Introduction

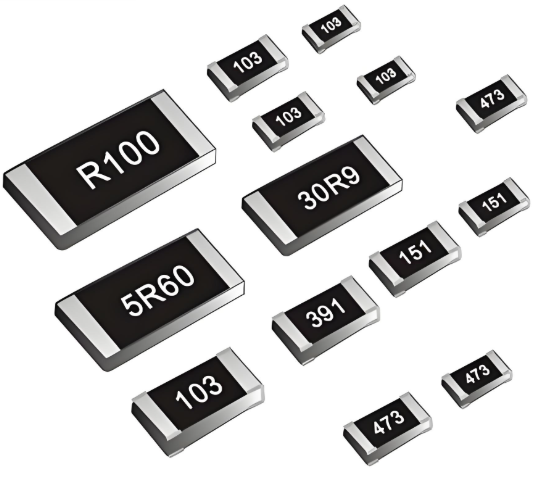

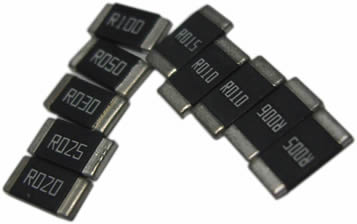

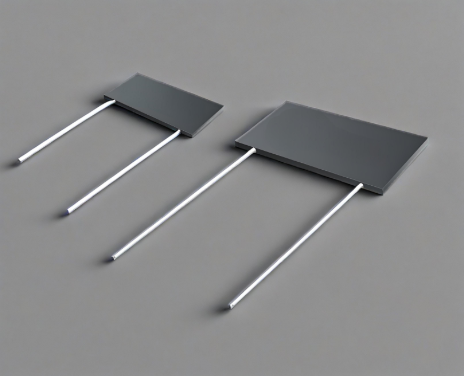

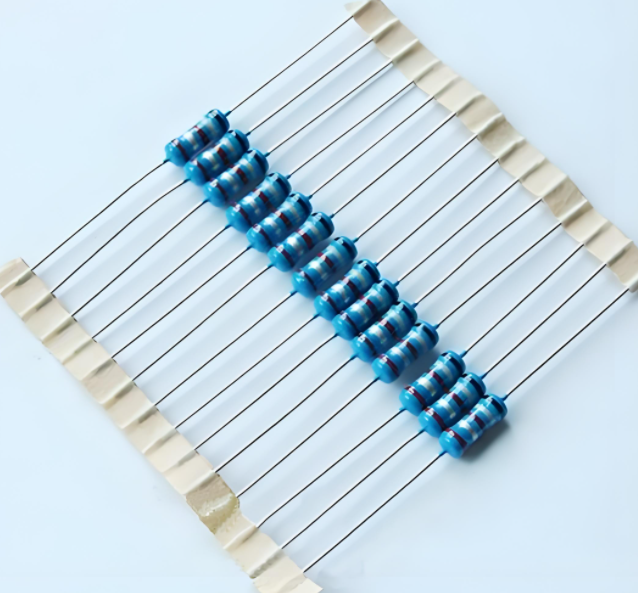

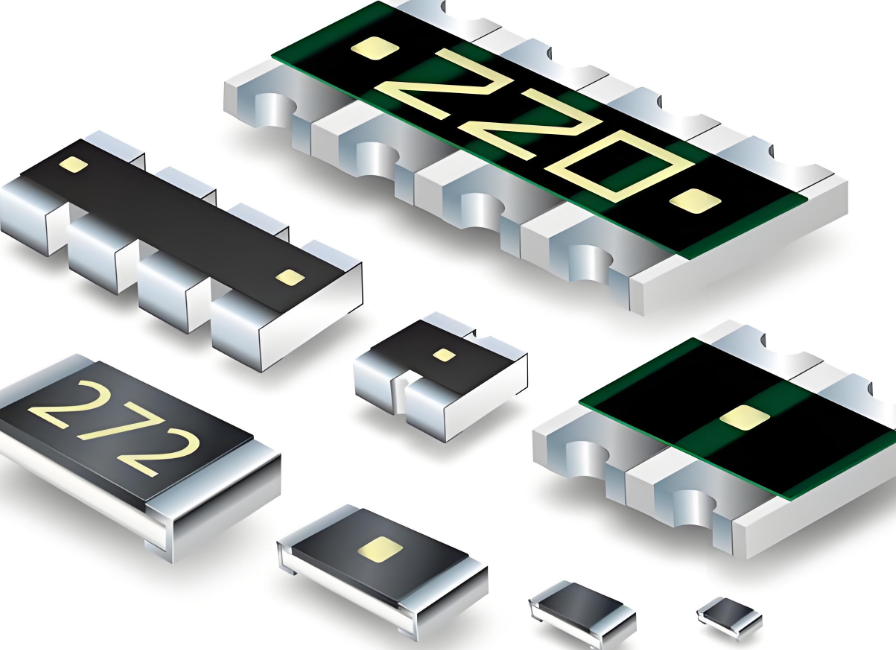

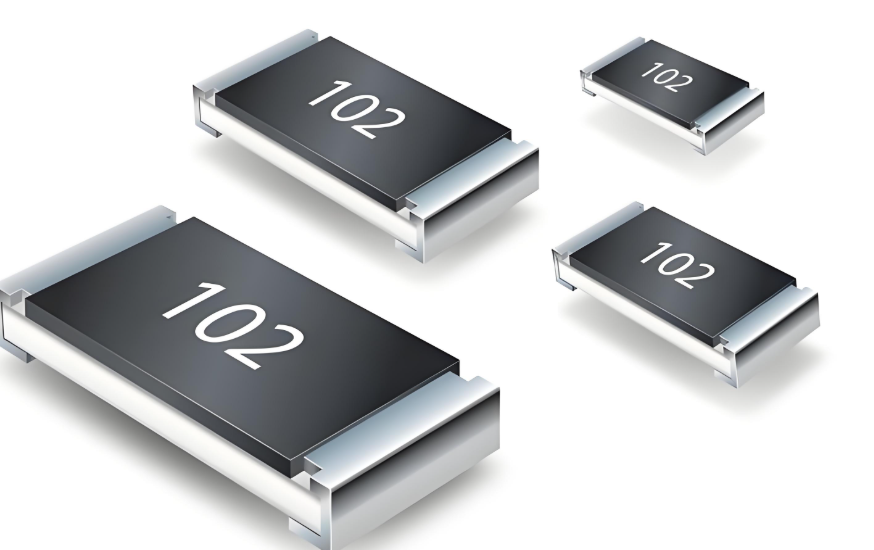

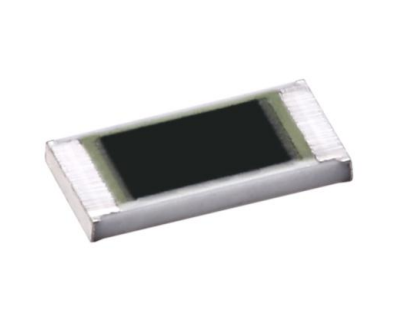

In the realm of electronics, the stability of components is crucial for ensuring reliable and consistent performance over time. One such component that plays a vital role in various electronic circuits is the Trimmable Thick Film Chip Resistor. These resistors are widely used due to their ability to be adjusted or "trimmed" to precise resistance values, making them ideal for applications requiring high precision. However, maintaining the stability of these resistors over extended periods is a challenge that engineers often face. This article explores the stability of Trimmable Thick Film Chip Resistors and provides insights into enhancing their long-term performance in electronic devices.

Common Stability Issues

