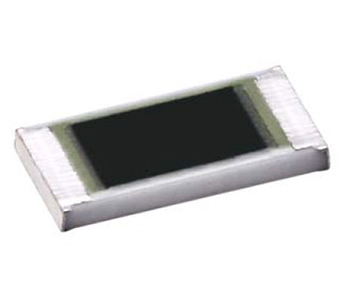

Thick Film Precision Chip Resistors: High - Performance Components for Reliable Electronics Manufacturing

In the rapidly evolving landscape of electronics manufacturing, the need for high - performance and reliable components has never been more critical. Thick film precision chip resistors have emerged as a cornerstone in this domain, offering a unique blend of precision, durability, and cost - effectiveness. This article explores the intricacies of thick film precision chip resistors, their manufacturing process, key performance characteristics, and diverse applications across various industries.

Table of Contents

Introduction

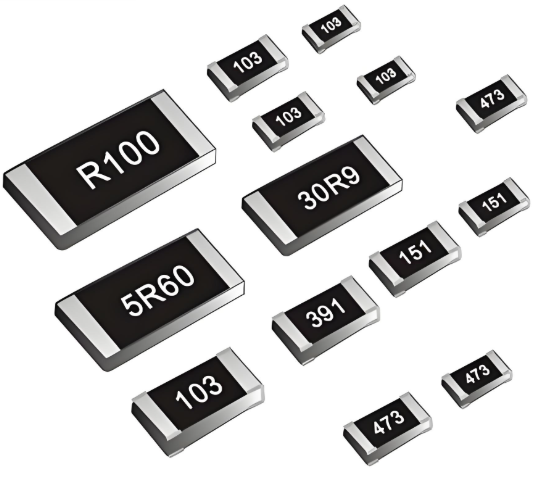

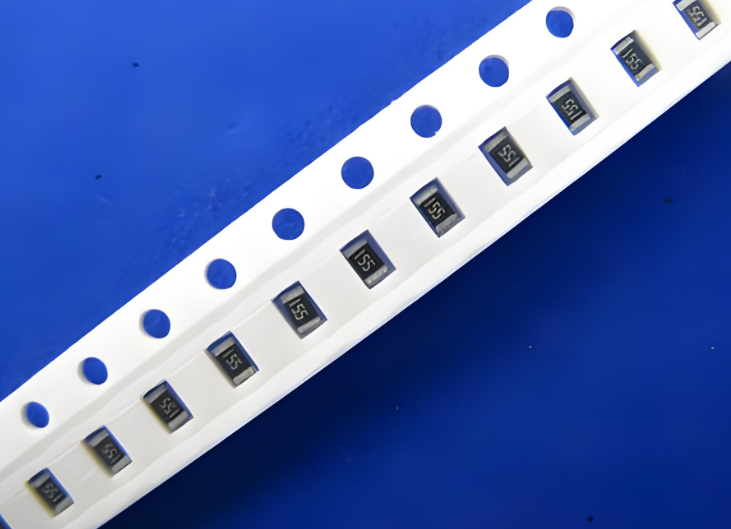

Thick film precision chip resistors are integral to modern electronics, providing reliable and precise resistance values in a compact form factor. These resistors are designed to meet the stringent demands of high - accuracy applications while offering robustness and cost - effectiveness. Their widespread use in consumer electronics, industrial control systems, and automotive electronics underscores their importance in ensuring the reliability and performance of electronic devices.

