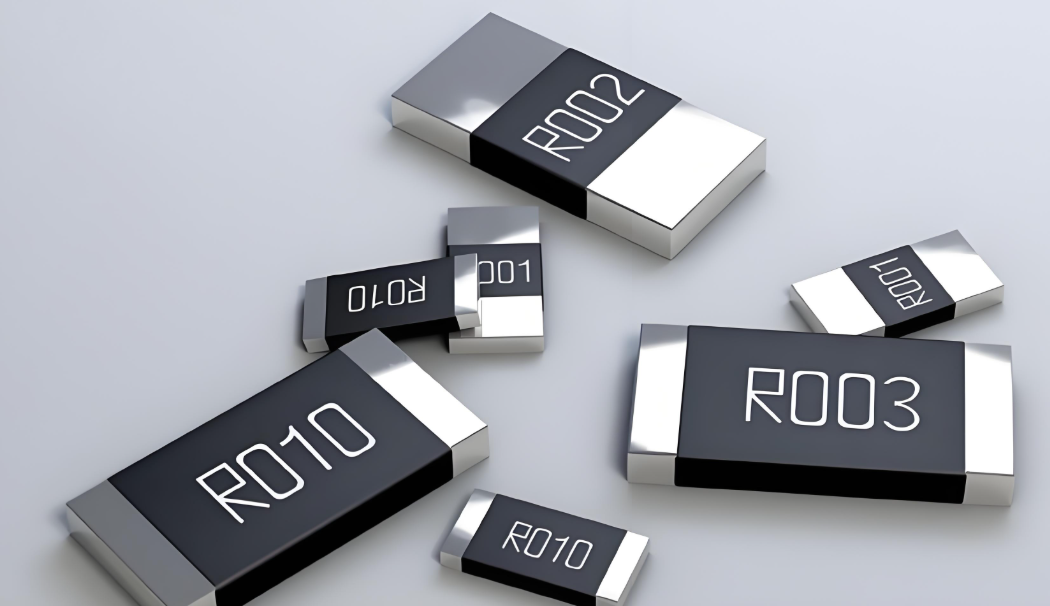

Title: Low Resistance Shunt Resistors: High-Precision Current Monitoring for Industrial Applications

Introduction

Low resistance shunt resistors are fundamental components for high-precision current monitoring in industrial applications. They enable accurate measurement of large currents while minimizing power loss, making them ideal for heavy machinery, energy storage systems, and industrial power electronics. This article provides a structured selection guide, real calculation data, and practical solutions to common challenges when applying Low Resistance Shunt Resistors in industrial environments.

Table of Contents

Why Low Resistance Shunt Resistors Are Essential

In industrial power systems, current can exceed hundreds or even thousands of amperes. Using Low Resistance Shunt Resistors ensures:

Minimal power loss due to reduced voltage drop.

High accuracy in current measurement, even under fluctuating loads.

Durability and stability in harsh operating conditions such as heat, vibration, and electrical noise.

Calculation Examples: Voltage Drop & Power Dissipation

For design, two key formulas are used:

Voltage drop: V = I × R

Power dissipation: P = I² × R

Below is a calculation table showing different resistor values in a 250 A and 500 A industrial system.

| Resistance (mΩ) | Current (A) | Voltage Drop (mV) | Power Dissipation (W) |

|---|---|---|---|

| 0.1 | 250 | 25 | 6.25 |

| 0.1 | 500 | 50 | 25 |

| 0.05 | 250 | 12.5 | 3.13 |

| 0.05 | 500 | 25 | 12.5 |

| 0.01 | 250 | 2.5 | 0.63 |

| 0.01 | 500 | 5 | 2.5 |

Observation: Lower resistance reduces energy loss but requires precise measurement circuitry since the voltage drop becomes very small.