Trimmable Thick Film Chip Resistors are known for their precision, but they can face several stability issues over time. These issues can lead to drift in resistance values, which can affect the overall performance of the electronic circuit. Some common stability issues include:

Temperature variations

Humidity and environmental factors

Long-term electrical stress

Physical vibrations and mechanical stress

Factors Affecting Stability

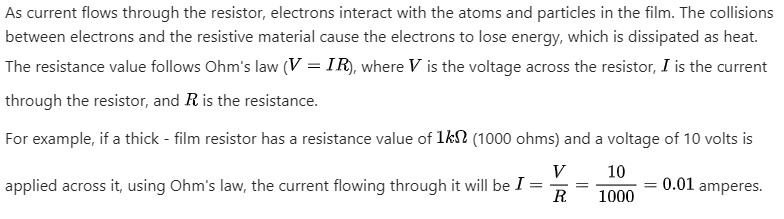

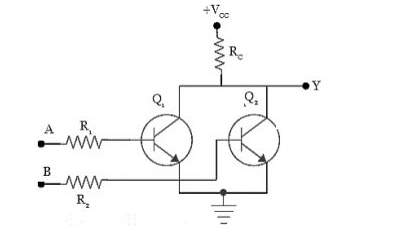

Several factors can impact the stability of Trimmable Thick Film Chip Resistors. Understanding these factors is essential for developing strategies to enhance their long-term performance. The table below outlines some key factors and their effects:

| Factor | Effect on Stability |

|---|---|

| Temperature | Higher temperatures can cause thermal drift, leading to changes in resistance values. |

| Humidity | High humidity can lead to moisture absorption, which can alter the resistor's characteristics. |

| Electrical Stress | Prolonged exposure to high voltage or current can cause degradation over time. |

| Mechanical Stress | Physical vibrations and mechanical stress can lead to micro-cracks and changes in resistance. |

