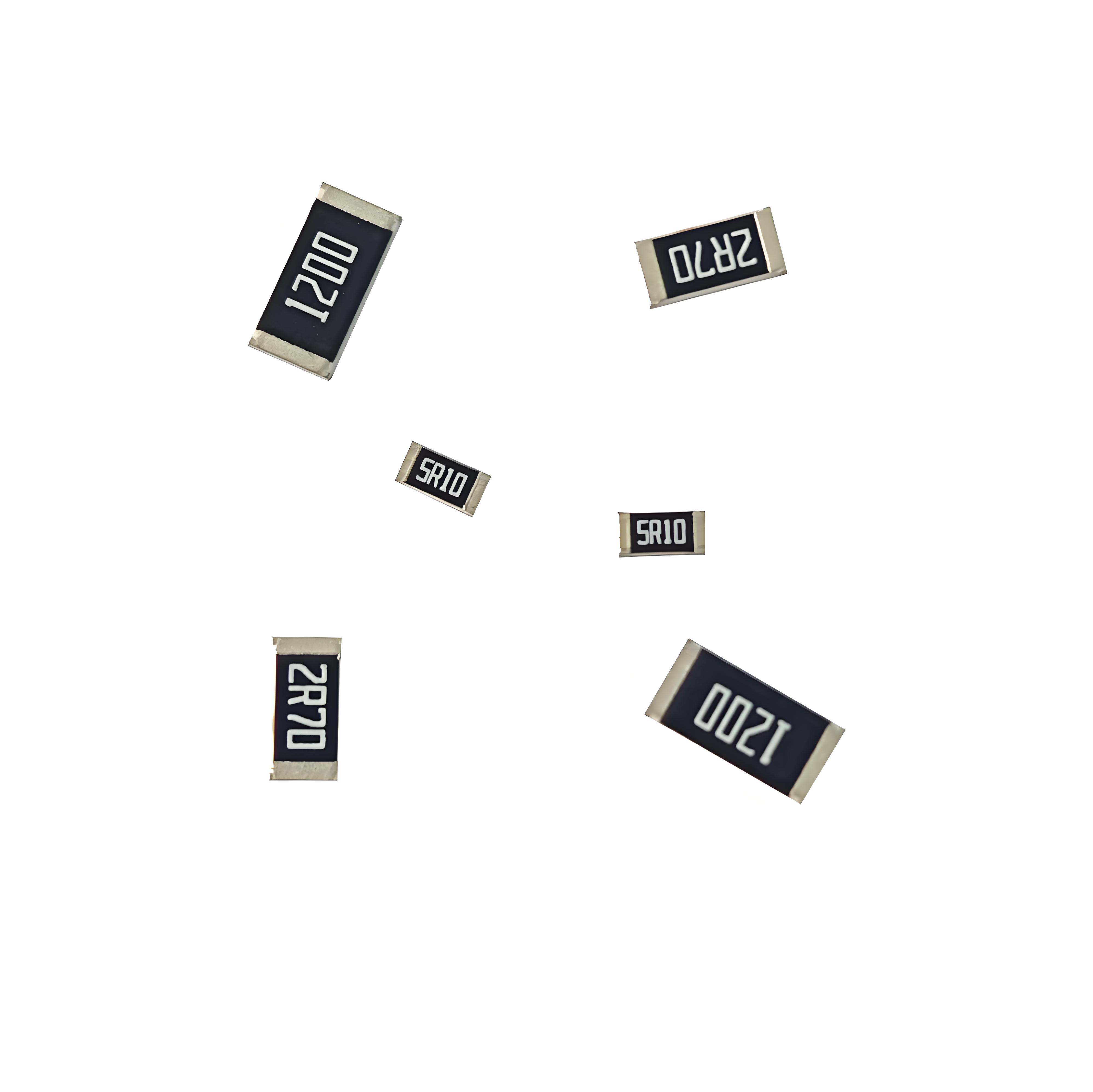

Thin Film Precision Resistor Design

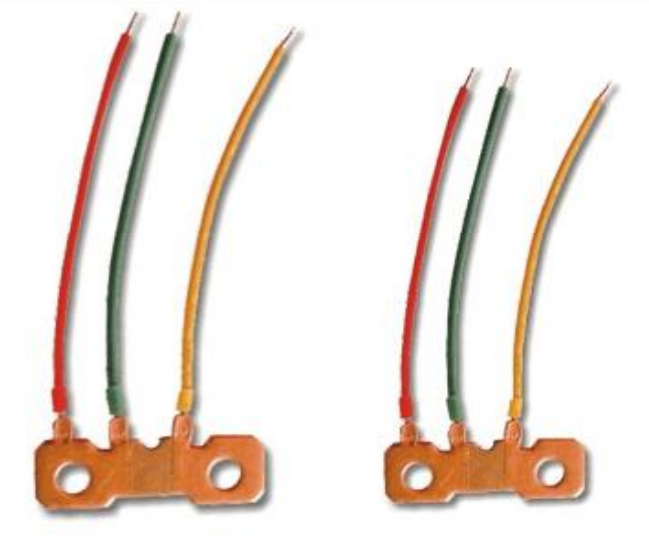

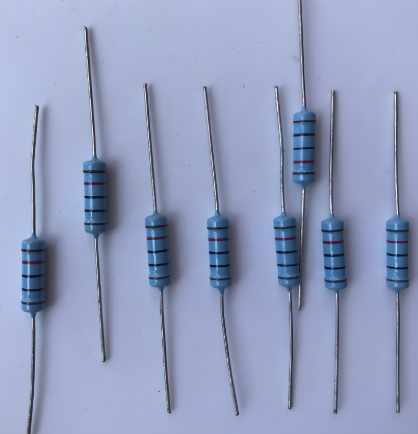

Thin film precision resistors are designed to achieve high precision and stability. Their design involves several key features:

Material

Thin film resistors are typically made from materials such as nichrome or tantalum nitride. These materials offer excellent stability and low temperature coefficients, making them ideal for precision applications.