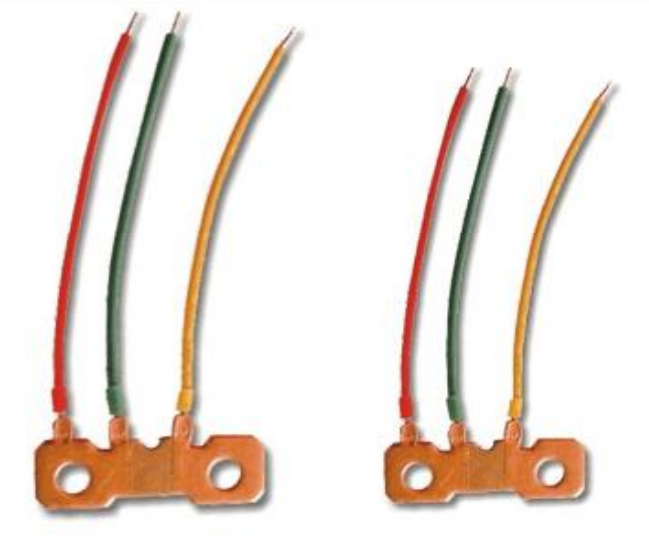

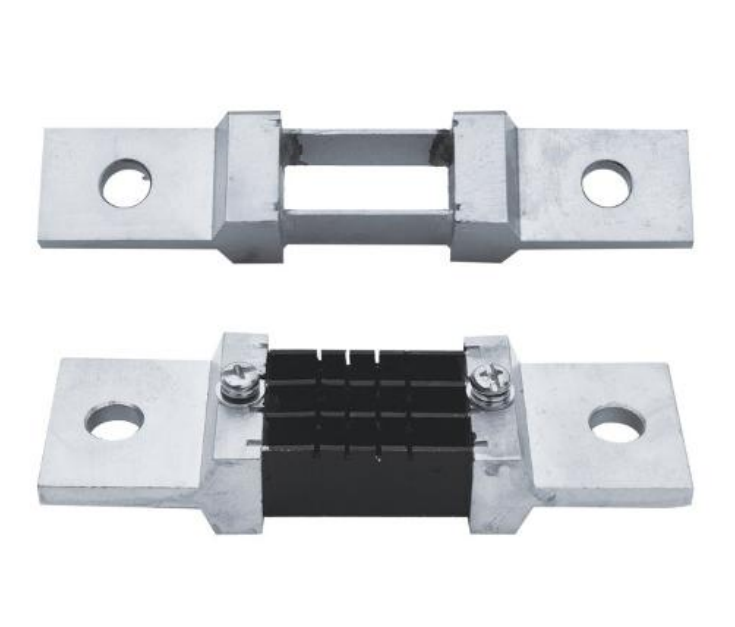

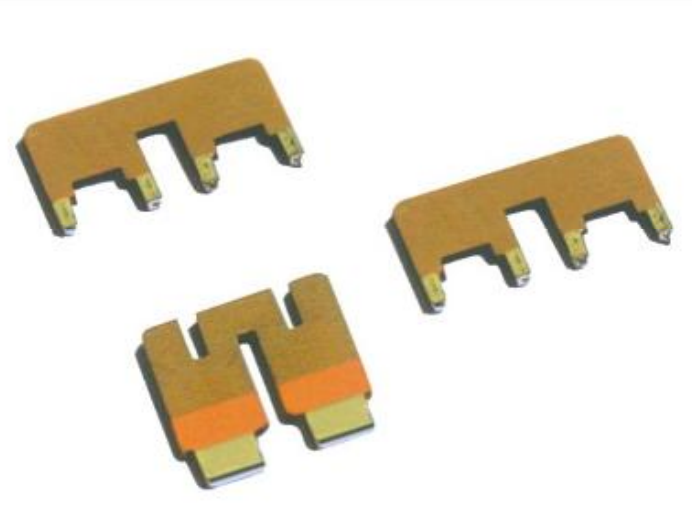

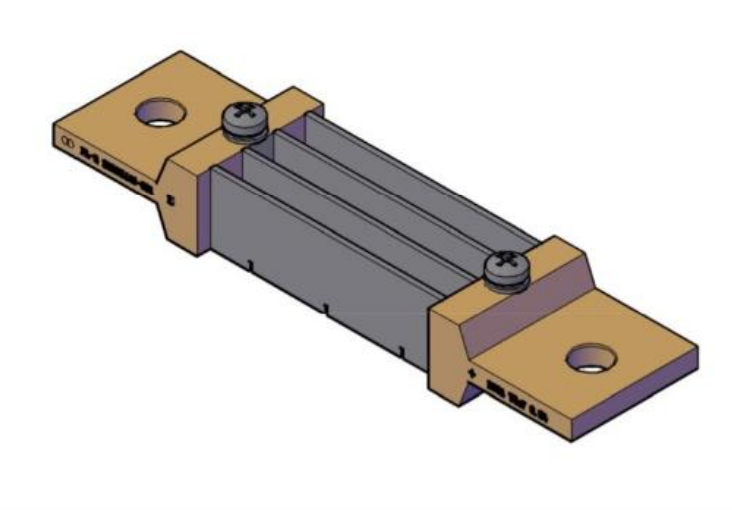