Enhancing Stability

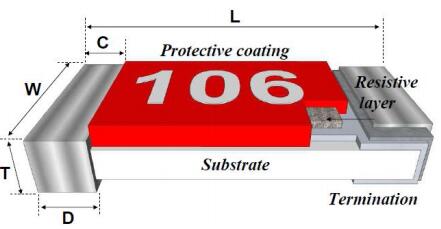

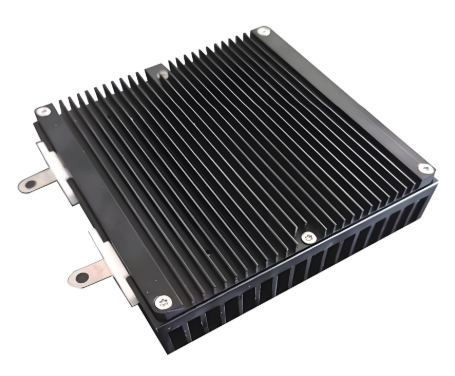

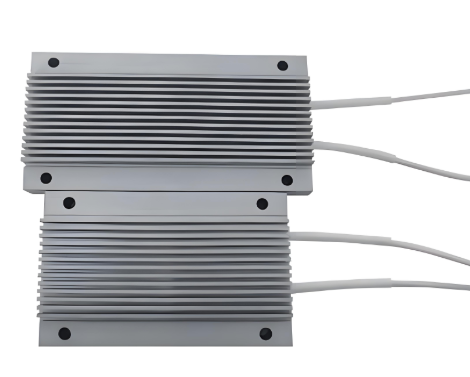

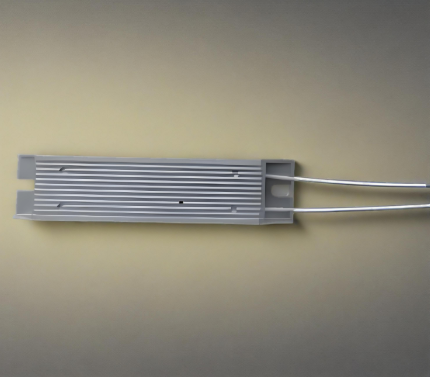

To address the stability issues of Trimmable Thick Film Chip Resistors, several strategies can be employed. One effective approach is to use resistors with low temperature coefficients of resistance (TCR). These resistors are designed to minimize the impact of temperature variations on their performance. Additionally, proper encapsulation and protective coatings can help mitigate the effects of humidity and environmental factors.

Another solution is to implement periodic trimming and calibration processes. By regularly checking and adjusting the resistance values, engineers can ensure that the resistors maintain their desired performance levels. The table below provides a comparison of different stability enhancement methods:

| Method | Description | Effectiveness |

|---|---|---|

| Low TCR Resistor | Resistors with low temperature coefficients to minimize thermal drift. | High |

| Encapsulation | Protective coatings to shield resistors from moisture and environmental factors. | Medium |

| Periodic Trimming | Regular adjustments to maintain precise resistance values. | High |

Case Study

To illustrate the effectiveness of these stability enhancement methods, consider a case study involving a precision electronic circuit used in a high-temperature industrial environment. The circuit initially experienced significant drift in resistance values due to temperature variations. By replacing the existing resistors with low TCR Trimmable Thick Film Chip Resistors and implementing a periodic trimming schedule, the stability of the circuit was significantly improved. The table below shows the before and after resistance values over a six-month period:

| Time | Initial Resistance | Resistance After Enhancements |

|---|---|---|

| 0 Months | 10.00 kΩ | 10.00 kΩ |

| 3 Months | 10.20 kΩ | 10.02 kΩ |

| 6 Months | 10.40 kΩ | 10.03 kΩ |

Conclusion

The stability of Trimmable Thick Film Chip Resistors is a critical factor in ensuring the long-term performance of electronic circuits. By understanding the factors that affect stability and implementing appropriate enhancement methods, engineers can significantly improve the reliability and precision of their designs. Using low TCR resistors, proper encapsulation, and periodic trimming are proven strategies to enhance stability. As demonstrated in the case study, these methods can effectively mitigate the effects of environmental and operational factors, ensuring consistent performance over time.