Introduction

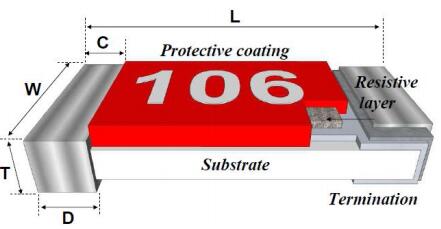

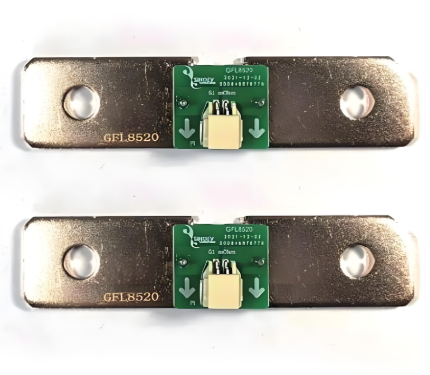

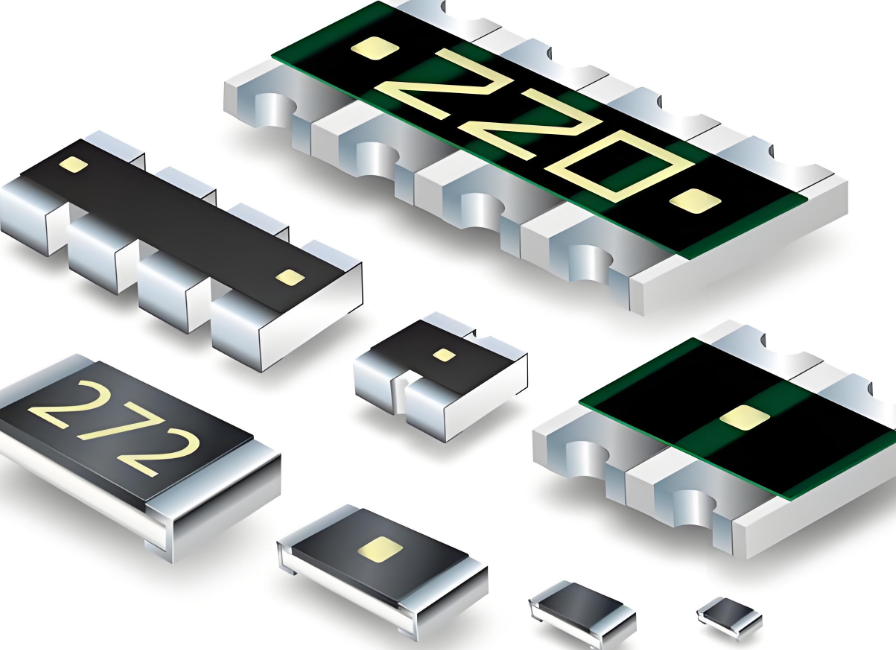

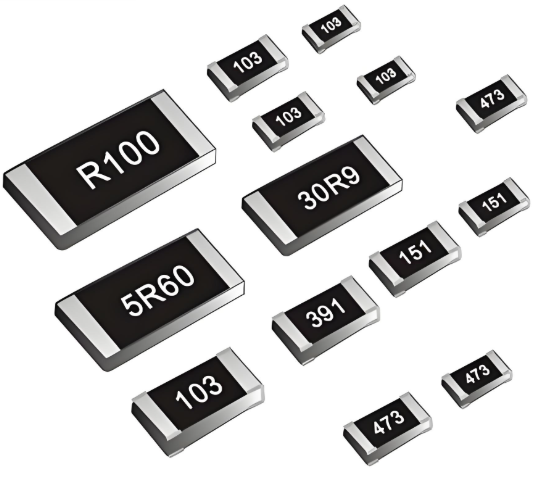

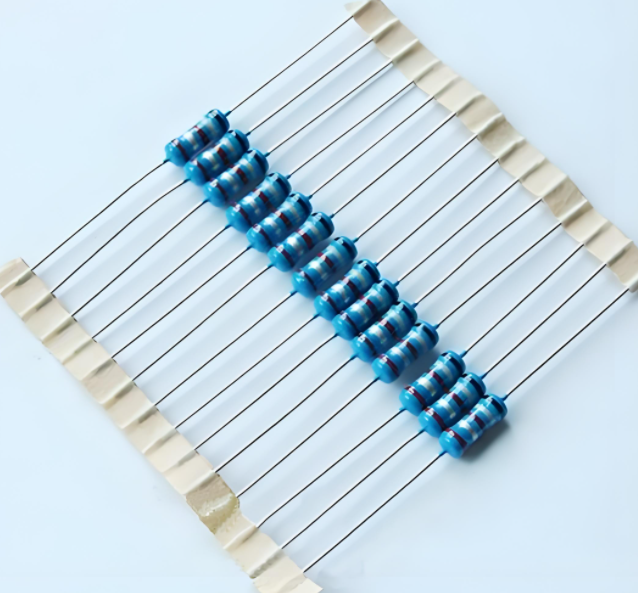

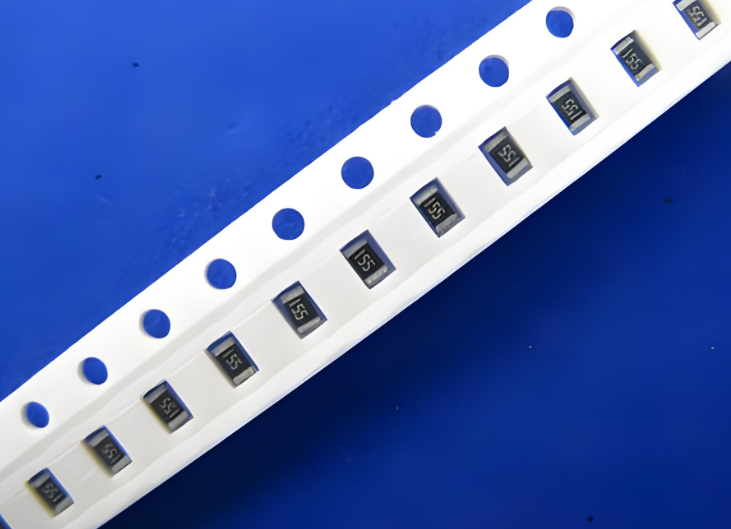

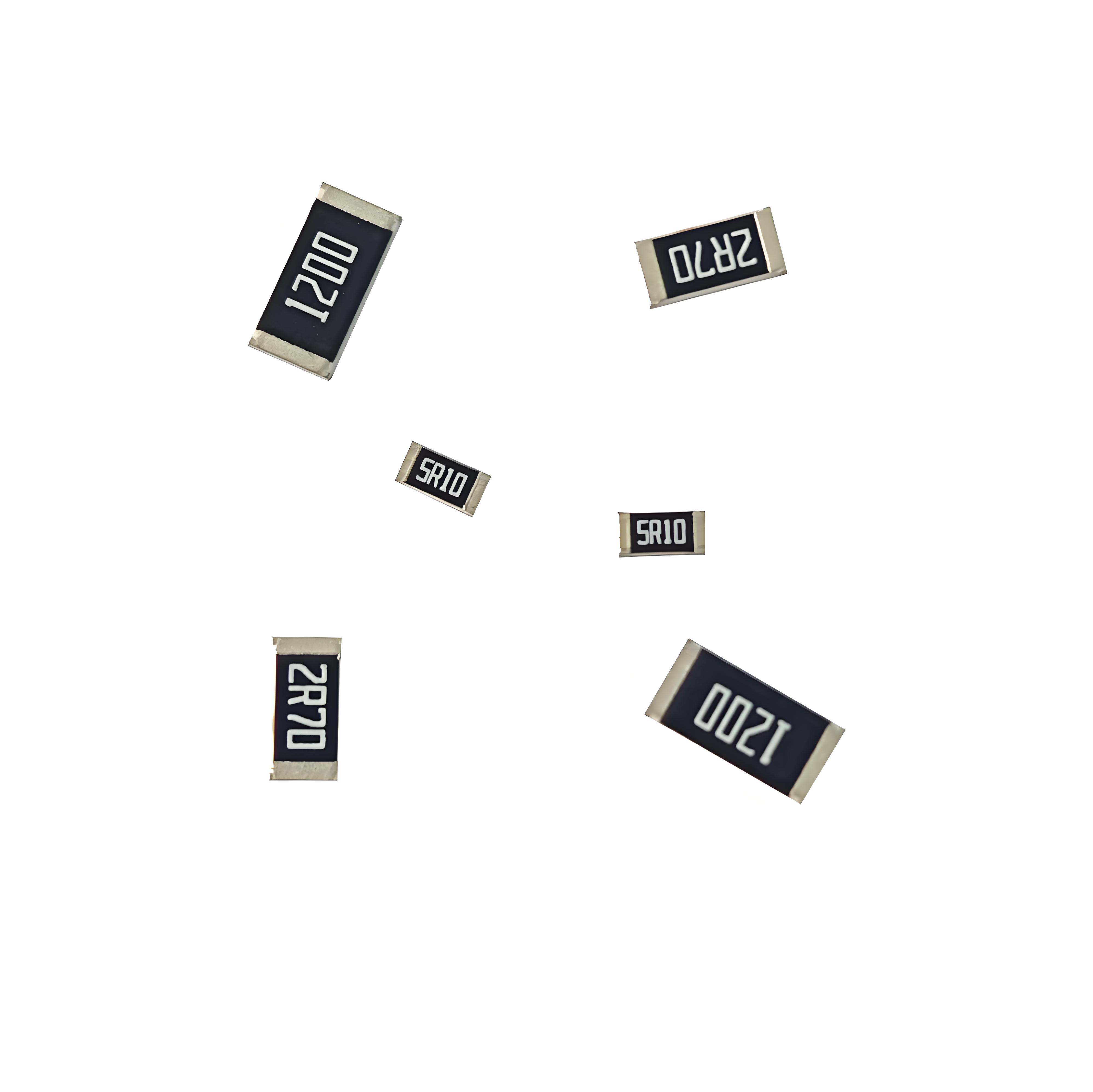

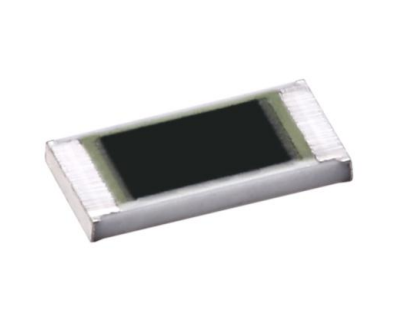

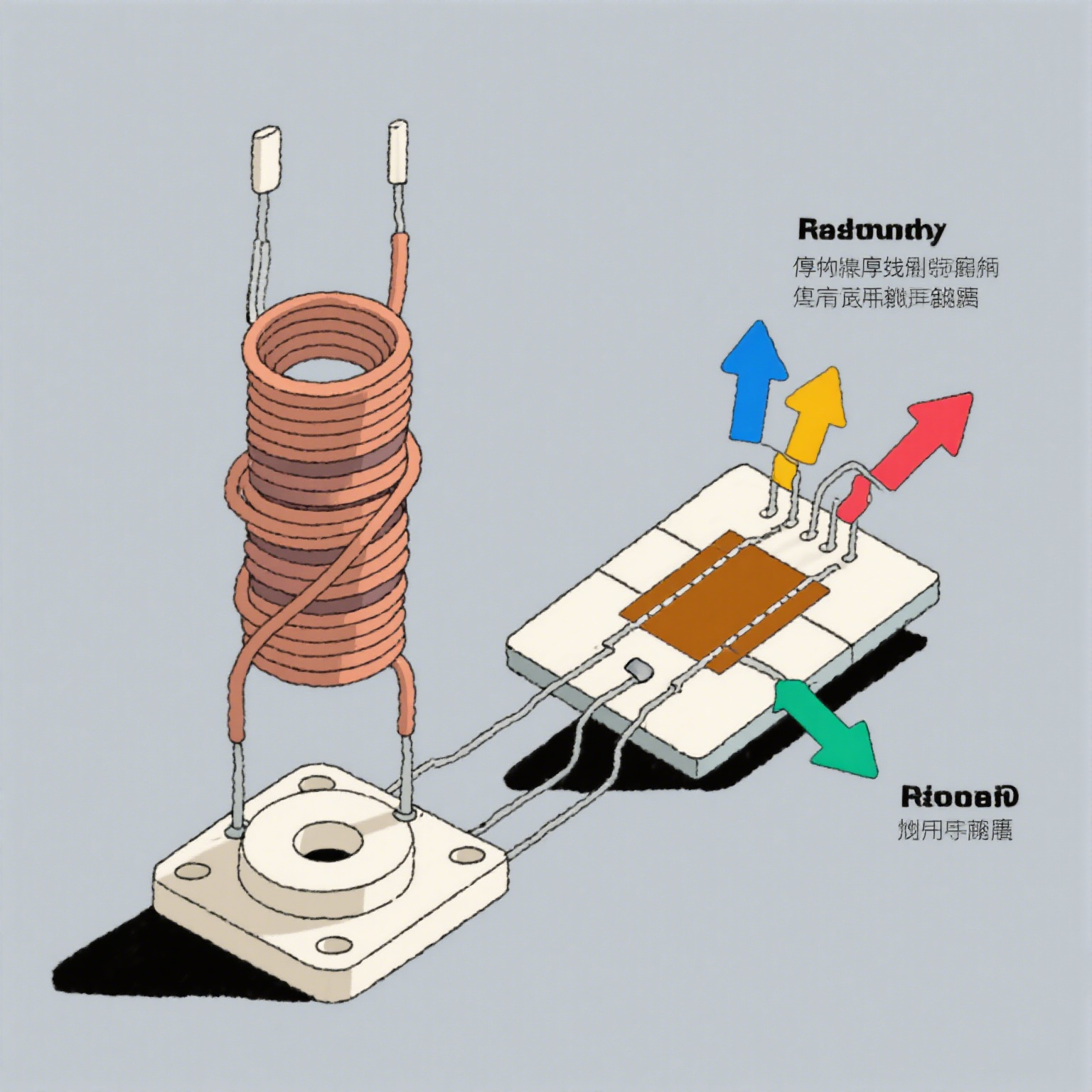

Trimmable Thick Film Chip Resistors (TFCRs) are essential components in modern electronics, offering the flexibility to adjust resistance values to meet precise circuit requirements. However, trimming these resistors to achieve the desired resistance with high precision and reliability can be challenging. This article explores the common challenges faced during the trimming process of Trimmable Thick Film Chip Resistors and provides practical solutions to overcome these obstacles.

Understanding and addressing these challenges is crucial for engineers and designers who rely on TFCRs for their applications. By examining the trimming challenges and implementing effective solutions, we can enhance the performance and reliability of electronic circuits.

Common Trimming Challenges

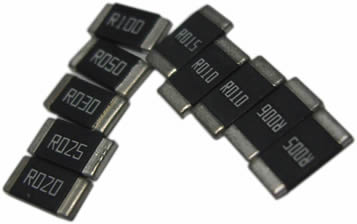