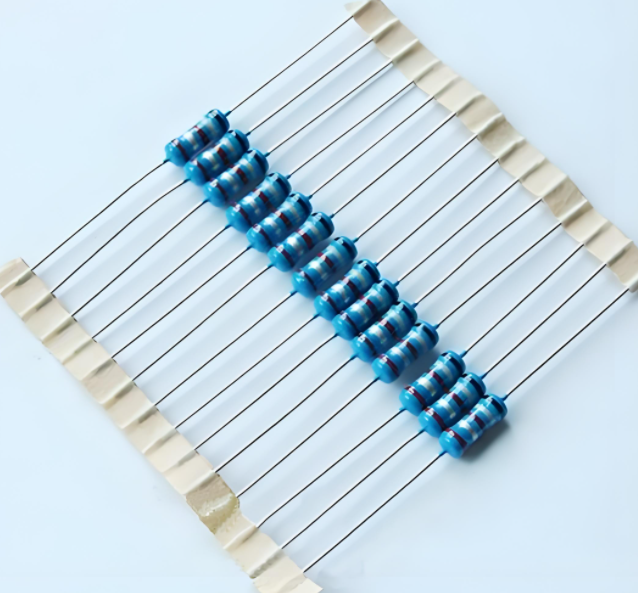

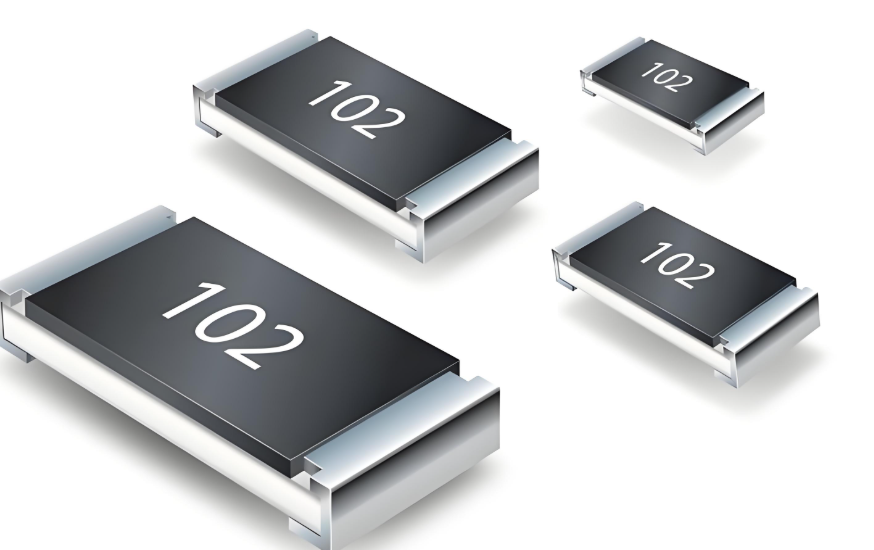

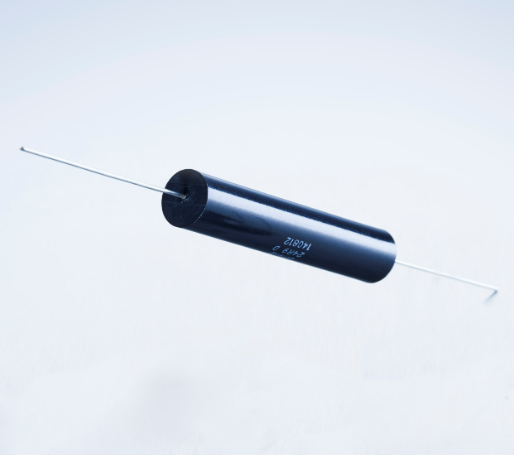

