Why Use Low TCR Resistors? The Key to Stable Circuit Performance

In electronic design, a resistor's value is often considered a constant. However, this is a simplification that can lead to significant performance issues in real-world applications. The critical characteristic that defines how a resistor's value changes with temperature is its Temperature Coefficient of Resistance (TCR). This article explores why specifying low TCR resistors is not just a best practice but a fundamental requirement for achieving stable and reliable circuit performance across industries.

What is TCR and How is it Measured?

TCR (Temperature Coefficient of Resistance) quantifies the change in a resistor's value as its temperature changes. It is expressed in parts per million per degree Celsius (ppm/°C). A positive TCR means the resistance increases with temperature, while a negative TCR means it decreases. For precision electronic circuits, the goal is to select components with a TCR as close to zero as possible.

The formula for calculating the resistance change is: Rfinal = Rnominal × [1 + (TCR × (Tfinal - Troom))]

The Hidden Cost of High TCR: A Data-Driven Look

The problem with high TCR resistors is their inherent instability. A seemingly small TCR value can lead to a large drift in resistance over a wide operating temperature range, introducing errors that compromise the entire system's accuracy.

Consider a common 10kΩ resistor in an automotive environment, where the temperature might swing from -40°C to 85°C (a ΔT of 125°C). The potential variation across different TCR grades is staggering:

| TCR Rating (ppm/°C) | Resistance Min (Ω) at -40°C | Resistance Nominal (Ω) at 25°C | Resistance Max (Ω) at 85°C | Total Variation (ΔΩ) |

|---|---|---|---|---|

| ±500 (Standard Thick Film) | 9,375 | 10,000 | 10,600 | 1,225 |

| ±100 | 9,875 | 10,000 | 10,150 | 275 |

| ±25 (Precision Thin Film) | 9,969 | 10,000 | 10,038 | 69 |

| ±5 (Ultra-Precision Foil) | 9,994 | 10,000 | 10,008 | 14 |

This data clearly shows that a standard resistor could drift by over 1.2kΩ, while a low TCR precision resistor drifts by less than 70Ω. This drift can be the difference between a functioning circuit and a failed one.

Key Applications Demanding Low TCR Resistors

The need for stable circuit performance makes low TCR resistors non-negotiable in several fields. The solution to thermal drift is to specify resistors with a TCR rating appropriate for the application's temperature range and accuracy requirements.

Precision Measurement and Test Equipment: Multimeters, source measure units (SMUs), and calibrators require stable reference networks to maintain their accuracy over time and temperature.

Medical Electronics: Devices like patient monitors and diagnostic imaging systems (MRI, CT scanners) must provide reliable readings regardless of internal heating or ambient conditions, making high reliability resistor components essential.

Automotive Systems: From engine control units (ECUs) to LiDAR sensors, components must operate reliably from frigid cold starts to scorching engine heat.

Audio Equipment: High-end amplifiers and DACs use low TCR resistors in their gain and filter stages to prevent distortion and maintain sound quality.

