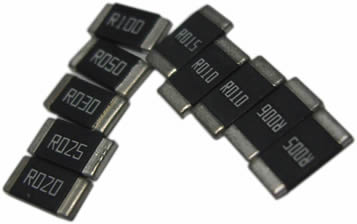

Low TCR Resistor Arrays: A Guide to Matched TCR, Precision, and Applications

In precision circuit design, managing individual component drift is challenging enough. But what happens when you need multiple resistors to track perfectly with each other across a wide temperature range? This is where standard discrete components fall short. Low TCR resistor arrays, or networks, solve this critical challenge by integrating multiple precision resistors onto a single monolithic substrate, ensuring exceptional stability and matched performance. This guide explores how these components are the key to achieving reliability in complex, temperature-sensitive applications.

The Problem of Mismatch: Beyond Individual TCR

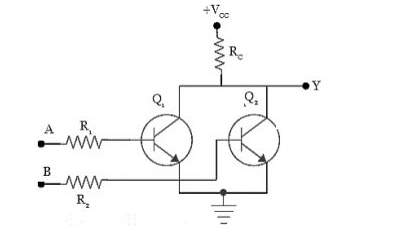

Imagine a precision differential amplifier or a voltage divider circuit built with discrete low TCR resistors. Even if each resistor has a excellent ±25 ppm/°C rating, their individual values will drift at slightly different rates. This resistor mismatch problem introduces errors that the circuit is designed to reject, leading to gain inaccuracies and offset voltages that degrade with temperature. This inherent mismatch negates the benefit of using precision components and is a major hurdle in achieving stable circuit performance.

What is Matched TCR? The Key Metric for Arrays

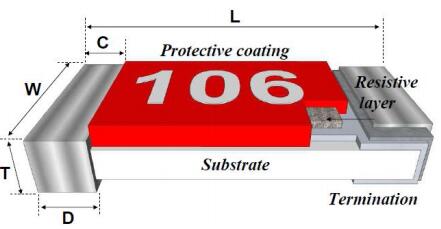

The solution to this problem is the use of resistor arrays with a low matched TCR or TCR tracking. This specification defines the maximum difference in TCR between any two resistors within the same package. Because the resistors are fabricated simultaneously on the same substrate from the same material, they experience nearly identical thermal drift.

The following table illustrates the dramatic improvement in performance a matched network offers over discrete resistors in a differential amplifier, assuming a 70°C temperature rise:

| Component Type | Individual TCR (ppm/°C) | Typical Matched TCR (ppm/°C) | Potential Resistance Divergence (ΔR) in 70°C ΔT | Impact on Circuit |

|---|---|---|---|---|

| Discrete Precision Resistors | ±25 | N/A (Unmatched) | Up to ±0.175% | Significant gain error and offset drift |

| Precision Resistor Array | ±25 | ±2 to ±5 | Only ±0.014% to ±0.035% | Excellent common-mode rejection and stability |