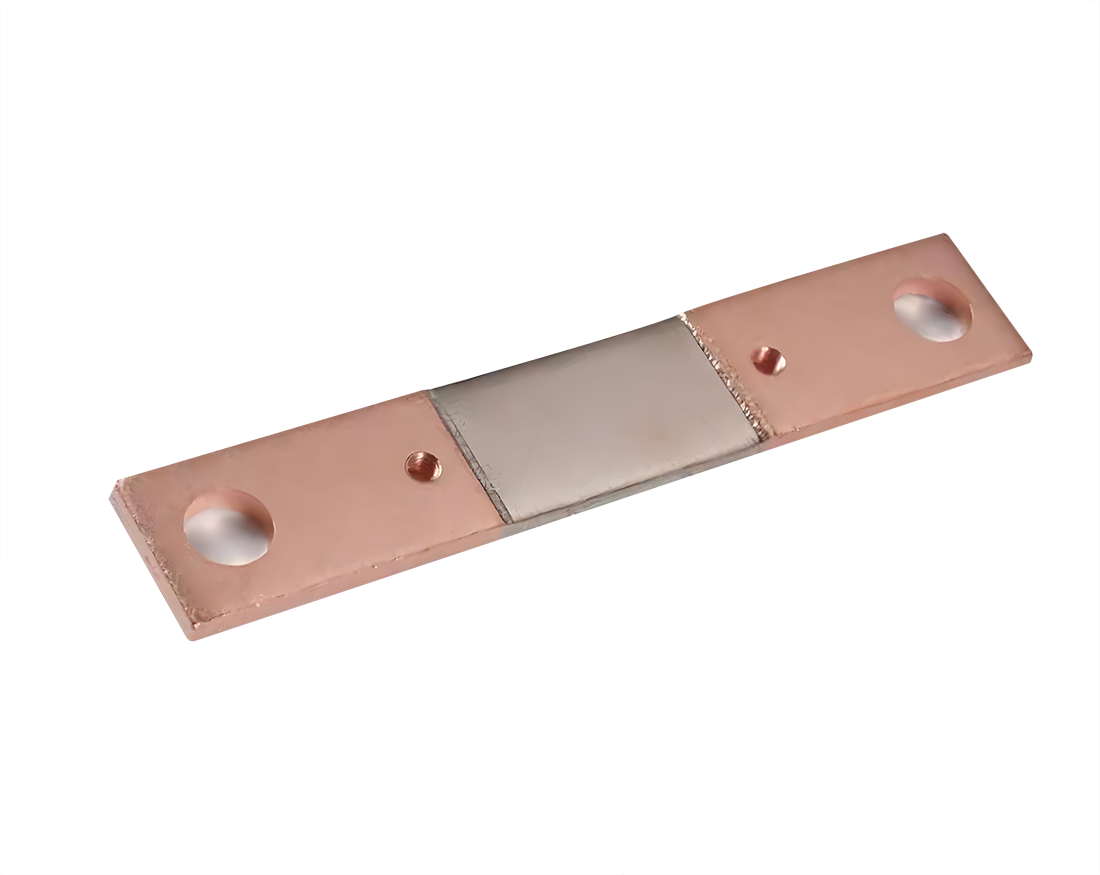

Comparison of Common Low Resistance Shunt Types

| Type | Resistance Range | Accuracy | Thermal Stability | Industrial Applications |