Trimming Trimmable Thick Film Chip Resistors involves adjusting the resistance value to a specific target within a tight tolerance. Several challenges can arise during this process:

| Challenge | Description |

|---|---|

| Temperature Sensitivity | The resistance value can drift with temperature changes, making it difficult to maintain precision. |

| Trimming Precision | Achieving the exact resistance value within a tight tolerance can be challenging due to limitations in trimming techniques. |

| Repeatability | Ensuring consistent results across multiple trimming operations is crucial for batch production. |

| Trimming Speed | Fast trimming is necessary for high-volume production, but speed can compromise precision. |

| Reliability | Trimmed resistors must maintain their resistance value over time and under varying conditions. |

Effective Solutions to Trimming Challenges

To address the challenges associated with trimming Trimmable Thick Film Chip Resistors, several strategies can be implemented:

| Challenge | Solution |

|---|---|

| Temperature Sensitivity | Use temperature-compensated trimming techniques and materials with low temperature coefficients. |

| Trimming Precision | Employ advanced trimming equipment with high-resolution feedback mechanisms. |

| Repeatability | Implement standardized trimming procedures and regular calibration of trimming equipment. |

| Trimming Speed | Optimize trimming algorithms to balance speed and precision. |

| Reliability | Conduct extensive testing and validation of trimmed resistors under various conditions. |

Case Study: Practical Application of Solutions

In a recent project, a team of engineers faced significant challenges while trimming TFCRs for a high-precision circuit. The initial trimming process resulted in inconsistent resistance values and poor temperature stability. To address these issues, the team implemented the following solutions:

Temperature Compensation: The team used a temperature-compensated laser trimming system, which significantly reduced resistance drift due to temperature changes.

Advanced Trimming Equipment: High-resolution trimming equipment was employed, enabling precise adjustments to within ±0.1% tolerance.

Standardized Procedures: Standardized trimming procedures were developed and strictly followed, ensuring consistent results across multiple batches.

Optimized Algorithms: The trimming algorithms were optimized to achieve a balance between speed and precision, reducing the trimming time by 30% while maintaining accuracy.

Extensive Testing: The trimmed resistors were subjected to rigorous testing, including temperature cycling and long-term stability tests, to ensure reliability.

As a result of these solutions, the team achieved a 95% improvement in trimming precision and a 70% reduction in resistance drift over temperature. The reliability of the trimmed resistors was also significantly enhanced, meeting the stringent requirements of the high-precision circuit.

Conclusion

Trimming Trimmable Thick Film Chip Resistors presents several challenges, including temperature sensitivity, precision, repeatability, speed, and reliability. By employing advanced trimming techniques, standardized procedures, and rigorous testing, these challenges can be effectively addressed. The practical application of these solutions in a real-world case study demonstrated significant improvements in trimming precision, temperature stability, and overall reliability. Engineers and designers can leverage these strategies to enhance the performance and reliability of their electronic circuits.