-

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention Methods

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention MethodsSulfur-induced corrosion remains a leading cause of resistor failure in harsh environments like oil refine...

-

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics IntroductionIn the harsh operational environment of oil refineries and petrochemical plants, a silent a...

-

Surge Resistor Function: How It Protects Circuits, Prevents Damage & Optimizes Performance in Electronics

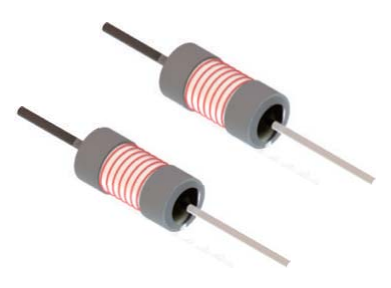

1. What Does a Surge Resistor Do Core Functions ExplainedA surge resistor is not just a passive component—it’s a first line of defense against electrical transients. Its primary functions include:...

-

High Voltage vs Standard Resistors: Voltage Ratings, Materials & Safety Compared

IntroductionWhen designing electronic circuits, engineers often face the critical choice between high voltage resistors and standard resistors. While both components regulate current flow, their diffe...

-

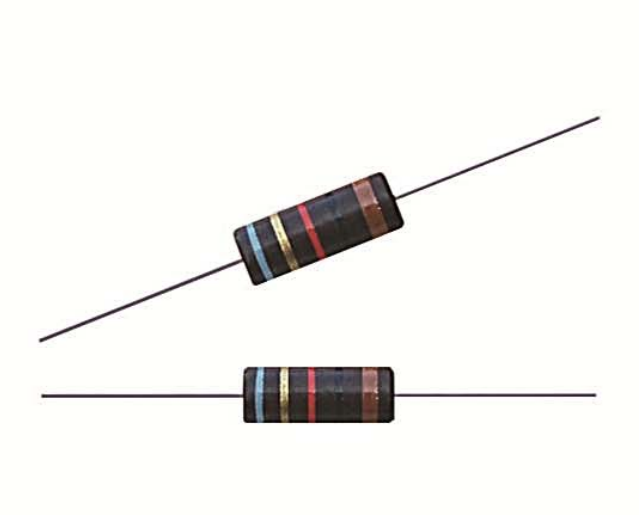

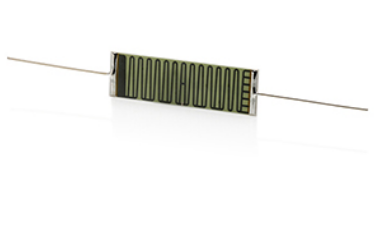

Exploring Different Types of Alloy Resistors: Materials, Applications, and Characteristics

Exploring Different Types of Alloy Resistors: Materials, Applications, and CharacteristicsWelcome to this guide on alloy resistors. In this article, we will explore the different types of alloy resist...

-

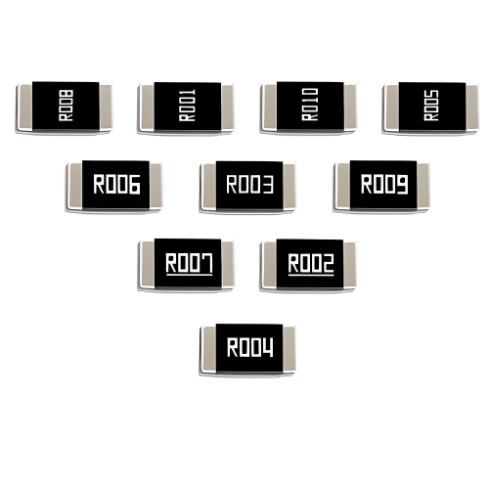

Standard vs. Sulfur Resistant Resistors: A Reliability Analysis

Standard vs. Sulfur Resistant Resistors: A Reliability AnalysisIntroductionIn the world of electronics design, component failure is often a silent and costly threat. Among the various failure modes, s...

-

Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base StationsBase stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution....

-

10kV High Voltage Resistors: Specifications, Applications & Top Suppliers for Industrial, Power Transmission & Test Equipment

Technical Specifications of 10kV High Voltage ResistorsTo ensure reliability in high-voltage environments, 10kV resistors must meet strict performance criteria. Below are critical parameters to evalua...

-

50kV High Voltage Resistors: Technical Specs, Industrial Use Cases & How to Choose the Right One for Power Grids, Test Labs & Renewable Systems

Technical Specifications of 50kV High Voltage Resistors50kV resistors must withstand high electrical stress while maintaining precision. Below are critical parameters to evaluate for reliability in de...