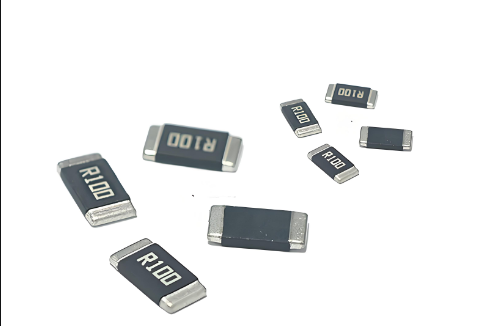

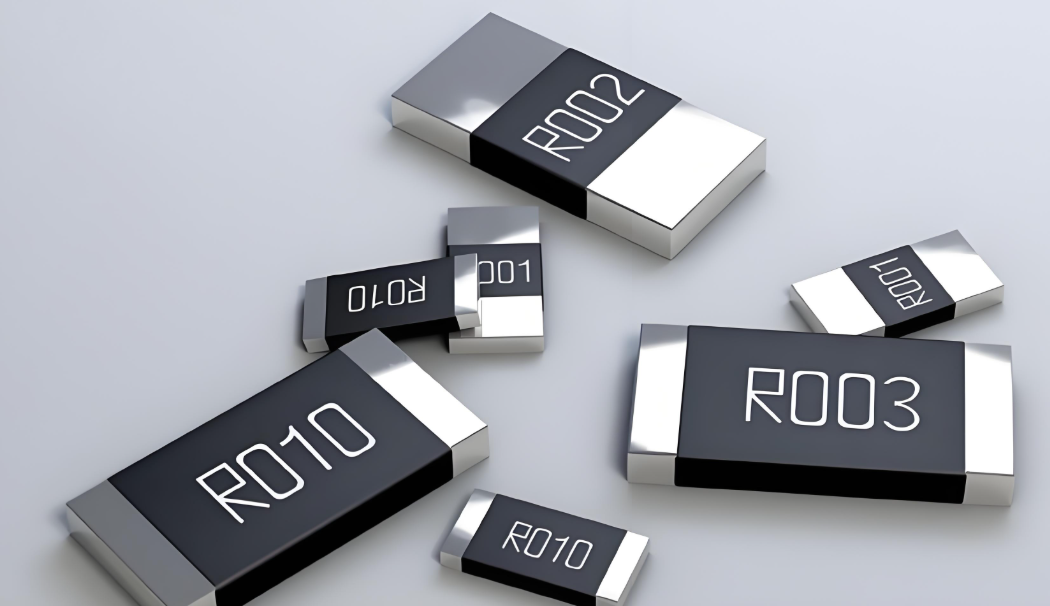

Technology Comparison: Thin Film vs. Thick Film Arrays

Not all integrated resistor networks are created equal. The technology used defines their ultimate performance in precision applications. The choice between thin and thick film is the primary decision for designers.

| Parameter | Thick Film Arrays | Thin Film Arrays (for Precision) |

|---|---|---|

| Typical Individual TCR | ±100 to ±250 ppm/°C | ±10 to ±50 ppm/°C |

| Matched TCR (Tracking) | ±25 to ±100 ppm/°C | ±2 to ±10 ppm/°C |

| Absolute Tolerance | ±1% to ±5% | ±0.1% to ±1% |

| Best For | Pull-up/Pull-down, Non-critical signal conditioning | Precision analog circuits, instrumentation, medical devices |

Key Specifications for Selecting Low TCR Resistor Networks

When selecting an array, several specifications work together to define its performance. Understanding these is crucial for electronic component selection.

| Specification | Description | Why it Matters for Precision |

|---|---|---|

| Matched TCR (Tracking) | The max difference in TCR between any two resistors. | The most critical spec for ensuring resistors drift together. |

| Ratio Tolerance | The initial error in the resistance ratio between two resistors. | Determines the initial accuracy of dividers or gain settings. |

| Power Rating per Resistor | Max power each element can dissipate. | Self-heating can induce drift, so derating is important. |

