Introduction

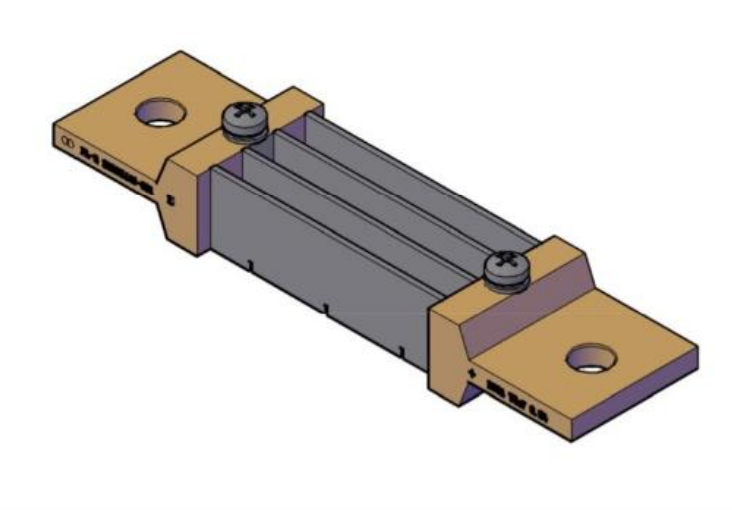

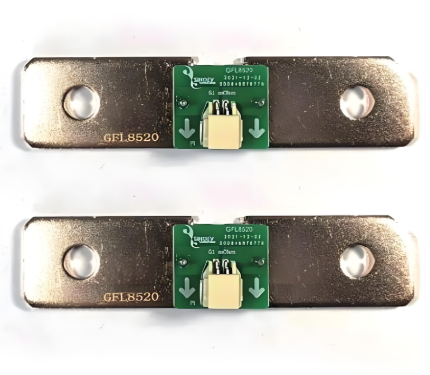

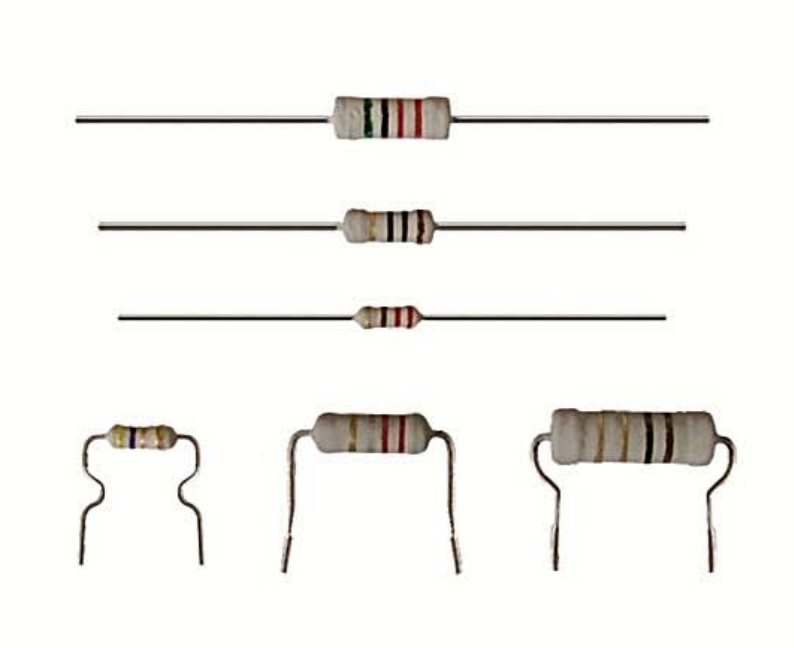

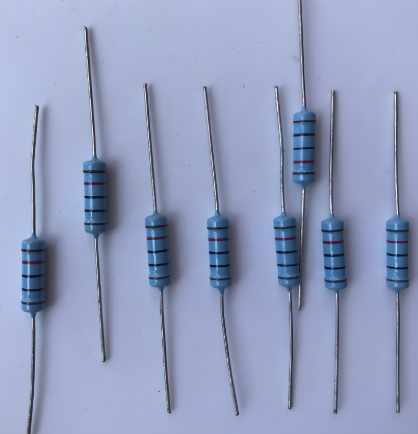

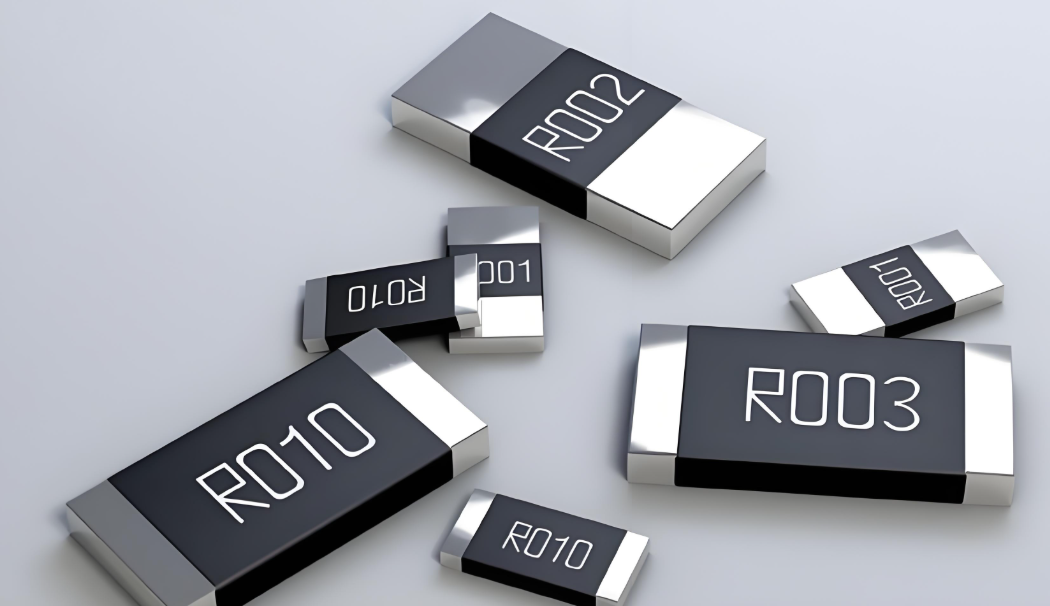

When designing electronic systems that require current measurement, engineers often face a critical choice: power shunt resistors or current sensors? Each solution has distinct advantages depending on application requirements like accuracy, cost, power handling, and isolation needs. This comprehensive comparison will help you determine which current sensing method works best for your specific application, whether it's electric vehicle battery monitoring, industrial motor control, or precision IoT devices.

Key Differences: Shunt Resistors vs. Current Sensors

| Parameter | Power Shunt Resistors | Current Sensors |

|---|---|---|

| Measurement Principle | Voltage drop across known resistance | Magnetic field detection (Hall effect/transformer) |

| Typical Accuracy | ±0.1% to ±5% | ±0.5% to ±3% |

| Cost Range | $0.10 - $10 | $5 - $100+ |

| Power Handling | Up to 1000A+ | Typically ≤ 200A |