-

100kV High Voltage Resistors: Technical Specs, Harsh Environment Applications & Expert Selection Guide for Power Grids, Particle Accelerators & Industrial Systems

Technical Specifications of 100kV High Voltage ResistorsTo perform reliably in 100kV systems, resistors must meet rigorous performance criteria. Below are critical parameters and their impact on funct...

-

How to Use Jumper Resistors for Prototyping & Breadboard Projects

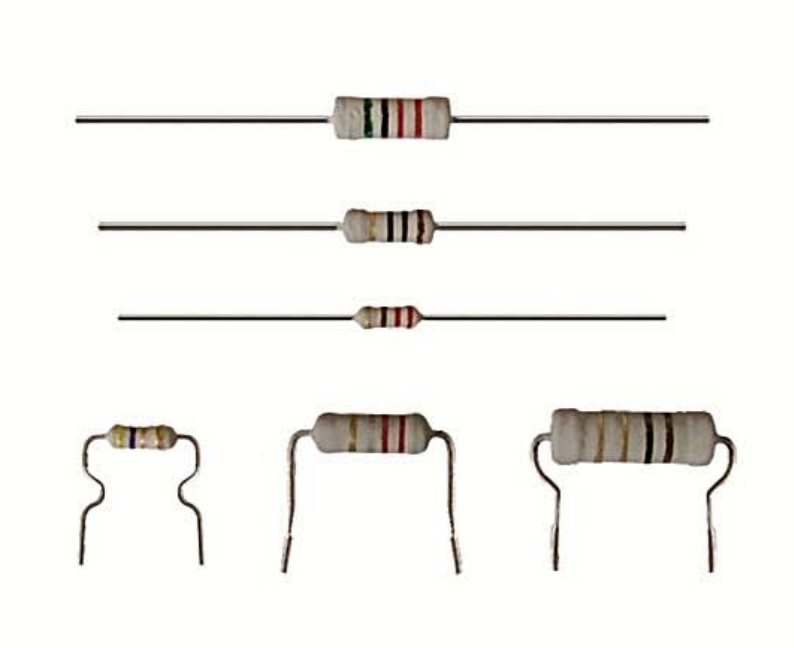

IntroductionJumper resistors are indispensable tools for electronics prototyping, offering a simple yet effective way to create connections in breadboard projects and PCB designs. Whether you're w...

-

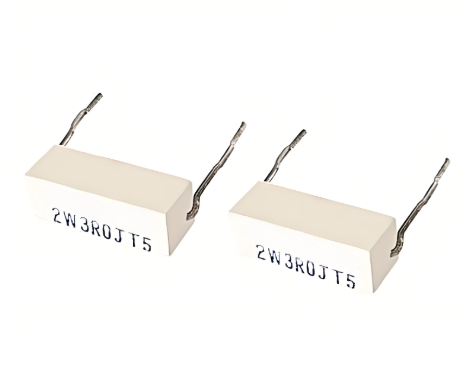

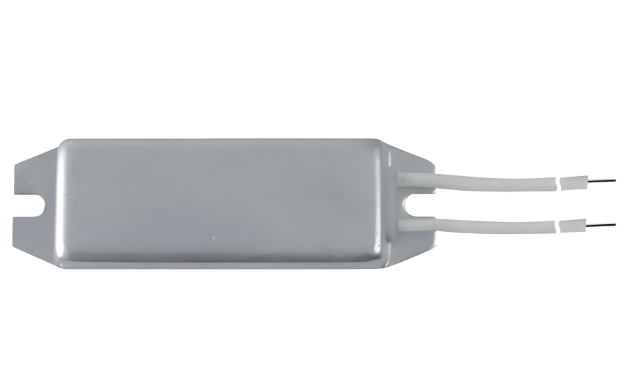

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained

600W Power Resistor: Comprehensive Technical Specifications & Applications Explained<!-- 引言 -->IntroductionPower resistors up to 600W play pivotal roles in various industrial sectors like elec...

-

What Is a KB Resistor? Definition, Function, Applications & Technical Specifications Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standardized nominal resistance value, most commonly 1kΩ (1,000Ω). Unlike variable resistors (e.g., pot...

