Introduction

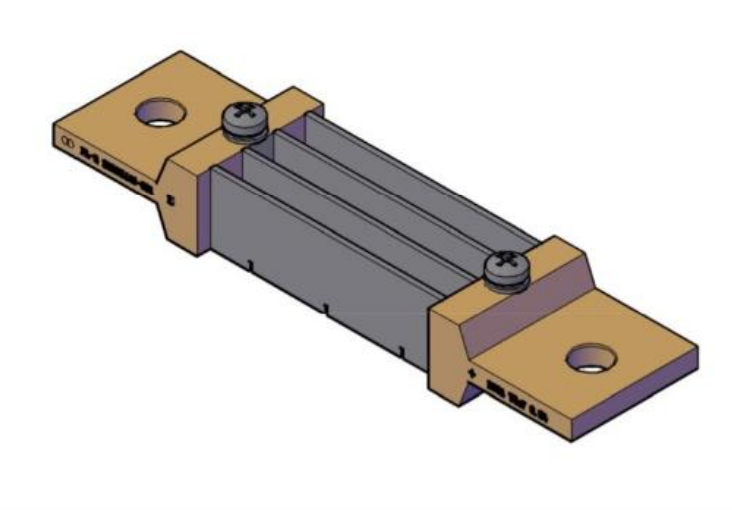

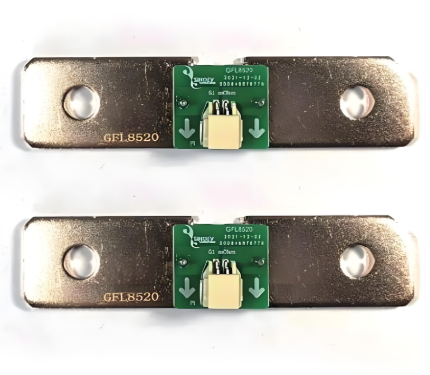

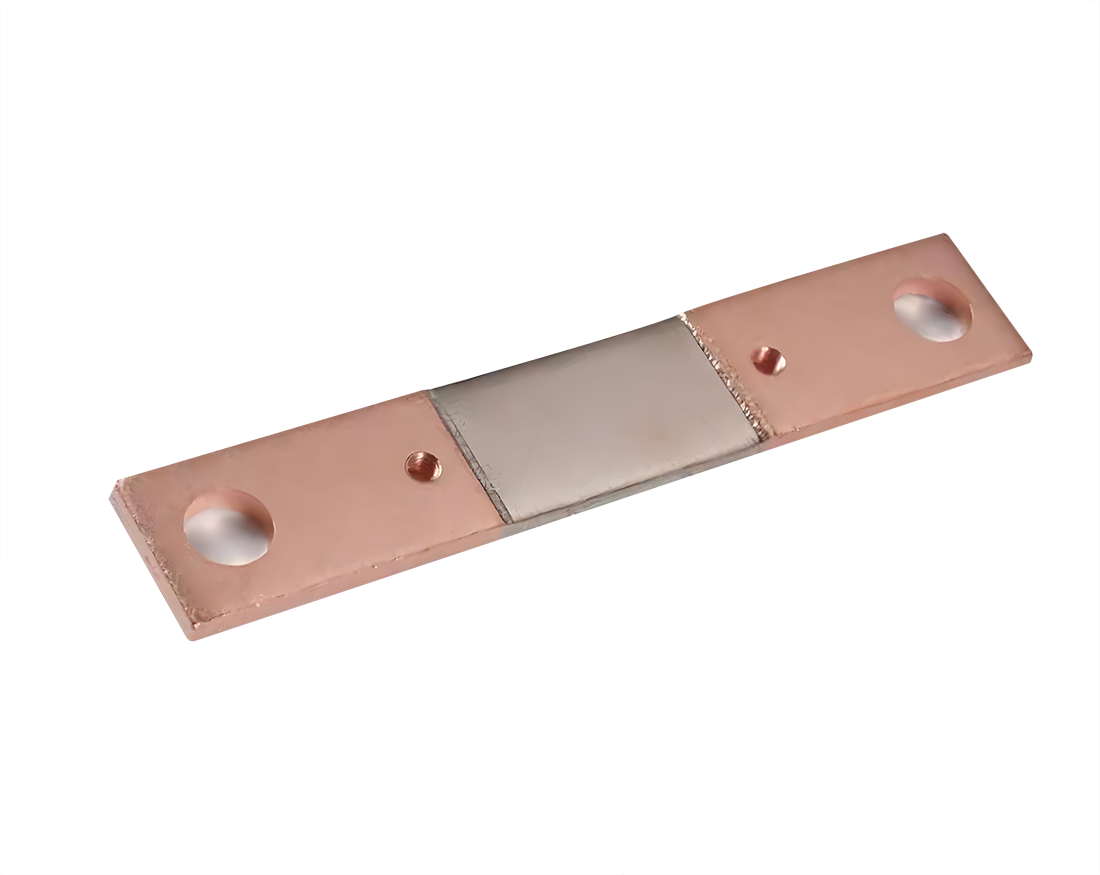

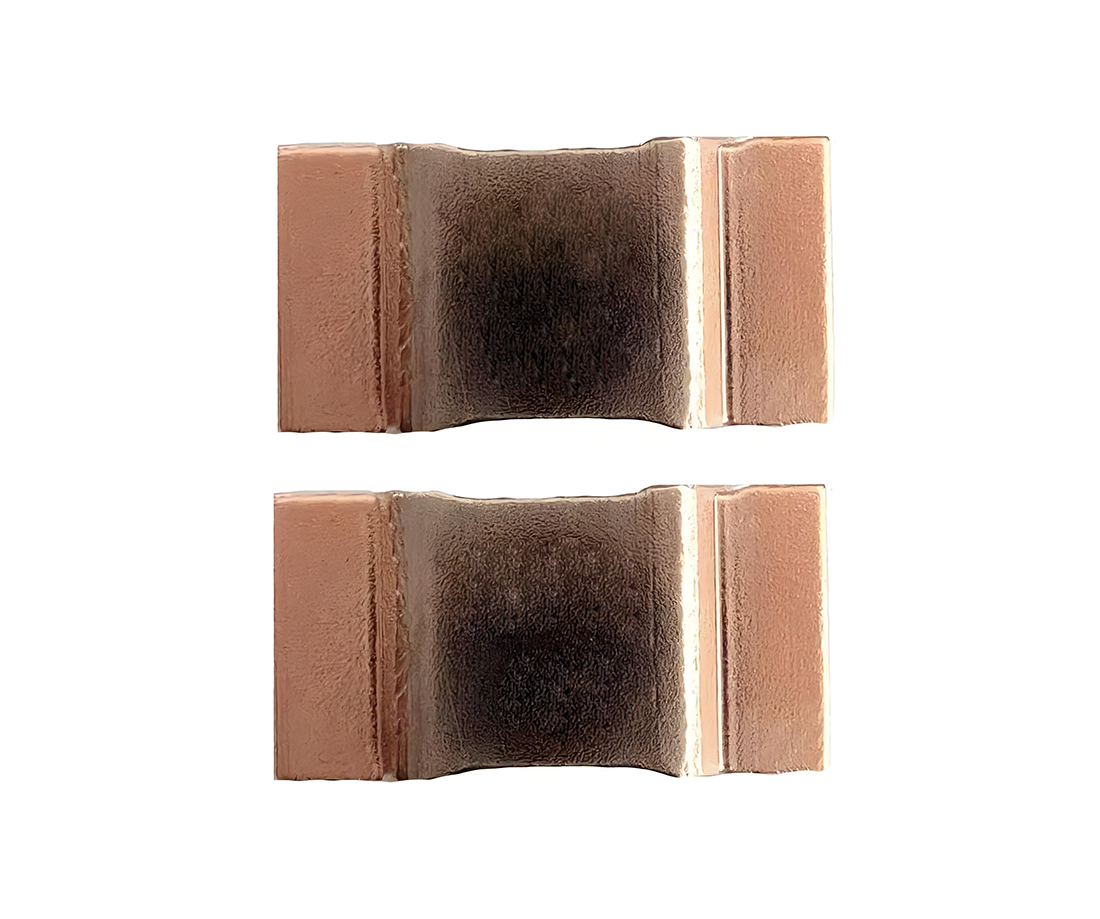

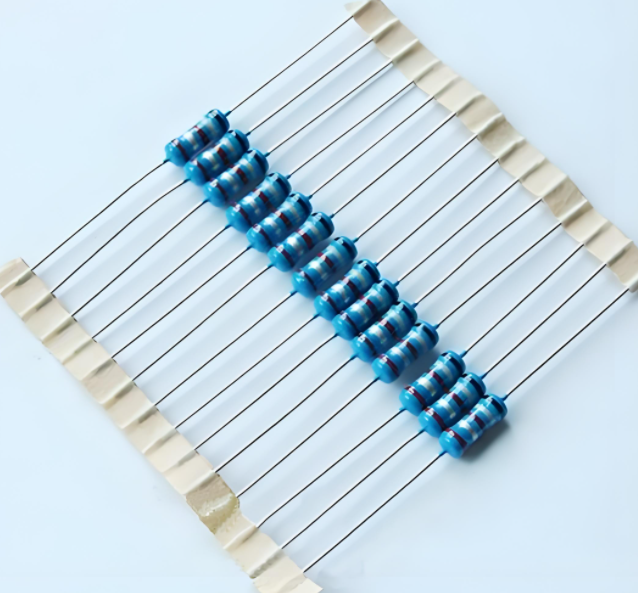

In the realm of electrical engineering and electronics, precise current measurement is crucial for a wide range of applications, from power systems to sensitive electronic circuits. The low inductance shunt resistor plays a vital role in achieving high-precision current sensing. This article delves into the applications, benefits, and technical specifications of low inductance shunt resistors, highlighting their significance in modern electrical systems.

We will also address a common challenge faced by engineers and provide a practical solution to ensure optimal performance when using low inductance shunt resistors.

Applications of Low Inductance Shunt Resistors

Low inductance shunt resistors are widely used across various industries due to their ability to provide accurate current measurements with minimal interference. Below are some key applications:

| Application | Description |

|---|---|

| Power Electronics | Used in inverters, converters, and motor drives for precise current monitoring. |

| Automotive Systems | Essential for battery management systems and electric vehicle powertrains. |

| Renewable Energy | Deployed in solar inverters and wind turbines for current sensing. |

| Industrial Automation | Utilized in PLCs and motor control systems for accurate current feedback. |

| Medical Equipment | Used in medical imaging devices and life support systems for reliable current sensing. |

Benefits of Low Inductance Shunt Resistors

The use of low inductance shunt resistors offers several advantages that make them indispensable in high-precision current sensing applications. These benefits include:

High Precision: Low inductance ensures minimal phase shift and accurate current measurement.

Low Power Loss: High precision with low resistance values results in minimal power dissipation.

Wide Frequency Range: Suitable for both DC and high-frequency AC applications.

Stability: Low temperature coefficient ensures consistent performance over a wide temperature range.