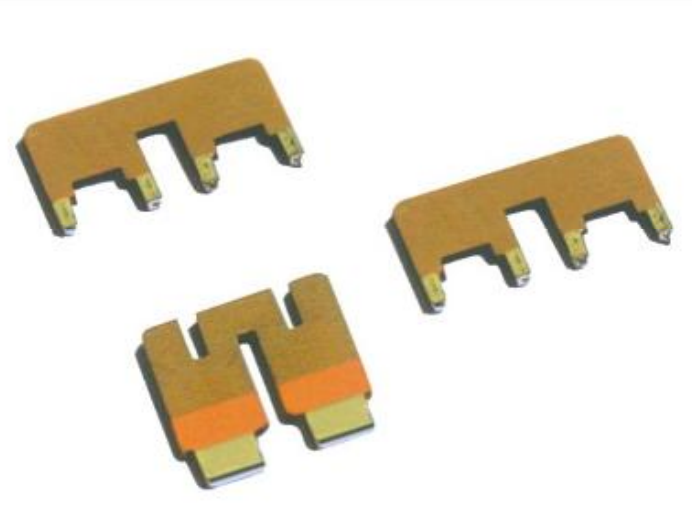

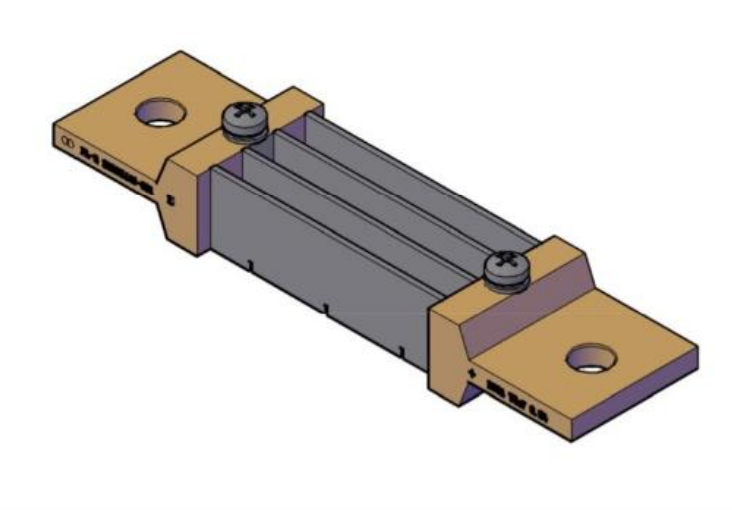

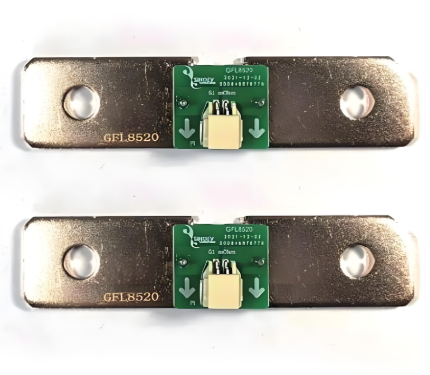

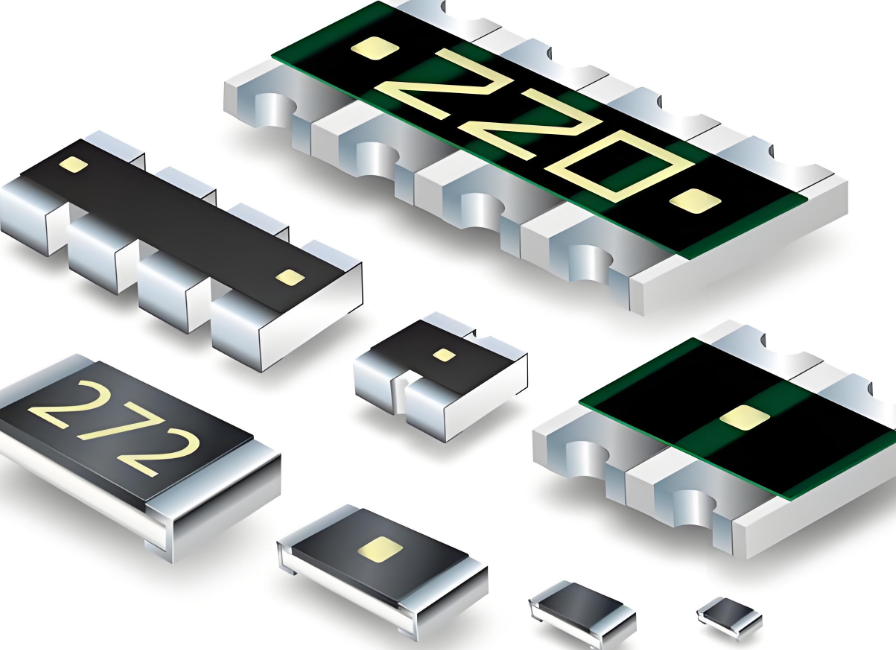

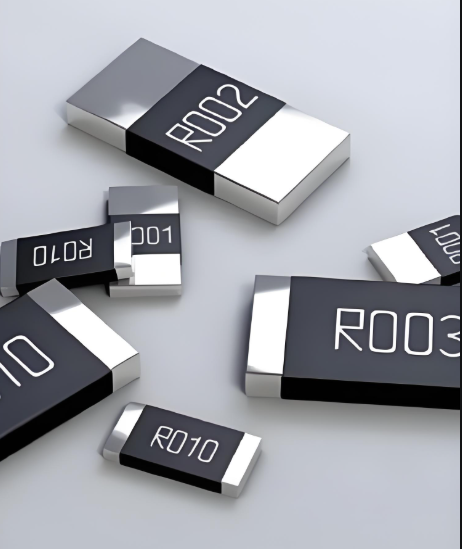

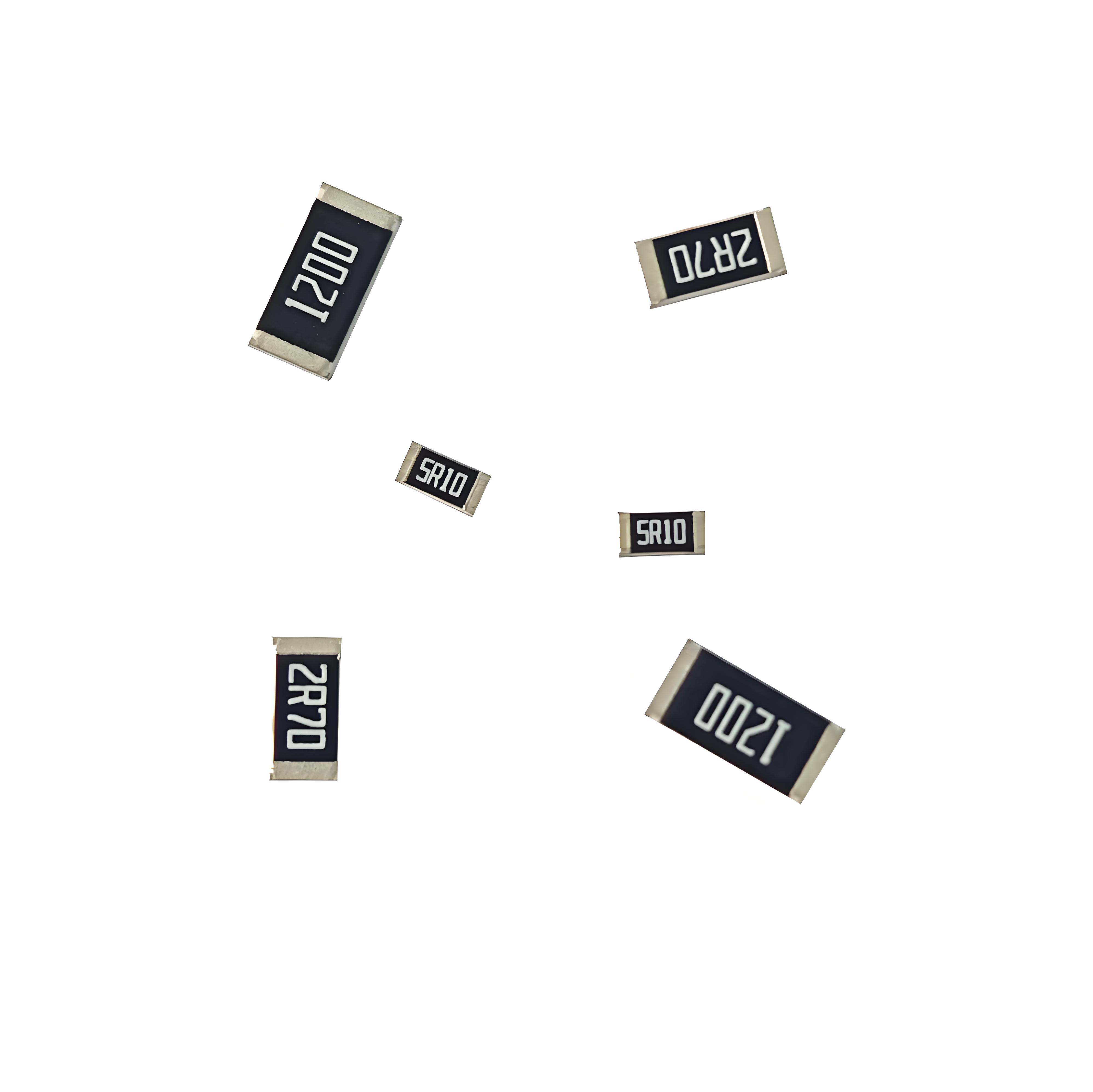

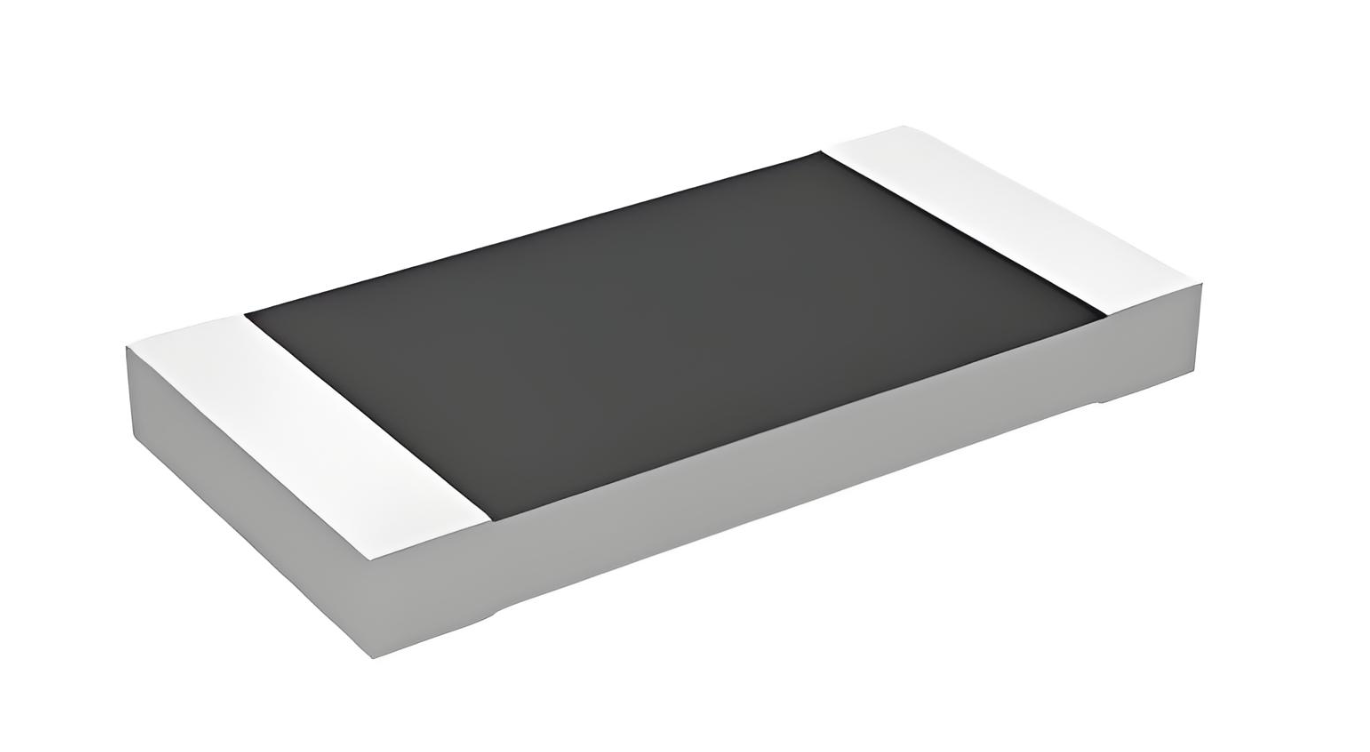

Design and Structure of Thick Film Precision Chip Resistors

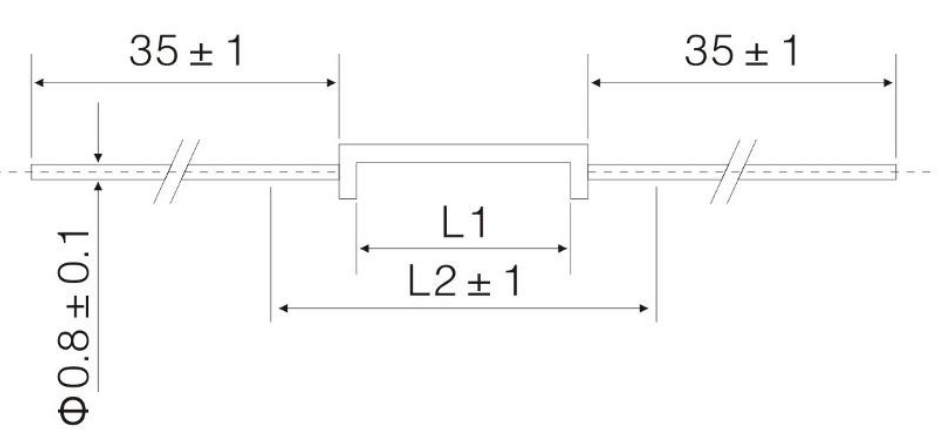

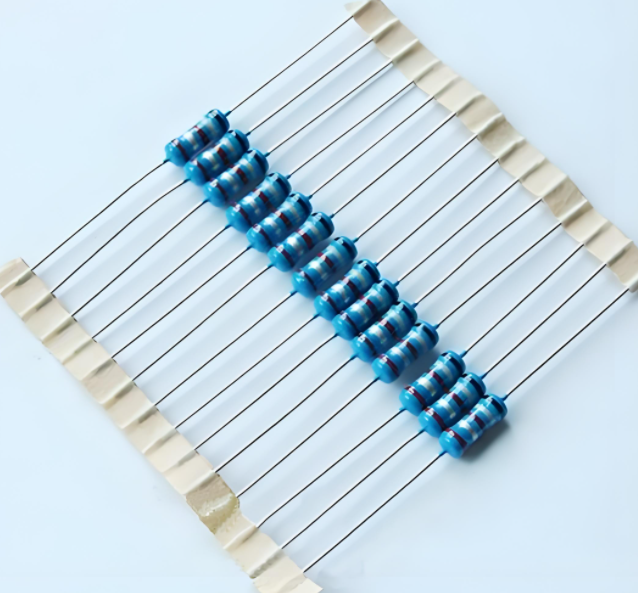

The design of thick film precision chip resistors is centered around achieving high precision and reliability. The resistive element is typically made from a specialized ceramic - metal composite material, which is deposited onto a ceramic substrate. This design allows for precise control over resistance values and ensures stability under varying operating conditions.

Key Components