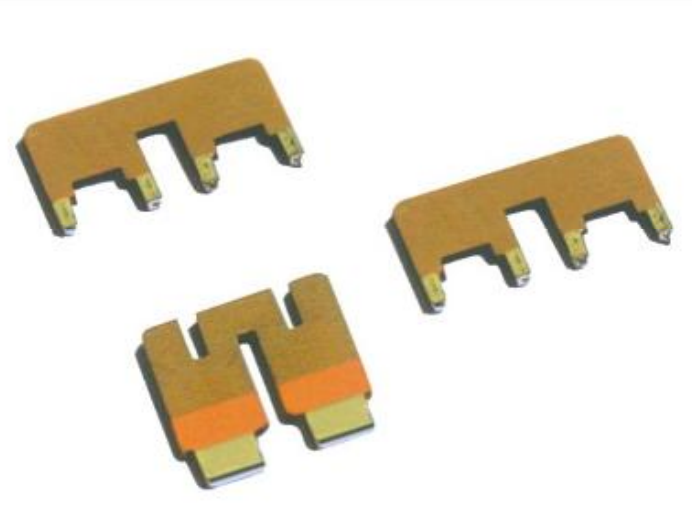

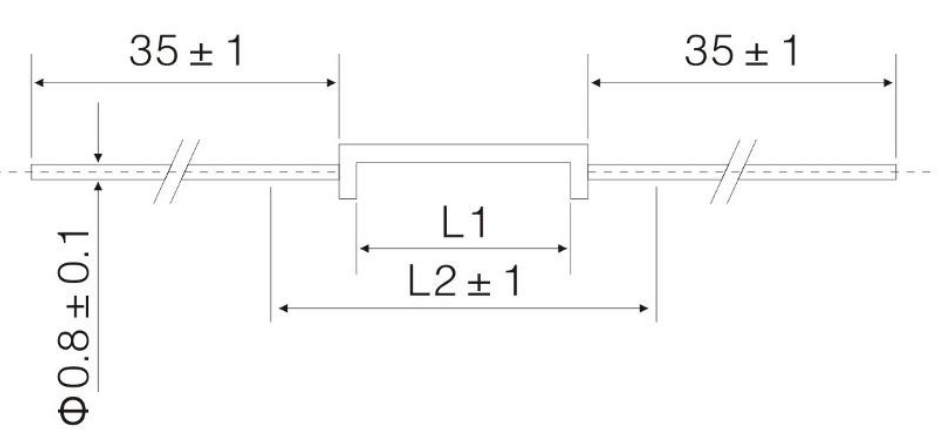

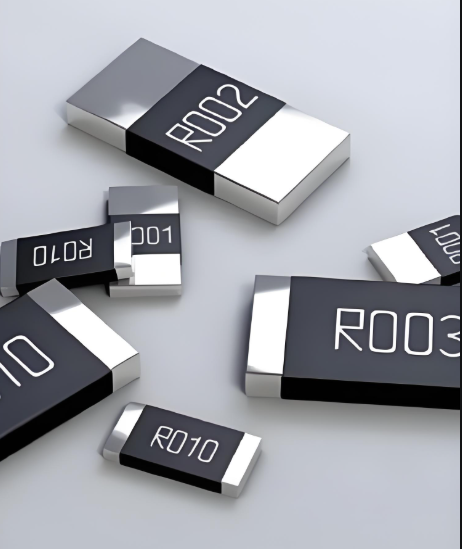

Geometry

The resistive element is deposited as a thin film onto a ceramic substrate and then patterned into a specific geometry. This allows for precise control over the resistance value and ensures consistency across different batches.

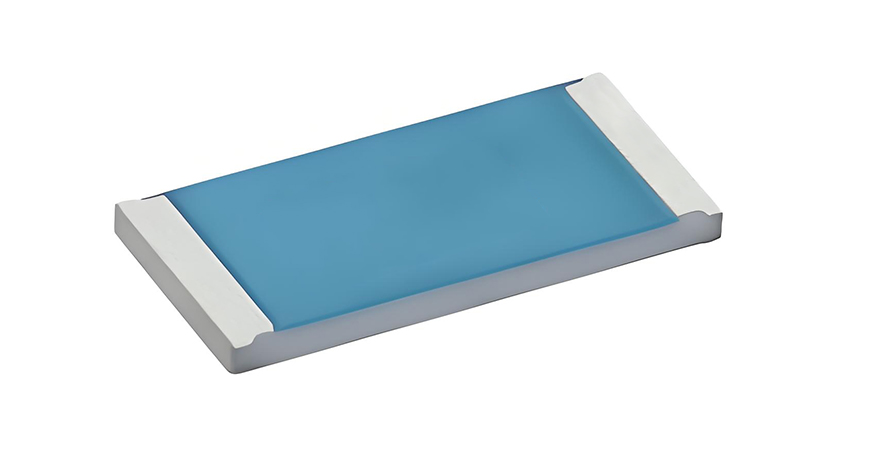

Protective Coating

A protective coating is applied over the resistive film to protect against environmental factors such as moisture and dust. This coating also helps to minimize resistance drift over time.