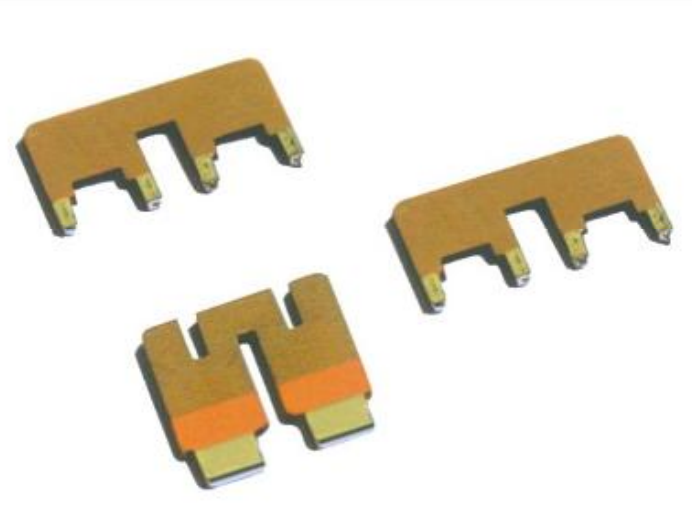

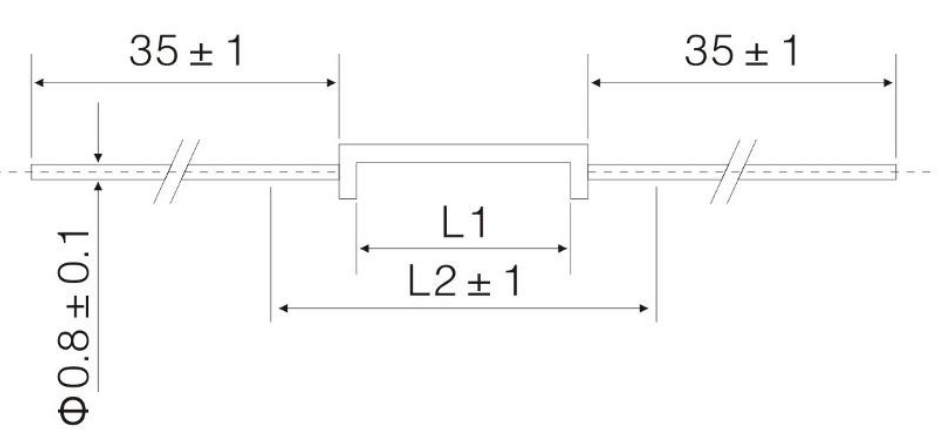

| Package Type (SIP, DIP, SIP) | The physical form factor of the network. | Affects board space and automated assembly compatibility. |