Resistive Material: A ceramic - metal composite that provides the desired resistance characteristics.

Substrate: A ceramic base, usually alumina, which offers excellent thermal stability and electrical insulation.

Terminations: Metal contacts that facilitate electrical connections and are compatible with surface - mount technology (SMT).

Manufacturing Process

The manufacturing process of thick film precision chip resistors involves several precise steps to ensure high - quality performance.

1. Paste Preparation

The resistive material is prepared as a thick film paste, which is a mixture of ceramic powder, metal powder, and organic binders. The composition is carefully formulated to achieve the desired resistive properties.

2. Deposition

The thick film paste is screen - printed onto the ceramic substrate in a specific pattern. This process allows for precise control over the thickness and geometry of the resistive element.

3. Drying and Firing

The printed substrate is dried to remove organic binders and then fired at high temperatures (typically 800 - 1000°C) to sinter the resistive material, forming a solid and stable resistive layer.

4. Laser Trimming

To achieve precise resistance values, the resistive element is laser - trimmed. This process involves selectively removing material to fine - tune the resistance to the specified tolerance.

5. Testing and Inspection

Each resistor undergoes rigorous testing to ensure it meets the specified resistance, temperature coefficient of resistance (TCR), and power rating. This includes visual inspection, electrical testing, and environmental testing to ensure reliability.

Performance Characteristics

Thick film precision chip resistors offer several key performance characteristics that make them suitable for a wide range of applications.

| Parameter | Thick Film Precision Chip Resistor |

|---|---|

| Resistance Tolerance | ±0.1% - ±1% |

| Temperature Coefficient of Resistance (TCR) | ±5 ppm/°C - ±20 ppm/°C |

| Power Rating | 0.1W - 5W |

| Operating Temperature Range | -55°C to +125°C |

| Size | Medium to Large |

| Cost | Low to Medium |

Applications

Thick film precision chip resistors are used in a variety of applications due to their reliability and performance characteristics.

1. Consumer Electronics

In devices such as smartphones, tablets, and laptops, these resistors are used in power management circuits, voltage dividers, and signal processing circuits. Their compact size and reliability make them ideal for mass production.