| Isolation | None (in-circuit) | Galvanic isolation available |

| Frequency Response | DC - 500kHz | DC - 200kHz |

Accuracy Showdown: Which Performs Better?

When evaluating high-precision current measurement, both technologies have tradeoffs:

| Accuracy Factor | Shunt Resistor | Current Sensor |

|---|---|---|

| Initial Accuracy | 0.1% (precision types) | 0.5% (typical) |

| Temperature Drift | ±5ppm/°C (low-TCR alloys) | ±100ppm/°C (typical) |

| Long-Term Stability | ±0.05%/year | ±0.2%/year |

Solution: Use manganin shunt resistors with 5ppm/°C TCR for stable performance where current sensors would drift excessively.

Cost Analysis: Budget Considerations

For projects where low-cost current sensing is critical, the price difference is significant:

| Current Range | Shunt Resistor Cost | Current Sensor Cost |

|---|---|---|

| 10A | $0.50 | $8.00 |

| 50A | $2.00 | $25.00 |

| 200A | $15.00 | $80.00 |

Isolation Requirements: When Safety Matters

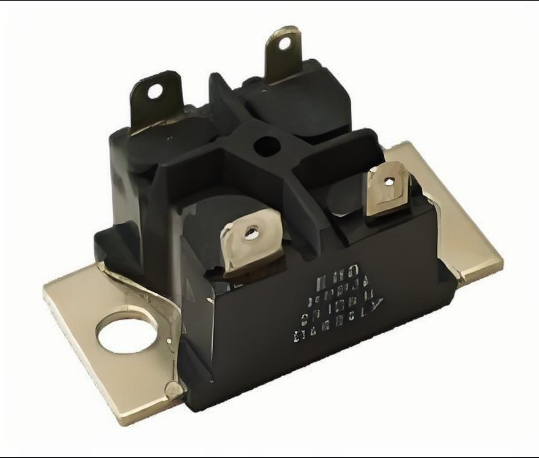

In applications requiring galvanic isolation for safety, current sensors dominate:

Shunt resistors require additional isolation amplifiers (adding $3-$20 to BOM)

Current sensors provide built-in isolation (typically 2-5kV)

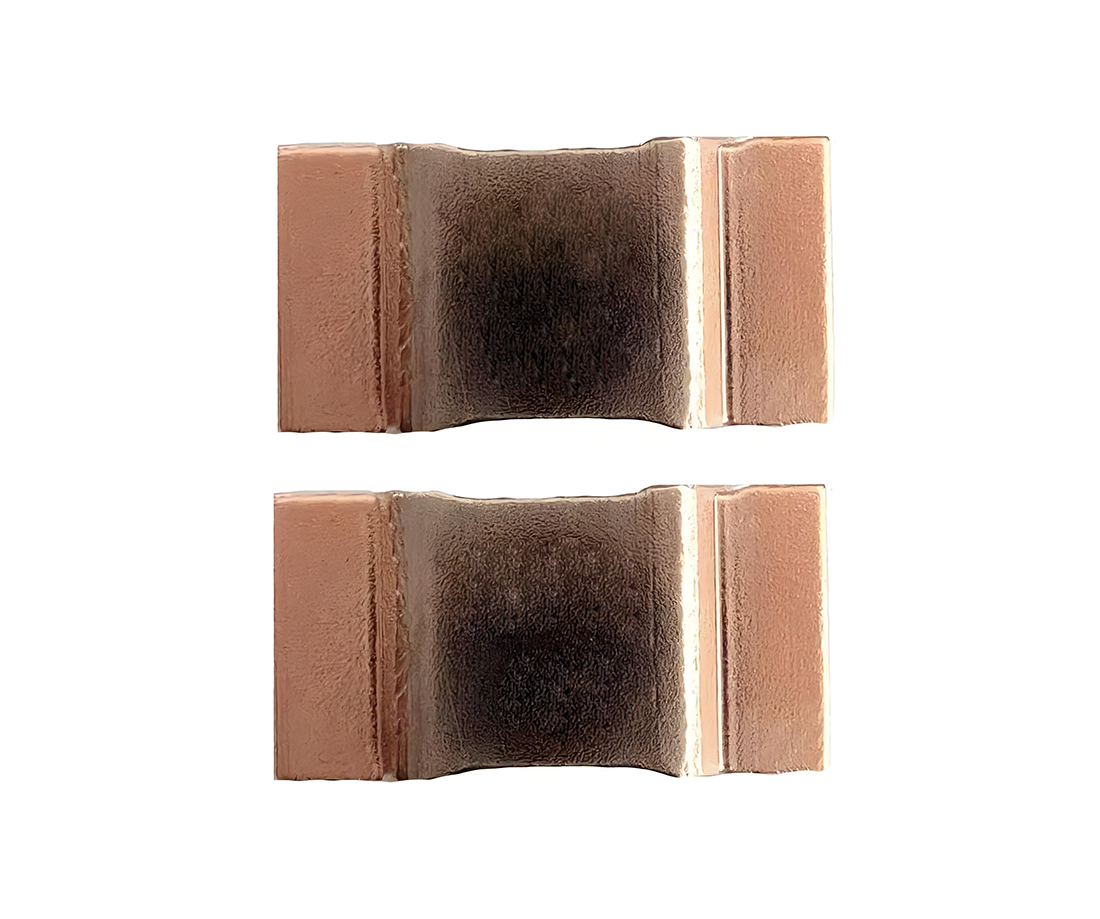

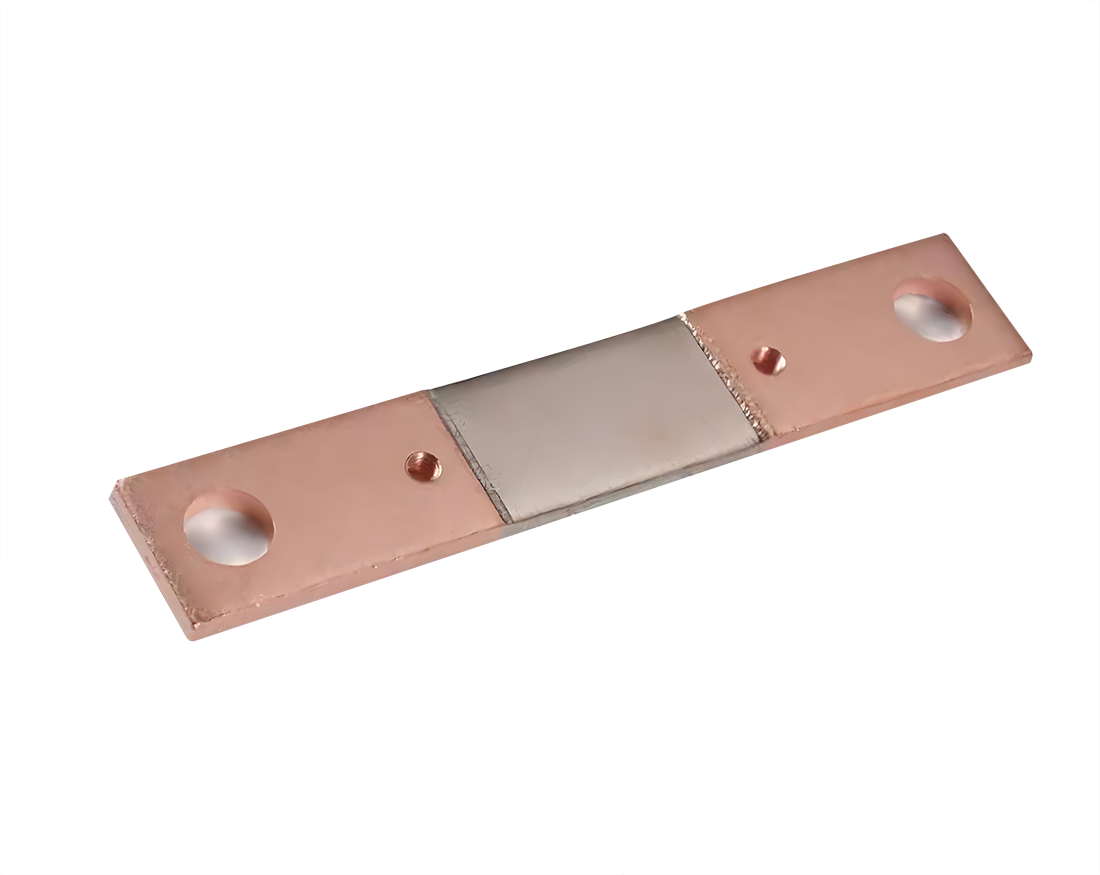

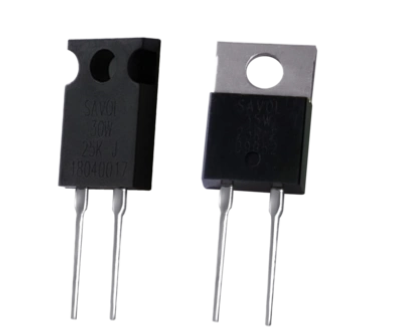

Thermal Challenges: Power Dissipation Solutions

A critical issue in high-current measurement is heat management:

| Current | Shunt Power Dissipation (5mΩ) | Sensor Power Loss |

|---|---|---|

| 10A | 0.5W | 0.1W |

| 50A | 12.5W | 0.15W |

| 100A | 50W | 0.2W |

Solution: Use ultra-low resistance shunts (0.1mΩ) with Kelvin connections, or switch to closed-loop Hall effect sensors for currents above 200A.

Application-Specific Guide: Making the Right Choice

| Application | Recommended Solution | Why? |

|---|---|---|

| EV Battery Monitoring | Precision shunt resistor | 0.1% accuracy needed, high current (300A+) |

| Solar Inverters | Isolated current sensor | Safety isolation, medium accuracy (1%) |

| Industrial Motor Control | Shunt + isolation amp | Cost-effective for 50-100A ranges |

| Consumer Electronics | Integrated current sensor IC | Small size, moderate accuracy sufficient |

For engineers wondering how to choose between shunt resistors and current sensors for power electronics, the decision ultimately depends on your specific requirements for accuracy, budget, power levels, and safety isolation. High-current applications typically favor shunts, while systems needing isolation or compact size may benefit more from current sensors.