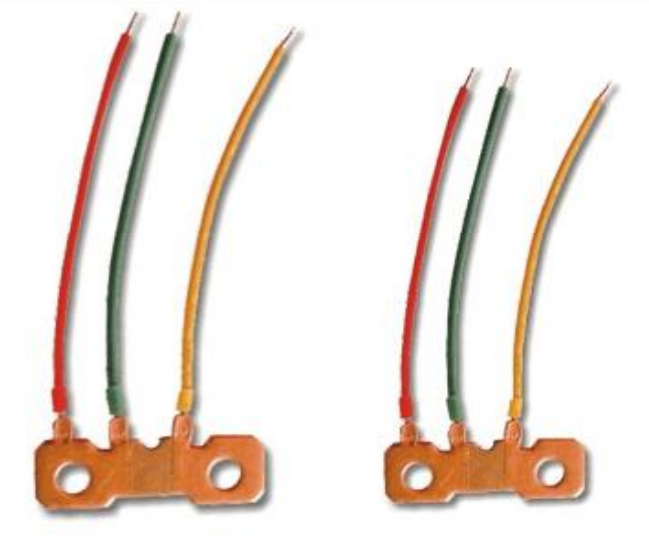

Solutions and Applications: Where Matched Arrays Are Essential

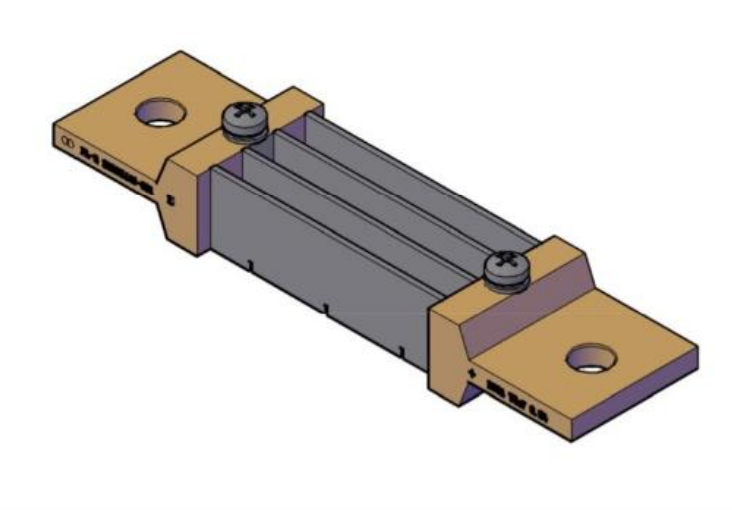

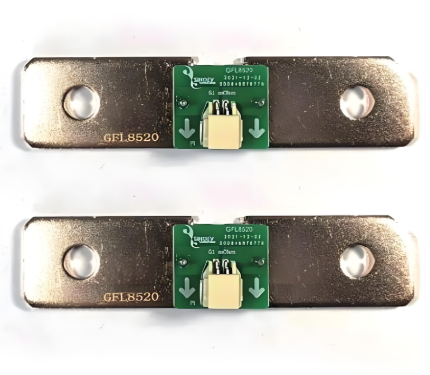

The solution to the mismatch problem is to replace discrete resistors with a single, monolithic low TCR resistor network. This approach is indispensable in several key areas:

Precision Amplifier Circuits: Providing matched gain-setting and feedback resistors for instrumentation amps and op-amps to maintain high CMRR and gain accuracy over temperature.

Voltage Divider Networks: Creating stable reference voltages for ADCs and DACs where ratio stability is more critical than absolute value.

Medical and Test Equipment: Ensuring accurate sensor readings and reliable measurements in environments where temperature can fluctuate.

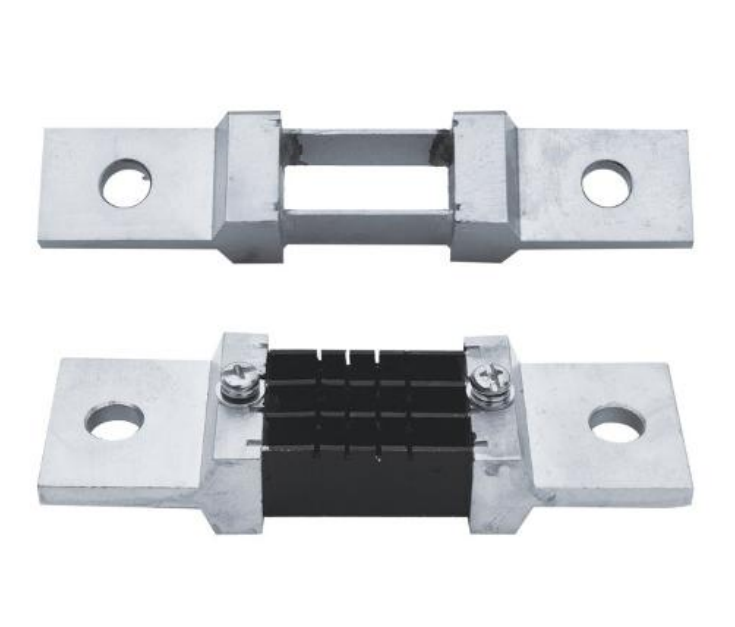

AEC-Q200 Qualified Arrays: Automotive systems use these networks in critical sensor modules and engine control units (ECUs) where reliability under harsh conditions is paramount.

Practical Selection Guide: Choosing the Right Array

Selecting the right component requires balancing performance and cost. Follow this decision flow:

Define the Critical Error Source: Is absolute value drift or ratio matching more important for your circuit? This dictates whether individual TCR or matched TCR is your priority.

Set Performance Targets: Based on your total acceptable error budget, calculate the required matched TCR and ratio tolerance.

Choose the Technology: Use the comparison table above. For most precision applications, thin film resistor networks are the default choice.

Confirm Package and Layout: Ensure the SIP or DIP package fits your board layout and that thermal considerations are addressed.

By integrating matched resistors onto a single substrate, low TCR resistor arrays provide a simple and effective solution to the complex problem of thermal mismatch, ensuring your precision designs perform reliably in the real world.