Manufacturing Process

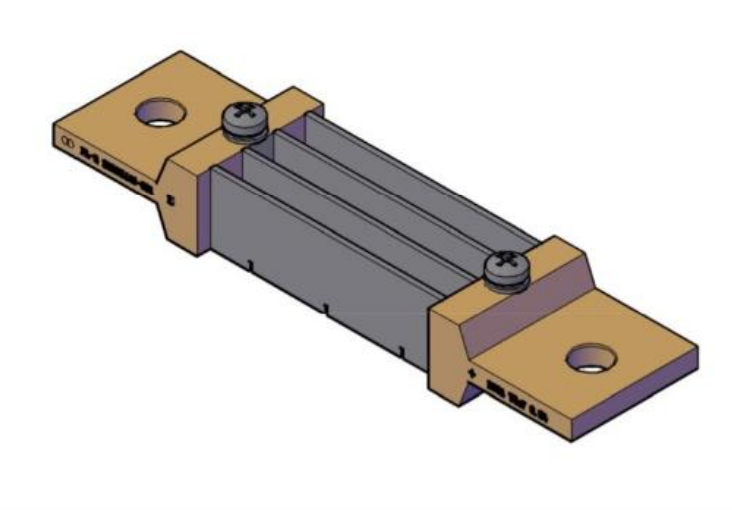

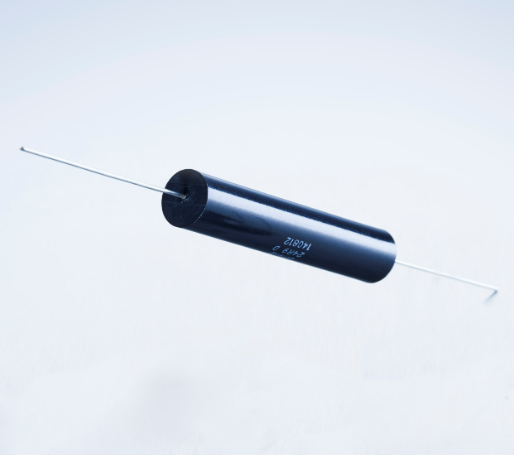

The manufacturing process of thin film precision resistors involves several sophisticated steps to ensure their high - quality performance.

Substrate Preparation

The ceramic substrate is carefully cleaned and polished to ensure a smooth and uniform surface for the deposition of the resistive film.

Resistive Film Deposition

The resistive material is deposited onto the substrate using advanced techniques such as sputtering or electron - beam evaporation. This creates a thin, uniform resistive layer with a thickness typically ranging from a few nanometers to several micrometers.

Patterning and Etching

Photolithography is used to pattern the resistive film into the desired geometry. The patterned film is then etched to remove the unwanted material, leaving behind the precise resistor pattern.

Protective Coating Application

A protective coating is applied over the resistive element to protect it from environmental factors and mechanical damage. This coating is typically applied using methods such as chemical vapor deposition or spin - coating.

Performance Characteristics

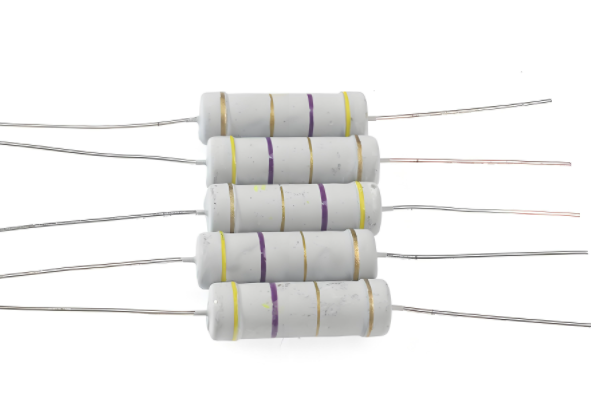

Thin film precision resistors are known for their exceptional performance in various critical parameters. The following table compares their key performance metrics with those of traditional wire - wound and thick - film resistors.

| Parameter | Thin Film Precision Resistor | Wire - Wound Resistor | Thick - Film Resistor |

|---|---|---|---|

| Resistance Tolerance | ±0.01% to ±0.1% | ±0.1% to ±1% | ±1% to ±5% |

| Temperature Coefficient of Resistance (TCR) | ±0.5 ppm/°C to ±5 ppm/°C | ±5 ppm/°C to ±100 ppm/°C | ±50 ppm/°C to ±200 ppm/°C |

| Operating Temperature Range | -55°C to +125°C | -40°C to +200°C | -55°C to +155°C |

| Power Rating | 0.1W to 1W | 0.5W to 10W | 0.1W to 5W |

| Frequenxy Response | Up to GHz | Up to MHz | Up to MHz |

As shown in the table, thin film precision resistors offer tighter resistance tolerance, lower TCR, and better frequency response compared to traditional resistors. These characteristics make them ideal for high - accuracy applications.