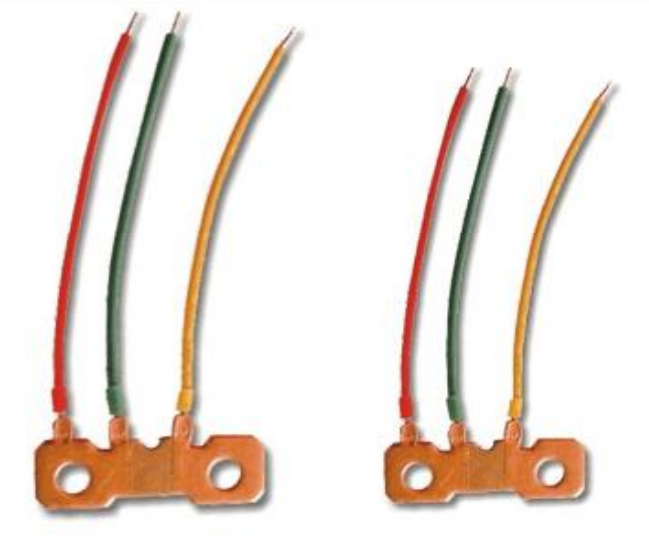

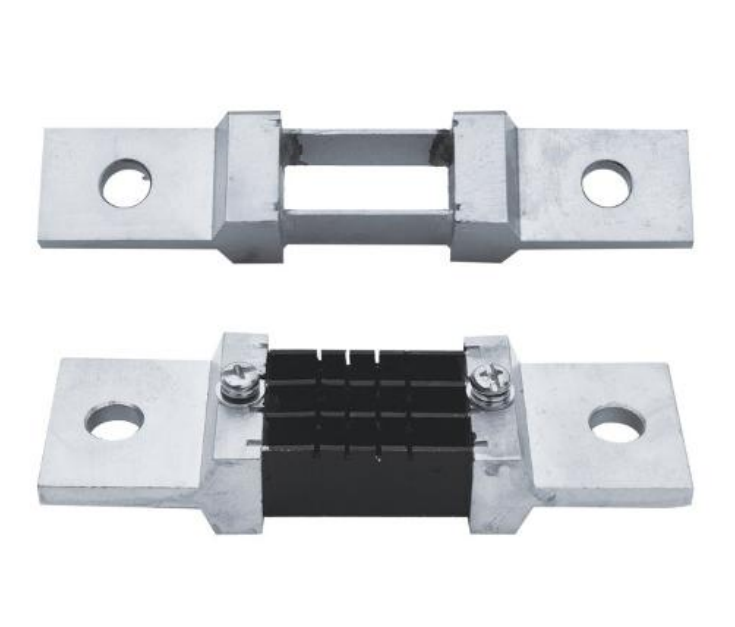

2. Industrial Automation

In industrial control systems, these resistors are used in control circuits, sensor interfaces, and power supplies. Their ability to withstand harsh operating conditions ensures long - term reliability.

3. Automotive Electronics

In automotive systems, these resistors are used in engine control units, infotainment systems, and advanced driver - assistance systems (ADAS). Their robustness and high - temperature performance make them suitable for automotive applications.

Problem and Solution

A common problem in the use of thick film precision chip resistors is the potential for resistance drift over time due to thermal and mechanical stress. This can lead to inaccuracies in electronic circuits and systems.

Solution: To mitigate resistance drift, manufacturers employ advanced materials and manufacturing techniques. For instance, using high - purity ceramic substrates and optimizing the thick film paste composition can enhance stability. Additionally, implementing robust laser - trimming processes ensures precise resistance values. Regular testing and calibration during the manufacturing process help identify and correct any deviations, ensuring long - term reliability.

Best Practices for Using Thick Film Precision Chip Resistors

Proper Soldering Techniques: Use proper soldering techniques to avoid thermal stress on the resistors. Excessive heat during soldering can affect the resistor's performance and stability.

Thermal Management: Implement effective thermal management solutions to prevent overheating. This can include the use of heat sinks or proper ventilation, especially in high - power applications.

Regular Testing and Calibration: Regularly test and calibrate the resistors to ensure their performance remains within the specified tolerance. This is especially important in high - accuracy applications where even small deviations can affect system performance.

Proper Storage and Handling: Store and handle the resistors in a controlled environment to prevent damage and contamination. This ensures that the resistor's performance is not affected by environmental factors.

Conclusion

Thick film precision chip resistors are essential components in modern electronics manufacturing, offering a balance of precision, reliability, and cost - effectiveness. Their robust design and manufacturing process make them suitable for a wide range of applications, from consumer electronics to automotive systems. By following best practices in their use and handling, engineers can ensure that these resistors continue to provide reliable and accurate performance in high - precision electronic systems.