Selecting the Right Resistor: A Practical Solution

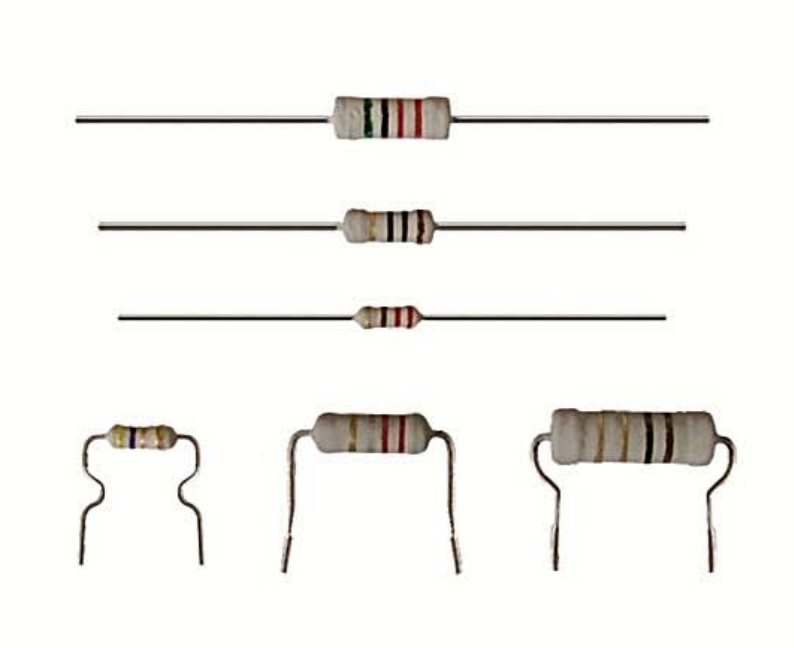

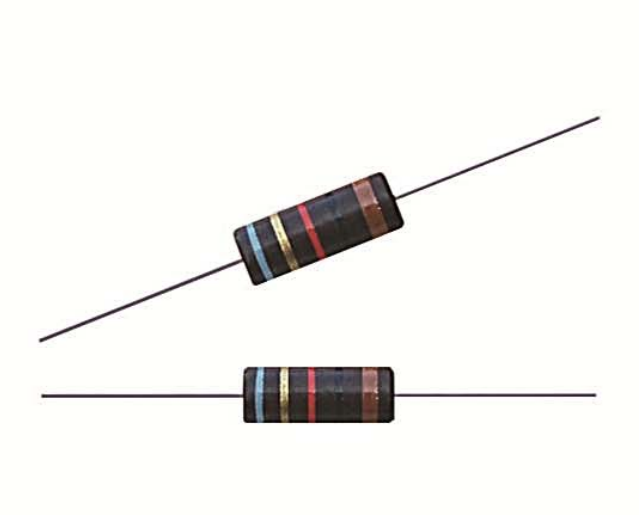

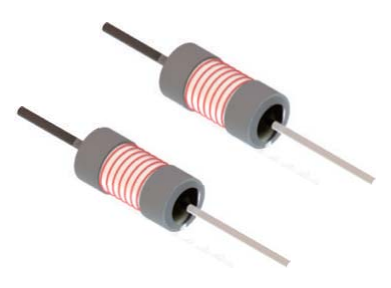

So, how do you select the right component to solve the thermal drift problem? The choice depends on your performance needs and budget. The following table breaks down the common resistor technologies and their typical TCR performance, serving as a guide for your electronic component selection process.

| Resistor Technology | Typical TCR Range (ppm/°C) | Best For |

|---|---|---|

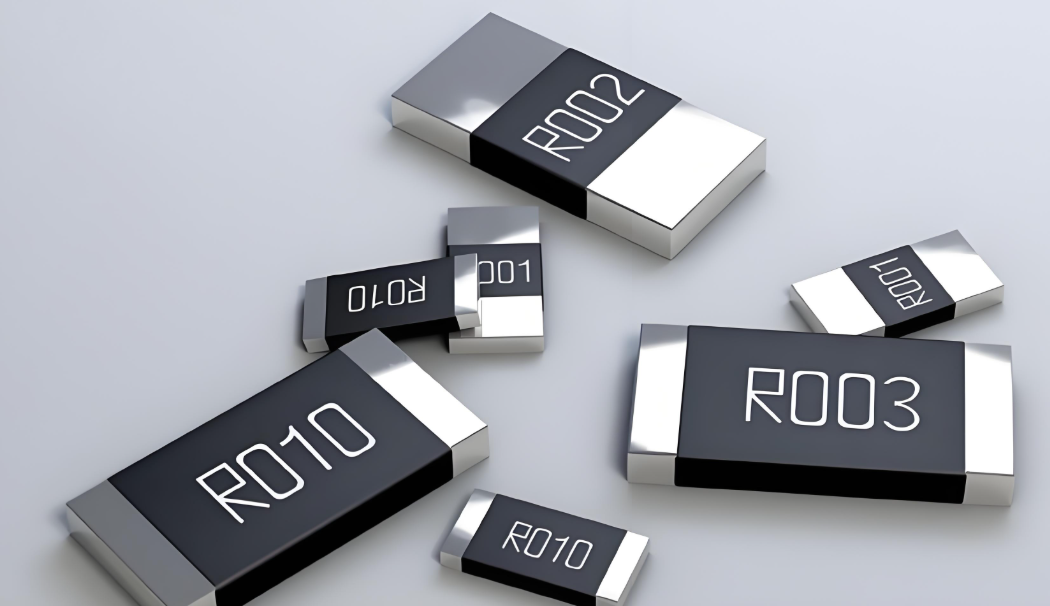

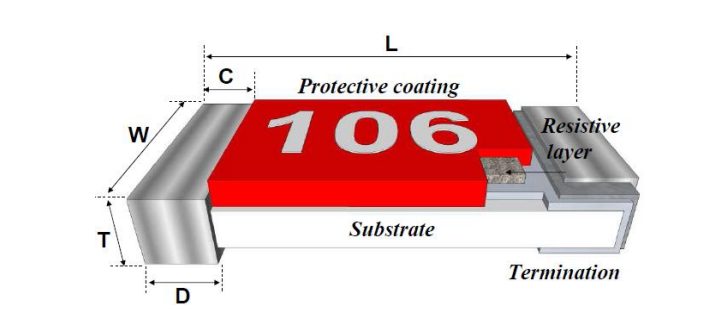

| Thick Film (Chip) | ±200 to ±500 | Consumer electronics, non-critical applications |

| Thin Film (Chip) | ±5 to ±50 | Precision analog circuits, instrumentation |

| Metal Foil | ±0.2 to ±5 | Ultra-high precision, aerospace, medical standards |

| Wirewound | ±10 to ±100 | Power applications where stability is secondary |

For most precision electronic circuits beyond consumer grades, thin film resistors offer an excellent balance of performance and cost. For the most demanding applications, metal foil is the ultimate solution to minimize temperature-related errors.

Conclusion: Investing in Stability

Ignoring TCR is a risk that can lead to unpredictable circuit behavior, costly recalibrations, and system failures. The question of why use low TCR resistors is answered by a universal design principle: stability matters. By understanding TCR and proactively selecting the right resistor technology for your application's environment, you invest in the reliability, accuracy, and longevity of your electronic products. Specifying a low TCR resistor is a simple and effective solution to eliminate one of the most significant variables in circuit design.