|---|---|---|---|---|

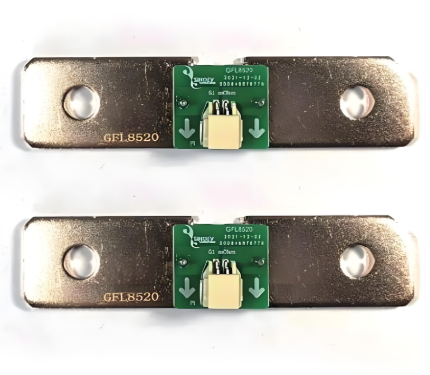

| Metal Foil | 0.01–1 mΩ | ±0.05% – ±0.5% | Excellent | Battery monitoring, calibration-grade instruments |

| Alloy Strip (Manganin) | 0.05–5 mΩ | ±0.1% – ±1% | Good | Motor drives, power converters |

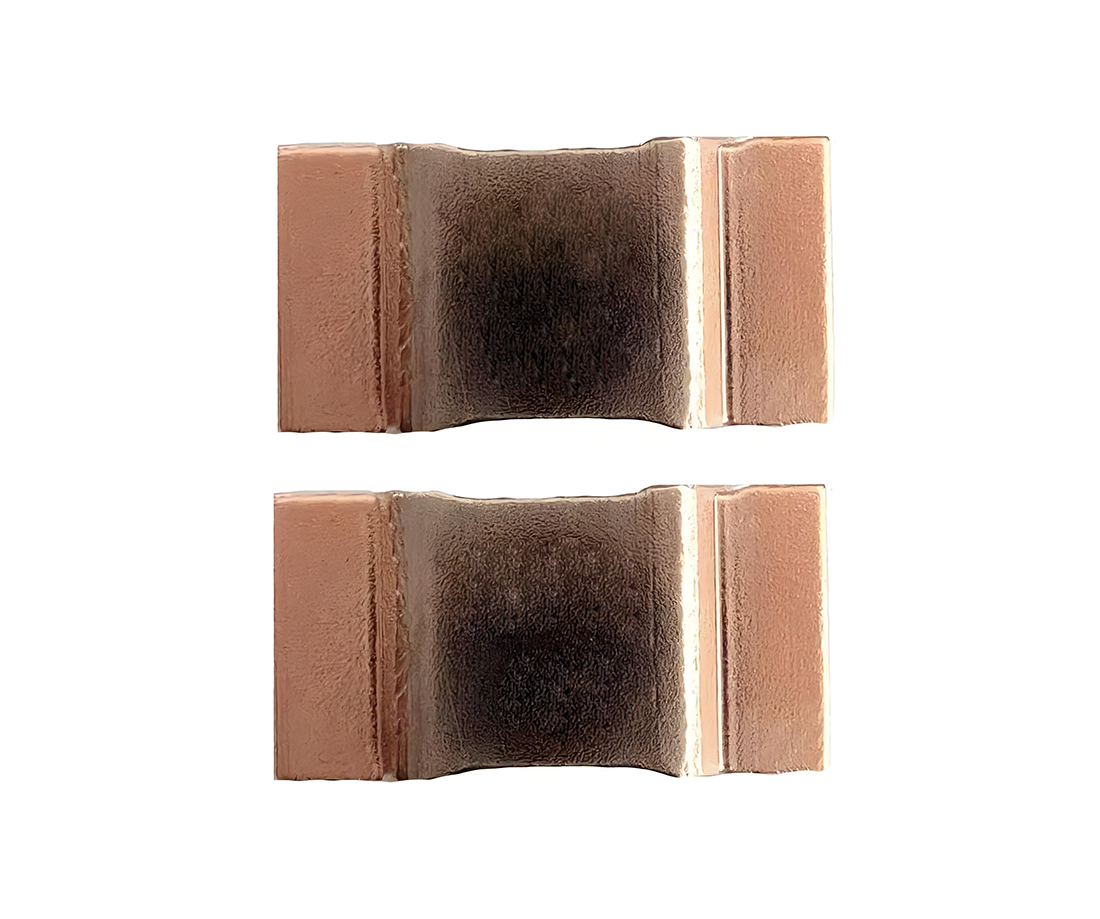

| Busbar Shunt | 0.01–0.5 mΩ | ±0.5% – ±2% | Moderate | Heavy industrial equipment, high current DC lines |

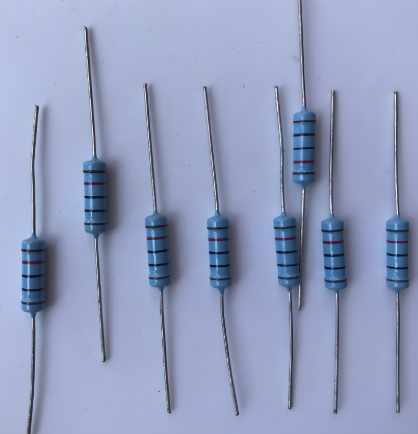

| Wire-Wound | 0.1–10 mΩ | ±0.5% – ±5% | Fair | Cost-sensitive systems |

Step-by-Step Selection Guide

Define maximum current: Know the peak and continuous current values of your system.

Choose target voltage drop: Usually between 50–100 mV at maximum current for industrial monitoring.

Calculate resistance: Use R = V/I to set the correct shunt value.

Check power rating: Ensure the shunt can dissipate heat safely with margin.

Consider temperature effects: Select low TCR materials for stable measurement.

Verify mechanical design: For industrial setups, ensure robust mounting and Kelvin connections.

Common Problem & Effective Solution

Problem: Measurement Errors in Industrial Power Systems

A factory motor control unit uses a 0.1 mΩ shunt at 400 A. The voltage drop is only 40 mV, but electrical noise in the system introduces ±5 mV error, which equals ±12.5% inaccuracy.

Solution: Optimized Shunt and Amplifier Design

Choose a slightly higher resistance (e.g., 0.2 mΩ) to increase signal voltage while keeping power loss acceptable.

Implement Kelvin connections to eliminate lead resistance errors.

Use a differential amplifier with high common-mode rejection and low noise.