Applications

Thin film precision resistors are used in a wide range of high - accuracy applications.

Medical Equipment

In medical devices such as imaging systems and patient monitors, thin film precision resistors ensure accurate readings and reliable performance. Their low TCR and tight tolerance help maintain precision in critical measurements.

Test and Measurement Equipment

These resistors are used in precision test and measurement instruments such as multimeters and oscilloscopes. Their high accuracy and stability ensure reliable and repeatable measurements.

Industrial Automation

In industrial control systems and automation equipment, thin film precision resistors provide the necessary accuracy for precise control and monitoring of processes.

Aerospace and Defense

The high reliability and stability of thin film precision resistors make them suitable for use in aerospace and defense systems, where they are used in guidance systems, communication equipment, and other critical applications.

Problem and Solution

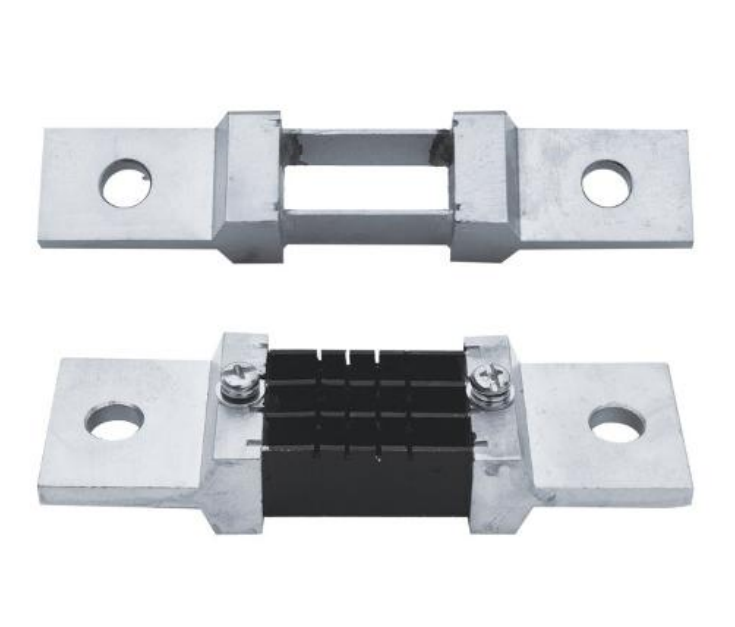

A common problem in high - precision resistor applications is achieving both low TCR and high - power handling capability. Traditional resistors with high power ratings often have higher TCRs, which can affect accuracy in temperature - varying environments.

Solution: Thin film precision resistors address this issue by offering a combination of low TCR and high - power handling capability. Their thin - film design allows for precise control over resistance and TCR, while their construction provides sufficient power rating for most applications. This makes them suitable for use in a wide range of high - accuracy electronic systems where both precision and power handling are required.

Best Practices

To maximize the benefits of thin film precision resistors, certain best practices should be followed.

Proper Soldering Techniques

Use proper soldering techniques to avoid thermal stress on the resistors. Excessive heat during soldering can affect the resistor's performance and stability.

Thermal Management

Implement effective thermal management solutions to prevent overheating. This can include the use of heat sinks or proper ventilation, especially in high - power applications.

Regular Testing and Calibration

Regularly test and calibrate the resistors to ensure their performance remains within the specified tolerance. This is especially important in high - accuracy applications where even small deviations can affect system performance.

Proper Storage and Handling

Store and handle the resistors in a controlled environment to prevent damage and contamination. This ensures that the resistor's performance is not affected by environmental factors.

Conclusion

Thin film precision resistors are essential for high - accuracy electronics due to their exceptional performance characteristics. Their low TCR, high precision, and excellent frequency response make them suitable for a wide range of critical applications. By following best practices in their use and handling, engineers can ensure that these resistors continue to provide reliable and accurate performance in high - precision electronic systems.