-

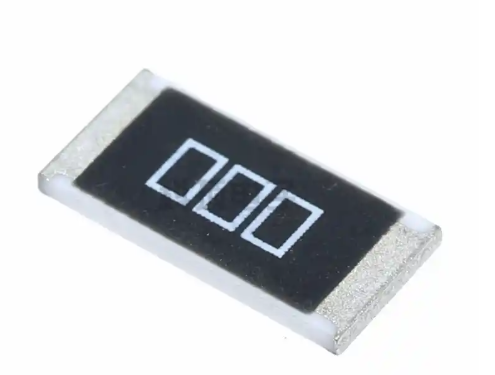

MELF Resistor Basics: Definition, Function, Applications & Key Specifications Explained

1. What Is a MELF Resistor Core DefinitionA MELF resistor is a leadless, surface-mountable resistor with a cylindrical metal electrode structure. Unlike traditional through-hole resistors (e.g., THT),...

-

How to Read Metal Film Resistor Specifications: Decoding Datasheets & Failure Analysis

<!-- Introduction -->How to Read Metal Film Resistor Specifications: Decoding Datasheets & Failure AnalysisMetal film resistors are widely used in precision electronics due to their stability, low...

-

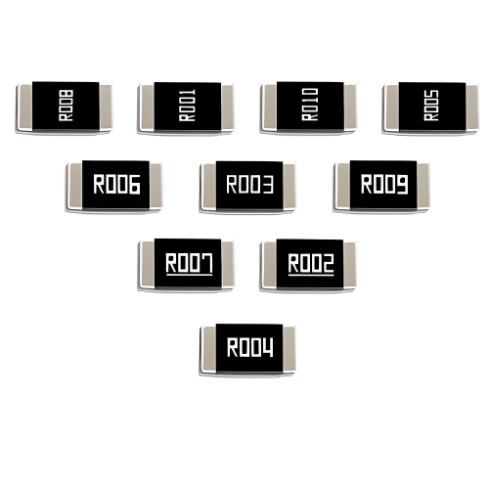

KB Resistor Definition: 1kΩ Standard Value, Tolerance & Temperature Coefficient Explained

1. What Is a KB Resistor Core DefinitionA KB resistor is a fixed, through-hole resistor with a standard resistance value, typically used in low-to-moderate power circuits. Unlike variable resistors (e...

-

High Voltage Resistors: Working Principle, Applications, Safety Tips & How to Choose the Right One

<!-- Introduction -->IntroductionHigh voltage resistors are critical components in circuits requiring precise voltage control under extreme electrical stress. Understanding their working principle, ap...

-

100W TO-247 Resistor: High-Power, Non-Inductive & Pulse-Load Resistant Solutions

The Powerhouse Resistor: 100W TO-247 Solutions for Demanding ApplicationsIn high-power electronics, the 100W TO-247 resistor has become a critical component for engineers dealing with pulse loads, the...

-

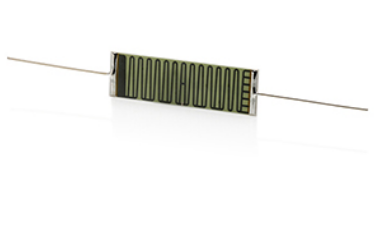

Alloy Resistor Advantages: Low TCR, High Power Handling & Stability Explained

<!-- Introduction -->Why Alloy Resistors Outperform Traditional OptionsIn precision electronics, resistor selection directly impacts system reliability. Alloy resistors have emerged as superior soluti...

-

High Ohmic Resistors: Precision, Stability & Low Leakage Solutions for HV Circuits

High Ohmic Resistors: Precision, Stability & Low Leakage Solutions for HV CircuitsHigh ohmic resistors (1MΩ to 10GΩ+) are critical components in high-voltage circuits where precision, long-term ...

-

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics

Combating Sulfur Corrosion in Refineries: A Guide to Selecting Sulfur-Resistant Electronics IntroductionIn the harsh operational environment of oil refineries and petrochemical plants, a silent a...

-

Standard vs. Sulfur Resistant Resistors: A Reliability Analysis

Standard vs. Sulfur Resistant Resistors: A Reliability AnalysisIntroductionIn the world of electronics design, component failure is often a silent and costly threat. Among the various failure modes, s...

-

Anti-Sulfur Resistors in Base Stations: Enhancing Reliability and Performance in Harsh Environments

The Problem: Sulfur-Induced Failures in Base StationsBase stations are often deployed in diverse environments, including industrial areas, coastal regions, and locations with high levels of pollution....

-

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention Methods

How to Protect Resistors from Sulfur Damage: Best Materials, Coatings & Prevention MethodsSulfur-induced corrosion remains a leading cause of resistor failure in harsh environments like oil refine...