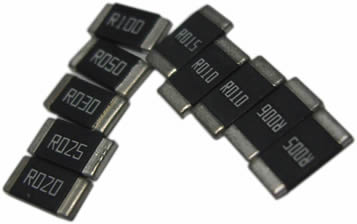

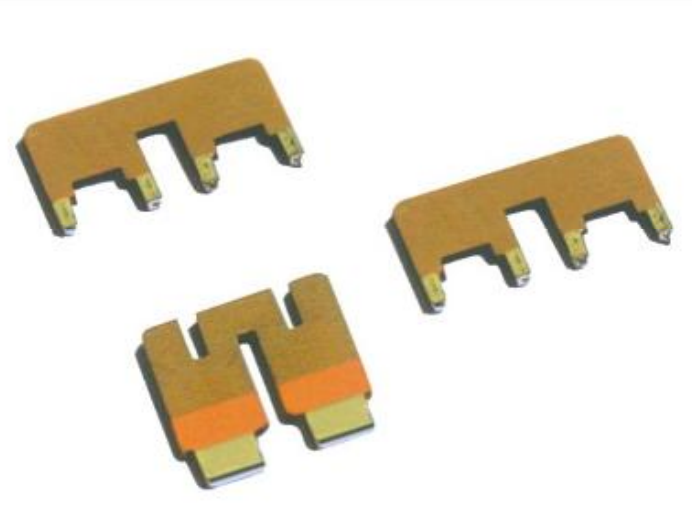

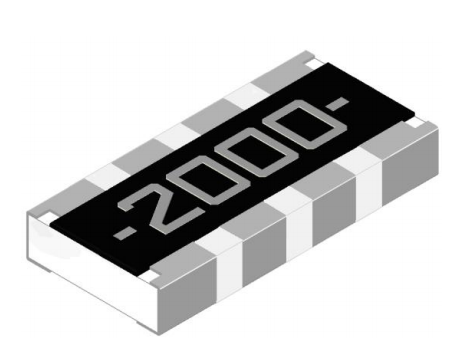

Compact Size: Available in small form factors for space-constrained applications.

Technical Specifications

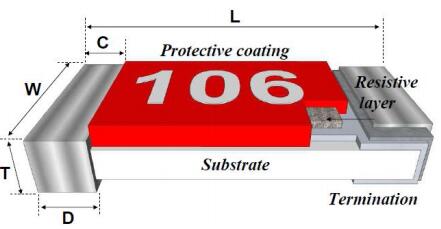

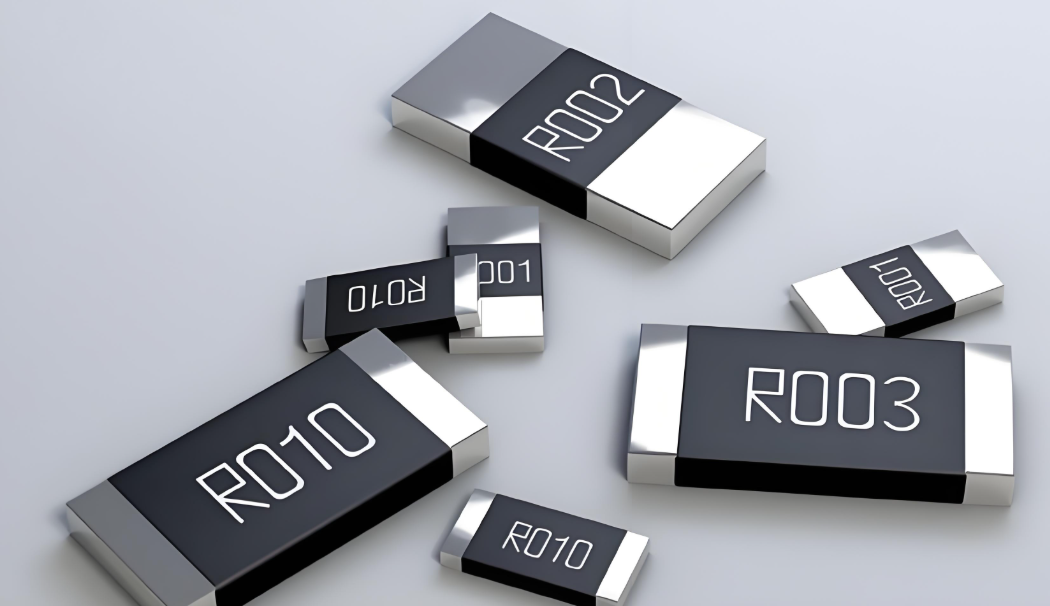

To select the right low inductance shunt resistor, it is essential to understand its key technical specifications. Below are some critical parameters:

| Parameter | Typical Value | Unit |

|---|---|---|

| Resistance | 0.01 to 1 | Ω |

| Inductance | Less than 10 | nH |

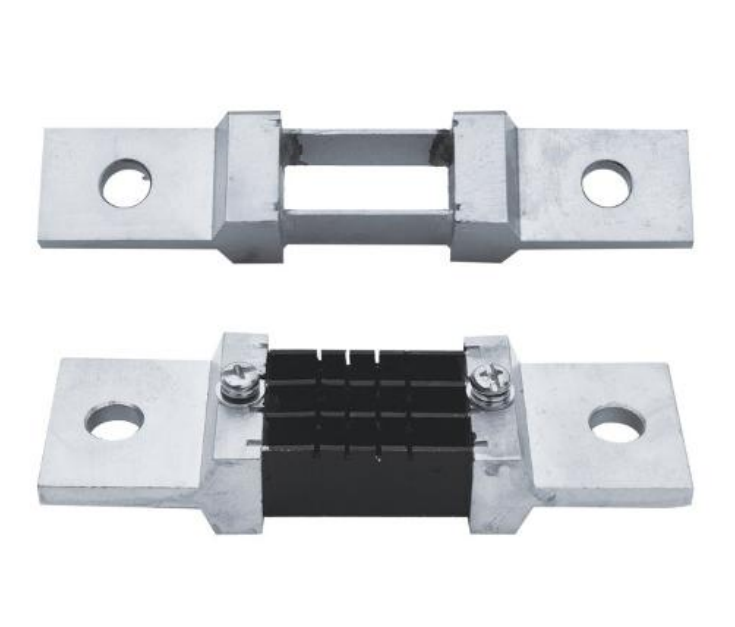

| Power Rating | 1 to 100 | W |

| Temperature Coefficient | ±25 | ppm/°C |

| Operating Temperature Range | -40 to +125 | °C |

Common Problem and Solution

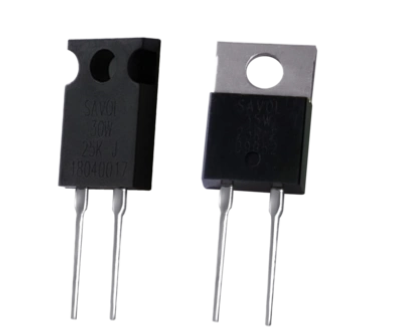

One common challenge faced by engineers when using low inductance shunt resistors is the thermal drift of resistance values. This can lead to inaccuracies in current measurements, especially in high-power applications.

Solution: To mitigate thermal drift, it is recommended to use shunt resistors with a low temperature coefficient (e.g., ±25 ppm/°C). Additionally, proper heat sinking and thermal management techniques should be employed to maintain a stable operating temperature. For instance, mounting the shunt resistor on a heatsink or using forced air cooling can help dissipate excess heat.

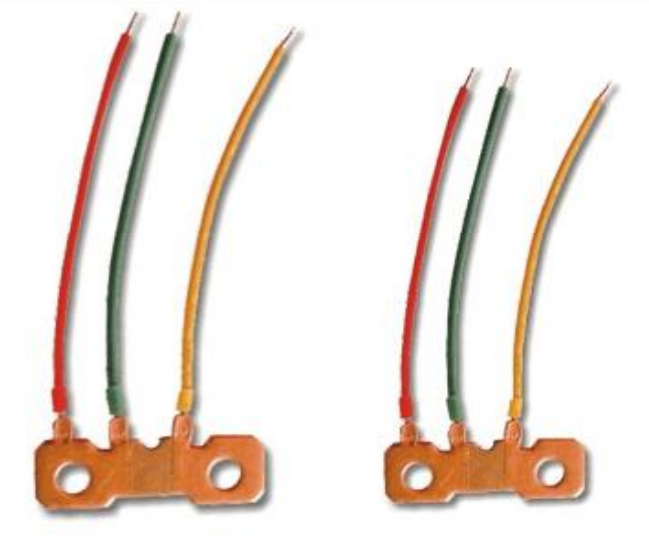

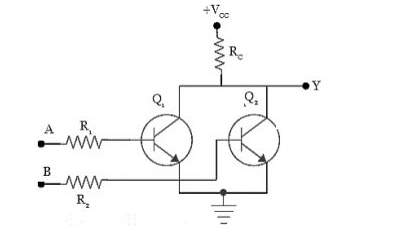

Another practical solution is to select shunt resistors with a four-terminal (Kelvin) configuration, which separates the current-carrying terminals from the voltage-sensing terminals. This configuration minimizes the impact of lead resistance and improves measurement accuracy.

Conclusion

Low inductance shunt resistors are essential components for high-precision current sensing in a variety of applications. Their benefits, such as high precision, low power loss, and wide frequency range, make them ideal for demanding electrical systems. By understanding the technical specifications and addressing common challenges like thermal drift, engineers can ensure optimal performance and reliability in their designs.