Calibrate the measurement chain at operating temperature for best accuracy.

This solution balances precision with efficiency, ensuring Low Resistance Shunt Resistors provide reliable monitoring in noisy industrial environments.

Buying Checklist for Industrial Applications

Rated current and resistance value with tight tolerance.

Continuous and surge power handling capacity.

Low temperature coefficient of resistance (TCR).

Robust housing and vibration resistance.

Availability of datasheet with thermal derating curves.

Kelvin terminal design for precise measurement.

Conclusion

Low Resistance Shunt Resistors are essential for accurate and efficient current monitoring in industrial applications. By balancing resistance value, voltage drop, and power dissipation, engineers can ensure stable and reliable measurement even in demanding environments. Following a structured selection process and addressing common issues like noise and thermal drift guarantees that these resistors deliver long-term accuracy and durability.

FAQ

Q: How low should the resistance be in industrial current shunts?

A: Typically between 0.01 mΩ and 0.2 mΩ for high current industrial systems, depending on the voltage drop you can tolerate.

Q: Can I use the same shunt resistor for both measurement and protection?

A: Yes, but it is better to separate them if high reliability is required. Use one shunt for precise monitoring and another for overcurrent protection.

Q: What is the main trade-off when choosing Low Resistance Shunt Resistors?

The trade-off is between low voltage drop and energy efficiency versus measurement accuracy and signal-to-noise ratio. The key is to find a balanced value based on your system’s needs.